Thingiverse

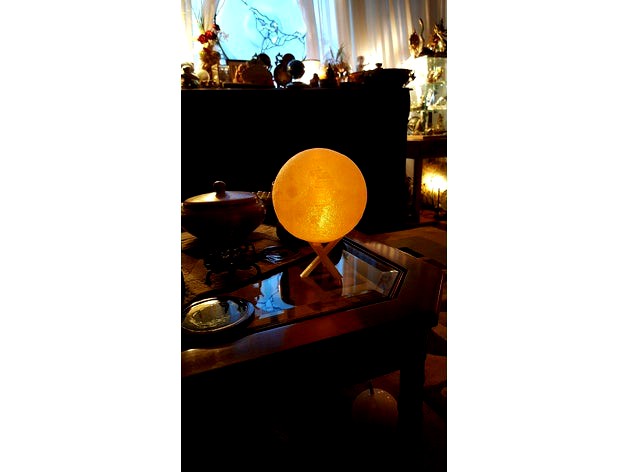

Moon Globe Night Light by mcandrewji

by Thingiverse

Last crawled date: 3 years ago

Please note The original "diffuser" component file had a scaling issue, has been replaced with "diffuserB" which should scale properly. The diffuser should be 15mm in diameter.

My Moon Globe is a compilation of the best parts of the following merged in a way that makes it unique and I hope a little more user friendly. In addition, my build uses a LED module with remote control for colour choice brightness and fade effects. https://www.ebay.ca/itm/232434506112 Circuit Board USB Remote Control 16-Color DIY 3D Printing Moon Light Night TE783 or similar. I have added a diffuser cap for the LED module to scatter the light a bit more evenly for I think better effect. You may need, to lightly scrape parts for better fit for final assembly. The light module slides into the base/cap holder at the center gently turn for snug fit once in place. The base cap threads nicely into the globe threaded collar it allows disassembly to service light module if need be. Connect the battery lead, charge the module. You can turn it on by touching the metal collar of the charge port or better use the convenient IR remote set on base of your choice and enjoy the fruits of the work.

https://www.thingiverse.com/thing:2531838

Glowing Moon by Brandonzhun.

I used this mount design for holding the light module from this post.

https://www.thingiverse.com/thing:2598082

Moon Lamp by WindoAC

I used and modified the threaded mounting design from this and the stand in my project.https://www.thingiverse.com/thing:1914642

Hot sale moon ball with LED light by stronghero

I used the moon globe and base from this post amended to incorporate the items mentioned from the previous two posts.

Sliced using Cura 3.04

Printed on an Anet A6 with PLA, MG Chemicals PLA 3D Printer Filament, 1.75 mm, 1 kg, Translucent (IMPROVED)

Extruder set at 210⁰C

Hot Bed set at 70⁰C

Globe printed at 0.2mm with skirt, no supports, 100%infill

Diffuser and holder printed at 0.2mm with brim, no supports, 100%infill

Base/Cap printed at 0.2mm, curved surface up with supports from bed and brim, 100% infill

As you, prepare for slicing ensure that all parts, are tightly settled flat on the build plate otherwise you may get some odd slicer behaviour. Always check the layer-by-layer view to be sure.

Happy printing!

My Moon Globe is a compilation of the best parts of the following merged in a way that makes it unique and I hope a little more user friendly. In addition, my build uses a LED module with remote control for colour choice brightness and fade effects. https://www.ebay.ca/itm/232434506112 Circuit Board USB Remote Control 16-Color DIY 3D Printing Moon Light Night TE783 or similar. I have added a diffuser cap for the LED module to scatter the light a bit more evenly for I think better effect. You may need, to lightly scrape parts for better fit for final assembly. The light module slides into the base/cap holder at the center gently turn for snug fit once in place. The base cap threads nicely into the globe threaded collar it allows disassembly to service light module if need be. Connect the battery lead, charge the module. You can turn it on by touching the metal collar of the charge port or better use the convenient IR remote set on base of your choice and enjoy the fruits of the work.

https://www.thingiverse.com/thing:2531838

Glowing Moon by Brandonzhun.

I used this mount design for holding the light module from this post.

https://www.thingiverse.com/thing:2598082

Moon Lamp by WindoAC

I used and modified the threaded mounting design from this and the stand in my project.https://www.thingiverse.com/thing:1914642

Hot sale moon ball with LED light by stronghero

I used the moon globe and base from this post amended to incorporate the items mentioned from the previous two posts.

Sliced using Cura 3.04

Printed on an Anet A6 with PLA, MG Chemicals PLA 3D Printer Filament, 1.75 mm, 1 kg, Translucent (IMPROVED)

Extruder set at 210⁰C

Hot Bed set at 70⁰C

Globe printed at 0.2mm with skirt, no supports, 100%infill

Diffuser and holder printed at 0.2mm with brim, no supports, 100%infill

Base/Cap printed at 0.2mm, curved surface up with supports from bed and brim, 100% infill

As you, prepare for slicing ensure that all parts, are tightly settled flat on the build plate otherwise you may get some odd slicer behaviour. Always check the layer-by-layer view to be sure.

