Thingiverse

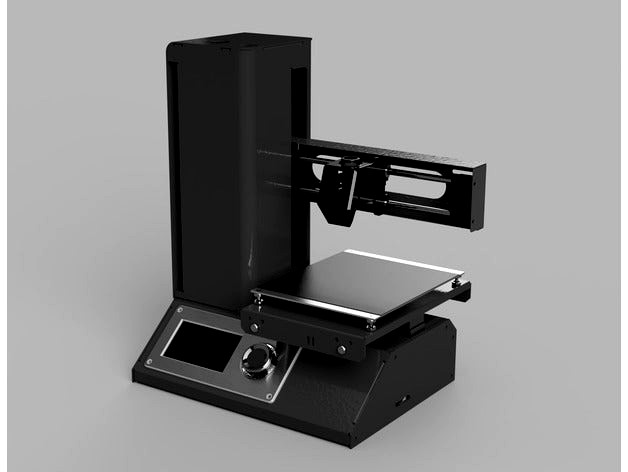

Monoprice Select Mini V2 Fusion 360 CAD Model by Kadah

by Thingiverse

Last crawled date: 3 years ago

Do you make mods for the MPSM and find it pain having to constantly reference your printer to dimensions, or worse, have to keep taking it apart to recheck some internal dimensions? Well I took apart mine to nothing and sketched everything so you don't have to.

This is a (hopefully) accurate Fusion 360 model of a MPSM v2 that seems to reperenst most reversions sold around the mid 2017 and later. Early v2's had a few minor differences. This may also mostly apply for v1 as well, but I never had a v1, so YMMV.

For shits and giggles there is an STL version on this thing, and the f3z export of rev11, but the actual current model can always be access via this link: http://a360.co/2A7naPE

Most things should be within +/- 0.1mm, which is less than what I can say about my Mini's construction. If you find an error, please leave a comment so I can fix it. I've been correcting the model as I work on some mods. I think I have it nearly complete now.

Things not modeled currently / Todo:

Extruder and extruder stepper

Hotend, but printhead is otherwise complete

Y idlers, stepper, or belt (unlikely to do belt, but might added a mockup stand-in later)

X stepper or belt

X idler (need to measure next time I have it off)

Spool holder (haven't seen a reason so yet)

Control board mockup

Cabling (yeah, no, lol)

Unicorns

Update 2017-12-08:

Added a stand in stl model for use with slicers that have the functionality to show a model of your printer. Origin should be set to 0,0,0. Untested, I don't use such a slicer myself.

Update 2019-07-13:

Fusion 360 finally supports exporting linked designs. I have exported the latest version of the main assembly, as well as each of the major sub assemblies, to the following formats: f3z, iges, step, and skp.

I have tested the skp files in the SketchUp Viewer and they appeared to work. Similarly, I imported the iges and step back in to Fusion 360 and those worked as expected.

The f3z files for Fusion 360, upload it in to a new folder, or new project, as each f3z file contains all the sub-designs in it. It is only necessary to import the "MPSM v2 v11.f3z" if you need the entire model, and it contains the major sub-assemblies as well which are easier to work with. There are 40 separate designs/assemblies in this file, it will take a while to import.

Note on x-axis rod spacing:

I believe 30mm is the ideal intended distance, however on mine the center-to-center distanced is 29.91mm +/-0.01mm on each end. This causes print heads using a spacing of 30mm to be too tight at end of travel.

If you are going to design a print head, for best results, either: measure the rod spacing (from outside-to-outside and subtract 6mm) on your actual printer and use that, or design your lower bearing holder to have slight vertical adjustment (something similar to an i3 style may work).

Tips for working with the model

With Fusion 360, it's a better idea to start a new design and drop in links to the sub-assemblies you require. This will keep the design much clearing (especially the timeline). Just set the top level component as active and drag needed sub-assemblies to the component tree. Hide unneeded components.

This is a (hopefully) accurate Fusion 360 model of a MPSM v2 that seems to reperenst most reversions sold around the mid 2017 and later. Early v2's had a few minor differences. This may also mostly apply for v1 as well, but I never had a v1, so YMMV.

For shits and giggles there is an STL version on this thing, and the f3z export of rev11, but the actual current model can always be access via this link: http://a360.co/2A7naPE

Most things should be within +/- 0.1mm, which is less than what I can say about my Mini's construction. If you find an error, please leave a comment so I can fix it. I've been correcting the model as I work on some mods. I think I have it nearly complete now.

