Thingiverse

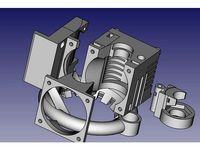

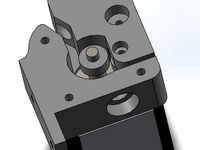

Kossel Mini Flying extruder inc new E3D Titan Version by DjDemonD

by Thingiverse

Last crawled date: 3 years ago

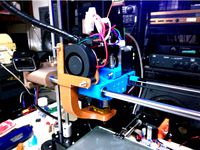

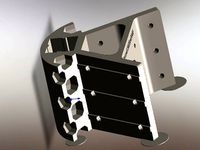

4-5-16 - New version available for e3d titan extruder. This can be run (if you're using 1.75mm filament) from a 20mm "pancake" nema 17 so the total extruder and flying bracket is only 250g. The old version with a standard 40mm nema 17 and lightweight extruder was 395g!

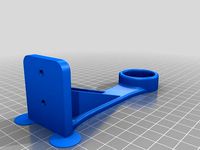

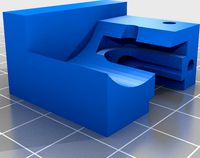

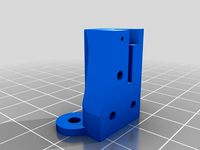

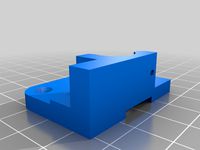

UPDATED - There are two carriages, one with the flying extruder loop fixed to it and standard belt clips. The other has quick release belt clips and moves the loop to fix on the top using the upper two bolts which hold the carriage onto the slides. Its only 2mm so the standard bolts should still work.

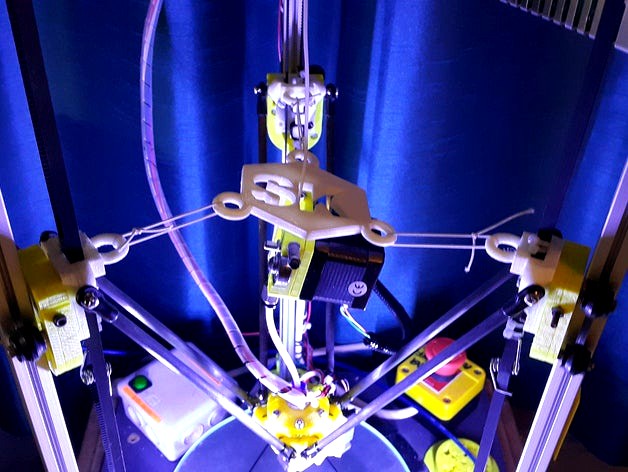

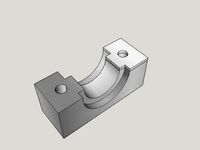

I made a flying extruder for a Kossel Mini Delta printer. Replace the carriages with these parts and string them to the extruder mount with some elastic material, I am using sewing elastic at present, but apparently modelling balloons work or silicone straps etc... Allow just enough tension to hold the extruder mount up, with extruder attached, centred between your three carriages. The additional parts to hold the elastic do make restringing the belts a little fiddly but I presume it's not something you are going to do very often.

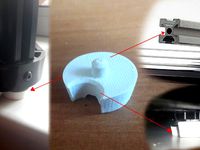

This has been designed for this extruder (http://www.thingiverse.com/thing:275593) but the file is public on tinkercad so feel free to alter it to fit whatever extruder you have (https://tinkercad.com/things/dJ0MpmOgcXt). The editable version of the titan flying extruder bracket is here (https://www.tinkercad.com/things/jYfQ3kHzbqz-djdemond-kossel-flying-extruder-e3d-titan-version). Aim to send the filament straight down the centre of the mount to the effector/hot end. In the photo the version I printed has my initials in the centre of the mount as a weight saving device and path for the filament to use, but in this version I have just left a large hole which should allow the filament path to be unhindered whatever extruder you are using.

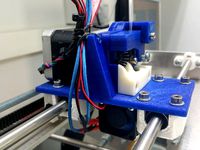

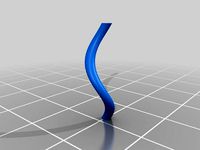

Attach the extruder to the effector/hot end with a bowden tube, which will now be somewhere between 4-6 times shorter than it was before, giving you hugely improved filament control, and adjust your retraction settings to be a little less aggressive I am now using 2mm at 150mm/s instead of 5mm at 100 mm/s. UPDATED - A small amount of downwards tension on the bowden tube helps so its not too long - too much bouncing around of flying extruder, or too short - too much tension on the elastics.

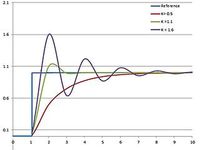

Despite this setup and the extruder now adding considerable mass to the carriages this is only fully affects the inertia of z direction moves and not in a way that seems to affect print quality, x and y direction moves are only marginally affected as the mount can swivel around relatively freely, so don't overdo the elastics, or have too short a bowden tube. Might be worth reducing your acceleration and xy jerk by 10% if it seems to be causing your corners to print less well than before.

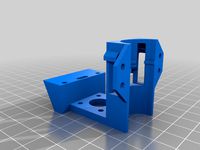

Update 02-06-16 I recently changed to an effector where most of the hot end is above the effector. As such the bowden tube using the titan flying bracket was too short to be flexible enough to function, so I made an inverted version for putting the extruder above the flying bracket to allow a slightly longer tube.

UPDATED - There are two carriages, one with the flying extruder loop fixed to it and standard belt clips. The other has quick release belt clips and moves the loop to fix on the top using the upper two bolts which hold the carriage onto the slides. Its only 2mm so the standard bolts should still work.

I made a flying extruder for a Kossel Mini Delta printer. Replace the carriages with these parts and string them to the extruder mount with some elastic material, I am using sewing elastic at present, but apparently modelling balloons work or silicone straps etc... Allow just enough tension to hold the extruder mount up, with extruder attached, centred between your three carriages. The additional parts to hold the elastic do make restringing the belts a little fiddly but I presume it's not something you are going to do very often.

This has been designed for this extruder (http://www.thingiverse.com/thing:275593) but the file is public on tinkercad so feel free to alter it to fit whatever extruder you have (https://tinkercad.com/things/dJ0MpmOgcXt). The editable version of the titan flying extruder bracket is here (https://www.tinkercad.com/things/jYfQ3kHzbqz-djdemond-kossel-flying-extruder-e3d-titan-version). Aim to send the filament straight down the centre of the mount to the effector/hot end. In the photo the version I printed has my initials in the centre of the mount as a weight saving device and path for the filament to use, but in this version I have just left a large hole which should allow the filament path to be unhindered whatever extruder you are using.

Attach the extruder to the effector/hot end with a bowden tube, which will now be somewhere between 4-6 times shorter than it was before, giving you hugely improved filament control, and adjust your retraction settings to be a little less aggressive I am now using 2mm at 150mm/s instead of 5mm at 100 mm/s. UPDATED - A small amount of downwards tension on the bowden tube helps so its not too long - too much bouncing around of flying extruder, or too short - too much tension on the elastics.

Despite this setup and the extruder now adding considerable mass to the carriages this is only fully affects the inertia of z direction moves and not in a way that seems to affect print quality, x and y direction moves are only marginally affected as the mount can swivel around relatively freely, so don't overdo the elastics, or have too short a bowden tube. Might be worth reducing your acceleration and xy jerk by 10% if it seems to be causing your corners to print less well than before.

Update 02-06-16 I recently changed to an effector where most of the hot end is above the effector. As such the bowden tube using the titan flying bracket was too short to be flexible enough to function, so I made an inverted version for putting the extruder above the flying bracket to allow a slightly longer tube.

Similar models

thingiverse

free

Titan Lightweight Flying Extruder Mount by 3d4uandme

...s centre of gravity (exact point depends on your stepper size/weight).

titan cover needs to be semi-built but loose to get it on.

thingiverse

free

Anycubic Kossel Extruder Top Rail Bracket Long by Mangosniper

... a bit more down to make the bowden tube shorter and to create some space between the extruder and my top mounted filament guide.

thingiverse

free

kossel effector with zprobe bracket by rattus911

...zprobe bracket by rattus911

thingiverse

kossel effector with zprobe bracket. i made this to fit e3d extruder and makerbot switch

thingiverse

free

Mini Kossel Effector Modified for E3D (Bowden) Hotend by ianlee74

...effector part for the mini kossel that was originally built for use with a jhead so that it could work with an e3d bowden hotend.

thingiverse

free

E3d V6 1.75mm Bowden hotend Bracket for MK2 short travel (there is newer version now holes for left or right) by RobMitshi

...ks, main bracket and added a clamp.

a full instuctable is at:

http://www.instructables.com/id/3d-printer-extruderhot-end-upgrade/

thingiverse

free

flying extruder mount for bmg

...unt will have the same center point for ptfe tube as the effector

if you want to help me create more stuff you can buy me a coffe

thingiverse

free

Kossel / Delta E3D Titan Clone Flying Extruder Mount by jharmn

...key-bak, mine is sort of rigged up at the moment.

provide a mount for the carriages; i used a leftover part from another project.

thingiverse

free

E3D Titan direct drive extruder for Ultimaker 2 by AnthonyB

...den pfte as a feeder line to the extruder.

apart from the titan mount all other parts are per pg35l direct drive extruder design.

thingiverse

free

Anet A6 E3D V6 X Carriage Direct Drive and/or Bowden (Final) by chekcian

...d.

for fan duct, new fan bracket and proximity sensor bracket. please get them here :-

https://www.thingiverse.com/thing:2341588

thingiverse

free

Tevo Tarantula E3DV6 Bowden Mount With BedLeveling mount by dave032285

...d v6 hot end, same as other carriage i posted but with a belt tensioner on one end. and a proximity sensor mount for bed leveling

Djdemond

thingiverse

free

50mm Towball cover Hitch Cap by DjDemonD

...50mm towball cover hitch cap by djdemond

thingiverse

cover for 50mm towball.

thingiverse

free

Duet3D Smarteffector Nimble Mount DjDemonD Remix by DjDemonD

...ess sensitive. you also need to consider the orientation of the large nut to you heatsink when assembling the hotend into the se.

thingiverse

free

Brio Wooden Train Tunnel by DjDemonD

...valley etc.. multiple units can be joined to make a longer tunnel. 80mm diameter so even fairly large trains can make it through.

thingiverse

free

Bowden pushfit locking ring for clone titan and y-splitter by DjDemonD

...for clone titan and y-splitter by djdemond

thingiverse

locking clip for trianglelabs clone titan and y-splitter bowden fittings.

thingiverse

free

3-Way Approach for Brio Thomas Engine Shed by DjDemonD

...ond

thingiverse

i bought one of these engine sheds but didn't have the approach track which is a custom piece so i made one.

thingiverse

free

Precision Piezo - 27mm and 20mm Piezo Disc drill guide. by DjDemonD

... djdemond

thingiverse

drilling guide for piezo discs to centre your drill.

see youtube video here: https://youtu.be/ms1fd0v5z68

thingiverse

free

Mechanical Z Endstop for DjDemonD/AndreasL Dual z axis smartrapcore alu by DjDemonD

...babystep z on the first print and used m206 to enter the home offset. (nb. if the nozzle was 1mm too high the m206 z would be 1.)

thingiverse

free

Paper Towel Holder Strengthened Remix by DjDemonD

...t to allow for the strengthening braces. since altering it, it works perfectly in fact i am even using some as spool holders too.

thingiverse

free

Sensor Test Rig by DjDemonD

...aver. i am not going to provide full build instructions, if you cannot figure out how to build it, should you be testing sensors?

thingiverse

free

Technics 1200 Turntable with spinning record by DjDemonD

... fits over a 5mm motor shaft and spins as my printer prints.

just bond it all together after assembly with superglue or acetone.

