Thingiverse

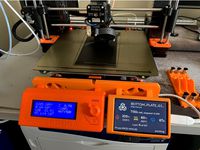

LCD + Hyperpixel 4" touchscreen cover for Prusa MK3/S/+ by puckpuck

by Thingiverse

Last crawled date: 3 years, 3 months ago

LCD cover that works with the awesome Hyperpixel 4" touchscreen.

No fitment issues from other similar covers.

This is for: MK3/MK3S/MK3S+

Letters stl is also included if you want to make this a multi color print.

The RPi + Hyperpixel screen will slide it properly, not too snug. The cover itself is centered properly for an MK3S. The angle of the cover maximizes gets as close to the original as possible, keeping clearance with the surface blow, and still allows the default knob (and custom ones) to have proper clearance with the print bed.

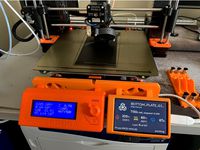

This cover does require you to solder power onto your RPi. Honestly if you are going to power the Hyperpixel 4" screen + a camera + cpu fan + Octoprint, you are risking it by going in with a USB connector, even one with 18 gauge wires. As such I recommend you solder 18 gauge wires onto the solder pads on your RPi, and wire those into a reliable 5V power source with at least 3 amps. See included picture for which solder pads to use. VCC=PP1/PP2. Ground=PP3/4/5/6

The main LCD mounts using the same screws and method as the original. I started with Prusa .step files for the LCD cover. You can hack away with the included Fusion 360 design if you like.

Though it will still work if you don't do this, I highly recommend you also trim the headphone jack on your RPi, since it sticks out more than anything else, and that 2mm matters. You won't be connecting headphones to this, so it shouldn't be an issue. Using a knife, score around the headphone jack, then snip it off with some wire cutters. I included pictures to show this.

For anyone asking, yes you can run a FanShim with a Hyperpixel 4". The key to doing this is to disable the fan's LED and button by specifying the --noled --nobutton command line options as part of the install-service script for the fan. I ran with just a heat sink and would get an occasional heat warning. Since installing the fan I've had no issues, even inside my enclosure.

Printing both the Letters and LCD cover multi-color using PrusaSlicer

Add the LCD Cover.stl

Add the Letters.stl

Select just Letters, and change the Position: x=175.85, y=76.75

Select both the Letters and LCD cover, make sure you have them both selected, and do the following moves in this order: rotate-Z=325, translate-X=4, translate-y=6. The values will reset to 0 after you do each one. Once done the part should now show as green and "printable" in PrusaSlicer

Since we rotated the part by -35 degrees, we should set offset the infill angle accordingly to minimize any gaps along the perimeter. As such set infill angle to: 10

Supports from build plate only (for the mounts)

Set extruders for each part

Slice and check the first 1-2 layers to make sure the letters are lined up perfectly. You may need to go back to step 2, and change y= by .25mm.

Printing just the cover

After adding the cover, rotate-Z=325

Offset X by 4 and Y by 6 and the part should show green on the bed for printing.

Since we rotated the part by -35 degrees, we should set offset the infill angle accordingly to minimize any gaps along the perimeter. As such set infill angle to: 10

Supports from build plate only (for the mounts)

Slice and print

Layer Height = 0.2mm

No fitment issues from other similar covers.

This is for: MK3/MK3S/MK3S+

Letters stl is also included if you want to make this a multi color print.

The RPi + Hyperpixel screen will slide it properly, not too snug. The cover itself is centered properly for an MK3S. The angle of the cover maximizes gets as close to the original as possible, keeping clearance with the surface blow, and still allows the default knob (and custom ones) to have proper clearance with the print bed.

This cover does require you to solder power onto your RPi. Honestly if you are going to power the Hyperpixel 4" screen + a camera + cpu fan + Octoprint, you are risking it by going in with a USB connector, even one with 18 gauge wires. As such I recommend you solder 18 gauge wires onto the solder pads on your RPi, and wire those into a reliable 5V power source with at least 3 amps. See included picture for which solder pads to use. VCC=PP1/PP2. Ground=PP3/4/5/6

The main LCD mounts using the same screws and method as the original. I started with Prusa .step files for the LCD cover. You can hack away with the included Fusion 360 design if you like.

