Thingiverse

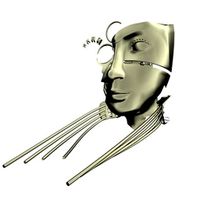

Making Monsters: 10 Servo Articulating Mask Kit by CoasterLabs

by Thingiverse

Last crawled date: 3 years ago

Project Premise/ The Idea

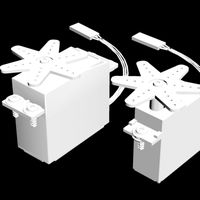

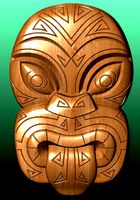

This is a project for Halloween that I've been wanting to do for SOOOOO long. Similar to the Chewbacca mask this is much more advanced. It is a mask that is covered with actuators that move a silicon mask to add realism. I'm hoping to either buy a basic mask and make a monster or just buy one pre-made from my local pop up shop and glue the actuator connections to certain points on the mask. There are 10 servos that will move certain connections and stretch and squash the mask to make it look like it is alive. The actuators or linear sliders are controlled by high tension fishing line that travels through some tubing that years ago I bought WAY too much of. The tubes run over my head and down my back to a backpack that contains a bank of 10 servos controlled by an Arduino Mega 2560 simply for available storage. I'm not sure what the monster will be or how I am going to arrange the sliders yet so this is a work in progress. Once I am done I will share the code, but meanwhile I will share parts as I make them.

I'm here to answer your questions so if you have any don't hesitate to ask! :D

Note: The bank of servos box is quite large so I will try and make it into separate parts for expandability and ease of printing for those with smaller printers.

Testing/Prototyping Log

September 16th, 2016:

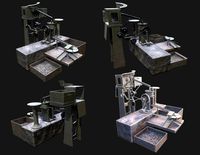

1 single servo box controller for Hitec standard servos are available as a proof of concept. The next piece I will upload probably tomorrow is that actual slider piece.

September 17th, 2016:

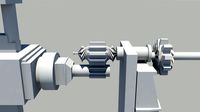

I've now uploaded the three parts to a proof of concept slider. This is just an example, but I will be making more actuators soon like ones that rotate or pan left and right instead of just this one linear slider so I have more options. I tried to make this linear slider as thin as possible, but I might try and redesign it to be even thinner. Right now it it 25mm wide, 65mm long and 13.5 mm high... As I type this they are printing. I will update this once they are done.

September 19th, 2016:

Sorry I haven't been updating this project, I've been studying for a teat I had earlier today. To go back the the parts I printed in the previous update ^^^ they didn't work. Don't get me wrong, the plug fit (printed flat with support and wall vertical) and the track admitted the plug well (printed flat as it, not vertically, which even if you did, it should be fine), but the slider, the most important piece of the proof of concept didn't fit, it was too tight that it wouldn't slide and for a moment was a stuck. I reprinted it slowly to not get any more ringing at 94.5% scale and it fits. However, that said the one thing I keep neglecting to remember is that the cord I'm using and the tubing rub too well that there is a lot of resistance I might let the cords sit in some WD-40 or vegetable oil to lubricate them or I could braid them to reduce contract with the inside of the tubing... I'm not sure what I'm going to do, but if I can't get that to work I might have to buy some cheap PTFE tubing... the expensive kind... ugh... I'm gonna do everything I can to avoid that... Meanwhile I am currently trying to first draw out a rotating actuator and reducing size and weight on the linear slider and the rotating one. Less contact, less friction... That's all I have for now. I'm gonna try and start with the first video soon covering most of what all the updates above explain, but I'm not sure when...

September 20th, 2016:

After class I quickly mocked up the rotating or rotary actuator so I could print them since my school has a decent enough 3D printer. The result was exactly what I designed... Which included the flaws too. For one the actual rotor is too loose in the housing and the lips on the housing adds really nothing too useful to the function of the entire actuator. I might just make a slim bare bones rotating actuator that is about 6mm thick or less than 6mm thick... It works, but not well enough and the rotor falls out more often than not...

