Thingiverse

Low Profile Filament Runout Sensor

by Thingiverse

Last crawled date: 4 years, 2 months ago

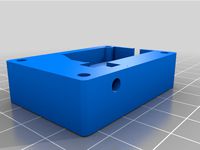

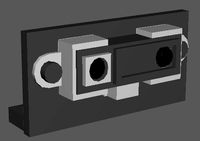

All the mechanical runout sensor designs I've found seem to have a major drawback: the microswitch is aligned with the filament path. That's fine for bowden setups, where the size doesn't really matter, but on my printer anything on top of the direct drive extruder reduces the available print volume. Of course you can place the sensor away from the extruder, but then you're always left with a length of wasted filament. I've also found a lot of them can be tricky to load/unload and tend to catch the filament.

So I designed my own to try and eliminate these issues. It uses a 5mm ball bearing to actuate a microswitch, which is mounted perpendicular to the filament path. A second ball bearing is used as a contact point rather than a 3d printed surface as I found it gives a much smoother contact; the filament slides through easily and doesn't catch even if it's been chewed up by the extruder or melted out of shape. It also allows for very smooth retraction back through the mechanism when a runout is detected. All that means you can mount the sensor right on top of the extruder, which was my goal with this design.

I've got a balco touch (Wanhao Di3 Plus clone) so I've got a file that'll fit nicely into the extruder assembly. The micro switch is mounted with m2 screws, which can thread directly into the printed part. I've also uploaded the Fusion 360 source files so that it can be adjusted to fit other printers, or to suit whatever size of micro switch or ball bearings you might have lying around.

So I designed my own to try and eliminate these issues. It uses a 5mm ball bearing to actuate a microswitch, which is mounted perpendicular to the filament path. A second ball bearing is used as a contact point rather than a 3d printed surface as I found it gives a much smoother contact; the filament slides through easily and doesn't catch even if it's been chewed up by the extruder or melted out of shape. It also allows for very smooth retraction back through the mechanism when a runout is detected. All that means you can mount the sensor right on top of the extruder, which was my goal with this design.

I've got a balco touch (Wanhao Di3 Plus clone) so I've got a file that'll fit nicely into the extruder assembly. The micro switch is mounted with m2 screws, which can thread directly into the printed part. I've also uploaded the Fusion 360 source files so that it can be adjusted to fit other printers, or to suit whatever size of micro switch or ball bearings you might have lying around.

Similar models

thingiverse

free

MAM - Filament Runout Sensor - Magnetic actuated Mircoswitch by MacNite

...unt it to the frame

ptfe tube

update 2020_08_20

i added slotted holes to mount the micro-switch to fine-tune the actuation point.

thingiverse

free

Optical filament runout sensor bracket for 30x30 extruded aluminum profile by stanoba

...ded profile. optical sensor is not suitable for transparent filaments, in that case use mechanical sensor (micro-switch) instead.

thingiverse

free

Titan Aero Clone fan/runout/sn04/cablechain/endstop mounting

...sor can be adjusted/fine tuned.

i believe i was using this as the reference cable chain: https://www.thingiverse.com/thing:611593

thingiverse

free

Extruder Mount with Runout Sensor for Extrusion Mounting by KerseyFabrications

... switch for filament run-out detection. it has a filament guide and is easy to load.

roller micro switch: https://amzn.to/33n80we

thingiverse

free

Runout sensor housing & Filament roller by jlorimer

...original, thing number 4835184

depending on how you orientate the stls in slicer you may need supports but these will be minimal.

thingiverse

free

Mechanical filament runout sensor bracket for 30x30 extruded aluminum profile by stanoba

...also transparent filaments. bom: 1x microswitch omron ss-3gl13p or similar 2x m2.5x10 1x m6x10 omron ss-3gl13p -...

