Thingiverse

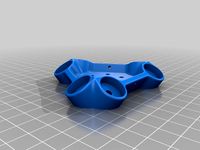

Max v3 Rostock Effector for Dual-Mount Titan Aero's by sean_tapscott

by Thingiverse

Last crawled date: 3 years ago

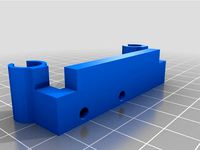

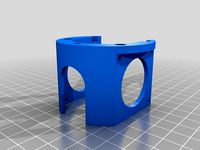

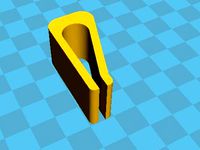

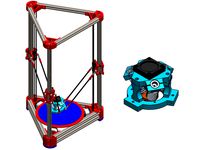

This is a prototype effector for the SeeMeCNC Max v3 Rostock.

Should be able to mount two Titan Aero Direct Drive extruders to it. Have not tested it, but it is very easily printable. I printed mine in black Ultimaker Nylon with a raft.

Included in the file set some offsets for the nozzles, estimated from the positions of the models using markers and TinkerCAD's rulers at midpoints.

L X: -19.95 Y: 7.76

R X: 16.95 Y: 2.76

Measured from each of the three effector mounts, The center point of the effector is also marked with a crosshairs.

You can the model in TinkerCad, the placement of the two direct drives is a mirrored solution and their relation follows closely the specifications detailed on E3D's wiki page here: https://wiki.e3d-online.com/wiki/Titan_Assembly#Mirrored_Titan

In Nylon, this weighs 52 grams. The motors should each weigh 140 grams, and the titan Aeros weigh ~108 grams each. Total should be ~548 grams, or nearly half a kilogram. In pounds, that is 1.2lb.

I hope that is enough information. Let me know if you'd like to know more.

https://www.tinkercad.com/things/83Wgmd1Kg3r-titanaero-effector-dual-mount

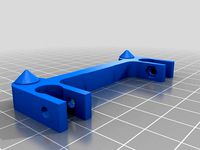

Edit 05/04/2017: The outer connections aren't placed far enough out for the stock arms. The stock arms are bulky, and can't handle an outside flush mount like the model currently has. I didn't want to reprint the entire thing, so I took a M3x20mm socket caps, a flat washer and some nuts as spacers to create enough space . I'll take a picture later, but be forewarned, the three outboards need to be moved outwards a bit for the arms to be able to reach them.

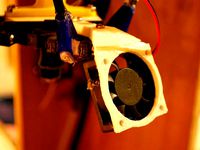

Edit 05/18/2017: Uploaded a new model. It is more successful at mounting to the arms. More secure, less sway. I drilled holes in the nylon on the bottom for the stock layer fans using a 5/64" drill bit. Do it in ventilation. One of the layer fans has a longer one than the other, that should go to the front side, you'll see. Stock fans fit with no modification.

Edit 05/26/2017: Here is a firmware version using Repetier Firmware 0.92.9 . I had to modify several sections, but if you hook everything up in the same way that I did, it should do fine. Extruder fans turn on when the extruders are above 50F. Layer fans are controlled as normal.

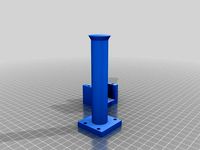

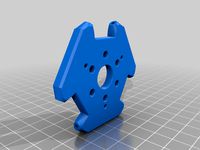

Edit 10/13/2017: Added a small model for mounting a Mini IR Differential leveling sensor. Upgrading my printer to the Duet Wifi board, and including this sensor. The mount will mount right at the center cross of the platform. Will add pictures soon.

Should be able to mount two Titan Aero Direct Drive extruders to it. Have not tested it, but it is very easily printable. I printed mine in black Ultimaker Nylon with a raft.

Included in the file set some offsets for the nozzles, estimated from the positions of the models using markers and TinkerCAD's rulers at midpoints.