Inc

thingiverse

free

Mike-Monsters Inc. by RedSpider3dp

...mike-monsters inc. by redspider3dp

thingiverse

mike-monsters inc.

thingiverse

free

Monsters Inc cookie cutter

...monsters inc cookie cutter

thingiverse

monster inc cookie cutter

thingiverse

free

Clé Monster Inc - Key Monster Inc by MrGamming14

... a creation make by me a fan of disneyland park and fan of walt disney

i have upload a lot of other key on my profil, so go check

thingiverse

free

HDL INc. by sarzilly

...hdl inc. by sarzilly

thingiverse

hdl logo

thingiverse

free

Monsters Inc. by SuperClam

...let those monsters know that you are willing to support their power

consumption needs.

screaming or laughing its all up to you.

thingiverse

free

Kettenspanner Fixie Inc. Hero // Chain tensioner Fixie Inc. Hero by dbreunig

...c. hero.

braucht zwei m4-schrauben und -muttern.

//

chain tensioner for fixie inc. hero. needs two additional m4 screws and nuts.

thingiverse

free

DYMOXOD Inc. by vladicxjo

...dymoxod inc. by vladicxjo

thingiverse

dymoxod: bo3m und1v1d3d

design by ratt

thingiverse

free

Gosling Inc. by AlexStormND

...stormndhttps://cults3d.com/en/users/alexstormndhttps://www.thingiverse.com/alexstormnd/designshttps://www.artstation.com/alexslon

thingiverse

free

Monsters, Inc. Boo's Door by Liang0108

...monsters, inc. boo's door by liang0108

thingiverse

monsters, inc. boo's door model.

thingiverse

free

monsters inc ornament by flabbergasted

...re is a total of three inserts; the m, the eye, and a circle border. the total ornament is three inches wide and half inch thick.

Titan

thingiverse

free

Titanic by Ludamega

...titanic by ludamega

thingiverse

titanic

thingiverse

free

Titanic by banana04

...titanic by banana04

thingiverse

titanic

thingiverse

free

titanic by dooley123

...titanic by dooley123

thingiverse

titanic model

thingiverse

free

The Titanic by dannydunlap

...the titanic by dannydunlap

thingiverse

this is a ship, but we called it the titanic.

thingiverse

free

Crazy Titan

...crazy titan

thingiverse

crazy titan

left rotation

attack type

thingiverse

free

Titan Glyphs by ProfAdam

...titan glyphs by profadam

thingiverse

titan glyphs for your own titanic models

thingiverse

free

Attack on titan Armored Titan Mask by HunteOfficia1

...ard steel blades of vertical maneuvering equipment when struck and withstanding the colossus titan's explosive transformation

thingiverse

free

model titanic by sagandbag2012

...model titanic by sagandbag2012

thingiverse

model titanic

thingiverse

free

Titanic 1 by Oversands

...titanic 1 by oversands

thingiverse

titanic v1

thingiverse

free

Titans Tower by MelerineTechnologies

... tower by melerinetechnologies

thingiverse

a modern rendition of titans tower from the teen titans television series and comics.

Kossel

thingiverse

free

kossel bottom by keisukelin

...kossel bottom by keisukelin

thingiverse

kossel bottom

thingiverse

free

Leg for kossel by exelon

...leg for kossel by exelon

thingiverse

leg for kossel

thingiverse

free

Extruder for kossel by spencer_chen7

...extruder for kossel by spencer_chen7

thingiverse

extruder for kossel

thingiverse

free

Kossel parts by breezer83

...kossel parts by breezer83

thingiverse

kossel parts

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

Kossel Medium by flux83

...kossel medium by flux83

thingiverse

vertex for upgraded kossel mini

thingiverse

free

Kossel Mini by salesmendesandre

...kossel mini by salesmendesandre

thingiverse

custom kossel mini

frame 20x20

thingiverse

free

leg for kossel by ionulet

...leg for kossel by ionulet

thingiverse

leg for kossel with channel for end- stop cables

thingiverse

free

Optical Endstops Mounts for Kossel (with Better Kossel carriages) by dellfer

...stops on the anycubic kossel with better kossel carriages by codefreak https://www.thingiverse.com/thing:2501337

more precission

thingiverse

free

kossel??????? by wangrui19890704

...kossel??????? by wangrui19890704

thingiverse

??2020?2060???

