Thingiverse

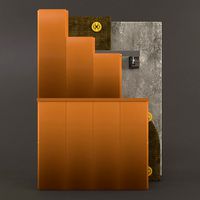

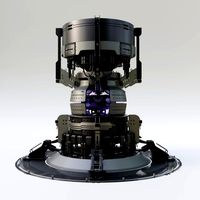

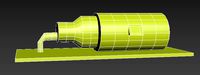

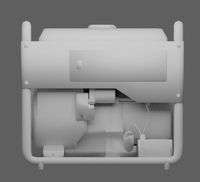

Linear Piston for a Magnetic Repulsion Electric Generator.

by Thingiverse

Last crawled date: 4 years, 3 months ago

This is a linear piston that will be used in a Magnetic Electric Generator project. This is currently a work in progress. The goal is to create a Magnetic Repulsion Piston that uses 1/2 inch N50 grade Neodymium Cylindrical Magnets. The piston will move linearly through a set of coils to generate Voltage and Current.

One preliminary test produced 7.2V DC with an output current of 1.0 Amps at 1300 RPM passing the piston through 3 Magnet Wire Coils that were 1/4 inch wide with 25 Feet of Magnet Wire wrapped around each Coil. The output measurements were taken across all of the coils which were connected in parallel. The Linear Piston does not have to move far about 1.25 inches back and forth through the 3 Magnet Wire Coils.

For each revolution of the drive wheel the repulsion piston will induce 6 power pulses inside of each individual coil. Since the magnets are 1/2 inch long the the North Pole is

approximately 1/4 inch long and the South Pole is approximately 1/4 inch long. So, a good starting point is to make sure the air gap between the two magnetic poles that are facing each other in a repulsion configuration are spaced 1/4 inches apart. This air gap distance produces good results. If you think of the magnetic field lines as a traveling wavefront you can try different coil wrapping techniques to study how they respond when a magnetic field is moving through them. A piece of magnetic film is useful to see the magnetic field lines in the repulsion area of the linear piston.

KS Metals sales brass tubing in 12 inch lengths which can be found at ACE Hardware stores. I got a 1/2 inch diameter tube to hold the 1/2 Neodymium Magnets. I got a 17/32 inch diameter brass tube to wrap the magnet wire coils around. The 1/2 brass tube will slide back and forth inside the 17/32 brass tube. The distance between the surface of magnets to the start of the magnet wire in the coils is around 45.25 thousandths of an inch. A light machine oil should be applied between the brass tubes to reduce friction. The closer you can get the magnet wire coils to the surface of the magnets the stronger the magnetic field is which will produce more Voltage and Current at a specific RPM.

I am trying to use 3D printing to build a small desktop version and get close to these same results.

These parts were designed using the Freeware Version of the EMachineShop software.

To watch a Video about this Linear Piston Generator project visit the following YouTube

link:

https://youtu.be/vvqzisL-Zrg

One preliminary test produced 7.2V DC with an output current of 1.0 Amps at 1300 RPM passing the piston through 3 Magnet Wire Coils that were 1/4 inch wide with 25 Feet of Magnet Wire wrapped around each Coil. The output measurements were taken across all of the coils which were connected in parallel. The Linear Piston does not have to move far about 1.25 inches back and forth through the 3 Magnet Wire Coils.

For each revolution of the drive wheel the repulsion piston will induce 6 power pulses inside of each individual coil. Since the magnets are 1/2 inch long the the North Pole is

approximately 1/4 inch long and the South Pole is approximately 1/4 inch long. So, a good starting point is to make sure the air gap between the two magnetic poles that are facing each other in a repulsion configuration are spaced 1/4 inches apart. This air gap distance produces good results. If you think of the magnetic field lines as a traveling wavefront you can try different coil wrapping techniques to study how they respond when a magnetic field is moving through them. A piece of magnetic film is useful to see the magnetic field lines in the repulsion area of the linear piston.

KS Metals sales brass tubing in 12 inch lengths which can be found at ACE Hardware stores. I got a 1/2 inch diameter tube to hold the 1/2 Neodymium Magnets. I got a 17/32 inch diameter brass tube to wrap the magnet wire coils around. The 1/2 brass tube will slide back and forth inside the 17/32 brass tube. The distance between the surface of magnets to the start of the magnet wire in the coils is around 45.25 thousandths of an inch. A light machine oil should be applied between the brass tubes to reduce friction. The closer you can get the magnet wire coils to the surface of the magnets the stronger the magnetic field is which will produce more Voltage and Current at a specific RPM.

