GrabCAD

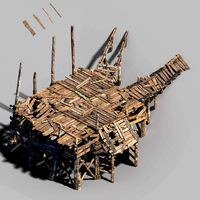

Low Profile Surface Mount Explosion Proof Fluorescent Light - 20,000 Lumens - Paint Booth Approved

by GrabCAD

Last crawled date: 1 year, 10 months ago

https://www.larsonelectronics.com/product/64357/low-profile-surface-mount-explosion-proof-fluorescent-light-20-000-lumens-paint-booth-approved

Made in the USA

The Larson Electronics EPL-48-216 Explosion Proof Fluorescent Light Fixture is NRTL Listed for United States and Canada, Class 1 Division 1 and Class 1 Division 2 for hazardous locations where flammable chemical/petrochemical vapors exist or have the potential to exist. The unit carries a T6 temperature rating, it is also approved for Paint Spray Booths.

*PLEASE NOTE: ANY FREE SHIPPING OFFERS DO NOT APPLY TO THIS EXPLOSION PROOF LIGHT FIXTURE*

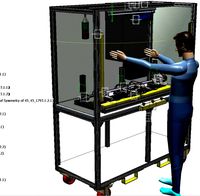

The EPL-48-216 fixture is a 4 foot long, 4 lamp, Class 1 Division 1 and Class 2 Division 1&2 explosion proof fluorescent light which is also approved for use in paint spray booth applications. This T6 temperature rated fixture comes standard with four T5 high output fluorescent lamps. The lamps are protected by heat and impact resistant Pyrex tubes and the fixture is constructed of copper free aluminum alloy. The lamp reflectors are corrosion resistant heavy gauge aluminum and coated with a high gloss reflective finish. This fixture is multi-voltage capable and is available with a variety of lamp options. The EPL-48-216 provides operators in hazardous locations with a reliable and affordable lighting solution that provides the best explosion proof protection available without sacrificing light quality or fixture durability.

Mounting Options: Unless otherwise specified, our standard, most popular configuration is the bracket end mounting shown enlarged below. We also offer a pendant mount for those needing to suspend the fixture away from the ceiling surface (i.e. suspend from pipe or conduit). Additional mounting configurations can be customized to meet the requirements on the application. Please contact us for special mounting configurations.

Adjustable Surface Mount Brackets: Each bracket is cinched to the bracket mounting peg on each side of the light. The angle of the bracket is set by tightening two cap screws on either side of the bracket. The cap screws act as a set screw. The bracket itself is mounted via a single bolt hole at the top the bracket. There are two brackets, one on each end of the light. Once the brackets are mounted to a surface (ceiling, floor or wall), the light fixture can be removed from the brackets by loosening the cap screws that hold the bracket to the mounting peg.

Suspension Mounting: Pendant mount fixtures hang from the ceiling and are suspended by rigid pipe. Each fixture features a 1/2” NPT junction box on one end, and a 1/2” NPT adjustable L-bracket on the other end of the fixture. Operators bring rigid pipe down to the threaded mounting hubs. Wiring is fed down through the rigid pipe to the junction box and tied in to the fixture’s lead wires, completing the electrical connection. The adjustable L-shape mounting bracket provides support for the opposite end of the fixture.

Made in USA Quality

1. Each unit dialectically tested.

2. Fixture arrives assembled and lamped to reduce installation time and cost. Adjustable mounting brackets enable the operator to choose any mounting angle for the fixture, where other models may only offer one or three choices.

3. Fixture constructed of extruded corrosion resistant copper free aluminum alloy.

4. Over-sized, finned ballast housing for 800 mA fixtures provides more heat dissipation and extends ballast life. Larger ballast box accommodates High Output lamp ballasts. Ballast housing easily accessible and externally mounted. Top and bottom covers secured with nuts and bolts, instead of threaded through holes, which can be damaged with dirt.

5. Heavy gauge extruded aluminum reflectors with high gloss reflective finish. Resists dents and corrosion.

6. A wrench is used to unscrew the end caps for relamping the fixture, while other models require the “tap and knock off” method to loosen the end cap.

