Thingiverse

KIS extruder - direct drive Nema 17 & Mk8 for 1.75 filament by Phil_Maddox

by Thingiverse

Last crawled date: 3 years ago

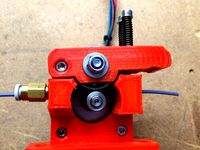

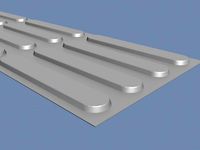

KIS-(Keep It Simple) Mk1 extruder for 1.75 filament

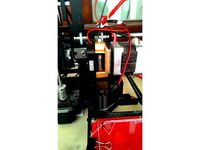

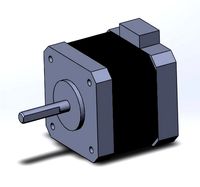

Using ideas from all over the net i have developed a simple adjustable tension DD extruder based on a Nema 17 & Mk8 filament drive bush.

The push fit for bowden tubes is based on the items supplied by E3D with their V6 kit.

The fitting sits in a 10mm dia hole 10mm deep and once in place a 2mm drill is used to drill through the printed holes and drill the sides of the push fit fitting. Following which 2 short lenghts of 1.75 filament can be inserted to secure the fitting in place. In itself quite secure and stable but to be on the safe side i use a small amount of hot glue as well.

Parts list

Mk8 drive bush

Spring ( 8mm OD X 18mm long)

Allen socket head M3 X 20mm > 3 pcs

Allen socket head M3 X 16mm > 1 pc

Allen socket head M3 X 12mm > 1 pc

Allen socket head M4 x 10mm > 1pc

M3 plain washer

SKF bearing 624-2Z

As an alternative spring guide bolt, a single Allen head M4 X 10 can be used ...(same bolt as holding the bearing in place) (as in the phtoto) in place of the M3 X 12 & M3 plain washers

Update 8th April 2015> Lever and body updated to R1

Minor geometry updates to improve pinch action on filament

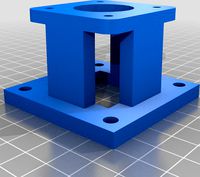

Update 5th Apr 2015 > added a couple of simple bracket options which both require longer screws ( M3 X 25)

Using ideas from all over the net i have developed a simple adjustable tension DD extruder based on a Nema 17 & Mk8 filament drive bush.

The push fit for bowden tubes is based on the items supplied by E3D with their V6 kit.

The fitting sits in a 10mm dia hole 10mm deep and once in place a 2mm drill is used to drill through the printed holes and drill the sides of the push fit fitting. Following which 2 short lenghts of 1.75 filament can be inserted to secure the fitting in place. In itself quite secure and stable but to be on the safe side i use a small amount of hot glue as well.

Parts list

Mk8 drive bush

Spring ( 8mm OD X 18mm long)

Allen socket head M3 X 20mm > 3 pcs

Allen socket head M3 X 16mm > 1 pc

Allen socket head M3 X 12mm > 1 pc

Allen socket head M4 x 10mm > 1pc

M3 plain washer

SKF bearing 624-2Z

As an alternative spring guide bolt, a single Allen head M4 X 10 can be used ...(same bolt as holding the bearing in place) (as in the phtoto) in place of the M3 X 12 & M3 plain washers

Update 8th April 2015> Lever and body updated to R1

Minor geometry updates to improve pinch action on filament

Update 5th Apr 2015 > added a couple of simple bracket options which both require longer screws ( M3 X 25)

Similar models

thingiverse

free

MK7 Extruder by wkkpatrick

... 5mm inner x 1

-bearing 604uu x 1

-m3 washer 8x0.8 x 2

-hex screw m3 20mm x 2

-hex screw m4 10mm x 1

-push fit connector (pc4-m6)

thingiverse

free

Extruder Nema23 MK8 by fawan21

...cs

bolt jp m4 x 16, 1 pc

bolt jp m4 x 50, 4 pcs

bearing 624zz, 1 pc

hex nut m3, 1 pc

hex nut m4, pcs

https://youtu.be/44dng7swzc8

grabcad

free

Geared extruder v.3

... some m4 nuts and washers to adjust spring tension

~ 25mm spring

mk8 gear for driving filament

2x 625zz bearings

1x 608zz bearing

thingiverse

free

Mini Kossel 1.75mm extruder by wallie

...et head cap screw

2x spring

1x m5 pneumatic straight threaded-to-tube adapter, push in 4 mm 4mm male

tools

m5 manual screw tap

thingiverse

free

Y carriage - Prusa Air 2 - Universal by Phil_Maddox

...cs ( linear bearing clamps)

m3 x 25mm allen head bolt - 4 pcs ( timing belt clamps)

m3 nyloc nut -18 pcs

m3 plain washer - 36 pcs

grabcad

free

Hobbed gear for 3D printer/Mk8 ( Nema 17)