Things not modeled currently / Todo:

Extruder and extruder stepper

Hotend, but printhead is otherwise complete

Y idlers, stepper, or belt (unlikely to do belt, but might added a mockup stand-in later)

X stepper or belt

X idler (need to measure next time I have it off)

Spool holder (haven't seen a reason so yet)

Control board mockup

Cabling (yeah, no, lol)

Unicorns

Update 2017-12-08:

Added a stand in stl model for use with slicers that have the functionality to show a model of your printer. Origin should be set to 0,0,0. Untested, I don't use such a slicer myself.

Update 2019-07-13:

Fusion 360 finally supports exporting linked designs. I have exported the latest version of the main assembly, as well as each of the major sub assemblies, to the following formats: f3z, iges, step, and skp.

I have tested the skp files in the SketchUp Viewer and they appeared to work. Similarly, I imported the iges and step back in to Fusion 360 and those worked as expected.

The f3z files for Fusion 360, upload it in to a new folder, or new project, as each f3z file contains all the sub-designs in it. It is only necessary to import the "MPSM v2 v11.f3z" if you need the entire model, and it contains the major sub-assemblies as well which are easier to work with. There are 40 separate designs/assemblies in this file, it will take a while to import.

Note on x-axis rod spacing:

I believe 30mm is the ideal intended distance, however on mine the center-to-center distanced is 29.91mm +/-0.01mm on each end. This causes print heads using a spacing of 30mm to be too tight at end of travel.

If you are going to design a print head, for best results, either: measure the rod spacing (from outside-to-outside and subtract 6mm) on your actual printer and use that, or design your lower bearing holder to have slight vertical adjustment (something similar to an i3 style may work).

Tips for working with the model

With Fusion 360, it's a better idea to start a new design and drop in links to the sub-assemblies you require. This will keep the design much clearing (especially the timeline). Just set the top level component as active and drag needed sub-assemblies to the component tree. Hide unneeded components.

Similar models

grabcad

free

Altoids tin

...usion 360 and then exported to the step and stl versions so may not be the same as fusion 360 model. it fails to upload f3z file.

thingiverse

free

Anycubic Predator Full Assembly

...gelog

06 dec 2019: initial release

07 dec 2019: updated stl's with a -50mm height offset for use as machine models in slicers

thingiverse

free

belt tensioner by xela442002

... designed this in fusion 360 and printed it on my own anycubic kossel but i am sure it will work just as well on other printers!!

thingiverse

free

Anet A8 X Belt Tensioner (for simhopp idler and gear) by anotherhowie

...ut wider in the cavity for the idler.

edit: may 7th 2018 - added the fusion 360 file, so you can tweak dimensions if you need to.

grabcad

free

Build This Side Table

...ternal references. the assembly file archive is linked in the youtube below as well if you have any trouble with the model here.

thingiverse

free

MPSM Y Axis Belt Tensioner - Fixed by xhorntail

...ont mount file is unchanged, as it works fine, i just uploaded it so you don't have to surf things to collect all your parts.

thingiverse

free

Aesculapian Staff Rod by AWS3D

...think this would be great for printers with dissolvable support however i only have a single extruder mpsm so i cannot test that.

grabcad

free

Universal Joint

...ssembled in fusion 360.

it also includes the motion study for a given animation.

download includes .f3z, .iges & .step files.

thingiverse

free

Y Belt Tensioner by pronerd34

...th square nuts that are called out on the bom for the am9 - metal frame for anet a8 by pheneeny.

update: added fusion 360 files

grabcad

free

Woofer 18 "

...awn in fusion 360 and exported as fusion 360 file (f3z) and dxf. the box design is only in (f3z) based on specs for b&c s18n.

