Thingiverse

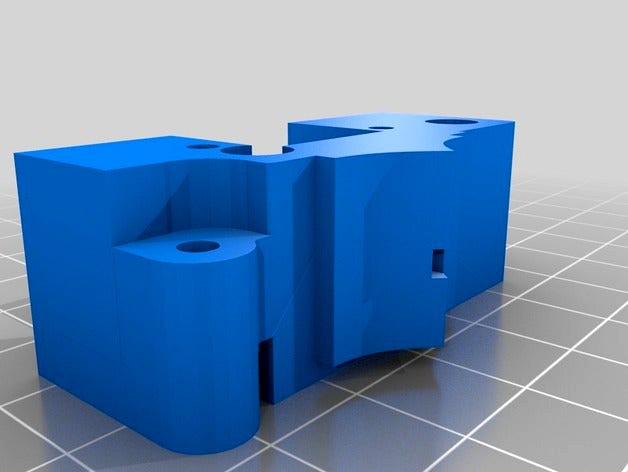

Lawsy's MK5 solidoodle extruder for ninjaflex E3D V6 edition by nebarnix

by Thingiverse

Last crawled date: 3 years ago

Update #2: The hole is too small and does need to be enlarged. I drilled it out with a 3/32" bit. THIS YIELDED THE FIRST SUCCESSFUL PRINT IN NINJAFLEX (at 230C) =D =D =D!

I'm working on a new design to fix these problems, but there are mesh errors in the original file that are difficult to work with. Stay tuned....

Update #1: Cura produces errors but Slic3r prints great. The ball bearing needs to be the same diameter as the hobbed bolt in this design. Mine is too big and I had to melt material away slowly using a heated screwdriver.

An attempt to merge the ninjaflex feature with the E3D V6 extruder.

There are currently two issues -- the curvature of the roller bearing doesn't quite match and had to be dremmeled slightly

The hole is a little rectangular and filament friction is high. Small 1cm cubes of ninjaflex fail 20% in.

There is also a strange ridge which should not be in the model but appears in slicing and keeps the E3D from sliding into an already tight fit. I had to shave it down with an X-acto. The fit required large clamps, which is not ideal.

Consider this model, for the time being, extremely experimental.

I'm working on a new design to fix these problems, but there are mesh errors in the original file that are difficult to work with. Stay tuned....

Update #1: Cura produces errors but Slic3r prints great. The ball bearing needs to be the same diameter as the hobbed bolt in this design. Mine is too big and I had to melt material away slowly using a heated screwdriver.

An attempt to merge the ninjaflex feature with the E3D V6 extruder.

There are currently two issues -- the curvature of the roller bearing doesn't quite match and had to be dremmeled slightly

The hole is a little rectangular and filament friction is high. Small 1cm cubes of ninjaflex fail 20% in.

There is also a strange ridge which should not be in the model but appears in slicing and keeps the E3D from sliding into an already tight fit. I had to shave it down with an X-acto. The fit required large clamps, which is not ideal.

Consider this model, for the time being, extremely experimental.

Similar models

thingiverse

free

Prusa i3 E3D-V6 mount - direct extruder carriage by SagentFreeman

... after a little sanding fine!

you may have to enlarge the hole at the extuder mount.

recommended to print in abs + aceton coating

thingiverse

free

E3D v6 hotend mounting plate with fan mount by nkvoll

... has 12mm radius, 6mm height, which fits perfectly. had to make this because all the other mounts i found came up a bit too thin.

thingiverse

free

Bowden setup for E3D v6 Hotend on Prusa I2 by Larry29996

...nd onto that mount.

24.08.17 - updated the model. i have printed it and the screw wont fit in, so i make the whole 0,2mm larger.

thingiverse

free

Solidoodle 3 fan duct/mount for E3D v6 upgade w/ OE extruder housing by Metaldrgn

...t-fan mount or bolt hole design to better secure the duct to the mount. it works great as is, it's just for greater rigidity.

thingiverse

free

Bull Dog Extruder Adapter E3D V6 with Probe by Gee_T

...me in the lite and xl, which have different alignment holes for the bracket. when i get a chance, i'll try post both.

thanks.

thingiverse

free

Reprap Neo Extruder Upgrade for Ninjaflex by Kakadu

...to avoid the filament to curle.

in combination mith my e3d v6 upgrade i can now easily print ninjaflex with the neo bowden setup.

thingiverse

free

Airtripper BSP Extruder (Main Body) for flexible plastic with 4mm hole by chrspcritter

...the top hole to fit the 4mm od ptfe tubing to get right next to the gear and bearing for best results in printing with ninjaflex.

thingiverse

free

4 bearing x carriage with high holes by Joe558

...this was printed for my folgertech in order to move the mk9 extruder up to better fit the e3d v6 without loosing printing height.

thingiverse

free

Folgertech FT-5 Stock Extruder / E3D V6 BLTouch Mount by CheopisIV

.... for now, it works okay...

added e3d direct.stl which is the mounting block without the bltouch bracket. not needed otherwise.

thingiverse

free

Wanhao Duplicator I3 Bowden Extruder for E3D V6 / Clone WITHOUT DUCT/FAN HOLE by jacob-danell

... printer didn't want to print the fan-hole. i don't need the fan-hole myself so i removed it. here is the model for that!