...er.

fits a 5 mm dia shaft ( nema 17 stepper) is 9mm dia x 11mm long

has a m3 hole for shaft grub screw

suited for 1.75mm filament

thingiverse

free

U-type direct drive extruder by Sharque

...

m3-nut - 3

m3 cap screw 40mm - 5

m3 cap screw 20mm - 2

m3 screw head noicheskoy - 1

4mm bearing - 1

direct drive gear mk7 or mk8

thingiverse

free

Bowden Extruder (Acrylic) by wkkpatrick

...0mm x 2

-hex screw m3 6mm x 2

-push fit connector (pc4-m6)

filament loading by thumb crank:-http://www.thingiverse.com/thing:7912

thingiverse

free

Direct drive extruder for MK8 gear and 3mm diameter filament by kileitza

...ar and 3mm diameter filament by kileitza

thingiverse

direct drive extruder for mk8 gear, 3mm diameter filament and nema 17 motor

thingiverse

free

Universal E3DV6 fan duct by ArcherEG

...m3 x 10mm

2 pcs din 912 socket head cap screw m3 x 35mm

4 pcs din 934 nut

2 pcs din 985 nut

2 pcs iso 7090 washer

3 pcs fan 30x30

Maddox

3dbaza

$3

MADDOX Freestanding Stone Bath (347586)

....0 x 169.89 x 75.0<br>polys: 88 002<br>verts: 88 425<br>render: corona<br>formats: 3ds max 2017, obj, fbx

3dbaza

$2

Maddox 12 Light Art Deco Opal Glass Pendant Chandelier (340132)

...t;br>xform: no<br>box trick: no<br>model parts: 13<br>render: v-ray<br>formats: 3ds max 2014, obj, fbx

thingiverse

free

Migbot Electron Prusa i3 20A 12V Power Supply Cover by Middleman

...by middleman thingiverse this is a remix of phil maddox#39;s power supply cover with switch for the migbot electron...

thingiverse

free

Universal Filament Filter and Lubricator Clip by DadHacks

...stay with the spool. thanks to creative tools and maddox for the originals to remix...

3dbaza

$18

Restoration Hardware Set (118066)

...hardware set (118066) 3dbaza restoration hardware set 3d model<br>sofa maddox <br>armchair maddox <br>coffee table grand framed <br>console table grand...

thingiverse

free

Part Cooler for Cyclops or J-end V6 30mmfans by MCmaks

...from tico, here:https://grabcad.com/library/e3d-v6-hotend-3 30mm fan model is from phil maddox ...

thingiverse

free

Chimera Part Cooler 30mm30mmfans by MCmaks

...the 30mm fan, 30x30x10 dc fan.step, is from phil maddox and can be found...

3dcadbrowser

free

Atlanta City

...georgia institute of technology, the biltmore, midtown, fox theatre, maddox park, coca-cola enterprises, bank of america plaza, emory crawford...

thingiverse

free

Duet WiFi Case Assembly | CR-10S 3D Printer by MP23Racing

...inadequate mechanical fastening. 3d cad design credit duet wifi_phil maddox - grabcad dc power supply_luca - grabcad urbest power...

thingiverse

free

Dual Power Supply Front End - alt lab supply by MCmaks

...by jeroen lodderswitch by milan samardzija30mm fan by phil maddox bom: find the tip size of your wall-wart/ac adapter...

Phil

turbosquid

$5

Phil

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$11

Phil Side Table

...phil side table

designconnected

alberta phil side table computer generated 3d model. designed by lagravinese, castello.

