Thingiverse

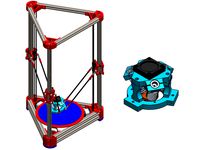

Kossel Mini Magnetic Ball Joint End Effector Upgrade by Chimes_Industries

by Thingiverse

Last crawled date: 3 years ago

First off, let me please ask that if you like these designs and find them useful please do like, follow and share my content. And if you have any ideas or concepts to modify the content I would love to hear!

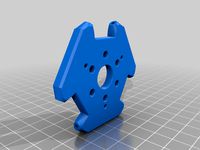

UPDATE (28/10/2017): I have added this part https://www.thingiverse.com/thing:2611279 to my Thingiverse Page for those who wish to convert their roller carriage style Kossel printer to magnetic joints.

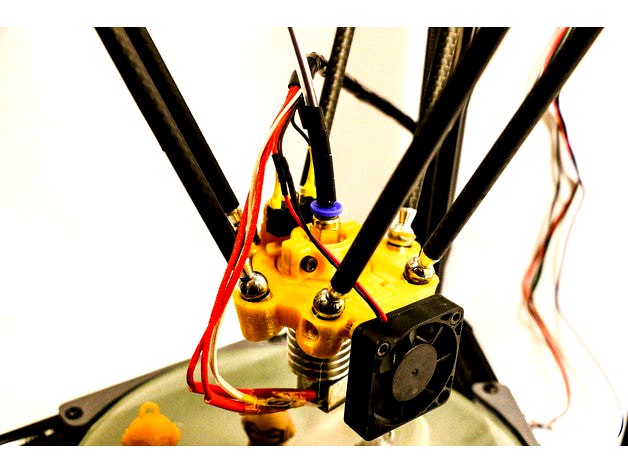

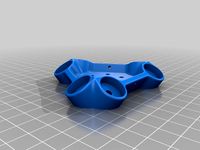

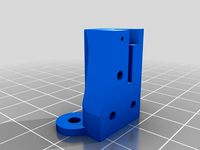

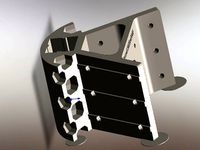

This is a magnetic ball joint upgrade for the Kossel Mini 3D printer range that use HIWIN style linear rails. The end effector is designed to use the e3d V6 style hotends as well as the various different clones that are available. This is a direct replacement to the rose/ball joint Micromake Kossel Mini sold by flsun.

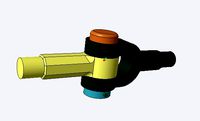

The effector also allows for auto bed levelling using a limit switch and the nozzle as the means of detecting the bed surface location.

The kit can be assembled using a wide variety of parts, though has been designed around the use of 10mm magnetic ball joints.

The finishing parts for this upgrade can be purchased here http://www.chimesindustries.com/shop or the parts can be purchased from a variety of different online stores.

Print it, assemble it, try it out and let me know what you think! :) The increase in rigidity in using magnetic joints as well as linear guide rails on the Kossel printer designs really improves the print output and removes the 'slop' in the system.

I have added some images showing a possible part cooling setup for the magnetic joint setup. They can be seen here: https://www.thingiverse.com/thing:2364103 and here: https://www.thingiverse.com/thing:2364083 There are mounts for e3d V5 and V6 hotends (~23mm and ~25mm OD heatsink) and clone variants.

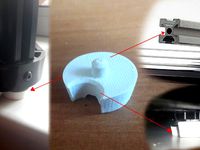

Also, if you do not have the ability to measure the length of the rods accurately to within tenths of a millimetre (0.1mm) then you may find this print helpful: https://www.thingiverse.com/thing:2355506 The pieces can be mounted to a piece of open beam aluminium extrusion ( e.g. one of your delta printer towers) and then each rod placed in the jig, adjusted to length and then fastened. This will ensure your rods are the same length and you do not experience any disconnects during printing and operation.

UPDATE (28/10/2017): I have added this part https://www.thingiverse.com/thing:2611279 to my Thingiverse Page for those who wish to convert their roller carriage style Kossel printer to magnetic joints.

This is a magnetic ball joint upgrade for the Kossel Mini 3D printer range that use HIWIN style linear rails. The end effector is designed to use the e3d V6 style hotends as well as the various different clones that are available. This is a direct replacement to the rose/ball joint Micromake Kossel Mini sold by flsun.

The effector also allows for auto bed levelling using a limit switch and the nozzle as the means of detecting the bed surface location.

The kit can be assembled using a wide variety of parts, though has been designed around the use of 10mm magnetic ball joints.

The finishing parts for this upgrade can be purchased here http://www.chimesindustries.com/shop or the parts can be purchased from a variety of different online stores.