Though it will still work if you don't do this, I highly recommend you also trim the headphone jack on your RPi, since it sticks out more than anything else, and that 2mm matters. You won't be connecting headphones to this, so it shouldn't be an issue. Using a knife, score around the headphone jack, then snip it off with some wire cutters. I included pictures to show this.

For anyone asking, yes you can run a FanShim with a Hyperpixel 4". The key to doing this is to disable the fan's LED and button by specifying the --noled --nobutton command line options as part of the install-service script for the fan. I ran with just a heat sink and would get an occasional heat warning. Since installing the fan I've had no issues, even inside my enclosure.

Printing both the Letters and LCD cover multi-color using PrusaSlicer

Add the LCD Cover.stl

Add the Letters.stl

Select just Letters, and change the Position: x=175.85, y=76.75

Select both the Letters and LCD cover, make sure you have them both selected, and do the following moves in this order: rotate-Z=325, translate-X=4, translate-y=6. The values will reset to 0 after you do each one. Once done the part should now show as green and "printable" in PrusaSlicer

Since we rotated the part by -35 degrees, we should set offset the infill angle accordingly to minimize any gaps along the perimeter. As such set infill angle to: 10

Supports from build plate only (for the mounts)

Set extruders for each part

Slice and check the first 1-2 layers to make sure the letters are lined up perfectly. You may need to go back to step 2, and change y= by .25mm.

Printing just the cover

After adding the cover, rotate-Z=325

Offset X by 4 and Y by 6 and the part should show green on the bed for printing.

Since we rotated the part by -35 degrees, we should set offset the infill angle accordingly to minimize any gaps along the perimeter. As such set infill angle to: 10

Supports from build plate only (for the mounts)

Slice and print

Layer Height = 0.2mm

Similar models

thingiverse

free

Control Panel for Hyperpixel 4" Touchscreen + LCD + Raspberry Pi4 for Octoprint and OctoDash Prusa MK3s+ 4.0 by paycraft

...rg/prints/47153-lcd-hyperpixel-4-touchscreen-cover

malolo's snap fit case pi4 case: https://www.thingiverse.com/thing:3723561

thingiverse

free

5" HDMI LCD Waveshare RPI Case by flos88

...by flos88

thingiverse

i started to design the front cover.

after the test print is successful i start with the base (45° angle).

thingiverse

free

Hyperpixel Touch Screen Mount plate for MK3S by Kondor2004

...berry pi 4b case (with prusa mk3s bracket)"

all credit goes to him for creating a nice case for raspberry pi 4b. thank you!

thingiverse

free

Displays holder HyperPixel 4.0 w RB + Prusa LCD ( Prusa i3 MK3s ) by JuroH

...rse

stand alone holder for 2 displays

hyperpixel 4.0 touch screen with raspberry 4 ( high resolution display )

prusa lcd display

thingiverse

free

Headphone Stand by Worti2

...o turn it in the right angle and you have to set "build plate adhesion" to "none".

have a lot of fun with it.

thingiverse

free

Mobile Raspberry Pi 4b, Touchscreen, Battery by joewhite7

...exchange the versions dependent of hdmi available or not.

using two 18650 batteries, battery life is about 6 hours for streaming.

thingiverse

free

Koss KSC-75 Ultra Mod by rklm

...the ksc-75 driver inside the grado g cushion pads (similary to the kph-30i ultra mod). which files should i...

thingiverse

free

LCD 4" by gespin7342

...lcd 4" by gespin7342

thingiverse

4inch rpi lcd (a) https://www.waveshare.com/4inch-rpi-lcd-a.htm

thingiverse

free

Artillery Part cooling fan for Prusa MK3 or bear upgrade by Mateomcg

...ering and spade. star may need minor sanding but should push fit into the space tightly and not need anything else to secure it.

thingiverse

free

Hyperpixel 4 + RPI 3B - Bear upgrade by tomasf71

... - bear upgrade

it is designed to use https://www.thingiverse.com/thing:3050607 for attaching to 20x40 v-slot aluminum extrusion.