Kadah

thingiverse

free

A10T/A20T/A30T Mixing Hotend Mockup by Kadah

...curate, possibly within +/-0.1mm.

as of sep2020, i have not printed with this hotend yet and cannot comment on how well it works.

thingiverse

free

MPSMv2 Dial Indicator Mount by Kadah

...price mp select mini z axis adjustable endstopmy modified endstop mount for v2

made in fusion 360. step file included. enjoy. :)

thingiverse

free

Bracket for Articulated Raspberry Pi Camera Mount with 4mm Holes by Kadah

...ion with a bit more material around the base of the mount. it would be fairly easy to make additional versions of this if needed.

thingiverse

free

Simple Clone Arduino Pro Mini Mount by Kadah

... usual with everything i've designed from scratch, the fusion 360 file is included. have fun adjusting this to your needs. :d

thingiverse

free

Monoprice MP Select Mini V2 Z Axis Adjustable Endstop Internal Mount by Kadah

... 2017 status update: i finally got a replacement mpsmv2 last month. i will likely be updating this design by the end of the year.

thingiverse

free

Parametric SMD Stacking Magnetic Mini Spools by Kadah

...ll unable to add that as a remixed-from due to thingiverse continuing to be a broken pile of garbage.

both of these are untested.

thingiverse

free

Magnetic Filament Filter (Updated Dec 2019) by Kadah

...f the holder.

the dust cloths last a long time in this thing and can be rotated around the "spring" part when it dirty.

thingiverse

free

Monoprice Select Mini V2 X End Cap Puller by Kadah

...rinthead carriage.

fusion file:

can't export as file due to current fusion limitation on linked designshttp://a360.co/2cbzmbh

Monoprice

thingiverse

free

Display frame for Monoprice MP10

...display frame for monoprice mp10

thingiverse

display frame for monoprice mp10

thingiverse

free

Bridge covers Monoprice MP10

...bridge covers monoprice mp10

thingiverse

bridge covers monoprice mp10

thingiverse

free

Monoprice Coin by Peyton_Guyot

...monoprice coin by peyton_guyot

thingiverse

print this!

thingiverse

free

Voxel Monoprice spool holder by avalero

...voxel monoprice spool holder by avalero

thingiverse

voxel monoprice spool holder

thingiverse

free

Monoprice select mini knob by BramRausch

...monoprice select mini knob by bramrausch

thingiverse

this is a replacement knob for the monoprice select mini.

thingiverse

free

Monoprice 3d printer hook by dmitriyf

...monoprice 3d printer hook by dmitriyf

thingiverse

this is an attachment to monoprice select 3d printer v2

thingiverse

free

monoprice ultimate spool mount by death4u

...older by danmannert to monoprice ultimate 3d printer. it clips into the slot on the top of the printer for the optional enclosue.

thingiverse

free

Monoprice Mini Delta Foot

...a foot for a monoprice mini delta. it helps to increase airflow under the printer. it also helps to reduce the volume of the fan.

thingiverse

free

Monoprice Select Mini Fan Guard

...y fan protection. this is an essential upgrade.

used it on the monoprice select mini pro (from www.3dprinthings.be).

perfect fit!

thingiverse

free

Monoprice Cable Tie Mount

... but had to cut down the straps a bit to make them work. designed a quick mount that fits the full strap, item 6457 on monoprice.

Fusion

3ddd

free

BoConcept Fusion

...boconcept fusion

3ddd

boconcept , fusion

boconcept fusion

3ddd

$1

Ford Fusion

...ford fusion

3ddd

ford

ford fusion

3ddd

$1

HANSA Fusion

...hansa fusion

3ddd

духовой шкаф , hansa

встраиваемый духовой шкаф hansa fusion

design_connected

$11

1520 Fusion

...1520 fusion

designconnected

dränert 1520 fusion computer generated 3d model. designed by aisslinger, werner.

3ddd

free

Диван BoConcept Fusion

...03]

артикул: 4990059fu032103

ссылка на продукт:

http://www.boconcept.com/ru-ru/furniture/living/sofas/fusion/10347/диван-fusion

3ddd

$1

Matthew Robinson / Fusion

... журнальный

solid wood tables matthew robinson / fusion

http://www.matthewrobinsonfurniture.co.uk/#!fusion

3ddd

$1

Best. Fusion

...а пристенная best fusion.

5930 полигонов.

wall mounted range hood best fusion.

5930 polygons.

file: max 2010, 2012; fbx; obj.

3ddd

free

Туалетный столик Fusion

...столик fusion

3ddd

трюмо , fusion

туалетный столик fusion

арт.108dwk

размеры: 120х47х76

design_connected

$13

Fusion Chair

...gnconnected

photo-realistic 3d models of the fusion chair from boconcept for 3d architectural and interior design presentations.