Print it, assemble it, try it out and let me know what you think! :) The increase in rigidity in using magnetic joints as well as linear guide rails on the Kossel printer designs really improves the print output and removes the 'slop' in the system.

I have added some images showing a possible part cooling setup for the magnetic joint setup. They can be seen here: https://www.thingiverse.com/thing:2364103 and here: https://www.thingiverse.com/thing:2364083 There are mounts for e3d V5 and V6 hotends (~23mm and ~25mm OD heatsink) and clone variants.

Also, if you do not have the ability to measure the length of the rods accurately to within tenths of a millimetre (0.1mm) then you may find this print helpful: https://www.thingiverse.com/thing:2355506 The pieces can be mounted to a piece of open beam aluminium extrusion ( e.g. one of your delta printer towers) and then each rod placed in the jig, adjusted to length and then fastened. This will ensure your rods are the same length and you do not experience any disconnects during printing and operation.

Similar models

thingiverse

free

E3D 30mm Fan for autolevel effector by abriggs12

...fit as the effector includes a zprobe in a similar manner to http://www.thingiverse.com/thing:868258 this is a remix of http://www.thingiverse.com/thing:340312...

thingiverse

free

Delta Effector w. Magnetic joints for E3D V6 by robkar

...d-looking, and with magnetic joints for minimal backlash.

here is the complete printer: http://www.thingiverse.com/thing:923830

thingiverse

free

Magnetic detachable autolevel z - probe for Kossel Mini effector with E3D v6 hotend by mechanicsnail

...ad file included. can be used with kossel mini openscad sources from github to render complete effector + hotend + probe picture.

thingiverse

free

mini kossel JT magnetic effector plate by davejavu123

...or plate by davejavu123

thingiverse

this works with the 30mm fan (thing:948319) and the mini kossel magnetic ball joint and rods

thingiverse

free

Geeetech Rostock301 magnetic effector upgrade by t_schatz

...cal magnets (top one countersunk).

the groove mount for the e3d v6lite hotend can be screwed to the effector for extra stiffness.

thingiverse

free

E3D v6 hotend complete mount (with groove) for Kossel mini 3D printer by gtrick90

... http://www.thingiverse.com/thing:653184

printed in pla, no single issue till now

https://www.youtube.com/watch?v=fjo8avcbbei

thingiverse

free

Effector and plates by Lykle

... of course you need 3 batwings.

this is used with brian's magnetic ball conversion. http://www.thingiverse.com/thing:883347

thingiverse

free

Magnetic Joint Carriage for Kossel Mini by cffellows

...ge provides the capability of building a kossel mini with magnetic ball joints using the magnetic effector from the cerberus pup.

thingiverse

free

Kossel Magetic Effector for E3D V6 Volcano by Canyonazo

...nd the magnetic carriages used of this assembly on that link

assembly not tested during printing yet. any feedback is apreciated.

thingiverse

free

The effector for E3D V6 by born_to_kill

... effector for e3d v6

and 15 mm magnets

distance between magnets 50 mm

carriage take here https://www.thingiverse.com/thing:496689

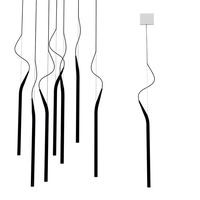

Chimes

turbosquid

$24

Chimes

...quid

royalty free 3d model chimes for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1520001)

turbosquid

$20

Chimes

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Bamboo Chimes

...quid

royalty free 3d model bamboo chimes for download as max on turbosquid: 3d models for games, architecture, videos. (1596529)

turbosquid

$10

Wind chimes

...osquid

royalty free 3d model wind chimes for download as max on turbosquid: 3d models for games, architecture, videos. (1278265)

turbosquid

$50

Star Chimes

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Wind Chimes

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$65

Wind chimes

...wind chimes

3dexport

simple rendering of the scene file

3d_export

$65

wind chimes

...wind chimes

3dexport

simple rendering of the scene file

turbosquid

free

Wind chimes 1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Furin - Wind Chimes

...n - wind chimes - gltf<br>- ten materials<br>- one texture: 2048x2048<br>enjoy the product and leave a comment.

Effector

3d_ocean

$5

Radial Sound Effector

...e spheres will expand with your song. fully customisable, change the color, the size of the spheres or even put in different s...