7. Explosion proof, impact and heat resistant Pyrex tubes provide lamp protection.

Lamp Options

F54-T5/850/HO – 54 watt, 5000 lumens per bulb, 20,000 hours life, 5000 Kelvin color, CRI 85 RHA-UNV-254-LT5 Ballast is THD<10% and HPF .98 (Suffix –50KT5)

F54-T5/841/HO - 50 watt, 4450 lumens per bulb, 20,000 hour life, 4100 Kelvin color, CRI 85 (Suffix -41KT5)

Made in the USA

The Larson Electronics EPL-48-216 Explosion Proof Fluorescent Light Fixture is NRTL Listed for United States and Canada, Class 1 Division 1 and Class 1 Division 2 for hazardous locations where flammable chemical/petrochemical vapors exist or have the potential to exist. The unit carries a T6 temperature rating, it is also approved for Paint Spray Booths.

*PLEASE NOTE: ANY FREE SHIPPING OFFERS DO NOT APPLY TO THIS EXPLOSION PROOF LIGHT FIXTURE*

The EPL-48-216 fixture is a 4 foot long, 4 lamp, Class 1 Division 1 and Class 2 Division 1&2 explosion proof fluorescent light which is also approved for use in paint spray booth applications. This T6 temperature rated fixture comes standard with four T5 high output fluorescent lamps. The lamps are protected by heat and impact resistant Pyrex tubes and the fixture is constructed of copper free aluminum alloy. The lamp reflectors are corrosion resistant heavy gauge aluminum and coated with a high gloss reflective finish. This fixture is multi-voltage capable and is available with a variety of lamp options. The EPL-48-216 provides operators in hazardous locations with a reliable and affordable lighting solution that provides the best explosion proof protection available without sacrificing light quality or fixture durability.

Mounting Options: Unless otherwise specified, our standard, most popular configuration is the bracket end mounting shown enlarged below. We also offer a pendant mount for those needing to suspend the fixture away from the ceiling surface (i.e. suspend from pipe or conduit). Additional mounting configurations can be customized to meet the requirements on the application. Please contact us for special mounting configurations.

Adjustable Surface Mount Brackets: Each bracket is cinched to the bracket mounting peg on each side of the light. The angle of the bracket is set by tightening two cap screws on either side of the bracket. The cap screws act as a set screw. The bracket itself is mounted via a single bolt hole at the top the bracket. There are two brackets, one on each end of the light. Once the brackets are mounted to a surface (ceiling, floor or wall), the light fixture can be removed from the brackets by loosening the cap screws that hold the bracket to the mounting peg.

Suspension Mounting: Pendant mount fixtures hang from the ceiling and are suspended by rigid pipe. Each fixture features a 1/2” NPT junction box on one end, and a 1/2” NPT adjustable L-bracket on the other end of the fixture. Operators bring rigid pipe down to the threaded mounting hubs. Wiring is fed down through the rigid pipe to the junction box and tied in to the fixture’s lead wires, completing the electrical connection. The adjustable L-shape mounting bracket provides support for the opposite end of the fixture.

Made in USA Quality

1. Each unit dialectically tested.

2. Fixture arrives assembled and lamped to reduce installation time and cost. Adjustable mounting brackets enable the operator to choose any mounting angle for the fixture, where other models may only offer one or three choices.

3. Fixture constructed of extruded corrosion resistant copper free aluminum alloy.

4. Over-sized, finned ballast housing for 800 mA fixtures provides more heat dissipation and extends ballast life. Larger ballast box accommodates High Output lamp ballasts. Ballast housing easily accessible and externally mounted. Top and bottom covers secured with nuts and bolts, instead of threaded through holes, which can be damaged with dirt.

5. Heavy gauge extruded aluminum reflectors with high gloss reflective finish. Resists dents and corrosion.

6. A wrench is used to unscrew the end caps for relamping the fixture, while other models require the “tap and knock off” method to loosen the end cap.