Flying

thingiverse

free

Fly by Alajaz

...fly by alajaz

thingiverse

fly..

thingiverse

free

CIRCUS (not flying)

...circus (not flying)

thingiverse

circus (not flying)

thingiverse

free

Flying Scotsman

...flying scotsman

thingiverse

an updated version of the flying scotsman, as it is now running on the british mainline.

thingiverse

free

Fly base

...fly base thingiverse basic supports for showing flying creatures on your game...

thingiverse

free

fly killer by sarginson84

...fly killer by sarginson84

thingiverse

fly killer

thingiverse

free

the flying dutchman by Syzguru11

...the flying dutchman by syzguru11

thingiverse

the flying dutchman

thingiverse

free

fly / fliege by Syzguru11

...fly / fliege by syzguru11

thingiverse

fly fliege

thingiverse

free

DINO FLY by 3dplaymaker

...dino fly by 3dplaymaker

thingiverse

dino fly

thingiverse

free

flying dragon by schneck007

...flying dragon by schneck007

thingiverse

a flying dragon

thingiverse

free

flying disc by trloutz

...flying disc by trloutz

thingiverse

flying disc

E3D

thingiverse

free

E3D fan Duck adapted for e3D mount by tambu22

...e3d fan duck adapted for e3d mount by tambu22

thingiverse

just try to adapt it to e3d mount

thingiverse

free

Extruder for E3D by xtopolx

...extruder for e3d by xtopolx

thingiverse

extruder for e3d

thingiverse

free

E3D mount by crota

...e3d mount by crota

thingiverse

e3d mount

thingiverse

free

UNI 3D E3D

...uni 3d e3d

thingiverse

e3d for uni 3d

thingiverse

free

Nozzle Holder E3D 8x / Düsenhalter E3D 8x by Walkabout77

...nozzle holder e3d 8x / düsenhalter e3d 8x by walkabout77

thingiverse

nozzle holder e3d 8x

thingiverse

free

E3D Support by Mamath

...e3d support by mamath

thingiverse

integrate e3d heat, for 40mm fan

thingiverse

free

E3d Cyclop and E3d Chimera by TanManGuy

... modeled up the cyclop and chimera

if looking for a fan shroud for it

(check this out- http://www.thingiverse.com/thing:614803)

thingiverse

free

E3D by alex16

...e3d by alex16

thingiverse

enclosure cooling e2d

thingiverse

free

3D model E3D V6 extruder

...3d model e3d v6 extruder.

e3d v6 radiator

e3d v6 volcano nozzle

e3d v6 heat break

e3d v6 heater block

e3d v6 volcano heater block

thingiverse

free

E3D Hemera Model

...e3d hemera model

thingiverse

official mounting cad for designing your own custom mounts for the e3d hemera.

Mini

thingiverse

free

mini castle mini mini golf by EdisonM

...mini castle mini mini golf by edisonm

thingiverse

play able with ball and putter in the "mini mini golf" model

thingiverse

free

Mini Clothesline - Mini Tendal

...mini clothesline - mini tendal

thingiverse

mini clothesline

mini tendal

thingiverse

free

mini mini golf by EdisonM

...mini mini golf by edisonm

thingiverse

actually playable mini mini golf course with putter and ball

thingiverse

free

Mini Schleuder / Mini Slingshot by Ju5tMak3

...mini schleuder / mini slingshot by ju5tmak3

thingiverse

mini schleuder / mini slingshot

have fun

thingiverse

free

mini bomba (mini pump) by neemiasmiranda

...mini bomba (mini pump) by neemiasmiranda

thingiverse

mini bomba

thingiverse

free

MINI by shteffs

...mini by shteffs

thingiverse

mini

thingiverse

free

Mini wrist, Mini poignet by Aleoduc74

...mini wrist, mini poignet by aleoduc74

thingiverse

mini poignet pour vitre ou petit meuble.