Hyperpixel

thingiverse

free

Raspberry Pi Hyperpixel Stand by major_tomm

...and for a raspberry pi and pimoroni hyperpixel 4.0

this is very much work in progress, i can't guarantee it will fit your pi.

thingiverse

free

HyperPixel 4.0 Pi 4 Case *BETA*

...for a raspberry pi 2-3 version here: https://www.thingiverse.com/thing:3153767

i've also provided the solidworks design file.

thingiverse

free

Hyperpixel 4 + RPI 3B - Bear upgrade by tomasf71

... - bear upgrade

it is designed to use https://www.thingiverse.com/thing:3050607 for attaching to 20x40 v-slot aluminum extrusion.

thingiverse

free

Raspberry Pi 400 - HyperPixel 4.0 mount by jwktje

...ove all supports after printing to get a good fit on the pi. especially underneath the screen.

i used this screen and this cable

thingiverse

free

Hyperpixel Touch Screen Mount plate for MK3S by Kondor2004

...berry pi 4b case (with prusa mk3s bracket)"

all credit goes to him for creating a nice case for raspberry pi 4b. thank you!

thingiverse

free

Hyperpixel 4 Square Raspberry 3 A+ Case

...e display or use longer ones, 2,5 x 10mm in my case.

i've updated files with a less holes and a no holes version of the case.

thingiverse

free

Hyperpixel 4.0 Pi 4 Model B Case

...or any modeling software for that matter), so it no doubt could stand to be cleaned up, but it works well enough for my purposes.

thingiverse

free

Displays holder HyperPixel 4.0 w RB + Prusa LCD ( Prusa i3 MK3s ) by JuroH

...rse

stand alone holder for 2 displays

hyperpixel 4.0 touch screen with raspberry 4 ( high resolution display )

prusa lcd display

thingiverse

free

Control Panel for Hyperpixel 4" Touchscreen + LCD + Raspberry Pi4 for Octoprint and OctoDash Prusa MK3s+ 4.0 by paycraft

...rg/prints/47153-lcd-hyperpixel-4-touchscreen-cover

malolo's snap fit case pi4 case: https://www.thingiverse.com/thing:3723561

thingiverse

free

HyperPixel Raspberry Pi NAS by Multimedia4Linux

...ousings has been fixed

x500-1000 rev. 04 (2020-12-03)

alternativ mounting solution for the casing top part added (part x500-1211)

Touchscreen

3d_ocean

$10

Touchscreen Phone

...r stand alone renderings. the button as well as speaker on the front are modelled for added realism and depth for those tight ...

turbosquid

$2

Touchscreen Kiosk

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$35

TF 700 Tablet PC 10 in touchscreen 3D Model

...export

universal tablet pc 10 in touchscreen android notebook

tf 700 tablet pc 10 in touchscreen 3d model plasticv 80776 3dexport

3d_ocean

$10

Sleek Touchscreen Smart Phone

... of multi-touch smart phone designs. the small details such as the buttons, camera lens, speaker and other components have bee...

3ddd

$1

Celular Samsung

...3ddd телефон , samsung samsung s5230 mid level full touchscreen ...

3d_export

$30

LG arena 3D Model

...arena 3d model 3dexport lg km900 arena phone mobile touchscreen lg arena 3d model s.e.3ddd 26566...

3d_export

$30

SONY Xperia Tablet 3D Model

...xperia tablet 3d model 3dexport sony xperia tablet android touchscreen sony xperia tablet 3d model barbarosa222 58716...

3d_export

$15

Iphone Black 3D Model

...black 3d model 3dexport phone electronics iphone cellphone smartphone touchscreen touch screen iphone black 3d model ryleyswan 81168...