L X: -19.95 Y: 7.76

R X: 16.95 Y: 2.76

Measured from each of the three effector mounts, The center point of the effector is also marked with a crosshairs.

You can the model in TinkerCad, the placement of the two direct drives is a mirrored solution and their relation follows closely the specifications detailed on E3D's wiki page here: https://wiki.e3d-online.com/wiki/Titan_Assembly#Mirrored_Titan

In Nylon, this weighs 52 grams. The motors should each weigh 140 grams, and the titan Aeros weigh ~108 grams each. Total should be ~548 grams, or nearly half a kilogram. In pounds, that is 1.2lb.

I hope that is enough information. Let me know if you'd like to know more.

https://www.tinkercad.com/things/83Wgmd1Kg3r-titanaero-effector-dual-mount

Edit 05/04/2017: The outer connections aren't placed far enough out for the stock arms. The stock arms are bulky, and can't handle an outside flush mount like the model currently has. I didn't want to reprint the entire thing, so I took a M3x20mm socket caps, a flat washer and some nuts as spacers to create enough space . I'll take a picture later, but be forewarned, the three outboards need to be moved outwards a bit for the arms to be able to reach them.

Edit 05/18/2017: Uploaded a new model. It is more successful at mounting to the arms. More secure, less sway. I drilled holes in the nylon on the bottom for the stock layer fans using a 5/64" drill bit. Do it in ventilation. One of the layer fans has a longer one than the other, that should go to the front side, you'll see. Stock fans fit with no modification.

Edit 05/26/2017: Here is a firmware version using Repetier Firmware 0.92.9 . I had to modify several sections, but if you hook everything up in the same way that I did, it should do fine. Extruder fans turn on when the extruders are above 50F. Layer fans are controlled as normal.

Edit 10/13/2017: Added a small model for mounting a Mini IR Differential leveling sensor. Upgrading my printer to the Duet Wifi board, and including this sensor. The mount will mount right at the center cross of the platform. Will add pictures soon.

Similar models

thingiverse

free

E3D Titan Aero mount for Rostock MAX by SublimeLayers

...thingiverse.com/rocky00717/designs) made to attach the berd air part cooling tube (it has a small designed-in support structure).

thingiverse

free

Titan Aero Extruder for Maxmicron by LukasKun

...: set the motor mount to the x carriage

2nd: install the titan aero extruder

3rd: set the fan in the blower then screw the 2 bolt

thingiverse

free

Rostock Max V1/2 Air Effector by crperryjr

...s with older rostock max arms. designed to work with diamond hot end mount, but should also work with any standard hot end mount.

thingiverse

free

Hot End Mount for E3D v6 on Rostock Max V2 by rspoering

...mount for the e3d and the flex3drive extruder. this will mount the e3d v6 and fan to the stock rostock max v2 effector platform.

thingiverse

free

E3D Titan Aero Layer Cooler by ngen33r

...nt layer cooler for the e3d titan aero. it uses a 40mm x 40mm blower fan and mounts direct to the front of the extruder assembly.

thingiverse

free

Titan Aero Fan Mounted BLTouch

...ptions for the titan aero so i made my own.

it mounts to the extruder fan in line with the nozzle so the offsets are: x +39 | y 0

thingiverse

free

Titan Aero flashforge creator pro carriage by foureasy

...teps/mm with stock extruder motor

printed in carbonx nylon at .2mm layer height

needs .125" thick washers under the platform

thingiverse

free

Kossel Clear magball to Rostock Max V2/V3 Effector by lowrizzle

...and came up with this. the end effect was that i was able to top-mount a volcano on an old unused printer and got it going again.

thingiverse

free

Rostock Max v2 stock effector to Smart Effector adaptor

...effector from 713maker (see pics).

i have e3d hotends but had to revert to the old 25mm hotend fan because of dimensional issues.

grabcad

free

Titan Aero mount for PMiniFab

...titan aero mount for pminifab

grabcad

titan aero mount for pminifab 3d printer.

