Thingiverse

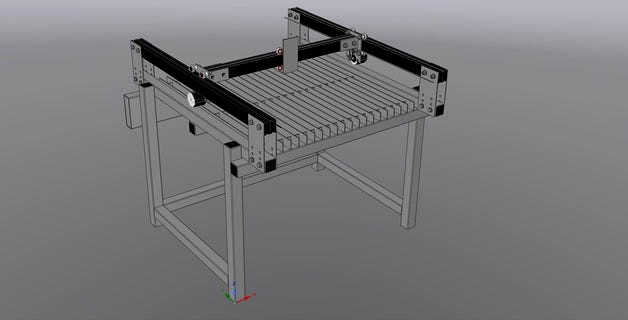

Inexpensive CNC Plasma Table

by Thingiverse

Last crawled date: 4 years, 3 months ago

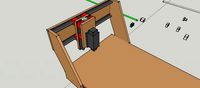

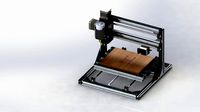

This build is designed around steel and phenolic resin (high end lab countertop material) scrap/drops and commonly available (US) parts and fasteners. Tubes were cut on a band saw, flats on a CNC plasma table, rails on a CNC router table, holes bored in drill press, and welds with an old-school buzz box. Target is 24x24" or larger work area, no machining, no 3D printed parts, fast enough to cut very thin material at 30-40 amps, for less than $200 (not including electronics).

Motion on stainless steel dual row RM2-2RS V bearings. GT2 belts will be upgraded ASAP and only appear because intended reinforced belts will not bend backwards over the idlers.

Wood in any photos was for alignment purposes. Current STEP export in zip file. All clearances will be applied in CAM or manually and are not present in the CAD file. CAD export to Parasolid binary (included) was converted to STEP. CAD in SpaceClaim and CAM in SolidCAM, ProNest, and Aspire.

Motion on stainless steel dual row RM2-2RS V bearings. GT2 belts will be upgraded ASAP and only appear because intended reinforced belts will not bend backwards over the idlers.

Wood in any photos was for alignment purposes. Current STEP export in zip file. All clearances will be applied in CAM or manually and are not present in the CAD file. CAD export to Parasolid binary (included) was converted to STEP. CAD in SpaceClaim and CAM in SolidCAM, ProNest, and Aspire.

Similar models

grabcad

free

CNC Plasma Table RENDERING ONLY

...cnc plasma table rendering only

grabcad

cnc plasma table with 2400mm x 1300mm cutting area.

there are no cad files for this...

grabcad

free

cnc plasma cutting machine. Part 1 - Table.

...cnc plasma cutting machine. part 1 - table.

grabcad

cnc plasma cutting machine. part 1 - table.

working area 1300х2800

grabcad

free

CNC plasma cutting table

...cnc plasma cutting table

grabcad

incomplete model of the cnc table for plasma cutting

grabcad

free

Simple cnc plasma table

...simple cnc plasma table

grabcad

simple cnc plasma cutting table

cg_trader

$10

Barbecue Design Dxf step 2d 3d models for Laser cutting

...xf for 2 mm mild steel . modular type assembly

full flat parts. easy collapsible

barbecue fire pit dxf file for cnc laser cutting

grabcad

free

CNC Plasma Table

...cnc plasma table

grabcad

cnc plasma table with 2400mm x 1300mm cutting area.

cg_trader

$3

Deer metal Art Dxf and step file | 3D

...r, water jet, cricut, cameo even wood cnc machines. this is a downloadable product that can be scaled to your needs or run as is.

cg_trader

$10

Barbecue Dxf And Step format Portable grill fire pit

...xf for 3 mm mild steel . modular type assembly

full flat parts. easy collapsible

barbecue fire pit dxf file for cnc laser cutting

3dwarehouse

free

Inexpensive CNC Plasma Table

...adcad link below. exported from cad, but modification of su file to fix orientation results in a huge skp file (at least for me).

cg_trader

$10

Two Different Sizes Barbecue Design Dxf and Step 3d | 3D

...esign dxf and step 3d | 3d

cg trader

cnc laser cutting or plasma

dxf for 3 mm mild steel . modular type assembly

full flat parts

Inexpensive

3d_export

$5

Fridge BOSCH

...fridge bosch 3dexport a good and inexpensive model for shooting...

