GrabCAD

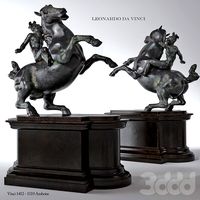

Leonardo Da Vinci Catapult

by GrabCAD

Last crawled date: 1 year, 11 months ago

This is my entry for the "Da Vinci Gear Challenge".

Link to the Creation: http://members.iinet.net.au/~rmine/Leonardo.html

Printing method used: FDM

3D Printer: Utlimaker 2

Material: M-ABS & Ninjaflex 3mm

Nozzle diameter: 0,4mm

Layer height: 0,2mm

Print time: ~45 hours

Post-processing:

- some pieces don't need support for print, others need.

- no tools or glue needed because of the "carpentery" joints.

- I have chosen this Catapult, because I did exactly the same a months weeks ago, but it was not 3D Printable a this time. So I changed everything.

- First I scalled it down to 7 meters to 500mm. But I've tried to keep the proportion and make it sturdy.

- Then all the joints were made so that the whole structure is sturdy. I asked my father for some Carpentery joints.

- Naturally I have let some tolerances for the joints, for that I used the equation system in Solidworks, so that it is easily changeable. Now the tolerance is 0,4mm.

Is it Printable ?

- I've printed the whole Catapult with my 3D Printer. For that, I used M-ABS, I bought some recently. And I was impressed how sturdy it is !

-So all parts can be easily printed with an FDM printer.

Update 14/05: Last Update, the Catapulte works ! To prove it, a little video of the catapult shooting a 9.5 mm ABS ball. It goes quite far I think !

Update 08/05: As I said yesterday, I've printed the Ninjaflex core of the upper arm (Part T2). But it doesn't work because of the shape of T2, I have to cut a slide away (see picture). I will print the newer part, and see if it works. I've also updated the Zip files of the functionnal catapult.

Update 07/05: I've added the Ladder that Leonardo DaVinci made to load the catapult with projectiles. I will also print the ninjaflex inlay and the ladder tomorrow (08/05).

Update 01/05: I've printed the arm, and winch. And it works !! The catapult shoots litlle 9.5mm balls 2-3 meters away ! But the arm is not finished, I've just printed the outer part out of ABS, I will print Wednesday the Ninjaflex part (inner core).

Update 30/04: I did a 6th version of part T2, but a special one.. the outside of Part T2 will be printed in ABS (1.5 mm widht) and the inner core in Ninjaflex ! I think this is gonna be the best solution, so that the Catapult is functionnal. The part can be seen in the folder "Part T_Simulation" - " Part T Flexible Core".

Update 27/04: Little update, I did 5 different versions of part T2: I did a test with 10N, 20N, and some of them 50N to see if they will bend/break.

Update 26/04: I did some simulation with 4 different types of Arms (Part T2) to see what kind of modification I have to make: Make a groove in the arm, make it smaller, bigger...

Update 24/04: The "Catapult Functionnal" zip file has been updated.

I've Printed A1-A2-B1-B2-D-E-F-G-H-I-J-K-L-M-N-O-P-Q, it's looking pretty good so far, I will adjust some parts in the next days.

Update 23/04: - Part T is now in 2 seperate pieces: T1-T2. Special Feature, the Original piece (T) was already bend, so it was not functionnal.. but now Part T2 is straight and fixed with a Scarf Joint to part T1 so that you can "charge the catapult ! And a big slot is carved into Part T2, so that the part won't break !

- I've zipped the two different version of the Catapult: the first one is "Catapult Not Functionnal), the seconde one "Catapult Functionnal"

Update 17/04: Part K-L-M-N are now printed, you can see the picture in "Cura Test Print", the fit is great and the ultimaker 2 did a great job !