3d_ocean

$12

3D Customizable Puzzle Set (16x10)

...mograph compatible (you can effect the pieces with mograph effector) - included also a non-mograph version with...

thingiverse

free

Effector by olo2000pm

...effector by olo2000pm

thingiverse

effector

thingiverse

free

CERAMBOT-Effector

...cerambot-effector

thingiverse

cerambot-effector

thingiverse

free

modulize effector by candyasdf

...ulize effector by candyasdf

thingiverse

mount things on effector with m3 screws

effector radius : 25.4mm

rod arm distance : 40mm

thingiverse

free

Delta Effector by zavier

...delta effector by zavier

thingiverse

delta effector with radial fan 50 and bltouch

thingiverse

free

D810 Effector by WhiteTiger13

...d810 effector by whitetiger13

thingiverse

this is d810 effector for d810 without autocalibration, and also cap for it.

thingiverse

free

Effector for Delta Printer

...effector for delta printer

thingiverse

effector for delta printer (3 color)

using diamond hotend

thingiverse

free

Delta effector magnetic by fpassos

...delta effector magnetic by fpassos

thingiverse

effector for e3dv6 hotend. i needed put the spheres (10mm) on the effector.

thingiverse

free

End Effector Gripper

...end effector gripper

thingiverse

end effector gripper

for a robotic arm

uses mg995 servo motor

Kossel

thingiverse

free

kossel bottom by keisukelin

...kossel bottom by keisukelin

thingiverse

kossel bottom

thingiverse

free

Leg for kossel by exelon

...leg for kossel by exelon

thingiverse

leg for kossel

thingiverse

free

Extruder for kossel by spencer_chen7

...extruder for kossel by spencer_chen7

thingiverse

extruder for kossel

thingiverse

free

Kossel parts by breezer83

...kossel parts by breezer83

thingiverse

kossel parts

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

Kossel Medium by flux83

...kossel medium by flux83

thingiverse

vertex for upgraded kossel mini

thingiverse

free

Kossel Mini by salesmendesandre

...kossel mini by salesmendesandre

thingiverse

custom kossel mini

frame 20x20

thingiverse

free

leg for kossel by ionulet

...leg for kossel by ionulet

thingiverse

leg for kossel with channel for end- stop cables

thingiverse

free

Optical Endstops Mounts for Kossel (with Better Kossel carriages) by dellfer

...stops on the anycubic kossel with better kossel carriages by codefreak https://www.thingiverse.com/thing:2501337

more precission

thingiverse

free

kossel??????? by wangrui19890704

...kossel??????? by wangrui19890704

thingiverse

??2020?2060???

Upgrade

turbosquid

$15

Upgraded Glock

...e 3d model upgraded glock for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1185950)

3ddd

$1

Calligaris / UPGRADE

...calligaris / upgrade

3ddd

calligaris

c материалом

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

turbosquid

$80

Custer Tank upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Domestos 1 upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Upgraded tea cup

...upgraded tea cup

3dexport

a cup with an unusual design and a unique shape for a more enjoyable tea experience

3d_export

$8

dixy outlander classic style upgraded poplar wood lounge chair

...utlander classic style upgraded poplar wood lounge chair

3dexport

dixy outlander classic style upgraded poplar wood lounge chair

turbosquid

free

AK-12 + Upgrades low-poly 3D model

...ow-poly 3d model for download as fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1501145)

evermotion

$700

Upgrade from V-ray 1.5 to 3.5 for 3ds max

...here is no need to purchase a new dongle - your current dongles will be reprogrammed to carry v-ray 3. evermotion 3d models shop.

evermotion

$300

Upgrade from V-Ray 2.0 to V-ray 3.5 for 3ds Max

... interface (gui) for editing settings on one machine and one render node for rendering on one machine. evermotion 3d models shop.

Joint

turbosquid

$5

Joint

...turbosquid

royalty free 3d model joint for download as blend on turbosquid: 3d models for games, architecture, videos. (1179882)

3d_export

$5

joint handle

...joint handle

3dexport

joint handle

3d_export

$5

knuckle joint

...knuckle joint

3dexport

this is a 3d model of knuckle joint

3d_export

$5

Knuckle Joint

...knuckle joint

3dexport

industry use knuckle joint

3ddd

$1

PENTA Joint

...penta joint

3ddd

penta

http://www.lampcommerce.com/en/catalogue/brands/penta-light/joint-floor-lamp

turbosquid

$49

Joint | Project

...squid

royalty free 3d model joint | project for download as on turbosquid: 3d models for games, architecture, videos. (1297983)

turbosquid

$10

universal joint

...squid

royalty free 3d model univresal joint for download as on turbosquid: 3d models for games, architecture, videos. (1309400)

turbosquid

$15

Joint Ashtray

...squid

royalty free 3d model joint ashtray for download as ma on turbosquid: 3d models for games, architecture, videos. (1199702)

turbosquid

$5

Unrolled joint

...e 3d model unrolled joint for download as blend, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1577889)