7. Explosion proof, impact and heat resistant Pyrex tubes provide lamp protection.

Lamp Options

F54-T5/850/HO – 54 watt, 5000 lumens per bulb, 20,000 hours life, 5000 Kelvin color, CRI 85 RHA-UNV-254-LT5 Ballast is THD<10% and HPF .98 (Suffix –50KT5)

F54-T5/841/HO - 50 watt, 4450 lumens per bulb, 20,000 hour life, 4100 Kelvin color, CRI 85 (Suffix -41KT5)

Similar models

grabcad

free

Surface Mount Explosion Proof, Waterproof Fluorescent Lights - T12 Hotbox Configuration

...s to 165 degrees f.

for other lamp optoins please see our epl-48-2l fixture that is approved for paint spray booth applications.

grabcad

free

Low Profile Explosion Proof Fluorescent Light Fixture - 2 Foot 4 Lamp Compact Design - 8000 Lumens

...quire different lamp options, please see our epl-24-2l for fluorescent lamps or our epl-24-2l-led for fluorescent style led lamps

grabcad

free

Explosion Proof Emergency Fluorescent light Combination - 4 foot - 2 T5HO lamps - Class I, Div I

...ubes provide lamp protection.

lamps

f54-t5/850/ho – 54 watt, 5000 lumens per bulb, 20,000 hours life, 5000 kelvin color, cri 85

grabcad

free

Explosion Proof High Bay Fluorescent Light Fixture for Paint Booths - 40,000 Lumens - Class 1 Div 1

...f .98 (suffix –50kt5)

f54-t5/841/ho - 50 watt, 4450 lumens per bulb, 20,000 hour life, 4100 kelvin color, cri 85 (suffix -41kt5)

grabcad

free

Explosion Proof T8 Fluorescent Light with Emergency Battery Backup -2ft 4 Lamp - Paint Booth Approve

...s provide lamp protection.

lamp options

f17-t8 – 1325 lumens per bulb (2650 lumens total), 24,000 hours life, 4100 kelvin color

grabcad

free

45 Degree Surface Mount Explosion Proof Emergency Fluorescent light Combination - 4 foot - 2 T5HO

...bes provide lamp protection.

lamps

f54-t5/850/ho – 354 watt, 5000 lumens per bulb, 20,000 hours life, 5000 kelvin color, cri 85

grabcad

free

EPL-48-1L Surface Mount Explosion Proof, Waterproof Fluorescent Lights -Paint Booth, Rigs - 1 Lamp

...h operators requiring a brighter color light than a traditional "cool white", this bulb can be useful. (suffix –t12dho)

grabcad

free

Surface Mount Explosion Proof, Waterproof Fluorescent Lights - T12 Very High Output - Oil Rigs - 2 L

... paint spray booths. for other lamp optoins please see our epl-48-2l fixture that is approved for paint spray booth applications.

grabcad

free

Surface Mount Explosion Proof Fluorescent Light - T8HO Lamps - 4 Foot 2 Lamp - Class 1 Div 1

...rex tubes provide lamp protection.

lamp options

f48-t8/ho - 48 watt, 4000 lumens per bulb, 18,000 hours life, 4100 kelvin color

grabcad

free

Explosion Proof Fluorescent Light for Paint Booths, Oil Rigs, Boats -2 Foot-8 Lamp-T5HO Bulbs

...

f24-t5ho – 2000 lumens per bulb, 20,000 hours life, 5000 kelvin color, cri 85 rha-unv-254-lt5 ballast is thd<10% and hpf .98

Lumens

3ddd

$1

Торшер LUMEN LAMP

...торшер lumen lamp

3ddd

lumen

торшер, высота 212см, вес 25кг. включите турбосмуз, сейчас отключен.

3ddd

$1

Люстра "LUMEN"

... aedile

люстра "lumen" производства "эдилит" /польша/

18х40вт., цоколь е14

3ddd

$1

Lumen Center Italia Quadro

...uadro

размер:↑ 58 cm, ↔ 60 см.

описание: настольный светильник, латунь, палладий, акрил, мрамор.