Happy printing!

Similar models

thingiverse

free

Moon Lamp by MalNivek

...y pmoews in https://www.thingiverse.com/thing:755855

extraordinary if printed in glowfill. i painted the base with acrylic paint.

thingiverse

free

Samurai Inserts for wolf howling at the moon by VinniePaz

...07nnre9w/ref=ox_sc_act_title_1?smid=atvpdkikx0der&psc=1

**

link to jonn2k's op:

https://www.thingiverse.com/thing:2845445

thingiverse

free

Snowman Globe by RoxyFrog

...rint better.

hope you enjoy printing it up.

i used led tealight candle lights in the bottom. you can also use a coloured light.

thingiverse

free

Moon Light Globe by melgrubb

... i was able to print without any other supports just fine.

i printed in inland's "luminous" (glow-in-the-dark) pla.

thingiverse

free

LED Caps for 5mm LEDs by jumekubo

...e to a project. i used an infill of 15% when printing, but varying this can result in some interesting ways to diffuse the light.

thingiverse

free

LED base for moon lamp by badbytes

...r led strip light for moon lamp. mount cutout for diffuser needs a little extra space.

https://www.thingiverse.com/thing:2378604

thingiverse

free

AIYEGO or Viewpick LED Bulb Replacement Base by AlwaysTinkering

... hot place or direct sunlight. it is snug but fits. i included the scad file if you want to play with changing the dimensions.

thingiverse

free

Moon Stand by ukwebb

...ommodate a 150mm ball/moon/deathstar etc!

i used a short strip of 12v leds wired to a switch and 2.1mm dc power jack to power it.

thingiverse

free

Diffuser for Moon Lamp Circuit Screw Cap for Progressive Detail Moon Lamp with Rechargeable Moon Station

...educe tube length if you really need to. just make sure the leds are covered by the cone, close to the tip but don't squeeze.

thingiverse

free

Dremel 43mm collar adapter by anotherhowie

...infill for a bit of strength. "remixed" from ozgurliman's similar thing, by creating from scratch, after i couldn't get...

Globe

3ddd

$1

Globe

...globe

3ddd

globe

шкаф для сувениров globe

3d_ocean

$5

Globe

...globe

3docean

earth geography globe planet shiny

a simple globe

archibase_planet

free

Globe

...globe

archibase planet

globe sphere terrestrial globe

globe paper n041014 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Globe

...globe

archibase planet

globe sphere

globe n080510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Globe

...globe

archibase planet

globe sphere

globe n270810 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Globe

...globe

archibase planet

globe sphere

globe n220513 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$9

Globes

...rt earth globe globes land map ocean sphere world

set of 4models of earth globes made in cinema4d. files included: .c4d .obj .3ds

archibase_planet

free

Globe

...globe

archibase planet

globe sphere

globe n251013 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Globe

...globe

archibase planet

globe sphere

globe n181113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Globe

...globe

archibase planet

terrestrial globe sphere

globe n010708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Moon

3d_export

$10

moon

...moon

3dexport

relief moon

3ddd

$1

Moon

...moon

3ddd

moon armchair

3ddd

$1

MOON 012

...moon 012

3ddd

moon

moon 012

3ddd

$1

Moon 026

...moon 026

3ddd

moon

диван moon 026

design_connected

$13

Moon

...moon

designconnected

davide groppi moon computer generated 3d model. designed by groppi, davide.

3ddd

$1

Moroso moon

...moroso moon

3ddd

moroso , moon

кресло moroso moon

3ddd

$1

MOON 016

...moon 016

3ddd

moon , угловой

диван moon 016

3ddd

$1

MOON 053

...moon 053

3ddd

moon , угловой

диван moon 053

3d_ocean

$7

MOON

...rth jupiter model moon nasa nature ocean photorealistic planet poly realistic render satellite science solar space system

3d moon

3ddd

$1

Диван Moon

...диван moon

3ddd

moon , модульный

диван для гостиной. moon

Night

3ddd

$1

Кровать Night-Night Riva 1920

...кровать night-night riva 1920

3ddd

riva

http://www.riva1920.it/it/prodotti/letti/night-night-262/

3ddd

$1

Night Stand

... night stand , прикроватная тумба

classical night stand

3d_export

$5

Night castle

...night castle

3dexport

night castle

3d_export

$5

night table

...night table

3dexport

night table

3d_export

$5

dragon night

...dragon night

3dexport

dragon night 3d model

3d_export

$5

Night city

...night city

3dexport

night city with roads and houses

turbosquid

$21

Night

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Foggy night

...foggy night

3dexport

move to a fabulous foggy night location.

3d_export

$5

King Of The Night

...king of the night

3dexport

king of the night. lord of the cold and the dead.

3ddd

$1

Night Stand

...night stand

3ddd

резьба , тумба

night stand for bedroom

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...