3d_export

$40

Google Nexus One 3D Model

...3d model 3dexport google nexus one phone mobile cellular touchscreen google nexus one 3d model h1studio 21421...

3d_export

$45

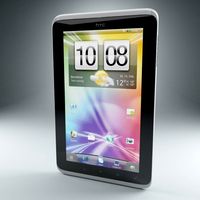

HTC Flyer Tablet 3D Model

...htc flyer tablet 3d model 3dexport touchscreen tablet htc 3d model 3ds max phone htc flyer...

Mk3

turbosquid

$50

cention mk3

...ty free 3d model cention mk3 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454148)

turbosquid

$129

MK3 Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$100

Toyota Supra MK3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$44

cention mk3 low poly

...d model cention mk3 low poly for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454666)

turbosquid

$30

Challenger I Mk3 Falcon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

American Frag hand grenade MK3

...free 3d model american frag hand grenade mk3 for download as on turbosquid: 3d models for games, architecture, videos. (1393624)

turbosquid

$20

Mk3 US Navy Combat Knife

...ty free 3d model mk3 us navy combat knife for download as fbx on turbosquid: 3d models for games, architecture, videos. (1172791)

3d_export

$29

Ford Fiesta MK3 Modified 3D Model

...7 tumerfx mtumer mehmet t?mer 1993 1995 1996 wrc special modifed modifiye

ford fiesta mk3 modified 3d model mtumer 30698 3dexport

3d_export

$99

Toyota Supra Mk3 19861993 3D Model

...ort fast coupe japan 1986 1987 1988 1989 1990 1991 1992 1993 tuning turbo

toyota supra mk3 19861993 3d model squir 62530 3dexport

turbosquid

$5

Timothy Oulton Mars Chair MK3

...on mars chair mk3 for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1209782)

Lcd

turbosquid

$20

lcd

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

LCD

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

LCD

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

LCD

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

lcd

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

lcd

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

lcd

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LCD

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Noti Lcd Sofa

...noti lcd sofa

3ddd

noti , lcd

3d model of noti lcd sofa

3d_ocean

$7

Lcd tube wall

...hrome electronic electronic lcd tv videowall

lcd tube wall you can put in the lcd your own texture or movie in it and animate it.

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

Cover

archibase_planet

free

Cover

...cover

archibase planet

cover place setting

cover n170807 - 3d model for interior 3d visualization.

3ddd

$1

cover

...cover

3ddd

ковер , круглый

cover decor

archibase_planet

free

Cover

...cover

archibase planet

cover place setting setting

servis-cafe1930 - 3d model for interior 3d visualization.

turbosquid

free

Coverings

...rings

turbosquid

free 3d model coverings for download as dwg on turbosquid: 3d models for games, architecture, videos. (1279391)

3d_export

$5

plug cover

...plug cover

3dexport

plug cover

turbosquid

$25

Covers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

manhole cover

...manhole cover

3dexport

manhole cover gost, stl, step

turbosquid

$5

Street Gas Cover Manhole Cover

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Bed cover

...bed cover

3ddd

постельное белье

very useful bed cover

3d_export

$5

cpu cover

...cpu cover

3dexport

cpu cover, cpu box, sheet metal container

4

turbosquid

$9

Office Chair 4-4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

doors- 4

...doors- 4

3dexport

doors 4

3d_export

$5

hinge 4

...hinge 4

3dexport

hinge 4

3ddd

$1

Штора №4

...штора №4

3ddd

штора №4

3d_export

free

playstation 4

...playstation 4

3dexport

playstation 4

3ddd

$1

nexus 4

...nexus 4

3ddd

lg , телефон

nexus 4

3ddd

$1

4 Poufs

...4 poufs

3ddd

пуф

4 soft poufs

turbosquid

$12

Calligraphic Digit 4 Number 4

...hic digit 4 number 4 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389332)

3ddd

$1

Dauphin 4+

...dauphin 4+

3ddd

кресло

dauphin 4+ конференц кресло

3ddd

$1

iPhone 4

...

3ddd

apple , iphone , телефон

модель iphone 4.