сайт: www.lumencenteritalia.com/

3ddd

$1

Lumen Center Italia Victory

...аллюминий, или хром. основание выполнено из металла. верхняя чаша - подвижная, позволяет направлять поток света в нужную сторону.

turbosquid

$8

Falmec - Lumen Isola 175 Design

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

lumen center italia №1

...ар ул. 40 летпобеды 144/4 тел. (861)257-73-38

e-mail: salon.monplaisir@gmail.com

салон итальянского света "монплезир"

3ddd

$1

lumen center italia №2

...ар ул. 40 летпобеды 144/4 тел. (861)257-73-38

e-mail: salon.monplaisir@gmail.com

салон итальянского света "монплезир"

3ddd

$1

Skyline by Francesco Giannattasio

... lumen

производительhttp://www.lumencenteritalia.com/en/products/contemporary/skyline

3ddd

$1

Настольные лампы Arte di Murano

... lume

настольные лампы arte di murano

model lp lume piccolo/small lumen h 50cm

model lg lume grande/big lumen h 71cm

archive3d

free

Chandelier 3D Model

...er lumen mec collezione cristallo 1415 n290410 - 3d model (*.3ds) for interior 3d visualization.

Fluorescent

3d_ocean

$6

Energy Bulb Fluorescent

...energy bulb fluorescent

3docean

bulb eco ecological energy bulb fluorescent lamp light lighting

energy bulb fluorescent.

turbosquid

free

Fluorescent lamp

...bosquid

free 3d model fluorescent lamp for download as blend on turbosquid: 3d models for games, architecture, videos. (1313789)

3d_export

$5

Fluorescent 3D Model

...fluorescent 3d model

3dexport

florasan light lamb fluorescent bulb white high poly

fluorescent 3d model husky 49990 3dexport

turbosquid

$14

Fluorescence Microscope

...l fluorescence microscope for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1610738)

turbosquid

$2

Fluorescent light

... 3d model fluorescent light for download as max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1531043)

turbosquid

$39

Fluorescent Bulb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Bulb fluorescent

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Bulb fluorescent

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$6

fluorescent bulb

...seful light much more efficiently than incandescent lamps or bulbs.<br>modeled in solidworks.<br>rendered in keyshot.

3d_export

$5

Fluorescent light bulb

...fluorescent light bulb

3dexport

realistic 3d model of fluorescent light bulb with v-ray materials.

Approved

3d_export

$30

Stamp 3D Model

...stamp invoice wooden handle office supply tool ink stamper approved documents letter form paper stamp 3d model tartino 27989...

cg_studio

$30

Stamp3d model

...rubber stamp invoice wooden handle supply tool ink stamper approved documents letter form paper .3ds .c4d .dxf .obj -...

3d_ocean

$12

Pumpkin Package

... stability and has earned the aethereal studios game ready stamp of approval. the autumn pumpkin package is optimized for both...

3ddd

$1

FREDERICIA FURNITURE 3Seats sofa No.1

...ard fabrics according to current price list. customer specified fabrics (com) upon factory approval.

dimensions in cm

206х86х83

3d_ocean

$9

Catwalk for structures

...for structures, heavy duty, aisc 360 and can/csa 16 approved used in mine plants and construction infrastructure, scale 1:1,...

3ddd

$1

FREDERICIA FURNITURE 2Seats sofa No.1

...rd fabrics according to current price list. customer specified fabrics (com) upon factory approval.

dimensions in cm

143x86x 83

3d_ocean

$8

Adidas Conext15 Official match ball

...adidas conext15 official match ball 3docean adidas approved ball brazuca conext conext15 field fifa football goal match...

3d_ocean

$8

Adidas Finale 2014/2015 Champions League Ball

...adidas finale 2014/2015 champions league ball 3docean adidas approved ball champions fifa finale football goal league net score...

3d_ocean

$8

Adidas Finale Berlin 2015

...adidas finale berlin 2015 3docean adidas approved ball berlin champions fifa final finale football goal league...

3d_ocean

$8

Puma evoPower 1 Statement and Statement 15

...puma evopower 1 statement and statement 15 3docean approved ball evo evopower fifa football goal kick official power...

