Thingiverse

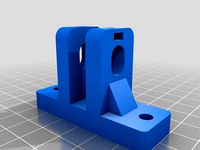

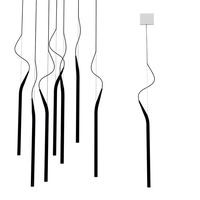

Monoprice Mini X Axis Idler End Block by saabotage900

by Thingiverse

Last crawled date: 3 years, 1 month ago

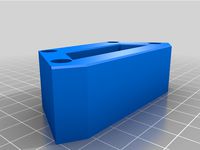

This is a Prusa Mini-inspired MP Mini X-end idler block. It significantly improves the stability and alignment of the X axis, by clamping down on the rods as opposed to just using friction fit that's pressed on. My first layer calibration improved dramatically after using this mount, where it maintained Z stability across the entire length of the X axis. This is also much easier to install compared to friction fit. Before, forcing friction fit blocks on sometimes resulted in crooked axis, off-center Z axis, and inconsistency as the parts fatigued.

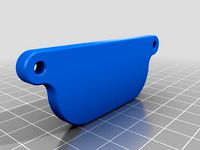

It contains two parts, the idler mount, and the X end block that houses the idler mount. My MP Mini also had a mis-drilled X end idler retainer, which resulted in a crooked belt. This idler retainer helps keep the idler straight, and the holes are centered so the belt doesn't ride one side.

Work in progress. Testing so far, no durability issues or fatigue when using PETG. Feedback welcome.

You'll need 3 M3 nuts (2 for the block, 1 for the idler) and a variety of M3 screws. Two M3 screws clamp the end onto the X axis rods, and another M3 screw acts as the pin for the pulley. Highly recommend a metal GT2 16T smooth pulley with bearings, as the screw will cut and wear grooves into the shaft of the stock plastic idler pulley.

Not designed to work with the stock X axis shroud.

Use PETG if you can, it's stronger and has just the right amount of flex. Otherwise, I believe PLA should work. 20-ish% infill, and 2 or 3 walls is sufficient for strength. Orient the parts flat side down for support-free printing. Dimensions are quite tight; the holes were designed at 6.1mm in diameter to let the rods slip in, then get clamped down. If you have to force the rods in the holes, then your printer's tolerances may need tuning and/or the rod entry points may need cleanup.

It contains two parts, the idler mount, and the X end block that houses the idler mount. My MP Mini also had a mis-drilled X end idler retainer, which resulted in a crooked belt. This idler retainer helps keep the idler straight, and the holes are centered so the belt doesn't ride one side.

Work in progress. Testing so far, no durability issues or fatigue when using PETG. Feedback welcome.

You'll need 3 M3 nuts (2 for the block, 1 for the idler) and a variety of M3 screws. Two M3 screws clamp the end onto the X axis rods, and another M3 screw acts as the pin for the pulley. Highly recommend a metal GT2 16T smooth pulley with bearings, as the screw will cut and wear grooves into the shaft of the stock plastic idler pulley.

Not designed to work with the stock X axis shroud.

Use PETG if you can, it's stronger and has just the right amount of flex. Otherwise, I believe PLA should work. 20-ish% infill, and 2 or 3 walls is sufficient for strength. Orient the parts flat side down for support-free printing. Dimensions are quite tight; the holes were designed at 6.1mm in diameter to let the rods slip in, then get clamped down. If you have to force the rods in the holes, then your printer's tolerances may need tuning and/or the rod entry points may need cleanup.