adds fan layer and bltouch

Sean

3ddd

$1

Sean Foster

... картина , рама , пейзаж

автор sean foster

turbosquid

$16

PROMEMORIA Sean

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Sean Spicer trophy

...

royalty free 3d model sean spicer trophy for download as max on turbosquid: 3d models for games, architecture, videos. (1156770)

turbosquid

$10

MADE Barstool Sean

...

royalty free 3d model made barstool sean for download as max on turbosquid: 3d models for games, architecture, videos. (1564047)

3ddd

free

Petal 50x50 Sean Dix

... журнальный

журнальный стол petal 50x50 от дизайнера sean dix. выполнен в двух оттенках. размер 50х50х50 см.

cg_studio

$29

sean armchair max3d model

...ir max3d model

cgstudio

.max .obj - sean armchair max 3d model, royalty free license available, instant download after purchase.

3d_export

$29

Sean Armchair 3D Model

...holstered white purple shiny design interior contemporary vray max high quality

sean armchair 3d model lostinsight 68435 3dexport

3ddd

free

Sean Armchair

...

-date created: april 8, 2013

-polys: 161,640 k

-verts: 162,620 k

-modeling type: polygonal/subdivison ready.

-3d software u

turbosquid

$3

Sean Dix Drum Dining Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Диван Casatua Day Bed от Sean Dix

...ua day bed от sean dix. материал: ткань, сталь, дерево. цвет: серо-коричневый, хром, орех светлый. размер: w2195*d970*h750sh390mm

Rostock

thingiverse

free

Endstop for Rostock by Raz0neR

...endstop for rostock by raz0ner

thingiverse

endstop for rostock.

thingiverse

free

Rostock Cooling by nobicore

...rostock cooling by nobicore

thingiverse

rostock cooling

thingiverse

free

ROSTOCK PARTS by OC3D

...rostock parts by oc3d

thingiverse

parts for our modified rostock extruder assembly

thingiverse

free

Rostock squirrel fan by MarioPanic

...rostock squirrel fan by mariopanic

thingiverse

rostock squirrel fan

thingiverse

free

FC Hansa Rostock by ron86

...fc hansa rostock by ron86

thingiverse

fc hans rostock logo

thingiverse

free

rostock mini carriage by cjol

...rostock mini carriage by cjol

thingiverse

carriage for my rostock mini project

thingiverse

free

Rostock and Rostock Mini Dual Extruder Mount by westonshakespear

...ht.

sorry about the pictures, my filament jammed for part of the print and i am waiting for a new part to print a better version.

thingiverse

free

Rostock mini clip by Scott_Chen

...rostock mini clip by scott_chen

thingiverse

rostock mini clip for printer base glass

thingiverse

free

Rostock Board holder by drewan

...rostock board holder by drewan

thingiverse

this is a clip for using a rostock board as a print surface.

thingiverse

free

Rostock Fan Bracket by ImprisonedByTime

...rostock fan bracket by imprisonedbytime

thingiverse

this bracket is for a 40mm fan to attach to the rostock 3d printer

Effector

3d_ocean

$5

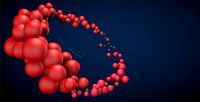

Radial Sound Effector

...e spheres will expand with your song. fully customisable, change the color, the size of the spheres or even put in different s...

3d_ocean

$12

3D Customizable Puzzle Set (16x10)

...mograph compatible (you can effect the pieces with mograph effector) - included also a non-mograph version with...

thingiverse

free

Effector by olo2000pm

...effector by olo2000pm

thingiverse

effector

thingiverse

free

CERAMBOT-Effector

...cerambot-effector

thingiverse

cerambot-effector

thingiverse

free

modulize effector by candyasdf

...ulize effector by candyasdf

thingiverse

mount things on effector with m3 screws

effector radius : 25.4mm

rod arm distance : 40mm

thingiverse

free

Delta Effector by zavier

...delta effector by zavier

thingiverse

delta effector with radial fan 50 and bltouch

thingiverse

free

D810 Effector by WhiteTiger13

...d810 effector by whitetiger13

thingiverse

this is d810 effector for d810 without autocalibration, and also cap for it.

thingiverse

free

Effector for Delta Printer

...effector for delta printer

thingiverse

effector for delta printer (3 color)

using diamond hotend

thingiverse

free

Delta effector magnetic by fpassos

...delta effector magnetic by fpassos

thingiverse

effector for e3dv6 hotend. i needed put the spheres (10mm) on the effector.

thingiverse

free

End Effector Gripper

...end effector gripper

thingiverse

end effector gripper

for a robotic arm

uses mg995 servo motor

Aero

3ddd

$1

AERO

...aero

3ddd

aero

стул, производитель aero. ссылка:http://www.mebelaero.ru/catalog/detail.html?id=6647

design_connected

$18

Aero

...aero

designconnected

wendelbo aero computer generated 3d model. designed by 365° north.

3ddd

$1

AERO BC30W

...aero bc30w

3ddd

aero , барный

артикул: bc30w

производитель: aero

3ddd

$1

TERMA AERO HG

...terma aero hg

3ddd

полотенцесушитель , aero

terma radiator aero hg

design_connected

$11

Aero Round

...aero round

designconnected

restoration hardware aero round computer generated 3d model.

design_connected

$11

Aero Oval

...aero oval

designconnected

restoration hardware aero oval computer generated 3d model.

design_connected

$16

Aero 027

...aero 027

designconnected

emu group aero 027 computer generated 3d model. designed by newman , paul.

3ddd

$1

desiree aero

...desiree aero

3ddd

фабрика - desiree

коллекция - aero

описание - диван/sofa

сайт -http://www.euromobil.com

design_connected

$11

Aero 026

...aero 026

designconnected

emu group aero 026 bar stools computer generated 3d model. designed by paul newman .

turbosquid

$12

aero plane

...

royalty free 3d model aero plane for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1544795)

Titan

design_connected

$18

Titan

...titan

designconnected

original btc titan computer generated 3d model.

3d_ocean

$25

RMS Titanic

...rms titanic

3docean

ship steamer titanic

3d model of the rms titanic

turbosquid

$49

Titan

...quid

royalty free 3d model titan for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1314276)

turbosquid

$8

Titan

...d

royalty free 3d model titan for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1545505)

3d_export

$15

eren yeager titan from attack on titan

...eren yeager titan from attack on titan

3dexport

3d model of eren titan

3d_export

$5

titanic new

...titanic new

3dexport

titanic 3d model normal quality for animation

3d_export

$100

Titan 3D Model

...titan 3d model

3dexport

silo launcher rocket titan

titan 3d model acquarius 37854 3dexport

3d_ocean

$25

Titan

...nfs nfshs one ps ps1 psone rod speed sports stakes titan transport vehicle

quality exterior and low polygon interior concept car.

3ddd

$1

Titanic Lamp(table)

...titanic lamp(table)

3ddd

titanic lamp(table)

turbosquid

$10

Titan chair

...osquid

royalty free 3d model titan chair for download as max on turbosquid: 3d models for games, architecture, videos. (1301533)

V3

3d_export

$5

Poison-v3

...poison-v3

3dexport

poison-v3

3ddd

$1

Curtain v3

...curtain v3

3ddd

полупрозрачная штора v3

turbosquid

free

v3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

potato v3

...potato v3

3dexport

turbosquid

$69

Skeletor v3

...royalty free 3d model skeletor v3 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1712713)

turbosquid

$49

Zombie v3

...

royalty free 3d model zombie v3 for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1342458)

turbosquid

$2

Bitcoin v3

...

royalty free 3d model bitcoin v3 for download as c4d and prj on turbosquid: 3d models for games, architecture, videos. (1182845)

turbosquid

$29

Turret V3

...alty free 3d model turret v3 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1217498)

turbosquid

$20

Radiators v3

... free 3d model radiators v3 for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1607437)

turbosquid

$10

Wheel V3S

...e 3d model wheel v3s for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1344250)

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)