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

turbosquid

$12

Armoured fighting vehicles armoured vehicles with explosion-proof wheels

...ured vehicles with explosion-proof wheels for download as max on turbosquid: 3d models for games, architecture, videos. (1629664)

3d_export

$16

yb2 high voltage explosion proof series three phase asynchronous motor 9 specifications in total

...cifications in total

3dexport

yb2 high voltage explosion proof series three phase asynchronous motor (9 specifications in total)

turbosquid

$2

Replacement RC Car Shock Proof Plank SJ11 Accessory Spare Parts 15-SJ11 for GPTOYS S911 S912 And Others

...1 for gptoys s911 s912 and others for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1193732)

3d_ocean

$1

Insulation Felt Seamless Pattern Background

...background 3docean background carpet ceilings closeup cloth cover dust proof fabric felt fiber fleece gray insulation insulation felt material...

3d_export

$20

Passport Collection 3D Model

...3dexport passport us usa united states travel document citizenship proof booklet realistic textures russia uk great britain france collection...

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

000

turbosquid

$15

Sofa 000

...free 3d model sofa 000 for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1401892)

turbosquid

$40

TIRE 000

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair 000

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

MOD A 000.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

electric engine BLDC with water cooling for printing 10 000 W stl

...with water cooling for printing 10 000 w stl for download as on turbosquid: 3d models for games, architecture, videos. (1632791)

3ddd

$1

Ручки для кухни Giusti WMN.721Y.128.XXX и WPO.721X.000.XXX

...установить свою степень сглаживания, изначально установлено 2.

в архиве библиотека материалов для ручек. всё настроено для vray.

3d_export

$5

baby

...3dexport baby head<br>poligon min 106 468 x 7 473 000 , max 6 859 000 x 7 473...

3ddd

$1

Статуетка

...статуетка 3ddd 000 00000 0000 00000 0 0 000 0 0 0...

3d_export

$6

Rome Centurion Sculpt

...sculpt 3dexport rome centurion high poly model .ztl 75 000 000...

3d_export

$5

Wendigo Ram Sculpt

...sculpt 3dexport wendigo ram high poly model .ztl 36 000 000...

Booth

3d_export

$10

Booth Devassa

...booth devassa

3dexport

booth 10x10

3d_export

$10

Booth VENEZA

...booth veneza

3dexport

booth 12x10

3d_export

$10

Booth MSD

...booth msd

3dexport

booth 8.00x6.00

3d_export

$10

Booth Oncoclincas

...booth oncoclincas

3dexport

booth 14.00x11.00

3d_export

$10

Booth SOLINFTEC

...booth solinftec

3dexport

booth 11.00x5.00

3d_export

$7

Booth Janssen

...booth janssen

3dexport

booth 6.00x6.00

3d_export

$7

Booth Astellas

...booth astellas

3dexport

booth 6.00x6.00

3d_export

$7

Booth Galvani

...booth galvani

3dexport

booth 4.00x4.50

3d_export

$5

exhibition booth

...exhibition booth

3dexport

exhibition booth

3d_export

$5

Booth Camil

...booth camil

3dexport

booth 6x3

Profile

3ddd

$1

Profile

... лофт , профиль , свип

описание ниже

3d_export

$5

profile anchor

...profile anchor

3dexport

profile anchor

3d_export

$5

profile fastener

...profile fastener

3dexport

profile fastener

3ddd

$1

Profil Doors

...

3ddd

profil doors , дверь

двери и наличник profil doors модели 7х и 15х, цвет капучино.

3ddd

$1

Profile chair

...rofile

http://www.casefurniture.co.uk/contemporary-furniture-products/contemporary-chairs-benches-stools/profile-chair/

3ddd

$1

Profil Doors

...dd

двери , profildoors

дверь profil doors

серия - vg

модель - 4vg

цвет - чёрный матовый

3d_export

$5

profile hand wheel

...profile hand wheel

3dexport

profile hand wheel

3d_export

$5

profile rotation handle

...profile rotation handle

3dexport

profile rotation handle

3d_ocean

$6

Low Profile Radiator

...low profile radiator

3docean

heat heater hot pipe radiator temperature thermostat warm

a low profile version of the radiator

3d_export

$10

Aluminum profile 3D Model

...aluminum profile 3d model

3dexport

aluminum profile window sample corner

aluminum profile 3d model 3dstocker 27361 3dexport

Surface

design_connected

$9

Surface

...surface

designconnected

rosenthal surface computer generated 3d model.

