Thingiverse

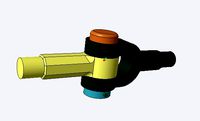

InMoov Articulating Neck Joint ReMix by alansrobotlab

by Thingiverse

Last crawled date: 3 years ago

This is a remix of Bob Houston's outstanding articulated neck mod.

https://www.youtube.com/watch?v=FPV6k8QfDY8

You'll need the following:

(3) 3m x 20mm socket head cap screws

(3) 3m x 12mm machine screws

(3) 3m washers

(7) #6 or #8 3/4" flathead screws or equivalent

(8) #4 1/2" flathead screws or equivalent

Print out every part with the following settings:

100micron layer height

6 perimeters

2mm tops and bottoms

15% infill

3-4mm brim

For ArtNeck_NeckV1 and ArtNeck_NeckUpperV2, I printed those with the same settings but with 250 micron layers. I just couldn't get the settings right to print NeckUpper at 100 microns.

Only these items will require supports:

ArtNeck_ServoHolderV2

ArtNeck_ServoJointUpperV2

Assembly

Drill out NeckUpper Ball Mounts to 2.5mm, then tap 3mm threads. Lightly sand the ball joints and attach to head using #8 screws.

Insert NeckLower into Neck with larger slot facing the back, align then drill, countersink and use a short machine screw to mate together. Make sure you shorten or snip the screw so that it doesn't extend into the neck. Mount new neck subassembly to InMoov with #8 screws. Mount Head NeckUpper to NeckLower. don't jostle.

Sand external surface of ServoPivot Mount point. Drill pivot hole to 2.5mm, then threads to 3mm. Use ServoPivot to drill out the mount holes from the shoulder frame. See photo. Put left servopivot into right facing inward, then drill for correct mount hole locations. countersink. To mount these, you're going to have to temporarily either remove the arm, or remove the rear shoulder panel. Mount using #8 screws.

Sand mating surface for ServoHolder. Drill pivot hold and servo mount holes to 3mm. Test fit into ServoPivot. Can/Should be tight. Mount to ServoPivot using 3mm washer and 12mm machine screw. Make very tight, turns out it doesn't need to pivot at all.

Drill PistonBaseSide to 3-4mm, temporarily mount to servos. Mount servos to ServoHolder using #4 machine screws.

Drill PistonBaseFront to 3-4mm. Remove neck front pistonbase, and temporarily mount to front Neck servo using #4 machine screws.

Enable neck front servo, and set to 90 degrees position. Grease up PistonBaseFront and balljoint. Test fit PistonFront attempting to mate with head level with floor. If all four orientations are either too high or too low, make a note of what change in rotation would be required to make head level (15 degrees, 45 degrees etc). Remove PistonBaseFront, unscrew horn and reset at desired position. Attach PistonBaseFront and try again. Use 20mm socket head cap screw to affix ball joint. Just turn head to side to access/affix front piston socket head cap screw.

Enable neck side servo, and set to 90 degrees position. Grease up PistonBaseSide and balljoint. Test fit PistonSide attempting to mate with head level with floor. If all four orientations are either too high or too low, make a note of what change in rotation would be required to make head level (15 degrees, 45 degrees etc). Remove PistonBaseSide, unscrew horn and reset at desired position. Attach PistonBaseSide and try again. Use 20mm socket head cap screw to affix ball joint.

Whatever control solution you're using, make sure you set sane max/min values for the new neck nod and side actions.

Enjoy! This is a very cool mod. :-)

Updates:

2016-02-28 NeckJointUpper to V3, widened mounting studs, shortened balljoint backplane for a few more degrees of freedom NeckJointLower to V3, thickened balljoint feature, now both slots are same size to match NeckJointUpper Added HK15328 servo horn if you're using that type of servo.

https://www.youtube.com/watch?v=FPV6k8QfDY8

You'll need the following:

(3) 3m x 20mm socket head cap screws

(3) 3m x 12mm machine screws

(3) 3m washers

(7) #6 or #8 3/4" flathead screws or equivalent

(8) #4 1/2" flathead screws or equivalent

Print out every part with the following settings:

100micron layer height

6 perimeters

2mm tops and bottoms

15% infill

3-4mm brim

For ArtNeck_NeckV1 and ArtNeck_NeckUpperV2, I printed those with the same settings but with 250 micron layers. I just couldn't get the settings right to print NeckUpper at 100 microns.

Only these items will require supports:

ArtNeck_ServoHolderV2

ArtNeck_ServoJointUpperV2

Assembly

Drill out NeckUpper Ball Mounts to 2.5mm, then tap 3mm threads. Lightly sand the ball joints and attach to head using #8 screws.