September 21st, 2016:

Like I said in the previous update (^^^^^) the rotary actuator didn't really work, the concept was there, but ultimately it didn't work. However, after I finished writing that update I mocked up a new rotary actuator. Remember how I said I was gonna make it less than or exactly 6mm thick? I did it! Obviously the tubing connection isn't 6mm thick in total, but the actual mechanism is. I'm pretty proud of it and how well it turned out. I minimized the amount of friction it has and when under tension from the pull/push fishing line and the elastic working against the fishing like, the lip acts as a lock to keep the rotor in place. If you don't understand what I'm saying go ahead and print it out and I'm sure you'll see what I mean... :D

September 26th, 2016:

I haven't really been updating this page, but I haven't really had a chance to really work on this project much. I will try to do more this weekend with creating the mask. I don't think it will be a full mask, but a mesh mask. So one that contains holes and is split into pieces... The other thing to note is that I did finally find the can of WD-40, but haven't gotten a chance to see if it will help the fishing line slide better. (also as of yesterday, I've misplaced the fishing line, so... yeah...)

October 13th, 2016:

Okay so I've been gone for a LONG time and haven't updated this project. The issue is one like I've probably mentioned before the string has too much friction within the tube and doesn't slide easily. Luckily I've since found the can of WD-40 (I found it a while ago, buy hey) so maybe that will work. ALSO, this season of American Horror Story hasn't really given us a monster to replicate so I think this will become more of a concept kit that you can use to glue to a cheep masquerade mask and use yourself. I'll be updated the photos over the course of next week since I haven't yet. Everything else works, but the unforeseen cable friction is really killing this project... I do have some chicken wire or stiff wire (it's bendable, but pretty stiff) so I will try that and report on it later.... Sorry for no videos, I will try and see if I can make some, but school is just getting in the way...

Failure Log

September 17th, 2016

Slider at 100% scale did not fit, far too tight, became lodged in track. Reprinted at 94.5%

September 20th, 2016

Rotor in rotating actuator is far too loose to function. Slim design is probably best.

Thingiverse Failure

September 21st, 2016

There seems to be some kind of compiler error going on with the Thingiverse upload system. When you select modelt to upload using the 'BROWSE' button the inevitably fail. When you drag and drop them, though, it works...

This is a project for Halloween that I've been wanting to do for SOOOOO long. Similar to the Chewbacca mask this is much more advanced. It is a mask that is covered with actuators that move a silicon mask to add realism. I'm hoping to either buy a basic mask and make a monster or just buy one pre-made from my local pop up shop and glue the actuator connections to certain points on the mask. There are 10 servos that will move certain connections and stretch and squash the mask to make it look like it is alive. The actuators or linear sliders are controlled by high tension fishing line that travels through some tubing that years ago I bought WAY too much of. The tubes run over my head and down my back to a backpack that contains a bank of 10 servos controlled by an Arduino Mega 2560 simply for available storage. I'm not sure what the monster will be or how I am going to arrange the sliders yet so this is a work in progress. Once I am done I will share the code, but meanwhile I will share parts as I make them.

I'm here to answer your questions so if you have any don't hesitate to ask! :D

Note: The bank of servos box is quite large so I will try and make it into separate parts for expandability and ease of printing for those with smaller printers.

Testing/Prototyping Log

September 16th, 2016:

1 single servo box controller for Hitec standard servos are available as a proof of concept. The next piece I will upload probably tomorrow is that actual slider piece.

September 17th, 2016:

I've now uploaded the three parts to a proof of concept slider. This is just an example, but I will be making more actuators soon like ones that rotate or pan left and right instead of just this one linear slider so I have more options. I tried to make this linear slider as thin as possible, but I might try and redesign it to be even thinner. Right now it it 25mm wide, 65mm long and 13.5 mm high... As I type this they are printing. I will update this once they are done.

September 19th, 2016:

Sorry I haven't been updating this project, I've been studying for a teat I had earlier today. To go back the the parts I printed in the previous update ^^^ they didn't work. Don't get me wrong, the plug fit (printed flat with support and wall vertical) and the track admitted the plug well (printed flat as it, not vertically, which even if you did, it should be fine), but the slider, the most important piece of the proof of concept didn't fit, it was too tight that it wouldn't slide and for a moment was a stuck. I reprinted it slowly to not get any more ringing at 94.5% scale and it fits. However, that said the one thing I keep neglecting to remember is that the cord I'm using and the tubing rub too well that there is a lot of resistance I might let the cords sit in some WD-40 or vegetable oil to lubricate them or I could braid them to reduce contract with the inside of the tubing... I'm not sure what I'm going to do, but if I can't get that to work I might have to buy some cheap PTFE tubing... the expensive kind... ugh... I'm gonna do everything I can to avoid that... Meanwhile I am currently trying to first draw out a rotating actuator and reducing size and weight on the linear slider and the rotating one. Less contact, less friction... That's all I have for now. I'm gonna try and start with the first video soon covering most of what all the updates above explain, but I'm not sure when...