3d_export

$18

surface-cracked surface 27

...surface 27

3dexport

surface-cracked surface 27<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...

3d_export

$18

surface-cracked surface 27

...surface 27

3dexport

surface-cracked surface 27<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...

3d_export

$5

surface base

...surface base

3dexport

surface base

3ddd

$1

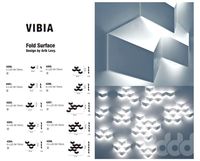

vibia fold surface

...vibia fold surface

3ddd

vibia fold surface , vibia

vibia fold surface

3d_export

$18

surface-yellow river dam-horizontal surface 03

...surface-yellow river dam-horizontal surface 03

3dexport

surface-yellow river dam-horizontal surface 03<br>3ds max 2015

3d_export

$18

surface-yellow river dam-horizontal surface 01

...surface-yellow river dam-horizontal surface 01

3dexport

surface-yellow river dam-horizontal surface 01<br>3ds max 2015

3d_export

$10

surface book 2

...surface book 2

3dexport

surface book 2 laptop

3ddd

$1

Modular Kurk Surface

...modular kurk surface

3ddd

modular

modular kurk surface

turbosquid

$9

cooking surface

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Paint

archibase_planet

free

Paints

...paints

archibase planet

paints paint

paints n241211 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Paint

...paint

archibase planet

jar of paint paint can

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

paint

...paint

3ddd

paint

archibase_planet

free

Paint

...paint

archibase planet

paint

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

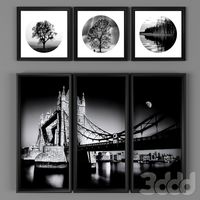

Painting

...painting

3ddd

картина

painting in double wooden frame decorated antique

3ddd

$1

The collection of paintings

...

картина , фото

collection of modern and contemporary paintings.

contemporary paintings.

turbosquid

$1

Painting

...ee 3d model painting for download as 3ds, obj, md3, and blend on turbosquid: 3d models for games, architecture, videos. (1207611)

turbosquid

free

Painting

... 3d model painting for download as ma, 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1219609)

3ddd

$1

PAINTINGS

...paintings

3ddd

панно

размеры:

1170х900

3ddd

$1

Paintings Frame

...paintings frame

3ddd

картины

paintings frame

20

3d_export

$15

rocks 20

...rocks 20

3dexport

rocks 3d model 20

3ddd

$1

DECOR MEDIEVO 20*20 MIX

...ллекция: bolonia

фабрика: mainzu

страна: испания

размер: 20x20 см

ссылка:http://www.mainzu.com/bolonia.php#prettyphoto

3d_export

$6

tap-20

...tap-20

3dexport

3ddd

$1

Bed 20

...bed 20

3ddd

постельное белье

bed 20. i hope you like it

software : 3dsmax + md + vray 2.4

turbosquid

$40

20 Shields

...turbosquid

royalty free 3d model 20 shields for download as on turbosquid: 3d models for games, architecture, videos. (1305068)

3d_export

$5

houseberg home 20

...houseberg home 20

3dexport

houseberg home 20

turbosquid

$10

Decor 20

...urbosquid

royalty free 3d model decor 20 for download as stl on turbosquid: 3d models for games, architecture, videos. (1677149)

turbosquid

$10

building 20

...osquid

royalty free 3d model building 20 for download as max on turbosquid: 3d models for games, architecture, videos. (1362227)

turbosquid

$2

Workout 20

...bosquid

royalty free 3d model workout 20 for download as max on turbosquid: 3d models for games, architecture, videos. (1607615)

turbosquid

$125

fd-20

...quid

royalty free 3d model fd-20 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218626)

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...