Thingiverse

Laser Bandsaw by Weldingrod1

by Thingiverse

Last crawled date: 3 years, 1 month ago

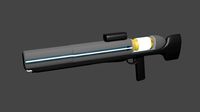

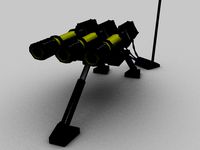

Cue the evil laughter... Yes, its a functional laser bandsaw!

First things first: this is not a toy, but it is presented purely for your amusement. If you choose to do something with this material, be warned: this device is hazardous! The laser can burn/cut you and ruin your vision! I have made a first cut at a suitable guard for this, but its a DRAFT of a guard, and needs work. You must ALSO wear laser goggles!

After listening to Max and Justin on the Home Shop Machinist Podcast talking about the next 100 years of home shop machine tools and the "laser bandsaw" I, of course, had to build one!https://thecogwheel.net/2017/10/01/home-shop-machinists-podcast-episode-11-shop-of-the-future/

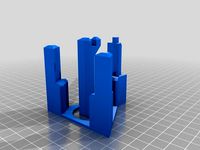

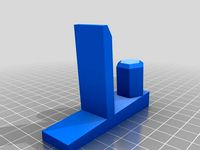

The laser is a NUBM44 installed in a Copper housing. The heat sink is totally custom made with about 0.002" of clearance between the housing and heat sink for heat sink paste. A Super X-drive (designed by Laseerer) powers the laser. I had fun boring out the hole to match the diode housing (tiny little boring bar) and cutting fins into it with a slitting saw. A pocket under the fan allows air to reach the fins, and the ends of the fins are sealed with Aluminum foil tape so that all the air exits around the lens and provides some air assist.

The black rectangle under the laser is the beam dump: a stack of box knife blades. You need this because the laser is on continuously, and you need a place for that energy to go SAFELY! The orange shielding material is from JTech Photonics, hot formed to fit around the laser heat sink. I cheated some and masked areas of the acrylic that I didn't want to have bend by using more Aluminum foil tape. That stuff is great, if irritatingly sharp!

To set it up, feed it a small current (under half an Amp, which will require around 4-5 Volts to get the diode to turn on). Put a sheet of paper on the table and adjust for minimum spot size (you are wearing your goggles, right?!?).

In use, move your target object through the beam slowly and it will cut! Paper and business cards cut pretty well. Single layer cardboard cuts ok-ish. Double layer mostly just burns. It will take black paint/ink off of stuff really fast. Craft foam and felt both cut well, if a bit stinky. Balsa cuts really fast and nicely!

I've got a higher resolution video on YouTube: https://youtu.be/1sBeiYIkn4k

First things first: this is not a toy, but it is presented purely for your amusement. If you choose to do something with this material, be warned: this device is hazardous! The laser can burn/cut you and ruin your vision! I have made a first cut at a suitable guard for this, but its a DRAFT of a guard, and needs work. You must ALSO wear laser goggles!

After listening to Max and Justin on the Home Shop Machinist Podcast talking about the next 100 years of home shop machine tools and the "laser bandsaw" I, of course, had to build one!https://thecogwheel.net/2017/10/01/home-shop-machinists-podcast-episode-11-shop-of-the-future/

The laser is a NUBM44 installed in a Copper housing. The heat sink is totally custom made with about 0.002" of clearance between the housing and heat sink for heat sink paste. A Super X-drive (designed by Laseerer) powers the laser. I had fun boring out the hole to match the diode housing (tiny little boring bar) and cutting fins into it with a slitting saw. A pocket under the fan allows air to reach the fins, and the ends of the fins are sealed with Aluminum foil tape so that all the air exits around the lens and provides some air assist.

The black rectangle under the laser is the beam dump: a stack of box knife blades. You need this because the laser is on continuously, and you need a place for that energy to go SAFELY! The orange shielding material is from JTech Photonics, hot formed to fit around the laser heat sink. I cheated some and masked areas of the acrylic that I didn't want to have bend by using more Aluminum foil tape. That stuff is great, if irritatingly sharp!

To set it up, feed it a small current (under half an Amp, which will require around 4-5 Volts to get the diode to turn on). Put a sheet of paper on the table and adjust for minimum spot size (you are wearing your goggles, right?!?).

In use, move your target object through the beam slowly and it will cut! Paper and business cards cut pretty well. Single layer cardboard cuts ok-ish. Double layer mostly just burns. It will take black paint/ink off of stuff really fast. Craft foam and felt both cut well, if a bit stinky. Balsa cuts really fast and nicely!