September 20th, 2016:

After class I quickly mocked up the rotating or rotary actuator so I could print them since my school has a decent enough 3D printer. The result was exactly what I designed... Which included the flaws too. For one the actual rotor is too loose in the housing and the lips on the housing adds really nothing too useful to the function of the entire actuator. I might just make a slim bare bones rotating actuator that is about 6mm thick or less than 6mm thick... It works, but not well enough and the rotor falls out more often than not...

September 21st, 2016:

Like I said in the previous update (^^^^^) the rotary actuator didn't really work, the concept was there, but ultimately it didn't work. However, after I finished writing that update I mocked up a new rotary actuator. Remember how I said I was gonna make it less than or exactly 6mm thick? I did it! Obviously the tubing connection isn't 6mm thick in total, but the actual mechanism is. I'm pretty proud of it and how well it turned out. I minimized the amount of friction it has and when under tension from the pull/push fishing line and the elastic working against the fishing like, the lip acts as a lock to keep the rotor in place. If you don't understand what I'm saying go ahead and print it out and I'm sure you'll see what I mean... :D

September 26th, 2016:

I haven't really been updating this page, but I haven't really had a chance to really work on this project much. I will try to do more this weekend with creating the mask. I don't think it will be a full mask, but a mesh mask. So one that contains holes and is split into pieces... The other thing to note is that I did finally find the can of WD-40, but haven't gotten a chance to see if it will help the fishing line slide better. (also as of yesterday, I've misplaced the fishing line, so... yeah...)

October 13th, 2016:

Okay so I've been gone for a LONG time and haven't updated this project. The issue is one like I've probably mentioned before the string has too much friction within the tube and doesn't slide easily. Luckily I've since found the can of WD-40 (I found it a while ago, buy hey) so maybe that will work. ALSO, this season of American Horror Story hasn't really given us a monster to replicate so I think this will become more of a concept kit that you can use to glue to a cheep masquerade mask and use yourself. I'll be updated the photos over the course of next week since I haven't yet. Everything else works, but the unforeseen cable friction is really killing this project... I do have some chicken wire or stiff wire (it's bendable, but pretty stiff) so I will try that and report on it later.... Sorry for no videos, I will try and see if I can make some, but school is just getting in the way...

Failure Log

September 17th, 2016

Slider at 100% scale did not fit, far too tight, became lodged in track. Reprinted at 94.5%

September 20th, 2016

Rotor in rotating actuator is far too loose to function. Slim design is probably best.

Thingiverse Failure

September 21st, 2016

There seems to be some kind of compiler error going on with the Thingiverse upload system. When you select modelt to upload using the 'BROWSE' button the inevitably fail. When you drag and drop them, though, it works...

Similar models

thingiverse

free

Herringbone Bearing (Sort of) by ninjaplatypus

...g it so i don't know if it even works yet. if it doesn't i am deeply sorry. deeply.

update:

doesn't work at all. oops

grabcad

free

exhaust turbo adapter

...rk, but i think they will. the turbo flange is a t3.

i had to make some updates 5/9/17 i haven't got to try the changes yet.

thingiverse

free

Shishi Odoshi "Deer Scarer" Shortened Tube by supyo

...r gothicgeek's mod, i just kinda eyeballed it.

when i've actually made the thing, i'll update this when any new info.

thingiverse

free

Samurai Mask Stencil by joeystoll42

...ead and try one for myself. i haven't printed it yet but i'm probably gonna do ninjaflex so it won't be as delicate.

grabcad

free

First test

...ut at the time i'm still making proves because i´m not so sure in the orientation of the bar elements,and the wall thickness.

thingiverse

free

Iron Man Mk1 Mark I Mask (Rear) by LukeSkypilot

...ed

i'm also designing a stand to display the finished helmet on (image shown) which will hopefully be up in the next few days

thingiverse

free

T800 actuators by rejaak

...m not sure at what scale i printed the t800..so i'm sorry if they are too small or too big. i never intended to upload these.

thingiverse

free

Storm window slide bolt by matthewharvey

...l, and i need to consult with the folks who run them as to which would be most appropriate. will update this once i try printing.

grabcad

free

Pneumatic Actuator

...;m sorry since i've been able to use few , although well detailed, pictures where the inside couldn't been exactly seen.

thingiverse

free

Electronic shifting servo mount (cable-actuated) by aiber

...this appeared: https://www.kickstarter.com/projects/1598276649/xshifter-worlds-first-universal-wireless-smart-shi http://www.xshifter.com/ which mounts similarly, & actuates similary. i haven't played with them & i'm not sure...