Update 16/04: I added some pictures of some pieces that I will print, to show how it fits together. (Part G-H-I-J)

Update 16/04: I have Printed the parts G-H-I-J with an Ultimaker 2 using Neofill ABS. I used fast printing settings, but with a 0.4mm tolerance, it's a nice fit.

Pictures of the print are in the "Cura test prints" folder

I also added: Part A-B-C Splitt in two seperate pieces, so that they are printable.

The joint that I use for the Parts split in half is in the folder "Part A-B-C in seperate pieces".

STL, IGES and SW Files are included in the ZIP.

During the next Weeks, I will print the parts and show how it prints.

Thank you Stratasys for bringing up this challenge !

I hope you enjoy it !

Leave a "♥"

Link to the Creation: http://members.iinet.net.au/~rmine/Leonardo.html

Printing method used: FDM

3D Printer: Utlimaker 2

Material: M-ABS & Ninjaflex 3mm

Nozzle diameter: 0,4mm

Layer height: 0,2mm

Print time: ~45 hours

Post-processing:

- some pieces don't need support for print, others need.

- no tools or glue needed because of the "carpentery" joints.

- I have chosen this Catapult, because I did exactly the same a months weeks ago, but it was not 3D Printable a this time. So I changed everything.

- First I scalled it down to 7 meters to 500mm. But I've tried to keep the proportion and make it sturdy.

- Then all the joints were made so that the whole structure is sturdy. I asked my father for some Carpentery joints.

- Naturally I have let some tolerances for the joints, for that I used the equation system in Solidworks, so that it is easily changeable. Now the tolerance is 0,4mm.

Is it Printable ?

- I've printed the whole Catapult with my 3D Printer. For that, I used M-ABS, I bought some recently. And I was impressed how sturdy it is !

-So all parts can be easily printed with an FDM printer.

Update 14/05: Last Update, the Catapulte works ! To prove it, a little video of the catapult shooting a 9.5 mm ABS ball. It goes quite far I think !

Update 08/05: As I said yesterday, I've printed the Ninjaflex core of the upper arm (Part T2). But it doesn't work because of the shape of T2, I have to cut a slide away (see picture). I will print the newer part, and see if it works. I've also updated the Zip files of the functionnal catapult.

Update 07/05: I've added the Ladder that Leonardo DaVinci made to load the catapult with projectiles. I will also print the ninjaflex inlay and the ladder tomorrow (08/05).

Update 01/05: I've printed the arm, and winch. And it works !! The catapult shoots litlle 9.5mm balls 2-3 meters away ! But the arm is not finished, I've just printed the outer part out of ABS, I will print Wednesday the Ninjaflex part (inner core).

Update 30/04: I did a 6th version of part T2, but a special one.. the outside of Part T2 will be printed in ABS (1.5 mm widht) and the inner core in Ninjaflex ! I think this is gonna be the best solution, so that the Catapult is functionnal. The part can be seen in the folder "Part T_Simulation" - " Part T Flexible Core".

Update 27/04: Little update, I did 5 different versions of part T2: I did a test with 10N, 20N, and some of them 50N to see if they will bend/break.

Update 26/04: I did some simulation with 4 different types of Arms (Part T2) to see what kind of modification I have to make: Make a groove in the arm, make it smaller, bigger...

Update 24/04: The "Catapult Functionnal" zip file has been updated.

I've Printed A1-A2-B1-B2-D-E-F-G-H-I-J-K-L-M-N-O-P-Q, it's looking pretty good so far, I will adjust some parts in the next days.

Update 23/04: - Part T is now in 2 seperate pieces: T1-T2. Special Feature, the Original piece (T) was already bend, so it was not functionnal.. but now Part T2 is straight and fixed with a Scarf Joint to part T1 so that you can "charge the catapult ! And a big slot is carved into Part T2, so that the part won't break !

- I've zipped the two different version of the Catapult: the first one is "Catapult Not Functionnal), the seconde one "Catapult Functionnal"

Update 17/04: Part K-L-M-N are now printed, you can see the picture in "Cura Test Print", the fit is great and the ultimaker 2 did a great job !