3ddd

$1

Кресло fusion

...ах ткани и кожи. на фотографии, фетр светло-серого цвета 2121/шпон дуба. в74xш97xг78см. [стулья - l042]

артикул: 4060058l0422121

Select

3ddd

$1

TUBADZIN SELECT

...max 2014, 2011.

fbx 2014, 2013, 2011,

obj

_____________________________________http://www.tubadzin.pl/en/collection/324

3ddd

$1

Плитка Selection

... supergres , плитка

плитка selection - supergres ceramiche

turbosquid

$15

Christmas Selection

...royalty free 3d model christmas selection for download as fbx on turbosquid: 3d models for games, architecture, videos. (1696333)

turbosquid

$39

Vases selection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

SELECTIVE RACKING SYSTEM

...yalty free 3d model selective racking system for download as on turbosquid: 3d models for games, architecture, videos. (1282512)

turbosquid

$10

Hansgrohe ShowerTablet Select

...ee 3d model hansgrohe showertablet select for download as max on turbosquid: 3d models for games, architecture, videos. (1336955)

turbosquid

$29

Chill selectional sofa

...odel chill selectional sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1465691)

3ddd

free

Lunaria - Nova, ASA Selection

... asa selection , dried flowers

ветка лунарии в вазе nova, asa selection

3ddd

$1

inno SELECT SLIM chair

...inno select slim chair

3ddd

inno

high detailed inno select slim chair

turbosquid

$29

Select Chaise Lounge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

V2

3d_export

free

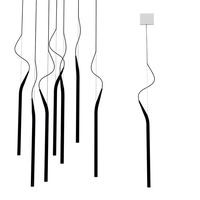

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

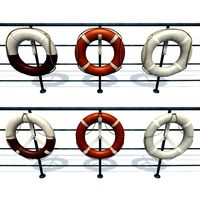

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)

360

3ddd

$1

360-panoramas_001

...360-panoramas_001

3ddd

панорамная фотография 360 град.

3ddd

$1

360-panoramas_002

...360-panoramas_002

3ddd

панорамная фотография 360 град.

разрешение - 9000х2250 px.

3ddd

$1

360-panoramas_022

...360-panoramas_022

3ddd

панорамная фотография 360 град.

разрешение - 9000х1600 px.

3ddd

$1

360-panoramas_008

...360-panoramas_008

3ddd

панорамная фотография 360 град.

разрешение - 8000х1500 px.

3ddd

$1

360-panoramas_021

...360-panoramas_021

3ddd

панорамная фотография 360 град.

разрешение - 9000х1600 px.

3ddd

$1

360-panoramas_020

...360-panoramas_020

3ddd

панорамная фотография 360 град.

разрешение - 9000х2250 px.

3ddd

$1

360-panoramas_003

...360-panoramas_003

3ddd

панорамная фотография 360 град.

разрешение - 9000х1500 px.

3ddd

$1

360-panoramas_010

...360-panoramas_010

3ddd

панорамная фотография 360 град.

разрешение - 9000х1564 px.

3ddd

$1

/ XBOX 360

... видеоприставка , джойстик

xbox 360,3dmax2011+vray

3ddd

$1

360-panoramas_018

...360-panoramas_018

3ddd

панорамная фотография 360 град.

разрешение - 9000х2250 px.

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Cad

turbosquid

$20

cad lab

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$36

Cad Classroom3d model

...cad classroom3d model

cgstudio

.max - cad classroom 3d model, royalty free license available, instant download after purchase.

turbosquid

$25

3D CAD Ring

...osquid

royalty free 3d model 3d cad ring for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1221561)

turbosquid

$20

3D CAD Earrings

...id

royalty free 3d model 3d cad earrings for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1221571)

turbosquid

$20

3D CAD Ring

...osquid

royalty free 3d model 3d cad ring for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1221564)

turbosquid

$15

3D CAD Earrings

...id

royalty free 3d model 3d cad earrings for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1221577)

turbosquid

$15

3D CAD RINGS

...squid

royalty free 3d model 3d cad rings for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1221568)

turbosquid

$12

3D CAD Ring

...osquid

royalty free 3d model 3d cad ring for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1221559)

turbosquid

$10

3D CAD Ring

...osquid

royalty free 3d model 3d cad ring for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1221585)

turbosquid

$10

3D CAD Ring

...osquid

royalty free 3d model 3d cad ring for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1221579)