Insert NeckLower into Neck with larger slot facing the back, align then drill, countersink and use a short machine screw to mate together. Make sure you shorten or snip the screw so that it doesn't extend into the neck. Mount new neck subassembly to InMoov with #8 screws. Mount Head NeckUpper to NeckLower. don't jostle.

Sand external surface of ServoPivot Mount point. Drill pivot hole to 2.5mm, then threads to 3mm. Use ServoPivot to drill out the mount holes from the shoulder frame. See photo. Put left servopivot into right facing inward, then drill for correct mount hole locations. countersink. To mount these, you're going to have to temporarily either remove the arm, or remove the rear shoulder panel. Mount using #8 screws.

Sand mating surface for ServoHolder. Drill pivot hold and servo mount holes to 3mm. Test fit into ServoPivot. Can/Should be tight. Mount to ServoPivot using 3mm washer and 12mm machine screw. Make very tight, turns out it doesn't need to pivot at all.

Drill PistonBaseSide to 3-4mm, temporarily mount to servos. Mount servos to ServoHolder using #4 machine screws.

Drill PistonBaseFront to 3-4mm. Remove neck front pistonbase, and temporarily mount to front Neck servo using #4 machine screws.

Enable neck front servo, and set to 90 degrees position. Grease up PistonBaseFront and balljoint. Test fit PistonFront attempting to mate with head level with floor. If all four orientations are either too high or too low, make a note of what change in rotation would be required to make head level (15 degrees, 45 degrees etc). Remove PistonBaseFront, unscrew horn and reset at desired position. Attach PistonBaseFront and try again. Use 20mm socket head cap screw to affix ball joint. Just turn head to side to access/affix front piston socket head cap screw.

Enable neck side servo, and set to 90 degrees position. Grease up PistonBaseSide and balljoint. Test fit PistonSide attempting to mate with head level with floor. If all four orientations are either too high or too low, make a note of what change in rotation would be required to make head level (15 degrees, 45 degrees etc). Remove PistonBaseSide, unscrew horn and reset at desired position. Attach PistonBaseSide and try again. Use 20mm socket head cap screw to affix ball joint.

Whatever control solution you're using, make sure you set sane max/min values for the new neck nod and side actions.

Enjoy! This is a very cool mod. :-)

Updates:

2016-02-28 NeckJointUpper to V3, widened mounting studs, shortened balljoint backplane for a few more degrees of freedom NeckJointLower to V3, thickened balljoint feature, now both slots are same size to match NeckJointUpper Added HK15328 servo horn if you're using that type of servo.

Similar models

thingiverse

free

NEMA 17 Motor Mount by tetralite

... head cap screws of whatever length needed to fasten the mount to the device. the two mounting holes for the part are 28mm apart.

thingiverse

free

Gear Head Adapter by jeremyrichardmann

...e apart the gearhead native mount, the part with the ball-socket joint can be natively screwed into this with a proper 3mm screw.

thingiverse

free

Finger hinge by zerker77

...mounts. the hinge is designed for 3mx16mm bolt. the hinge mount has a hole and countersink, to accept a 3m socket head cap screw.

thingiverse

free

DSLR Tilt by LeoRover

...camera_holder side, then by two small m2 screws on the horn and then using m3x8 screws attach servo to the base. that's it ;)

thingiverse

free

Improved Ball and Socket Joint

... between the lobes, it's more like 90 degrees if you go against them.

the threaded designs can take considerably more weight.

thingiverse

free

Dash Mount with 17mm Ball by RealmKnight

..., etc or i drilled two holes to use m3 screws to attach it to the removable section of my jeep dash. v2 has the holes pre-drilled

grabcad

free

Socket head cap screw M8

...rks which doesn't have smart fasteners. the length can be selected during placement in the assembly and can be adjusted after

thingiverse

free

Bear head parts for 1/12 scale action figure by Shigeru

...bear head parts for 1/12 scale action figure by shigeru

thingiverse

you can use a 3mm ball joint for the neck. have fun!!

grabcad

free

BallJoint

...balljoint

grabcad

balljoint model for kira

updated mates to limit movement of ball

thingiverse

free

![[3in1] Ball & Socket Joint with Screw Hole by DENOVATOR](/t/8858583.jpg)

[3in1] Ball & Socket Joint with Screw Hole by DENOVATOR

...by denovator

thingiverse

ball joint & socket with thread hold. ball snaps tightly into itself. using 'm10x1.5' bolt.