Update 16/04: I added some pictures of some pieces that I will print, to show how it fits together. (Part G-H-I-J)

Update 16/04: I have Printed the parts G-H-I-J with an Ultimaker 2 using Neofill ABS. I used fast printing settings, but with a 0.4mm tolerance, it's a nice fit.

Pictures of the print are in the "Cura test prints" folder

I also added: Part A-B-C Splitt in two seperate pieces, so that they are printable.

The joint that I use for the Parts split in half is in the folder "Part A-B-C in seperate pieces".

STL, IGES and SW Files are included in the ZIP.

During the next Weeks, I will print the parts and show how it prints.

Thank you Stratasys for bringing up this challenge !

I hope you enjoy it !

Leave a "♥"

Similar models

thingiverse

free

Leonardo Da Vinci Catapult by Alexis67

...e catapult works perfectly ! it shoots the small 3d printed balls 9 foot away or 3 meters ( which is quite impressive i think !).

thingiverse

free

Ninjaflex / Flexible Filament Adapter for Duplicator i3 V2 by ninjaplatypus

... speed at 60% with a 325% first layer height on buildtak. also i changed the infill overlap which was 15% on my settings to 30 %.

thingiverse

free

Assembled catapult without support by Genapart

...e: the trigger and the arm are more resistant.

07/01/17

new update: increased of the 4 trigger axes to make them easier to print.

thingiverse

free

Printable Catapult by NoobMaker

...i\'ve modified the design some. hopefully this will scale and print ok, i don\'t have any way to test it at the present.

thingiverse

free

Garmin Edge 800/1000 bike mount by Goose_A340

...ause they don't fit. get the right set.

latest update: a version for 25 mm handlebars (just the handlebar parts were updated)

thingiverse

free

Kid Boo Easy to print by Santy777

... splitted it in 4 parts (legs, body, arm dx and arm sn);

i've also upgraded the body part with some useful supports,

enjoy ;)

thingiverse

free

Bike Helmet Mirror Ball Joint by MinersC

...ole of the larger piece, and since i use abs a little acetone fuses them together. seems to fit better and provide more strength.

thingiverse

free

Neslon Refit 1/1700 by kscalemodels

... make easier to print

update 04-11-2019 how did i forget to include a part? don't know but here's the round bit mid ships

thingiverse

free

![The Ultimate Catapult, almost. [Seej] by roguemat](/t/806478.jpg)

The Ultimate Catapult, almost. [Seej] by roguemat

...#39;ve done things right. i've also included the sketchupfile so you guys can have your way with it. and a zip of everything.

thingiverse

free

Ball Joint Fan mount for Printrbot Simple by adamxcarey

... replaced that cup joint with the bigger one. i've also included a 'middle piece' of 2x ball joint to extend the arm.

Catapult

3d_export

$5

medieval catapult

...medieval catapult

3dexport

this is a catapult

turbosquid

$30

Catapult

...turbosquid

royalty free 3d model catapult for download as ma on turbosquid: 3d models for games, architecture, videos. (1266660)

turbosquid

$11

Catapult

...urbosquid

royalty free 3d model catapult for download as max on turbosquid: 3d models for games, architecture, videos. (1491788)

turbosquid

free

catapult

...urbosquid

royalty free 3d model catapult for download as c4d on turbosquid: 3d models for games, architecture, videos. (1381505)

turbosquid

$10

Catapult

...d

royalty free 3d model catapult for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1409408)

turbosquid

$85

Catapult

...alty free 3d model catapult for download as 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1610894)

turbosquid

$5

Catapult

...alty free 3d model catapult for download as 3ds, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1309806)

turbosquid

$40

Catapult

...free 3d model catapult for download as 3ds, obj, 3dm, and skp on turbosquid: 3d models for games, architecture, videos. (1270846)

turbosquid

$15

Catapult

...free 3d model catapult for download as fbx, obj, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1608939)

turbosquid

$55

Catapult

...3d model catapult for download as 3ds, obj, fbx, 3dm, and skp on turbosquid: 3d models for games, architecture, videos. (1338352)

Leonardo

3ddd

$1

Leonardo it.

