Thingiverse

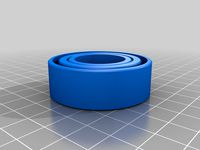

Minimalistic Mk8 Replacements by gth

by Thingiverse

Last crawled date: 3 years, 1 month ago

There's a few of these designs around, and while maybe veterans may already know, the purpose wasn't obvious to me at first so here's my attempt to explain the parts, function and reasons for this thing:-

Firstly, the references to MK7 and MK8 are two versions of the same part - i.e. the top section of the replicator extrusion equipment.

The stock Makerbot Replicator has a stepper motor that controls the feedrate of filament into the heater element below it.

Pushing filament up against this stepper motor is a plastic "delrin plunger" - http://store.makerbot.com/mk7-delrin-plunger.html

This plunger encounters wear due to friction, causing less pressure on the filament against the stepper drive. Eventually the filament will exhibit feedrate problems, causing symptoms such as premature melting down in the heater/nozzle areas below.

Another cause of problems is that the plunger does not tolerate changes in filament diameter very well, if at all - such changes can be due to quality control issues of the roll of filament, or even just a small kink in the plastic.

-- SO... in order to ensure a constant pressure forcing the filament against the stepper motor, the very clever emmett - http://www.thingiverse.com/emmett - came up with a spring loaded lever.

Subsequently to that, Doogiekr made a design modification meaning one could use the handles from 'bulldog' clips - http://www.thingiverse.com/thing:32315 /

My derivative here contains some slight changes in the evolution of this part:

a) Removed support elements in the design that needed to be cut out after printing

b) Ugly design hacks in SketchUp to fix mesh errors with rounded corners in my local SketchUp (not a reflection of anyone else's design skills but mine)

c) Modified to fit a 688 bearing with dimensions of: 8mm inner diameter, 16mm outer diameter and 5mm width. The inner race had an approximate diameter of 10.5mm - See note below!

d) Simplified the 'pin' as my replicator seemed to struggle to print the original tiny, rather complex pin.

e) Made the 'left' design in Sketchup a 'component' and then flipped it over the red axis ensuring both left and right designs are identical.

!! NOTE !! Bearings with a 16mm or larger outer diameter will not work with dual extruder models!

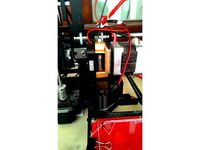

On my Dualstrusion Replicator 1, the two 688 bearings I used would touch as soon as both extruders have filament loaded. As such, dual extruders require a smaller outer diameter on your bearings.Refer to the last image in the sequence for a close-up photo of the bearings touching.

Provided the inner diameter of your bearings is 8mm, the STL design should work as is. Bearings with a smaller inner diameter would require a modification to the design of the holding pin, etc.

Firstly, the references to MK7 and MK8 are two versions of the same part - i.e. the top section of the replicator extrusion equipment.

The stock Makerbot Replicator has a stepper motor that controls the feedrate of filament into the heater element below it.

Pushing filament up against this stepper motor is a plastic "delrin plunger" - http://store.makerbot.com/mk7-delrin-plunger.html

This plunger encounters wear due to friction, causing less pressure on the filament against the stepper drive. Eventually the filament will exhibit feedrate problems, causing symptoms such as premature melting down in the heater/nozzle areas below.

Another cause of problems is that the plunger does not tolerate changes in filament diameter very well, if at all - such changes can be due to quality control issues of the roll of filament, or even just a small kink in the plastic.

-- SO... in order to ensure a constant pressure forcing the filament against the stepper motor, the very clever emmett - http://www.thingiverse.com/emmett - came up with a spring loaded lever.

Subsequently to that, Doogiekr made a design modification meaning one could use the handles from 'bulldog' clips - http://www.thingiverse.com/thing:32315 /

My derivative here contains some slight changes in the evolution of this part:

a) Removed support elements in the design that needed to be cut out after printing

b) Ugly design hacks in SketchUp to fix mesh errors with rounded corners in my local SketchUp (not a reflection of anyone else's design skills but mine)

c) Modified to fit a 688 bearing with dimensions of: 8mm inner diameter, 16mm outer diameter and 5mm width. The inner race had an approximate diameter of 10.5mm - See note below!

d) Simplified the 'pin' as my replicator seemed to struggle to print the original tiny, rather complex pin.

e) Made the 'left' design in Sketchup a 'component' and then flipped it over the red axis ensuring both left and right designs are identical.

!! NOTE !! Bearings with a 16mm or larger outer diameter will not work with dual extruder models!