Similar models

thingiverse

free

Hictop 3dp11 Adjustable Y Idler Mount by SaberShip

...rts:

x1 stock 608zz idler bearing

x1 stock m3 bolt and nut

x2 stock m5 bolts

x2 stock m5 t-slot nuts

x2 m3 x 10 screws

x2 m3 nuts

thingiverse

free

Prusa i3 MK2 X-Idler Tensioner by Jasenk

... kit came with extras that i used.

the pully slide (x-end-idler-front-tensioner) fits one way. if it's tight flip it around.

thingiverse

free

Ender 3 V2 Linear Rail Direct Drive X-Axis Conversion V1 by VonTaube

...

crimp belt and tension

see ender 3 v2 direct drive link below for extruder install infohttps://www.thingiverse.com/thing:4621486

thingiverse

free

BD's Tarantula X-Axis Motor and Idler Mounts by bdwalker1

... to adjust your z-carriages or drill new holes in the acrylic if the holes don't line up perfectly for your particular build.

thingiverse

free

MP Select Mini X support bracket by rally25rs

...ace over the stock mp select mini's x axis end cap. i used this to eliminate some sag of that axis after extending the rods.

thingiverse

free

X axis end clamp by bunjatec

...ll need to print :

1x end clamp

2x end clamp fixings

the clamp then holds the ends of the x stage rods and stops them poking out.

thingiverse

free

Hictop 3dp11 Adjustable Y Idler Mount 2.0 by SaberShip

...ler pulley for 6mm wide gt2 belt

1x m5 x30 bolt

1x m5 nylon lock insert nut (regular m5 nut may work)

2x m3 x10 screws

2x m3 nuts

thingiverse

free

X-axis pulley cover for Velleman k8200 by dan241297

...ocated to a hole on the other side of the x-axis belt.

the following additional screws are required:

m2 x 8mm

m3 x 30mm

m3 x 40mm

thingiverse

free

Prusa i3 X-Axis Tensioner by BillyKalfus1

...rew pulls the tensioner closer to the back of the axis mount, pulling the pulleys back, and increasing the tension in the x-axis.

thingiverse

free

Coolice XY Idler Mount Left & Right by helicopterguru

...#39;t undo the clamping action once assembled.

update 2/1/2018 ; new version added suitabel for m3 nuts rather than brass inserts

Saabotage900

thingiverse

free

Monoprice MP Mini Knob by saabotage900

...erate underneath the bed without intrusion. prints well without supports. the bottom is thin enough to show the leds behind it.

thingiverse

free

Thrustmaster T16000M mount for Poang Ikea Chair by saabotage900

...e900

thingiverse

a mount to secure the t16000m hotas onto the ikea poang chair. amazingly comfortable setup, and easy to print.

thingiverse

free

"Chat Bubble": Minimalist Low-Profile Bearing Spool Holder for MK3S, MK3S+ by saabotage900

...rint bed stl sets are available at: https://www.prusaprinters.org/prints/55288-chat-bubble-minimalist-low-profile-bearing-spool-h

Monoprice

thingiverse

free

Display frame for Monoprice MP10

...display frame for monoprice mp10

thingiverse

display frame for monoprice mp10

thingiverse

free

Bridge covers Monoprice MP10

...bridge covers monoprice mp10

thingiverse

bridge covers monoprice mp10

thingiverse

free

Monoprice Coin by Peyton_Guyot

...monoprice coin by peyton_guyot

thingiverse

print this!

thingiverse

free

Voxel Monoprice spool holder by avalero

...voxel monoprice spool holder by avalero

thingiverse

voxel monoprice spool holder

thingiverse

free

Monoprice select mini knob by BramRausch

...monoprice select mini knob by bramrausch

thingiverse

this is a replacement knob for the monoprice select mini.

thingiverse

free

Monoprice 3d printer hook by dmitriyf

...monoprice 3d printer hook by dmitriyf

thingiverse

this is an attachment to monoprice select 3d printer v2

thingiverse

free

monoprice ultimate spool mount by death4u

...older by danmannert to monoprice ultimate 3d printer. it clips into the slot on the top of the printer for the optional enclosue.

thingiverse

free

Monoprice Mini Delta Foot

...a foot for a monoprice mini delta. it helps to increase airflow under the printer. it also helps to reduce the volume of the fan.

thingiverse

free

Monoprice Select Mini Fan Guard

...y fan protection. this is an essential upgrade.

used it on the monoprice select mini pro (from www.3dprinthings.be).

perfect fit!

thingiverse

free

Monoprice Cable Tie Mount

... but had to cut down the straps a bit to make them work. designed a quick mount that fits the full strap, item 6457 on monoprice.