Alansrobotlab

thingiverse

free

HK15328D by alansrobotlab

...ferent than the hitec servos, so you need to take that into account in your designs.

designed using onshapehttp://www.onshape.com

thingiverse

free

InMoov LowArmSideV1 for Square Potentiometer by alansrobotlab

...rse

a quick hack to support the newer hitec servos with the square potentiometer.

the potentiometer fits into the recess snugly.

thingiverse

free

HK15338 by alansrobotlab

....

designed using onshapehttp://www.onshape.com

2015-10-27: quick update, put wire grommet on correct side and reuploaded models.

thingiverse

free

InMoov JawHingeV1 with Opening for Wires by alansrobotlab

...mix of jawhingev1 with an opening for those running wires down through the neck.

i also added some mounting holes to the sides.

thingiverse

free

InMoov 180 degree rotational wrist mod for Anar's Solid CAD Forearm by alansrobotlab

...ar's solid cad forearm by alansrobotlab

thingiverse

180+ degree rotational wrist mod for anar's solid cad inmoov forearm

thingiverse

free

InMoov PivPotentiometerV3 remix for #4 screws, for newer HiTec Rectangular Potentiometer by alansrobotlab

... with larger screw holes a bit further out. makes it alot easier to affix with #4 screws.http://www.thingiverse.com/thing:254664

thingiverse

free

InMoov Faster Rotate/Twist for Bicep by alansrobotlab

...the shoulder pivot next. :-)

i'm not sure how much faster i can make it, as the position of rotgear and rotworm are fixed.

thingiverse

free

InMoov Remix to Allow Full 180 Degree Wrist Rotation by alansrobotlab

... forearm assembly, but edited the cableholder and rotawrist2 models to support my changes.http://www.thingiverse.com/thing:514995

thingiverse

free

InMoov Torso Mods for the XBoxOne Kinect by alansrobotlab

... back.

2016-01-25 sensormount updated, fixed recessed screw holes

2016-01-24 recessed the sensor a bit more. frame parts updated

thingiverse

free

Rostock Max OpenPnP Conversion by alansrobotlab

...easy to adapt to other larger format delta style printers as well.

i'll add in some basic instructions and a parts list soon.

Inmoov

turbosquid

$29

inMOOV by Nina Lieven

...model inmoov by nina lieven for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1230519)

thingiverse

free

InMoov KeyChain !!! by Alessandruino

...inmoov keychain !!! by alessandruino

thingiverse

this is an inmoov keychain for you or a fantastic jewel for your inmoov :)

thingiverse

free

Inmoov by joseph02

...inmoov by joseph02

thingiverse

porte clé inmoov, 2 couleurs. imprimé sans raft ni support.

thingiverse

free

inmoov full by ambroise

...inmoov full by ambroise

thingiverse

inmoov full

thingiverse

free

INMOOV EYELID ( PAUPIERES POUR INMOOV ) by heisenberg333

...ov parts .it's made very good .

you can see full tutorial on attached excel file

https://www.youtube.com/watch?v=h_jdau9v5zq

thingiverse

free

Inmoov Legs by kike1978

...inmoov legs by kike1978

thingiverse

inmoov custom legs, not articulated.

thingiverse

free

InMoov Head by Mindylee

...inmoov head by mindylee

thingiverse

inmoov open source hardware

thingiverse

free

inmoov top mouth by mix3rn

...inmoov top mouth by mix3rn

thingiverse

inmoov

thingiverse

free

Stand Inmoov

...the servo drive head.

with this body, you can move your head upright. for movement, you can use the standard inmoov vertical stem

thingiverse

free

back battery inmoov by ambroise

...back battery inmoov by ambroise

thingiverse

back battery inmoov

Articulating

turbosquid

$60

Articulated doll

...e 3d model articulated doll for download as max, obj, and ztl on turbosquid: 3d models for games, architecture, videos. (1277424)

turbosquid

$10

articulated lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$11

Articulated Industrial Light

...articulated industrial light

designconnected

o. c. white articulated industrial light computer generated 3d model.

cg_studio

$169

Articulated Truck3d model

...cgstudio

.3ds .c4d .lwo .max .obj - articulated truck 3d model, royalty free license available, instant download after purchase.

3d_export

$90

Design Bus Articuled 3D Model

...design bus articuled 3d model

3dexport

design bus articuled

design bus articuled 3d model basshunter 8620 3dexport

turbosquid

$59

Articulated truck 45f

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$130

Caterpillar 725 Articulated Truck

...for close-up renders. scene contain textures, standart scanline, mentalray and vray materials. - high quality polygonal model ...