...leonardo it.

3ddd

дверь

leonardo it. дверь

3ddd

free

Leonardo Halmar

...leonardo halmar

3ddd

leonardo halmar , стул

кресло руководителя leonardo halmar

design_connected

$13

Leonardo

...leonardo

designconnected

santa & cole leonardo pendant lights computer generated 3d model. designed by antoni arola.

3ddd

$1

Leonardo

...leonardo

3ddd

leonardo

кухня леонардо

fbx - сгладить фасады и мойку

общее кол.полигонов около 320 000

turbosquid

$10

Leonardo

...alty free 3d model leonardo for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1537039)

3ddd

$1

GIROFLEX / LEONARDO

...giroflex / leonardo

3ddd

giroflex , кресло

офисное кресло leonardo фабрика giroflex

3ddd

$1

Bellavista Leonardo

... кофейный , круглый

кофейный столик bellavista leonardo

3ddd

$1

ASNAGHI INTERIORS LEONARDO

... leonardo , барный

стул для бара

asnaghi interiors leonardo

60 200 poly

3ddd

$1

leonardo da vinci

...leonardo da vinci

3ddd

всадник , лошадь

leonardo da vinci

turbosquid

$15

Leonardo chair

...uid

royalty free 3d model leonardo chair for download as max on turbosquid: 3d models for games, architecture, videos. (1422679)

Vinci

3d_export

$9

clcok vinci

...clcok vinci

3dexport

clcok vinci

3ddd

$1

willisau vinci chair

...willisau vinci chair

3ddd

willisau , vinci

vinci chair from willisau ag.

design_connected

$13

Vinci chair

...vinci chair

designconnected

willisau vinci chair computer generated 3d model. designed by ballendat, martin.

3ddd

$1

BOVA-комод-vinci

...bova-комод-vinci

3ddd

bova , комод

bova-комод-vinci

3ddd

$1

leonardo da vinci

...leonardo da vinci

3ddd

всадник , лошадь

leonardo da vinci

3d_export

$25

a - leonardo da vinci

...a - leonardo da vinci

3dexport

a - leonardo da vinci<br>antiquity

turbosquid

$10

Pouf Vinci

...ty free 3d model pouf vinci for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1507069)

turbosquid

$30

Da Vinci

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

machine- leonardo da vinci

...machine- leonardo da vinci

3dexport

machine- leonardo da vinci

3d_export

$25

mortar - leonardo da vinci

...mortar - leonardo da vinci

3dexport

mortar - leonardo da vinci

Da

3ddd

$1

Luce da Vivere

...luce da vivere

3ddd

luce da vivere

luce da vivere mary 387/6+3

3ddd

$1

Luce da Vivere

...luce da vivere

3ddd

luce da vivere

luce da vivere

cristalline 494/12 rosso/cromo

turbosquid

$6

Cabinet DA

...ty free 3d model cabinet da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1637312)

turbosquid

$6

Bookcase DA

... free 3d model bookcase da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639996)

turbosquid

$5

Wardrobe DA

...y free 3d model wardrobe da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1661117)

turbosquid

$5

Partition DA

... free 3d model partition da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1640359)

3ddd

$1

Ecstacity_LAMPADA DA TERRA

...ecstacity_lampada da terra

3ddd

ecstacity

торшер ecstacity_lampada da terra

3ddd

$1

leonardo da vinci

...leonardo da vinci

3ddd

всадник , лошадь

leonardo da vinci

turbosquid

$60

DA-ExoticWeapons

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

DA-SpikedChainMace

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.