Coasterlabs

thingiverse

free

Project X Community by CoasterLabs

...project x community by coasterlabs

thingiverse

test

thingiverse

free

GoPro Posable Clip Mount by CoasterLabs

...clip mount by coasterlabs

thingiverse

exceptional to the fairly expensive jaws: flex clip: $49.99.... print all at 100% infill.

thingiverse

free

Inspirational Quotes for a MAKER by CoasterLabs

.... enjoy.... print and be merry.... (i'd suggest printing 75% scale or lower as it is quite big unless you have the space....)

thingiverse

free

Ninja Hand Chopper! Slice and Dice... by CoasterLabs

...p it on your hand and start slicing and dicing fruit with your 'hand' in minutes... 'shing. shing. shing. slice.'

thingiverse

free

Replacement for SpikenzieLabs Solder:Time™ Acrylic Case by CoasterLabs

...board and battery nice and snug. this might require some sanding of the case and pcb up at the top, but mine has worked decently.

thingiverse

free

Deltaprintr Replacement Carriages by CoasterLabs

...) fits perfectly into the provided effector?! (plate where all the arms) it a little bit of a tight fit, but works really well...

thingiverse

free

Holiday Light Necklace/Bulbs by CoasterLabs

...ch, you take full responsibility to all effects of the sequence which includes strobing and bright light values. use responsibly.

Articulating

turbosquid

$60

Articulated doll

...e 3d model articulated doll for download as max, obj, and ztl on turbosquid: 3d models for games, architecture, videos. (1277424)

turbosquid

$10

articulated lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$11

Articulated Industrial Light

...articulated industrial light

designconnected

o. c. white articulated industrial light computer generated 3d model.

cg_studio

$169

Articulated Truck3d model

...cgstudio

.3ds .c4d .lwo .max .obj - articulated truck 3d model, royalty free license available, instant download after purchase.

3d_export

$90

Design Bus Articuled 3D Model

...design bus articuled 3d model

3dexport

design bus articuled

design bus articuled 3d model basshunter 8620 3dexport

turbosquid

$59

Articulated truck 45f

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$130

Caterpillar 725 Articulated Truck

...for close-up renders. scene contain textures, standart scanline, mentalray and vray materials. - high quality polygonal model ...

3d_export

$22

articulated dump truck

...ost popular and not very 3d file formats, as well as textures for shaders.<br>format: 3ds max, obj, fbx, 3ds, lwo, c4d, dae

turbosquid

free

Rigged articulated bus acordion bus for games

...or download as max, max, unitypackage, max, fbx, obj, and 3ds on turbosquid: 3d models for games, architecture, videos. (1599911)

3d_export

$24

dubai bus articulated

...ed check if our models are useful for your project and leave a like if you like this model.<br>thank you for your interest!

Servo

turbosquid

$30

Servo

...d model servo for download as obj, blend, dae, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1394011)

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

turbosquid

$1

Servo Moter

...quid

royalty free 3d model servo moter for download as blend on turbosquid: 3d models for games, architecture, videos. (1650816)

turbosquid

free

Motor/Servo

...osquid

royalty free 3d model motor/servo for download as obj on turbosquid: 3d models for games, architecture, videos. (1522522)

turbosquid

$60

Servo Skull

...

royalty free 3d model servo skull for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1318573)

3d_export

$5

Servo 3D Model

...rvo 3d model

3dexport

servo

servo 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl pasqualesiciliano 104590 3dexport

turbosquid

$50

Servo Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Servo Motor

...model servo motor for download as 3ds, max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1324153)

turbosquid

$29

Servo Set

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

machine servo

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Monsters

3d_export

$5

monster

...monster

3dexport

very realistic monster

3d_export

free

monster

...monster

3dexport

bloody monster! (looks terrifying)

3d_ocean

$12

Monster

... this code “envatoguest2016” . visit our store high details 3d character model for small monster , useful for animations, movi...