thingiverse

free

Filament runout sensor mount by rkirstine

...nd of the filament is reached. example of the end stop: https://folgertech.com/collections/sensors-and-modules/products/end-stop

thingiverse

free

Dual Filament Runout Sensor Mount

...using my design here (https://www.thingiverse.com/thing:4104446), the filament path for the second extruder will line up as well.

thingiverse

free

Filament runout sensor by kranix

...on both the in and out side, i run a bowden from the extruder back to this sensor, where it fits snugly and is held without glue.

thingiverse

free

3D Printer Filament Runout Sensor Encloser

...ation about the firmware configuration is available at the official marlin documentation found here.

filament runout sensor demo

Runout

3d_export

$6

clamping mechanism of heavy workpiece

...load<br>the inertia force at the maximum acceleration of horizontal runout is less than the retraction side thrust of cylinder.<br>selection...

thingiverse

free

Filament runout sensor by TA1AUB

...filament runout sensor by ta1aub

thingiverse

filament runout sensor

thingiverse

free

Runout filament sensor by davidix68

...runout filament sensor by davidix68

thingiverse

ender 3 runout sensor microswitch case

thingiverse

free

runout sensor -bowden by chroja

...runout sensor -bowden by chroja

thingiverse

runout sensor -bowden

v5 optimalize design

thingiverse

free

Filament runout sensor by jos

.../webshop/cartesio-shop/electronics/filament-runout-sensor

for assembly :http://mauk.cc/mediawiki/index.php/filament_runout_sensor

thingiverse

free

Filament runout by pochetto

...y pochetto

thingiverse

easy filament runout.

1 endstop

1 led

nel firmware attivare la funzione di fine filo e assegnare un pin.

thingiverse

free

Filament runout sensor support by 100s99s

...filament runout sensor support by 100s99s

thingiverse

support for filament runout sensor of direct drive.

thingiverse

free

Swivel mount runout sensor by notnyt

...swivel mount runout sensor by notnyt

thingiverse

608 bearing mounted filament runout sensor

thingiverse

free

Filament runout sensor fastener by Cherepok

...filament runout sensor fastener by cherepok

thingiverse

movable adjustable mount for bigtreetech filament runout sensor.

thingiverse

free

Runout gauge for pulley by tom4cad

...runout gauge for pulley by tom4cad

thingiverse

20t pulley with 5 mm bore. measured runout 0,07 mm

edit

tool with 8mm hole added

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

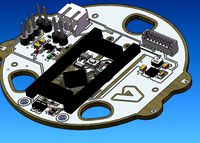

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Profile

3ddd

$1

Profile

... лофт , профиль , свип

описание ниже

3d_export

$5

profile anchor

...profile anchor

3dexport

profile anchor

3d_export

$5

profile fastener

...profile fastener

3dexport

profile fastener

3ddd

$1

Profil Doors

...

3ddd

profil doors , дверь

двери и наличник profil doors модели 7х и 15х, цвет капучино.

3ddd

$1

Profile chair

...rofile

http://www.casefurniture.co.uk/contemporary-furniture-products/contemporary-chairs-benches-stools/profile-chair/

3ddd

$1

Profil Doors

...dd

двери , profildoors

дверь profil doors

серия - vg

модель - 4vg

цвет - чёрный матовый

3d_export

$5

profile hand wheel

...profile hand wheel

3dexport

profile hand wheel

3d_export

$5

profile rotation handle

...profile rotation handle

3dexport

profile rotation handle

3d_ocean

$6

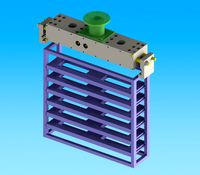

Low Profile Radiator

...low profile radiator

3docean

heat heater hot pipe radiator temperature thermostat warm

a low profile version of the radiator

3d_export

$10

Aluminum profile 3D Model

...aluminum profile 3d model

3dexport

aluminum profile window sample corner

aluminum profile 3d model 3dstocker 27361 3dexport

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.