thingiverse

free

Mini Bat

...mini bat

thingiverse

mini bats.

thingiverse

free

Mini-Windeisen

...mini-windeisen

thingiverse

mini-windeisen

thingiverse

free

Mini cadeira

...mini cadeira

thingiverse

mini cadeira

Extruder

thingiverse

free

Extruder

...extruder

thingiverse

extruder for 3dprinter

thingiverse

free

Linear extrude, rotation extrude by jtirado

...linear extrude, rotation extrude by jtirado

thingiverse

linear extrude, rotation extrude

thingiverse

free

extruder by brunoschoofs

...extruder by brunoschoofs

thingiverse

extruder

thingiverse

free

Extruder Catcher/Extruder Holder by Verdandi

...extruder catcher/extruder holder by verdandi

thingiverse

for holding extruder.

thx for clicking

designed on sketch up

thingiverse

free

extruder by nekro

...extruder by nekro

thingiverse

cooler extruder

thingiverse

free

Extruder by DViktor

...extruder by dviktor

thingiverse

extruder with three fans (1 unmanaged extruder and 2 managed to product) fans 20x20x10

thingiverse

free

Extruder Knob

...extruder knob

thingiverse

yet another extruder knob.

thingiverse

free

Extruder by ImHuman

...extruder by imhuman

thingiverse

my first extruder. my design.

thingiverse

free

BMG extruder

...bmg extruder

thingiverse

bmg extruder model : step, wrl, stl

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

New

thingiverse

free

New by 3DBOXPRINTING

...new by 3dboxprinting

thingiverse

new to start a new week, a new thing.

have a nice week!

thingiverse

free

New by EvgDem

...new by evgdem

thingiverse

new

thingiverse

free

New Whig

...new whig

thingiverse

new whig party

thingiverse

free

5/8x24 new new by KevinIhle

...5/8x24 new new by kevinihle

thingiverse

5/8x24 thread

thingiverse

free

new strife

...new strife

thingiverse

fixed posed models of the new strife model from darksiders genesis

thingiverse

free

New Tsurikawa by shopbymara

...new tsurikawa by shopbymara

thingiverse

new

thingiverse

free

New pyramid by aegreenart624785

...new pyramid by aegreenart624785

thingiverse

new

thingiverse

free

New Lay

...new lay

thingiverse

my most popular model is lay

here is a new version i hope it is

as liked as her predecessor

thingiverse

free

new roller by justinbarrera14

...new roller by justinbarrera14

thingiverse

roller new

thingiverse

free

death (new) by Syzguru11

...death (new) by syzguru11

thingiverse

death (new)

Version

thingiverse

free

Shocker Hand Final Version.. New Full version !! ...KEYCHAIN Version Final by marc_1988

... by marc_1988

thingiverse

now 2 versions !! .... new full....

keychain version of shocker hand final

print,share, and have fun.

thingiverse

free

beafy version by Bemothelaiemo

...beafy version by bemothelaiemo

thingiverse

beafy version for fanless psu

thingiverse

free

Pumpkin Version 2

...pumpkin version 2

thingiverse

version 2 of my pumpkin.

thingiverse

free

Poro (Ekko version)

...poro (ekko version)

thingiverse

warlock3dmodels poro, but as an ekko version.

thingiverse

free

Better version by AlexMaker816

...better version by alexmaker816

thingiverse

better version of heart box

thingiverse

free

lite version by Mitche11S

...lite version by mitche11s

thingiverse

i built this model by analogy with the simplified version.

thingiverse

free

5015Blowerduct Inverted version

...5015blowerduct inverted version

thingiverse

inverted version of 5015blowerduct.

the spacer is used to prevent deflection.

thingiverse

free

Repaired version by Snake83

...repaired version by snake83

thingiverse

repaired version of the a https://www.thingiverse.com/thing:841122/#comments

thingiverse

free

thicker version by Finch666

...thicker version by finch666

thingiverse

thicker version, my original got warped under tension.

thingiverse

free

2016 version by totof60

...2016 version by totof60

thingiverse

just add the 2016 version

from http://www.thingiverse.com/thing:193755