On my Dualstrusion Replicator 1, the two 688 bearings I used would touch as soon as both extruders have filament loaded. As such, dual extruders require a smaller outer diameter on your bearings.Refer to the last image in the sequence for a close-up photo of the bearings touching.

Provided the inner diameter of your bearings is 8mm, the STL design should work as is. Bearings with a smaller inner diameter would require a modification to the design of the holding pin, etc.

Similar models

thingiverse

free

Replicator Delrin Plunger Replacement by rkelley

...replicator delrin plunger replacement by rkelley

thingiverse

fits the mk7 and mk8 stepstruders.

thingiverse

free

mk7 ball bearing extruder drive by jag

...ble to quickly release the tension so that you can pull the filament out and replace it easily without having to run the stepper.

thingiverse

free

MK8 Extruder Rep2 Mod by builtbybogus

...s the notorious delrin plunger with a ball bearing. extruder reliability is increased and it actually fits perfectly in the rep2.

thingiverse

free

Delrin Plunger Replacement for Replicator 2 MK8 Extruder by FunbieStudios

...pgrade to arrive, we designed and printed out a replacement head for it. it still makes use of the stock screw and rubber o-ring.

thingiverse

free

MK7 MK8 Extruder filament guide by sidney81716

...mk7 mk8 extruder filament guide by sidney81716

thingiverse

filament guide for mk7/mk8 extruder

thingiverse

free

Makerbot MK8 1.75mm Filament all-Metal Bowden Extruder Wire feeder Ultimate Upgrade by Vanadusan

...ations search on www.instructables.com for: mk8 metal bowden extruder wire feeder ultimate upgrade)

i am sorry for my english ;)

cults

free

Extruder with MK8 drive gear and 688 bearing for dagoma discovery200

...with mk8 drive gear and 688 bearing for dagoma discovery200

extruder with mk8 drive gear and 688 bearing for dagoma discovery200

thingiverse

free

D-bot mk7 extruder by Masterjuggler

... better filament grip and less grinding due to the increased surface area contacting the filament from the larger outer diameter.

thingiverse

free

Slide bearing and sleeve for filament spool

...shape

sleeve inner diameter 47,5mm for a snug fit, will cause problems if printed with a non-flexible filament

sleeve height 18mm

thingiverse

free

MK7 / MK8 extruder holder for QU-BD One/Two Up by Wiper

...d be assemble together with qu-bd oneup / twoup bearing holder for extruder, and probably with some parts of the original holder.

Gth

3d_ocean

$16

Ford_Mustang GTH 2006 wheel

...ated in real units of measurement. model with physically accurate materials. model is separated on parts and correctly named. ...

3d_ocean

$10

Ford Mustang GTH 2006 rim

...ed in real units of measurement. model with physically accurate materials. model is separated on parts and correctly named. so...

3d_export

$30

FordMustang GTH 2006 wheel 3D Model

... type muscle vehicle part of avto car ford_mustang gth 2006

fordmustang gth 2006 wheel 3d model creativeideastudio 53501 3dexport

3d_export

$20

Ford Mustang GTH 2006 rim 3D Model

...o ford mustang type muscle vehicle part of avto car gth 2006

ford mustang gth 2006 rim 3d model creativeideastudio 53550 3dexport

cg_studio

$35

Ford Mustang GTH 2006 wheel3d model

... .lwo .max .mb .obj .xsi - ford mustang gth 2006 wheel 3d model, royalty free license available, instant download after purchase.

cg_studio

$20

Ford Mustang GTH 2006 rim3d model

...bx .lwo .max .mb .obj .xsi - ford mustang gth 2006 rim 3d model, royalty free license available, instant download after purchase.

unity_asset_store

$15

Cartoon Car GTH

...te your workflow with the cartoon car gth asset from rcc design. find this & other land options on the unity asset store.

thingiverse

free

Switch Block by gth

...switch block by gth

thingiverse

mounting block for handlebar switches.

thingiverse

free

Replicator1 Tool Holder by gth

...ding accessory that sits on the side of the replicator. positions for sd cards, hex wrenches (aka allen keys), scraper cards etc.

thingiverse

free

Replicator1 - 3 x Corners by gth

...rners by gth

thingiverse

this derivative is the same as the original - just three corners into one file to print them in one go.

Mk8

3d_export

$99

Mitsubishi Lancer Ralliart sedan 2004 3D Model

...lancer ralliart sedan 2004 3d model 3dexport mitsubishi ralliart mk8 2004 2005 4-door sedan saloon japan japanese eighth generation...

3d_ocean

$89

Mitsubishi Lancer Ralliart sedan 2004

...2004-2005 4-door eighth generation japan japanese mitsubishi mitsubishi ralliart mk8 ralliart saloon sedan the 3d model was created on...

thingiverse

free

MK8 by IsaiRochaSegura

...chasegura

thingiverse

in this thing i share a replace bar for mk8 extruder. i include the solidworks files for any modification.

thingiverse

free

MK8 Duct by ombranova

...mk8 duct by ombranova

thingiverse

duct for extruder mount mk8 on prusa i3

thingiverse

free

MK8 Flex Guide by loganjkd

...mk8 flex guide by loganjkd

thingiverse

just an inset for the mk8

thingiverse

free

MK7 / MK8 Mold by JMDesigns

...mk7 / mk8 mold by jmdesigns

thingiverse

mk7 / mk8 mold

thingiverse

free

Support extruder MK8 by rickshaolin

...support extruder mk8 by rickshaolin

thingiverse

support extruder mk8

thingiverse

free

MK8 Fan bracket by rocktang2003

...mk8 fan bracket by rocktang2003

thingiverse

mk8 fan bracket

thingiverse

free

HyperCube Mk8 mount by machala737

...hypercube mk8 mount by machala737

thingiverse

remix hypercube mk8 mount

thingiverse

free

mk8 fan holder by everythingother

...mk8 fan holder by everythingother

thingiverse

this is mk8 amazing fan holder

Minimalistic

3d_export

$20

minimalist rings

...minimalist rings

3dexport

minimalist rings

3d_export

$5

minimalistic beach

...minimalistic beach

3dexport

minimalistic scenes for your symbols or other ideas

3d_ocean

$2

Minimalist Ring

...ring 3docean fish minimalist ring this is a very minimalistic ring design. its shape is inspired by a fish...

3d_ocean

$15

minimalist house

...minimalist house

3docean

architecture minimalist modern

a simple modern house, ready to render in mental ray

3d_export

$15

minimalist table

...list table

3dexport

this is a minimalist table with wood and aluminum materials. in the rar file i've included .stl and .obj

3d_export

$7

modern minimalist bedroom

...modern minimalist bedroom

3dexport

modern minimalist bedroom

turbosquid

$100

Minimalist homes

...d

royalty free 3d model minimalist homes for download as rvt on turbosquid: 3d models for games, architecture, videos. (1253698)

turbosquid

$70

minimalist apartment

...oyalty free 3d model minimalist apartment for download as max on turbosquid: 3d models for games, architecture, videos. (1566613)

turbosquid

$25

The House is Minimalist

...lty free 3d model the house is minimalist for download as skp on turbosquid: 3d models for games, architecture, videos. (1246947)

turbosquid

$18

Tableware minimalistic

...alty free 3d model tableware minimalistic for download as max on turbosquid: 3d models for games, architecture, videos. (1545233)

Replacements

3d_export

$12

replaceable bristle

...replaceable bristle

3dexport

this is 3d printable replaceable bristle toothbrush.

3d_export

$34

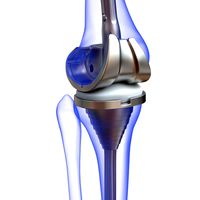

Knee Replacement

...h meets the lower leg. ... during a total knee replacement, the end of the femur bone is removed and replaced with a metal shell.

3d_export

$44

Hip Replacement

...omponents. the damaged femoral head is removed and replaced with a metal stem that is placed into the hollow center of the femur.

turbosquid

$59

Hip replacement

...el hip replacement for download as ma, c4d, lwo, lxo, and obj on turbosquid: 3d models for games, architecture, videos. (1520195)

turbosquid

$10

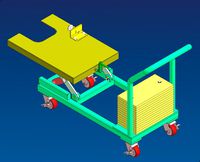

Module replacment station

...alty free 3d model module replacment station for download as on turbosquid: 3d models for games, architecture, videos. (1271271)

3d_export

$8

tool replacement gearbox

...tool replacement gearbox

3dexport

eccentric lifting mechanism, you can process according to available drawings.

turbosquid

$7

Globe Oil Atomizer Replacement Housing

... oil atomizer replacement housing for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1253839)

turbosquid

free

SLICE Ceramic Scapel (Replaceable Blade)

... (replaceable blade) for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1363525)

3d_export

$19

Knee Replacement Implant

...ntimeter<br>__________________________<br>poly count :<br>polygon count - 217440<br>vertex count - 108776

turbosquid

$19

(Project) Bad odor filtering sytem with support rail and pulley that assure a comfortable gel filter element replacement.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.