3d_export

$10

Phil sofa by Flexform 3D Model

...phil sofa by flexform 3d model

3dexport

phil sofa flexform

phil sofa by flexform 3d model boroda 63457 3dexport

3ddd

$1

Диван PHIL от FLEXFORM

...d

flexform , phil

размеры 2300х1020х840. обивка — съемная кожа или ткань www.flexform.it

turbosquid

$20

LeComfort PHIL KING BED

... 3d model lecomfort phil king bed for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1565752)

turbosquid

$4

Philips Fit Phil Bathroom Wall Light

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Бионическая ваза от дизайнера Phil Ki

...шением для современного интерьера, бионический дизайн основан на структуре молекульных связей и точной геометрии в сложной форме.

turbosquid

$80

EVSP MK1

...evsp mk1 turbosquid royalty free 3d model phil james for download as on turbosquid: 3d models for...

3ddd

$1

Кровать HULSTA / SERA

...3ddd тумба , лампа , hulsta , loveluxe прикроватная тумбочка:http://art4living.ru/prikrovatnaya-tumbochka-longhi-loveluxe-philamp;nbsp; кровать:http://ru.hulsta.com/ru_ru/product_ru_ru/sleeping/sera/beds/var/9314/index.html лампа...

3d_ocean

$39

Medical Bottles

...caps capsule clinic dietary houspital jar liquid medical pharmacy phil place plus product salp supplement template variants vray medical...

Kis

design_connected

$16

Ki

...ki

designconnected

horm ki computer generated 3d model. designed by bellini, mario.

3ddd

$1

ki

...lacquer, the ki chairs have been presented in an open pore ash

lacquer

!

nish since 2013.http://www.horm.it/project/ki/

3ddd

$1

Ki

...ssed decoration reminiscent of the diamond pattern of stitched fabric upholstery, is the formal feature for a chair that combines

3ddd

$1

Natuzzi KI

...natuzzi ki

3ddd

natuzzi

natuzzi ki

turbosquid

$100

KI-DRONE

...bosquid

royalty free 3d model ki-drone for download as blend on turbosquid: 3d models for games, architecture, videos. (1588023)

turbosquid

$13

Ki Chair

... model ki chair for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1641492)

cg_studio

$189

Ki-843d model

...ki-843d model

cgstudio

.3ds .c4d .lw .max - ki-84 3d model, royalty free license available, instant download after purchase.

turbosquid

$4

Kawasaki Ki-100

... model kawasaki ki-100 for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1323236)

turbosquid

$25

Kawasaki KI 78

...el kawasaki ki 78 for download as 3ds, dxf, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1220324)

turbosquid

$15

Teapot Tefal KI 400D

...efal ki 400d for download as max, max, max, 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1538447)

Mk8

3d_export

$99

Mitsubishi Lancer Ralliart sedan 2004 3D Model

...lancer ralliart sedan 2004 3d model 3dexport mitsubishi ralliart mk8 2004 2005 4-door sedan saloon japan japanese eighth generation...

3d_ocean

$89

Mitsubishi Lancer Ralliart sedan 2004

...2004-2005 4-door eighth generation japan japanese mitsubishi mitsubishi ralliart mk8 ralliart saloon sedan the 3d model was created on...

thingiverse

free

MK8 by IsaiRochaSegura

...chasegura

thingiverse

in this thing i share a replace bar for mk8 extruder. i include the solidworks files for any modification.

thingiverse

free

MK8 Duct by ombranova

...mk8 duct by ombranova

thingiverse

duct for extruder mount mk8 on prusa i3

thingiverse

free

MK8 Flex Guide by loganjkd

...mk8 flex guide by loganjkd

thingiverse

just an inset for the mk8

thingiverse

free

MK7 / MK8 Mold by JMDesigns

...mk7 / mk8 mold by jmdesigns

thingiverse

mk7 / mk8 mold

thingiverse

free

Support extruder MK8 by rickshaolin

...support extruder mk8 by rickshaolin

thingiverse

support extruder mk8

thingiverse

free

MK8 Fan bracket by rocktang2003

...mk8 fan bracket by rocktang2003

thingiverse

mk8 fan bracket

thingiverse

free

HyperCube Mk8 mount by machala737

...hypercube mk8 mount by machala737

thingiverse

remix hypercube mk8 mount

thingiverse

free

mk8 fan holder by everythingother

...mk8 fan holder by everythingother

thingiverse

this is mk8 amazing fan holder

Nema

3d_export

$5

Electric Motor Nema 17

...electric motor nema 17

3dexport

40mm stepper motor nema 17 1.5a (17hs4401) motor 4-wire for 3d printer

turbosquid

$3

Nema 17

...rbosquid

royalty free 3d model nitro engine for download as on turbosquid: 3d models for games, architecture, videos. (1449252)

turbosquid

$1

Nema 17 Stepper motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Nema 17 Stepper Motor 59Nm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple model of Nema 8 stepper motor