I've got a higher resolution video on YouTube: https://youtu.be/1sBeiYIkn4k

Similar models

thingiverse

free

Two Blue Laser Diode Beam Combiner by Lob0426

....com/site/dtrlpf/home/diode-modules/12mm-copper-modules

edited size of object. increased cooling area. dimensions changed 8/10/16

thingiverse

free

12mm Laser Bracket for FlashForge Creator Pro by TokenGTx

...to help a little more with cooling (i have a 7w laser diode, which is the reason for the larger fan and extra heat sink funciton.

thingiverse

free

Air Assist nozzle to fit chinese 15w diode laser etcher cutter by jrs824

...l go unaffected in that respect. the hose should be able to be routed across to the back with the wires, i just didnt do that yet

grabcad

free

Heat Sink - 14-Pin Laser Diode

...or ild, or diode laser) is a semiconductor device similar to a light-emitting diode in which a diode pumped...

thingiverse

free

Air Assist Tube for Laser Diode by hwright14

...rom blocking the beam and reducing the power. it also keeps the parts cleaner.

the mounting points are seperated by 43mm and 5mm.

thingiverse

free

Air Assist Nozzle for Diode Lasers by ThothLoki

...ort back and let me know how it works for you.

if you find this useful and want to buy me a beer: https://www.paypal.me/thothloki

grabcad

free

Profile Cutter for Laser Marker Machine

... is used as fixture to hold a thin sheet or foil to cut profiles and shapes under laser marker machine using high intenisty beam,

thingiverse

free

The nozzle on the laser diode by Jeefse

...rse

the nozzle on the laser diode,to connect the air pressure allows the low power laser to cut thick material, in fewer passes.

thingiverse

free

K40 Air Assist and Laser by iClint

...k40. laser diode is sight for 50.8mm.

requires:

2x m3 square nuts

2x m3x8mm screws

1/4" bsp press air fitting

5v laser diode

thingiverse

free

"Caution! Laser Beam" ornament by gingercoons

...the laser warning symbol. ready to laser cut and adorn your workshop, or anywhere else you want to practice stylish laser safety.

Weldingrod1

thingiverse

free

Cowboy Boot by Weldingrod1

...verse

i needed a model of a cowboy boot so i could wrap something to go with a "get a new pair of boots" certificate.

thingiverse

free

Christmas tree topper/star by Weldingrod1

...christmas tree topper/star by weldingrod1

thingiverse

this is a stellated dodecahedron to fancy up your tree!

thingiverse

free

Drying stand for nasal irrigator by Weldingrod1

...d for nasal irrigator by weldingrod1

thingiverse

this is a stand that fits the neilmed nasal irrigator and allows it to drip dry

thingiverse

free

Hand Punch Hangers by Weldingrod1

...omized to fit the two smaller sizes of whitney brand hand punches. the smaller one will fit the harbour freight hand punch also.

thingiverse

free

Stackable extruder by Weldingrod1

...s (oriented for the huxley) and are arranged to be stackable. the one that takes markers would, of course, use white filament...

thingiverse

free

Emaker Huxley electronics enclosure by Weldingrod1

...d to work with the emaker huxley electronics. it clears the sd card and accomodates the connector orientation used on the huxley

thingiverse

free

Milwaukee close quarters drill hangar by Weldingrod1

...od1

thingiverse

this is a custom fitted hangar for a milwaukee close quarters drill. it will probably fit the other brands too.

thingiverse

free

Y belt clamp with end stop by Weldingrod1

...y weldingrod1

thingiverse

if you replace your y axis belt clamp with this it will provide a place for the limit switch to touch.

thingiverse

free

Indicator Holder for Emaker Huxley print head by Weldingrod1

...huxley print head by weldingrod1

thingiverse

this will let you mount a test indicator on your huxley to really level up the bed!

thingiverse

free

Tape hangars by Weldingrod1

...ts and double units. the double unit is sized for two full size rolls to fit properly.

they stick up nicely with command strips.

Bandsaw

turbosquid

$60

bandsaw

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

bandsaw.3DS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

Bandsaw

...bandsaw

thingiverse

an unknown brand of a metal bandsaw.

free3d

free

Bandsaw v1

...bandsaw v1

free3d

bandsaw v1 printable, low poly model.

thingiverse

free

Proxxon Bandsaw by raccoo

...proxxon bandsaw by raccoo

thingiverse

proxxon bandsaw

thingiverse

free

Bandsaw Dısc

...sc

thingiverse

bandsaw disc

upper part

diameter: 82.3mm

thickness: 3mm

lower part

diameter: 69mm

thickness: 20mm

screw holes 2mm

thingiverse

free

Crank for Bandsaw by stepbystep

...crank for bandsaw by stepbystep

thingiverse

crank handle for harvey bandsaw

for knob (crank2.stl)need pause at 23.1mm

thingiverse

free

Bandsaw Vacuum Adaptors

...bandsaw vacuum adaptors

thingiverse

i have a grizzly bandsaw and i design few custom vacuum adaptors for it.

thingiverse

free

Haussmann bandsaw foot by Ohmcircuit

...haussmann bandsaw foot by ohmcircuit

thingiverse

foot for haussmann bandsaw

thingiverse

free

Rexon bandsaw by raccoo

...rexon bandsaw by raccoo

thingiverse

Laser

3d_export

$5

laser

...laser

3dexport

a 3d laser

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

cnc laser mount opt lasers

...eive the engraving and cutting laser heads this cnc machine laser mount was designed for, read the article on the following page:

turbosquid

$20

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

laser sword

...laser sword

3dexport

it is a blue laser sword with a metal frame

3d_ocean

$19

Laser Turret

...be used in any sf type of game, especially in tower defense games. - laser turret: 3025 polygons - props: 270 polygons - textu...

3d_export

free

workbee cnc laser mount for opt lasers

...the specifications of engraving and cutting laser heads this mount was designed for, please take a look at the following website:

3d_export

free

shapeoko cnc laser mount for opt lasers

...ind out the opportunities that adding a cutting and engraving laser head to your cnc can bring, take a look at the website below: