Thingiverse

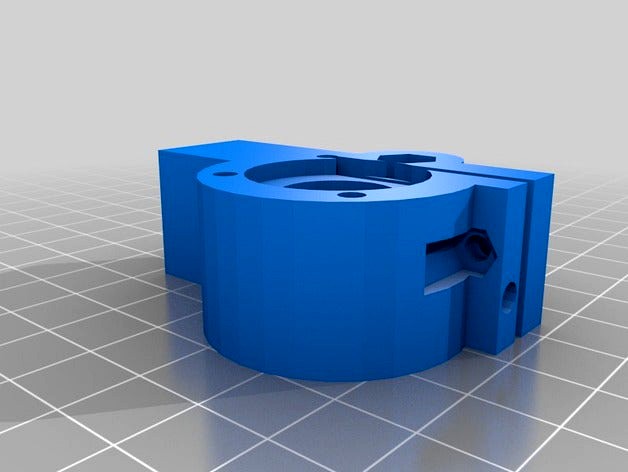

Mini Kossel Extruder for 3mm filament by Tearabite

by Thingiverse

Last crawled date: 4 years, 4 months ago

I was stuck using 3mm filament because my other printer uses it and I wanted to be able to share filament. But all the other 3mm extruders I could find would cause a lot of skipping and grinding on the filament. So I just took Johan's original design and tweaked a bunch of stuff to make it work smooth.

1) Increased filament path diameter for 3mm filament (plus some wiggle room)

2) Moved the bearing 1mm farther away from the filament path to decrease pressure.

3) Extended the push-to-connect mount point outward and increased the diameter. This is to suit the E3D v6 bowden coupler.

4) Increased the diameter of the pulley hole. My pulley was grinding on the inside of the extruder and introducing a lot of unnecessary friction.

5) Increased the diameter of the indention for the gearhead. The motor I have (phidgets) didn't seat smoothly with the original values and so when it was mounted it would get tilted slightly, knocking the pulley into the wall and causing friction.

And that's it. Everything else is the same. Im finally printing successfully with a bowden extruder with 3mm filament on my mini Kossel.

For those curious, I am using 1/4th microstepping. Anything more than that was exacerbating the skipping and missed steps.

UPDATE (6/19/14): Moved the bearing 0.25mm closer to the pulley to improve grip a little more. If you're using cheap filament, use a 35mm M3 with a spring on it to tension the clamp.

1) Increased filament path diameter for 3mm filament (plus some wiggle room)

2) Moved the bearing 1mm farther away from the filament path to decrease pressure.

3) Extended the push-to-connect mount point outward and increased the diameter. This is to suit the E3D v6 bowden coupler.

4) Increased the diameter of the pulley hole. My pulley was grinding on the inside of the extruder and introducing a lot of unnecessary friction.

5) Increased the diameter of the indention for the gearhead. The motor I have (phidgets) didn't seat smoothly with the original values and so when it was mounted it would get tilted slightly, knocking the pulley into the wall and causing friction.

And that's it. Everything else is the same. Im finally printing successfully with a bowden extruder with 3mm filament on my mini Kossel.

For those curious, I am using 1/4th microstepping. Anything more than that was exacerbating the skipping and missed steps.

UPDATE (6/19/14): Moved the bearing 0.25mm closer to the pulley to improve grip a little more. If you're using cheap filament, use a 35mm M3 with a spring on it to tension the clamp.