Idler

3d_export

$20

telescopic stacker belt conveyor

...and the actual components are as follows cema c idler cema c impact roller dodge bearing avoid tension bearing...

3d_export

$49

Liebherr R9250 Tracks - Crawler

...main parts: bottom rollers car bodies final drives top idler front idlers slewing rings-turntable bearings sprockets text track chains...

3d_export

$119

JD - 953MH Tracked Log Loader

...boby with engine<br>main body bolts<br>main body grilles<br>pedals<br>right - front idlerlt;br>right - rear idler<br>right track chain<br>right track links<br>right track protector<br>right...

3d_export

$129

JD - 959MH Tracked Feller Buncher

...boby with engine<br>main body bolts<br>main body grilles<br>pedals<br>right - front idlerlt;br>right - rear idler<br>right track chain<br>right track links<br>right track protector<br>right...

3d_export

$119

JD - 959MH Tracked Log Loader

...boby with engine<br>main body bolts<br>main body grilles<br>pedals<br>right - front idlerlt;br>right - rear idler<br>right track chain<br>right track links<br>right track protector<br>right...

3d_export

$119

JD - 953MH Tracked Harvester

...tool - lower<br>moving limbing tool - upper<br>pedals<br>right - front idlerlt;br>right - rear idler<br>right feed rollers<br>right track chain<br>right track links<br>right...

thingiverse

free

Idler seat by jcen517

...idler seat by jcen517

thingiverse

idler seat

thingiverse

free

Idler by GEON_3D

...idler by geon_3d

thingiverse

idler para extrusor 1,75

imprimir en abs, petg o cualquier material resistente

thingiverse

free

wade idler by nautilux

...wade idler by nautilux

thingiverse

wade idler reforzado

thingiverse

free

Idler Frame by Dinusha

...idler frame by dinusha

thingiverse

idler frame specially for the belt conveyors.

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Block

archibase_planet

free

Blocks

...blocks

archibase planet

blocks bricks toy

toy blocks - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Block

...block

3dexport

3d_export

$10

The guillotine and the block

...the guillotine and the block

3dexport

the guillotine and the block autocad 2013

3d_ocean

$8

Concrete Blocks

... blocks, barriers or cover for characters during a fire fight. each one has its own diffuse map, specular and normal map in tg...

archibase_planet

free

Glass block

...glass block

archibase planet

glass block brick

glass block n211009 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$99

city block

...city block

3dexport

city block 3d model. include max, obj and fbx files.

3d_ocean

$3

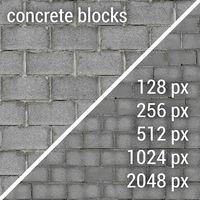

Concrete Blocks Textures

...res

3docean

block blocks concrete seamless wall walls

a couple of seamless textures with two differents sizes of concrete blocks.

3d_export

$5

plummer block

...plummer block

3dexport

this is an 3d model of plummer block assembly where seven parts are required to assemble this.

design_connected

$16

Block 2

...block 2

designconnected

henry pilcher block 2 computer generated 3d model. designed by pilcher, henry.

3d_export

$7

concrete blocks on pallets

...concrete blocks on pallets

3dexport

concrete blocks on pallets, 3 types of blocks. there are all the necessary textures.

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

End

archibase_planet

free

Cigarettes end

...d

archibase planet

cigarettes end cigarette stub cigar-butt

cigarette-end - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

turbosquid

$10

End Table

...rbosquid

royalty free 3d model end table for download as max on turbosquid: 3d models for games, architecture, videos. (1570610)

turbosquid

$5

End Table

...urbosquid

royalty free 3d model end table for download as ma on turbosquid: 3d models for games, architecture, videos. (1622809)

turbosquid

$3

End Table

...rbosquid

royalty free 3d model end table for download as fbx on turbosquid: 3d models for games, architecture, videos. (1315115)

3d_export

$5

rope end ring

...rope end ring

3dexport

rope end ring

turbosquid

$2

End Tables

...

royalty free 3d model end tables for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1706896)

turbosquid

$14

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1403051)

turbosquid

$12

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1574707)