...del of nema 8 stepper motor for download as ipt, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1543132)

3d_export

$5

simple model of nema 17 stepper motor

...ort

simple model, useful to prototype robots, 3d printers and other electronic diy projects<br>step and .ipt file included

3d_export

$5

simple model of nema 8 stepper motor

...robots, 3d printers and other electronic diy projects<br>current model: 20bygh33-0604a<br>step and .ipt file included

3ddd

free

Larte Luce

...class="star five "></div></div></li><li><img src="http://b.3ddd.ru/media/cache/sky_user_avatar_comment/avatar/users/117489.jpg" alt="ci-nema" width="35" height="35" class="img"><div class="name"><a href="/users/ci-nemaquot;>ci-nema</a></div><div class="raiting"><div class="star five "></div></div></li></ul><div class="more"><a href="/3dmodels/show/larte_luce/voted">еще</a></div></div><div class="number" rating="30" count="6"...

thingiverse

free

Nema 14 to Nema 17 Adapter by lukepat

...nema 14 to nema 17 adapter by lukepat

thingiverse

created a adapter for nema 14 to nema 17 mount.

thingiverse

free

Distance Nema 17 and Nema 23 by Krzysztof_Handtke

...distance nema 17 and nema 23 by krzysztof_handtke

thingiverse

distance to nema motors to build a cnc milling machine.

75

turbosquid

$16

RPG-75

...-75

turbosquid

royalty free 3d model rpg-75 for download as on turbosquid: 3d models for games, architecture, videos. (1626420)

turbosquid

$30

Cz 75

...squid

royalty free 3d model cz 75 for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1193409)

turbosquid

$15

Chair 75

...alty free 3d model chair 75 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1497562)

turbosquid

$15

Curtain 75

...ty free 3d model curtain 75 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1435983)

turbosquid

$6

Table 75

...alty free 3d model table 75 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1503902)

turbosquid

$6

Lamp 75

...yalty free 3d model lamp 75 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1500803)

turbosquid

$6

Bedcloth 75

...y free 3d model bedcloth 75 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1531153)

turbosquid

$20

Bath 75

... free 3d model bath 75 for download as max, dxf, fbx, and dwg on turbosquid: 3d models for games, architecture, videos. (1277140)

turbosquid

$12

Sofa 75

... free 3d model sofa 75 for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1631865)

3ddd

$1

Ванна DIANA_170-75

...ванна diana_170-75

3ddd

diana , ванна

ванна diana, размер: 170-75

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

17

3d_export

$6

rocks 17

...rocks 17

3dexport

rocks 3d model 17

3ddd

$1

PLANTS 17

...plants 17

3ddd

цветок , горшок

plants 17,, pots in diameter 100,80,60,40cm,,, enjoy

3d_export

$6

tap-17

...tap-17

3dexport

3d_export

$6

set-17

...set-17

3dexport

3d_export

$27

C-17 Globemaster

...c-17 globemaster

3dexport

c-17 globemaster

3ddd

free

Renault FT-17

...renault ft-17

3ddd

ft-17 , renault , танк

turbosquid

$40

cottage 17

...bosquid

royalty free 3d model cottage 17 for download as max on turbosquid: 3d models for games, architecture, videos. (1377003)

turbosquid

$30

Apartment 17

...squid

royalty free 3d model apartment 17 for download as max on turbosquid: 3d models for games, architecture, videos. (1432680)

turbosquid

$10

Surfboard 17

...squid

royalty free 3d model surfboard 17 for download as max on turbosquid: 3d models for games, architecture, videos. (1375686)

turbosquid

$7

Rock 17

...turbosquid

royalty free 3d model rock 17 for download as obj on turbosquid: 3d models for games, architecture, videos. (1486522)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)