3d_export

$5

Cardan Joint 3D Model

...cardan joint 3d model

3dexport

cardan joint

cardan joint 3d model fau 71171 3dexport

Magnetic

3d_ocean

$2

Magnet

...magnet 3docean 3d 3ds max electric magnet magnetic magnetism max model polygon realistic tesla magnet created in...

turbosquid

$6

Magnet

...

turbosquid

royalty free 3d model magnet for download as obj on turbosquid: 3d models for games, architecture, videos. (1548733)

turbosquid

$6

magnet

...uid

royalty free 3d model magnet for download as 3dm and max on turbosquid: 3d models for games, architecture, videos. (1670606)

turbosquid

$1

Magnet

...y free 3d model magnet for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1215037)

turbosquid

$7

Magnet

...agnet for download as blend, unitypackage, fbx, gltf, and obj on turbosquid: 3d models for games, architecture, videos. (1576588)

3d_export

$5

magnetic knife holder

...magnetic knife holder

3dexport

ordinary magnetic knife holder

archive3d

free

Fridge magnet 3D Model

...3d model archive3d refrigerator magnet fridge magnet magnet toy magnetic s n280712 - 3d model (*.3ds) for interior 3d...

turbosquid

$35

Magnetic butterflies

...alty free 3d model magnetic butterflies for download as blend on turbosquid: 3d models for games, architecture, videos. (1315792)

turbosquid

$2

Magnetic Board

...quid

royalty free 3d model magnetic board for download as ma on turbosquid: 3d models for games, architecture, videos. (1264141)

turbosquid

$977

Magnetic Lego

...oyalty free 3d model magnetic lego for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1142761)

Ball

turbosquid

$5

Ball on a Ball

...uid

royalty free 3d model ball on a ball for download as obj on turbosquid: 3d models for games, architecture, videos. (1484719)

archibase_planet

free

Ball

...ball

archibase planet

ball golf ball

ball - 3d model (*.gsm+*.3ds) for 3d visualization.

3d_export

$5

ball

...ball

3dexport

ball

archibase_planet

free

Ball

...ball

archibase planet

ball football soccer ball

ball n100714 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

3d_export

$5

ball

...ball

3dexport

soccer ball

archibase_planet

free

Ball

...ball

archibase planet

ball football

ball n100914 - 3d model (*.gsm+*.3ds+*.max) for 3d visualization.

3d_ocean

$5

Snooker Balls

... set balls snooker snooker balls white ball yellow ball

set snooker balls format include : .c4d .3ds .obj build in cinema 4d r13

3d_export

free

ball

...ball

3dexport

this is 3d model ball's

3d_ocean

$2

Soccer Ball

...soccer ball

3docean

ball red and yellow ball red ball soccer ball

a gorgeous red and yellow seamless soccer ball

3d_ocean

$5

Billard Balls

...low poly billiard balls. numbering from 1 to 15 plus the cue ball. each of the balls excluding the cue ball has a 4k texture map.

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Industries

design_connected

$13

Industrial

...industrial

designconnected

dreizehngrad industrial computer generated 3d model.

3ddd

free

Industrial chair

...industrial chair

3ddd

industrial

industrial chair

3d_export

$5

industrial furniture - industrial table 01

...industrial furniture - industrial table 01

3dexport

"industrial table 01"

3ddd

free

Industrial table

...дустриальный , кофейный , стол

industrial table

3ddd

$1

L-Industry

...l-industry

3ddd

l-industry

промышленные светильники l-industry . диаметр × высота 320х492мм

3d_export

$5

industrial machine

...industrial machine

3dexport

industrial machine

3d_export

$5

industrial oven

...industrial oven

3dexport

industrial oven

3d_export

$5

industrial wheel

...industrial wheel

3dexport

industrial wheel

3ddd

$1

REFLECTOR INDUSTRIAL

...reflector industrial

3ddd

reflector industrial

3ddd

$1

Industrial light

...industrial light

3ddd

grange

industrial light.

End

archibase_planet

free

Cigarettes end

...d

archibase planet

cigarettes end cigarette stub cigar-butt

cigarette-end - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

turbosquid

$10

End Table

...rbosquid

royalty free 3d model end table for download as max on turbosquid: 3d models for games, architecture, videos. (1570610)

turbosquid

$5

End Table

...urbosquid

royalty free 3d model end table for download as ma on turbosquid: 3d models for games, architecture, videos. (1622809)

turbosquid

$3

End Table

...rbosquid

royalty free 3d model end table for download as fbx on turbosquid: 3d models for games, architecture, videos. (1315115)

3d_export

$5

rope end ring

...rope end ring

3dexport

rope end ring

turbosquid

$2

End Tables

...

royalty free 3d model end tables for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1706896)

turbosquid

$14

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1403051)

turbosquid

$12

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1574707)