3d_ocean

$15

Monster

...monster

3docean

android game ios java main model monster playdesign

polycount :1118 texture :1024×1024png

3d_ocean

$8

Monster Man

...monster man

3docean

giant monster

monster man software: 3ds max, mental ray.

turbosquid

$60

MONSTER

...turbosquid

royalty free 3d model monster for download as max on turbosquid: 3d models for games, architecture, videos. (1220728)

turbosquid

$60

Monster

...turbosquid

royalty free 3d model monster for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320840)

turbosquid

$19

Monster

...turbosquid

royalty free 3d model monster for download as max on turbosquid: 3d models for games, architecture, videos. (1248452)

turbosquid

$15

Monster

...turbosquid

royalty free 3d model monster for download as ztl on turbosquid: 3d models for games, architecture, videos. (1417804)

turbosquid

$15

Monster

...turbosquid

royalty free 3d model monster for download as max on turbosquid: 3d models for games, architecture, videos. (1293042)

Mask

turbosquid

$1

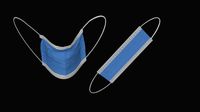

Dust Mask Medical Mask Face Mask Surgical Mask

...k face mask surgical mask for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1533329)

3d_export

$5

Mask

...mask

3dexport

african mask

turbosquid

$2

Riggged Surgical mask face mask dust mask medical mask

...sk dust mask medical mask for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1536257)

archibase_planet

free

Mask

...mask

archibase planet

mask sculpture decor

mask - 3d model for interior 3d visualization.

3d_export

$19

masks tech metal masks wearable futuristic masks

... tech metal masks wearable futuristic masks

3dexport

masks, tech metal masks, wearable, futuristic masks zip contain fbx obj max

archibase_planet

free

Mask

...mask

archibase planet

mask sculpture decor

mask-decor - 3d model for interior 3d visualization.

archibase_planet

free

Mask

...mask

archibase planet

mask

swimming mask - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Mask

...mask

archibase planet

picturesque element mask

mask n050608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Mask

...mask

archibase planet

mask picturesque element

mask n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Mask

...mask

archibase planet

mask ornament decoration

mask decor n240211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Kit

turbosquid

$3

Bathroom Kit Baño kit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Kit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

Drift Kit

...drift kit

3dexport

turbosquid

$40

BitCoin Kit

...urbosquid

royalty free 3d model bitcoin kit for download as on turbosquid: 3d models for games, architecture, videos. (1519068)

turbosquid

$9

Industrial kit

...osquid

royalty free 3d model industrial kit for download as on turbosquid: 3d models for games, architecture, videos. (1144117)

turbosquid

$6

Kit Vases

...

turbosquid

royalty free 3d model kit vases for download as on turbosquid: 3d models for games, architecture, videos. (1285114)

turbosquid

free

Survival Kit

...rbosquid

royalty free 3d model survival kit for download as on turbosquid: 3d models for games, architecture, videos. (1637721)

turbosquid

$50

Ninja Kit

...rbosquid

royalty free 3d model ninja kit for download as fbx on turbosquid: 3d models for games, architecture, videos. (1672364)

turbosquid

$35

Brushes Kit

...osquid

royalty free 3d model brushes kit for download as max on turbosquid: 3d models for games, architecture, videos. (1216721)

turbosquid

$19

Medical kit

...osquid

royalty free 3d model medical kit for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486089)

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.

Making

3d_export

$5

make make planet

...make make planet

3dexport

turbosquid

$1

Make

...ke

turbosquid

royalty free 3d model make for download as obj on turbosquid: 3d models for games, architecture, videos. (1403181)

3ddd

free

make up

...make up

3ddd

косметика

makeup

turbosquid

$65

Make an interior

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Make Up Stand

...bosquid

royalty free 3d model make up stand for download as on turbosquid: 3d models for games, architecture, videos. (1542368)

turbosquid

$12

make up table

...quid

royalty free 3d model make up table for download as max on turbosquid: 3d models for games, architecture, videos. (1280789)

turbosquid

$1

Make up desk

...oyalty free 3d model make up desk for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1222023)

turbosquid

$1

Make up desk

...oyalty free 3d model make up desk for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1222007)

turbosquid

$29

Ammo making machine

...aking machine for download as max, unitypackage, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1572915)

turbosquid

$29

Making light Collection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.