I am trying to use 3D printing to build a small desktop version and get close to these same results.

These parts were designed using the Freeware Version of the EMachineShop software.

To watch a Video about this Linear Piston Generator project visit the following YouTube

link:

https://youtu.be/vvqzisL-Zrg

Similar models

thingiverse

free

Scotch Yoke linear driven Magnetic Repulsion Piston.

...al drive shaft and scotch yoke pin.

these 3d parts were designed using the freeware version of the emachineshop software package.

thingiverse

free

variable magnetic field humbucker by rdubouil

...till a little bit present which gives a unique configuration.

adding the option to split the pickup gives even more possibilities

grabcad

free

Coil

...asically when the neodymium magnet moves, it generate electricity and light up the leds.

led

neodymium

circuit board

copper wire

grabcad

free

DC Motor

... parts of the dc motor. a tutorial to it from the youtube channel, solidworks tutorials is also added if you want to recreate it.

grabcad

free

Solenoid

...ound a metallic core, which produces a uniform magnetic field in a volume of space when an electric current is passed through it.

grabcad

free

Low RPM Magnet Generator 1 - 2 kW

... pcs (3 phase).

number of turns in coil = 145.

wire diameter: 1.12 mm

60 volts = about 250 rpm

use: water power, wind power, etc.

thingiverse

free

Linear Motion Machine using Rack & Pinion and Lever & Fulcrum Techniques.

... device while it is being operated.

these 3d parts were designed using the freeware version of the emachineshop software package.

thingiverse

free

Linear Magnetic Piston Center Punch Crimping Tool for 1/2 diameter Brass Tubes

... punches to the crimping tool handles.

these parts were designed using the freeware version of the emachineshop software package.

thingiverse

free

Coil Housing by OregonStateRheology

...oregonstaterheology

thingiverse

this is a coil housing. with wires wrapped around it, an electromagnetic field can be generated.

3dwarehouse

free

Brushless internal propulsion motor

...near velocity, l is distance between conductors of exciting coil. #electric_motor #internal_propulsion #internal_propulsion_motor

Repulsion

turbosquid

$7

dark repulser

...quid

royalty free 3d model dark repulser for download as obj on turbosquid: 3d models for games, architecture, videos. (1331380)

turbosquid

$7

Sword - Dark Repulser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$6

Dark repulser sword

...051392 vertices - 2527166 unusual sword is made in 2 colors, everything is smoothed. if you have any questions or wishes - write.

turbosquid

$3

Dark Repulser Kirito Sword SAO Lowpoly Style

... kirito sword sao lowpoly style for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1691216)

turbosquid

$26

Sao Kirtos Dark Repulser Sword cosplay prop

...word cosplay prop for download as max, dwg, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1587623)

3d_export

free

elucidator

...ord art online. this sword is a demonic monster drop from a boss on the 50th floor that kirito wields along with «dark repulser».

3d_export

$10

railgun

...also acts on the rails, leading them to mutual repulsion<br>mostly the model is used in unity. for animation, write...

3d_export

$30

hms prince of wales warship

...made of tris and quad polygons and are separated into 146 clearly named layers, to help you to import them into your 3d software.

3d_export

$20

elucidator - sword art online

...] in the design art by the illustrator of the novels, a small cross is emblazoned on the flat of the blade, just beneath the tip.

free3d

free

dark repulser

...dark repulser

free3d

kirito's dark repulser from anime sword art online

Piston

3d_ocean

$4

Piston

...rmats included: .c4d, .obj – the model contains 5130 polygons – not rigged, scene setup / lighting / environments from the pre...

3d_export

$3

piston

...piston

3dexport

3d design piston (solidworks)

3d_export

free

piston

...piston

3dexport

piston model, more files here:

3d_export

$5

piston

...piston

3dexport

3d drawing of a piston of an automotive combustion engine.

3d_export

$12

piston

...piston

3dexport

piston models are modelled in max and riged with manuel technics. animated as eternal loop.

3d_export

$5

piston

...ne, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod.

3d_ocean

$20

Piston Engine

...ax 2011 with rig set up and animation loop if you have some questions, please contact me through my profile page. render versi...

turbosquid

free

Piston

...piston

turbosquid

free 3d model piston for download as obj on turbosquid: 3d models for games, architecture, videos. (1320057)

3d_export

$5

piston

...piston

3dexport

поршень

turbosquid

$15

Piston

...

turbosquid

royalty free 3d model piston for download as dwg on turbosquid: 3d models for games, architecture, videos. (1323338)

Linear

3ddd

$1

Linear Diffusers

...linear diffusers

3ddd

диффузор

set of linear diffusers for ceiling.

design_connected

$27

Linear Sofa

...linear sofa

designconnected

scp linear sofa computer generated 3d model.

design_connected

$18

Atlantis linear

...atlantis linear

designconnected

terzani atlantis linear pendant lights computer generated 3d model. designed by barlas baylar.

3d_export

$5

light linear unit

...light linear unit

3dexport

light linear unit

turbosquid

$5

Linear Actuator

...

royalty free 3d model linear actuator for download as blend on turbosquid: 3d models for games, architecture, videos. (1589061)

turbosquid

$29

Linear panel

...oyalty free 3d model linear panel for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1391254)

turbosquid

$12

Linear Chandelier

...y free 3d model linear chandelier for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1574289)

turbosquid

$10

Grohe Lineare

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Linear Unit 3D Model

...linear unit 3d model

3dexport

linear unit force torque velocity

linear unit 3d model fau 71218 3dexport

Magnetic

3d_ocean

$2

Magnet

...magnet 3docean 3d 3ds max electric magnet magnetic magnetism max model polygon realistic tesla magnet created in...

turbosquid

$6

Magnet

...

turbosquid

royalty free 3d model magnet for download as obj on turbosquid: 3d models for games, architecture, videos. (1548733)

turbosquid

$6

magnet

...uid

royalty free 3d model magnet for download as 3dm and max on turbosquid: 3d models for games, architecture, videos. (1670606)

turbosquid

$1

Magnet

...y free 3d model magnet for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1215037)

turbosquid

$7

Magnet

...agnet for download as blend, unitypackage, fbx, gltf, and obj on turbosquid: 3d models for games, architecture, videos. (1576588)

3d_export

$5

magnetic knife holder

...magnetic knife holder

3dexport

ordinary magnetic knife holder

archive3d

free

Fridge magnet 3D Model

...3d model archive3d refrigerator magnet fridge magnet magnet toy magnetic s n280712 - 3d model (*.3ds) for interior 3d...

turbosquid

$35

Magnetic butterflies

...alty free 3d model magnetic butterflies for download as blend on turbosquid: 3d models for games, architecture, videos. (1315792)

turbosquid

$2

Magnetic Board

...quid

royalty free 3d model magnetic board for download as ma on turbosquid: 3d models for games, architecture, videos. (1264141)

turbosquid

$977

Magnetic Lego

...oyalty free 3d model magnetic lego for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1142761)

Electric

3d_export

$5

Electric pole

...electric pole

3dexport

electric pole for street, electricity line

3ddd

$1

electric mixer

...electric mixer

3ddd

electric mixer , миксер

electric mixer

3ddd

$1

electrical installation

...electrical installation

3ddd

electrical installation , розетка

electrical installation

turbosquid

$19

The electric water heater electric

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Electrical Outlet electric splitter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$20

Electric Guitar

...electric guitar

3docean

electric electric guitar guitar music music instrument

model of a electric guitar created in maya.

3d_ocean

$12

Electric Shaver

...electric shaver

3docean

electric electric shaver hair removal personal care shaver shaving

electric shaver created in 3ds max.

3ddd

$1

electrical switch

...h

3ddd

electrical , розетка

electrical switch from bticino company

series livinglight

3d_export

$7

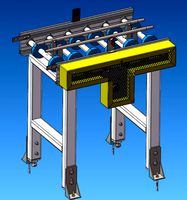

Electric Conveyor

...electric conveyor

3dexport

electric conveyor

3d_export

$5

electric drums

...electric drums

3dexport

electric drums

Generator

3d_export

$17

Generator

...generator

3dexport

generator

archibase_planet

free

Generator

...base planet

generator electric generator

generator electric n300715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

design_connected

$20

Generation

...generation

designconnected

knoll generation computer generated 3d model. designed by formway design.

3d_export

$8

generator

...generator

3dexport

generator - obj, 3ds, fbx.

3d_export

$7

generator

...generator

3dexport

generator extures 4k resolution, basecolor -normal -metallic -ao-roughness-height tris:3084

turbosquid

free

generator

...rator

turbosquid

free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1492909)

3ddd

$1

general

...general

3ddd

генерал

turbosquid

$99

generator

...urbosquid

royalty free 3d model generator for download as ma on turbosquid: 3d models for games, architecture, videos. (1514125)

turbosquid

$20

Generator

...rbosquid

royalty free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1244841)

turbosquid

$2

Generator

...rbosquid

royalty free 3d model generator for download as fbx on turbosquid: 3d models for games, architecture, videos. (1245541)