Thingiverse

Kerf Compensation for Lasercutters by enhydra

by Thingiverse

Last crawled date: 4 years, 8 months ago

If you want to cut wooden boxes with a lasercutter, then the assembly will be easier if you generate the interlocking pieces with press fit. With the generator in the link below it's easy to get a reference cut with whom you can define the appropriate compensation.

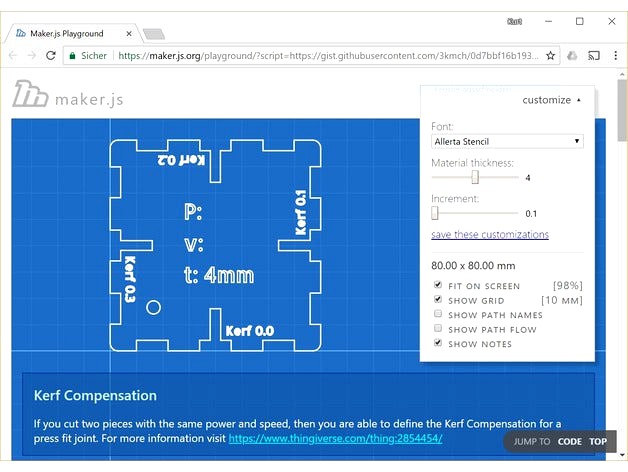

Visit the Kerf Compensation Site and hit run.

Enter the thickness of your material [mm] and skip the Increment for now (don't care about the font).

Download the file and cut 2 pieces.

Look for the connection where the pieces fit together without play (or with press fit). https://youtu.be/Q_kA19hMXbM

Note the result of formula: (0.3 + 0.3)/2 = Kerf 0.3 | or (0.3 + 0.45)/2 = Kerf 0.375

Offset the outline of your shape on your computer accordingly (expand outer shapes and shrink inner).

Example:

You want to cut a square with a side lenght of 50mm. In the drawing on your computer the square measures exactly 50 by 50mm. Due the laser, which burns off some material, you have to add a Kerf Compensation (see image #1). So expand the square by eg. 0.3mm (2 times X).

Perhaps it's a good idea if you note the applied Power and Speed on one (or both) pieces and bind them together. If you don't get a press fit even with max Kerf, then increase the increment by 0.05 or 0.1mm.

Visit the Kerf Compensation Site and hit run.

Enter the thickness of your material [mm] and skip the Increment for now (don't care about the font).

Download the file and cut 2 pieces.

Look for the connection where the pieces fit together without play (or with press fit). https://youtu.be/Q_kA19hMXbM

Note the result of formula: (0.3 + 0.3)/2 = Kerf 0.3 | or (0.3 + 0.45)/2 = Kerf 0.375

Offset the outline of your shape on your computer accordingly (expand outer shapes and shrink inner).

Example:

You want to cut a square with a side lenght of 50mm. In the drawing on your computer the square measures exactly 50 by 50mm. Due the laser, which burns off some material, you have to add a Kerf Compensation (see image #1). So expand the square by eg. 0.3mm (2 times X).

Perhaps it's a good idea if you note the applied Power and Speed on one (or both) pieces and bind them together. If you don't get a press fit even with max Kerf, then increase the increment by 0.05 or 0.1mm.