3d_export

$22

articulated dump truck

...ost popular and not very 3d file formats, as well as textures for shaders.<br>format: 3ds max, obj, fbx, 3ds, lwo, c4d, dae

turbosquid

free

Rigged articulated bus acordion bus for games

...or download as max, max, unitypackage, max, fbx, obj, and 3ds on turbosquid: 3d models for games, architecture, videos. (1599911)

3d_export

$24

dubai bus articulated

...ed check if our models are useful for your project and leave a like if you like this model.<br>thank you for your interest!

Neck

3d_export

$7

Pork neck

...pork neck

3dexport

pork neck

3d_export

free

Gold chain for neck

...gold chain for neck

3dexport

metal gold chain for neck

3d_export

$6

neck brush

...neck brush

3dexport

3d_export

$69

throgs neck bridge

...throgs neck bridge

3dexport

throgs neck bridge. low poly. max 12. fbx. obj. 3ds. one texture.

3d_export

$5

round neck gourd

...round neck gourd

3dexport

turbosquid

$4

Dummy neck for jewelry

...alty free 3d model dummy neck for jewelry for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1603064)

3d_export

$90

Neck nerves 3D Model

...neck nerves 3d model

3dexport

anatomy

neck nerves 3d model evarobin3d 15676 3dexport

turbosquid

$150

double neck guitar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$150

Double Neck Guitar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Square Neck Dress

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Joint

turbosquid

$5

Joint

...turbosquid

royalty free 3d model joint for download as blend on turbosquid: 3d models for games, architecture, videos. (1179882)

3d_export

$5

joint handle

...joint handle

3dexport

joint handle

3d_export

$5

knuckle joint

...knuckle joint

3dexport

this is a 3d model of knuckle joint

3d_export

$5

Knuckle Joint

...knuckle joint

3dexport

industry use knuckle joint

3ddd

$1

PENTA Joint

...penta joint

3ddd

penta

http://www.lampcommerce.com/en/catalogue/brands/penta-light/joint-floor-lamp

turbosquid

$49

Joint | Project

...squid

royalty free 3d model joint | project for download as on turbosquid: 3d models for games, architecture, videos. (1297983)

turbosquid

$10

universal joint

...squid

royalty free 3d model univresal joint for download as on turbosquid: 3d models for games, architecture, videos. (1309400)

turbosquid

$15

Joint Ashtray

...squid

royalty free 3d model joint ashtray for download as ma on turbosquid: 3d models for games, architecture, videos. (1199702)

turbosquid

$5

Unrolled joint

...e 3d model unrolled joint for download as blend, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1577889)

3d_export

$5

Cardan Joint 3D Model

...cardan joint 3d model

3dexport

cardan joint

cardan joint 3d model fau 71171 3dexport

Remix

turbosquid

$5

MODA Collection Remix Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

remix yamaha rm1x

...remix yamaha rm1x

3dexport

geometry triangles 15.2k vertices 7.6k pbr no textures 1 materials 1 uv layers yes

3d_ocean

$5

Vray fabric Kvadrat remix green - tileable

...th vray and 3dsmax. high-resolution texture images (2000×2000 px) file included: shader vray 2.40 texture image 3ds max 2011 file

turbosquid

$20

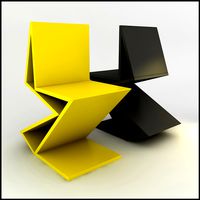

Gerrit Rietveld 1938 Zig Zag Chair Remix

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

multicolored remix parametric table furniture

... fbx, obj, mtl, archive with textures. the model has no glitches. render and materials - vray . without using plugins. good use!

3ddd

$1

Barovier&Toso / Manhattan Remix 7192

... 004293-142405

в коллекции есть люстры 7, 9, 12 рожковые. диаметр соответственный 1000, 1250, 1500 мм.

3ddd

$1

Muuto fiber chair

...grey/grey, dusty green/dusty green, nature/oak, natural white/oak upholstery options remix 183/black, remix 133/grey, remix 643/dusty red leather options black...

3ddd

$1

Barovier&Toso 7190-7195

...7190-7195 3ddd barovier&toso потолочнай люстра фабрики barovier&toso;, коллекция manhattan remix артикул 7190-7195. размеры в inches: 39"...

3d_export

$5

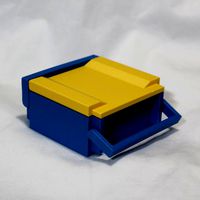

3D Locking Handle Weatherproof Storage Box Container

...handle weatherproof storage box container 3dexport new, improved and remixd! no screws required. print-in-place. weatherproof. parametric. 2 parts. easy...

cg_studio

$49

HTC One Mini 2 Amber Gold3d model

...cell phone mobile cellular super lcd touchscreen touch screen remix amber gold .max .obj .mb .lwo .fbx .c4d .3ds...