Nebarnix

thingiverse

free

Angel Girl by nebarnix

...angel girl by nebarnix

thingiverse

because some of our loved little ones can't be with us today

thingiverse

free

Tree Flakes by nebarnix

... flakes by nebarnix

thingiverse

its a thing. i was playing with an idea that didn't really work out, but, i liked it anyway?

thingiverse

free

A HeatSync Labs Pendant! by nebarnix

...tsync labs pendant! by nebarnix

thingiverse

show off your favorite hackerspace love! print in orange then switch to black. win!

thingiverse

free

Place Medals by nebarnix

... for the science fair winners! yay!

there's also now a fourth, because i needed a consolation prize!

todo: make placebo award

thingiverse

free

Solidoodle3 40mm fan shroud - Printrboard Version by nebarnix

...dle3 40mm fan shroud - printrboard version by nebarnix

thingiverse

remixed this to fit a 40mm fan onto the printrboard version.

thingiverse

free

Cosmonaut's Day Egg 2015 by nebarnix

...hingiverse

this year, cosmonaut's day falls on orthodox easter. i thought it would be awesome to make an egg to commemorate!

thingiverse

free

Ricoh Theta Mast Mount by nebarnix

...

float your theta in mid-air!

made to fit a 10m telescoping fiberglass mast (fits over the second element, which is more sturdy)

thingiverse

free

Thomas & Friends Adventures Adapter by nebarnix

...rse

thomas & friends adventures new track to old track adapter

you may need to mirror the parts

so check before you print!

thingiverse

free

Printable Cygnus by nebarnix

...ep them from breaking so easily once printed. printing the version with struts is highly recommended if you are clumsy like me :)

thingiverse

free

Deltaprintr Blower Cooling Shroud by nebarnix

...rtens the nozzle length and makes the clamp thinner to fit the laser cut wood used on the deltaprintr. use an m3 screw and enjoy!

Lawsy

thingiverse

free

VisPrinter lawsy fork by lawsy

...ent here focusing on adding functionality and a gui that works on a 800x480px touch screen.

https://github.com/mlaws/visprinter

thingiverse

free

Filament Guide for Lawsy's MK4 Jigsaw by bowvmi2001

...9;s mk4 jigsaw by bowvmi2001

thingiverse

remake of hesselhartmans' filament guide so that works with lawsy's mk4 jigsaw.

thingiverse

free

Hoff Cup by lawsy

...up/mug embossed with the 3d face of david hasselhoff. created using phototomesh v3: http://www.ransen.com/phototomesh/default.htm

thingiverse

free

Higher top for lawsy's carriage. by Randomloser

...r part of the carriage.

i also added two extra nut holes for the hotend mounting.

just print it like lawsy's normal carriage.

thingiverse

free

Solidoodle Pengod700 holders by lawsy

...doodle pengod700 holders by lawsy

thingiverse

clips onto the solidoodle frame and holds a pengpod (or other ~12mm thick device).

thingiverse

free

Solidoodle Electronics Cover by lawsy

...y lawsy

thingiverse

a robust electronics case that should withstand quite an impact. designed to take two 30mm fans for cooling.

thingiverse

free

Lawsy's MK5 solidoodle extruder for ninjaflex by MikeT71

...would not bend between extruder rollers and extruder. the original holder is for the e3d (v.5), so it has the larger slot in it.

thingiverse

free

Solidoodle Door Handle by lawsy

...imple door handle for when the standard magnetized holder loses its stick. easy to print and force fitting together in two parts.

thingiverse

free

Solidoodle Extended Filament Guide by lawsy

...ent guide by lawsy

thingiverse

extended guide that helps the filament through the rear panel and clear of the z rods and screws.

thingiverse

free

Modified lawsy Solidoodle Carriage for Bulldog Lite Extruder by 3dmi-go

...he bulldog lite extruder. so far it's working very well and i'm getting some pretty good test prints.

lawsy / cc by 3.0

Mk5

turbosquid

free

Sten mk5

...ee 3d model sten mk5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1472891)

humster3d

$75

3D model of Magnum MK5 2014

...y a detailed 3d model of magnum mk5 2014 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$99

Volkswagen Golf Mk5 3door 2004 3D Model

...2006 2007 2008 2009 3-door hatchback compact family city germany

volkswagen golf mk5 3door 2004 3d model humster3d 70274 3dexport

cg_studio

$99

Volkswagen Golf Mk5 3-door 20043d model

...x .lwo .max .mb .obj - volkswagen golf mk5 3-door 2004 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of Volkswagen Golf Mk5 3-door 2004

...model of volkswagen golf mk5 3-door 2004 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$75

3D model of Volkswagen Golf Mk5 5-door 2004

...model of volkswagen golf mk5 5-door 2004 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$89

Volkswagen Golf Mk5 3-door 2004

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

3d_ocean

$89

Volkswagen Golf Mk5 5-door 2004

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

3d_export

$70

toyota supra mk5 a90 fast and furious

... was rendered at 3dsmax 2017 with vray3.6<br>saved for max 2014<br>toyota supra 3d model clean topology with interior

vizpark

$15

HDRI Skydome 30

...scenes. the exposure images were taken with a canon mk5 camera. all images were manually adjusted and corrected with...

Solidoodle

thingiverse

free

Solidoodle by diogo_manuel

...solidoodle by diogo_manuel

thingiverse

solidoodle souporte tools

thingiverse

free

solidoodle toolkeeper by ali55

...solidoodle toolkeeper by ali55

thingiverse

solidoodle tool keeper

thingiverse

free

Solidoodle Logo by kepster

...solidoodle logo by kepster

thingiverse

a logo i created for my solidoodle 2

thingiverse

free

Solidoodle logo by SLAM-ER

...hing to the front of the print bed. all rights belong to solidoodle, i am not affiliated with or a representitive of solidoodle.

thingiverse

free

Solidoodle clip by pesce

...dle clip by pesce

thingiverse

this is a simple clip, that you can use to attach various things to the frame of the solidoodle...

thingiverse

free

GoPro Solidoodle Clip by boulderbuff64

...gopro solidoodle clip by boulderbuff64

thingiverse

this is a gopro bracket that clips to a solidoodle frame

thingiverse

free

Solidoodle Z-Endstop by frankcusano

...solidoodle z-endstop by frankcusano

thingiverse

replacement z-endstop for solidoodle 2 or 3.

thingiverse

free

Solidoodle Spool Holder by frankcusano

...solidoodle spool holder by frankcusano

thingiverse

replacement spool holder for a solidoodle 2 or 3.

thingiverse

free

Solidoodle tool holder by _steezy_

...solidoodle tool holder by _steezy_

thingiverse

simple tool holder for standard tools that came with my solidoodle 4

thingiverse

free

Recup box for solidoodle by FOmenal

...recup box for solidoodle by fomenal

thingiverse

i make this full parametrique box for my solidoodle to make clean.

Ninjaflex

thingiverse

free

Ninjaflex Test by demomansample

...t by demomansample

thingiverse

this is a test print for ninjaflex. this will help you configure your printer to print ninjaflex.

thingiverse

free

Ninjaflex Spacer by fozzybear

...ninjaflex spacer by fozzybear

thingiverse

spacer for the ninjaflex roll.

thingiverse

free

NinjaFlex K8200 by dntppe

...ninjaflex k8200 by dntppe

thingiverse

i modified the extruder base for ninjaflex

thingiverse

free

NinjaFlex Flexiband by David_Ahlzadeh

... my robo 3d printer. if you are testing out ninjaflex out on your 3d printer too i recommend using this as your first test print.

thingiverse

free

NinjaFlex Silver Necklace by DiabaseEngineer

...ninjaflex silver necklace by diabaseengineer

thingiverse

print it in ninjaflex at 70mm/s with the flexion extruder

thingiverse

free

NinjaFlex Frisbee by RobotMama

...ally cool flying abilities :d so it is a frisbee now.

the white version is pla, the transparent is petg and the orange ninjaflex.

thingiverse

free

cuboid 150w coque ninjaflex by forange

...cuboid 150w coque ninjaflex by forange

thingiverse

coque ninjaflex

thingiverse

free

Kindle Fire NinjaFlex by ttturner68

...kindle fire ninjaflex by ttturner68

thingiverse

ninjaflex is too soft to do hard arcs from the table, this version address it.

thingiverse

free

Anti-Vibration Mount NINJAFLEX by Nilltan

...anti-vibration mount ninjaflex by nilltan

thingiverse

a anti-vibration foot thats it´s made of ninjaflex.

thingiverse

free

PrintrBot Metal NinjaFlex adapter by dubi

...printrbot metal ninjaflex adapter by dubi

thingiverse

my take on the printrbot extruder mod for ninjaflex filament.

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Edition

turbosquid

$33

Natuzzi Editions

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Guitar_MJ-Edition

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Editable Fountain

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

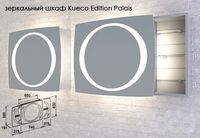

Kueco Edition Palais

...kueco edition palais

3ddd

keuco

зеркальный шкаф kueco edition palais

design_connected

$16

369 Classic Edition

...369 classic edition

designconnected

walter knoll 369 classic edition computer generated 3d model.

3ddd

$1

Martz Edition

...martz edition

3ddd

martzedition

http://www.martzedition.com/a-500-3

3ddd

$1

Martz Edition

...martz edition

3ddd

martzedition

http://www.martzedition.com/b-400-3

design_connected

$25

Chester - Limited Edition

...nnected

established & sons chester - limited edition computer generated 3d model. designed by future systems, amanda levete.

3ddd

$1

KROKEN LIMITED EDITION

...d

rochebobois

autumn/winter collections 2012 rochebobois paris

kroken limited edition armchairhttp://m.roche-bobois.com

3ddd

$1

stilwerk limited edition

...stilwerk limited edition

3ddd

3000х1200х750