3d_export

$5

Collection of colored pencils 3D Model

...colored pencils 3d model 3dexport collections rainbow pencils color inexpensivey collection of colored pencils 3d model mixanik 57025...

3d_export

$25

Computer Desk 3D Model

...desk computer 3ds max simple mouse monitor keyboard cheap inexpensive computer desk 3d model banana 8536...

3d_export

free

Soviet stone fence

...approached by officials with a demand to develop an inexpensive universal fence for strategic objects. it is from this...

3d_export

$15

ambubag ventilator covid-19 crisis

...covid-19 crisis 3dexport this is the coceptual design for inexpensive ventilator to save people who are infected with the...

3d_export

$75

uss fahrion ffg22 ohp class frigate

...united states in the mid-1970s as general-purpose escort vessels inexpensive enough to be bought in large numbers to replace...

thingiverse

free

Inexpensive Colorimeter by jamesdmendez

...ive colorimeter by jamesdmendez

thingiverse

this is a colorimeter that relies on leds for both the light source and measurement.

thingiverse

free

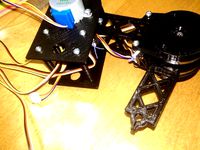

Inexpensive SCARA arm (2D) w/ 28BYJ-48 steppers by dacb

...b in mcp folder: https://github.com/beckdac/scara ) to control the arm from the command line includes threaded server with homing

thingiverse

free

BI 2.5 Inexpensive enclosure 2.5 by joker55

... 1/14/15 i still need to make some flaps to fill the gap at the bottom sides & gopro mount.. will post when i can get to it.

thingiverse

free

Inexpensive Replicator 2 Side Enclosure. by byllc

...on me that if you coated one side of a 'wall' with mylar you could use just about anything to create the enclosure walls.

Plasma

3d_ocean

$25

Plasma Cannon, Plasma Turret

...ily be used in any sf type of game, especially in tower defense games. - plasma cannon: 4462 polygons - textures: 6000...

3d_ocean

$19

Plasma Turret

... be used in any sf type of game, especially in tower defense games. - plasma turret: 6239 polygons - props: 522 polygons - tex...

turbosquid

$10

Plasma

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

plasma lamp

...plasma lamp

3dexport

detailed normal scale plasma lamp used indoors as a decorative object

turbosquid

$3

Plasma drone

...rbosquid

royalty free 3d model plasma drone for download as on turbosquid: 3d models for games, architecture, videos. (1337186)

turbosquid

$15

plasma gun

...bosquid

royalty free 3d model plasma gun for download as fbx on turbosquid: 3d models for games, architecture, videos. (1324248)

turbosquid

$12

Plasma Corvette

...id

royalty free 3d model plasma corvette for download as obj on turbosquid: 3d models for games, architecture, videos. (1442325)

turbosquid

$1

Plasma Rifle

...squid

royalty free 3d model plasma rifle for download as obj on turbosquid: 3d models for games, architecture, videos. (1485980)

turbosquid

$25

Plasma Pistol

...free 3d model plasma pistol for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559545)

turbosquid

$10

Plasma Grenade

...d model plasma grenade for download as max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1280730)

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)

Table

3ddd

free

Table

...table

3ddd

table

table

archibase_planet

free

Table

...table

archibase planet

table glass-table round table glass table

table n240311 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...e

archibase planet

table dining-room table dinner table round table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

table

...table

3dexport

table classic-table

archibase_planet

free

Table

...se planet

table glass table round table glass-table

table tonin habitat n280111 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table dining-room table dinner table

table - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table coffee table glass table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table glass-table coffee table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table writing table office table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$5

Table

...table

3docean

dining table furniture home kitchen table

simple wooden table.