Thingiverse

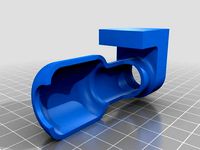

Igus 8mm bushing and SC8UU compatible housing by MKSA

by Thingiverse

Last crawled date: 3 years ago

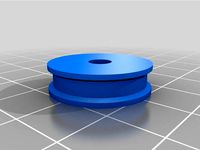

The bushings are made from Igus filament (size 8X12X12), the housing can be PLA, ABS whatever. Igus supplies stl files for their standards press fit bushing but these are too thin. The one I designed are thick enough, a bit oversized so you can bring them to the correct sizes and finish and are to be press fitted too. You have to finish the exterior with abrasive or files but for the inside, better to use a reamer or eventually a good sharp drill bit once installed to get the proper diam and finish. Done properly will lead to virtually no play, yet a smooth travel.

For linear motion, the bushing with groves works best.

They are smaller, shorter, lighter than the chinese LM8UU series yet are better and can be used with cheap SS rods. These don't last long with ball bearings as they are too soft.

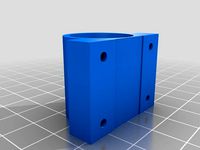

The housing is compatible with the SC8UU, just shorter, only two screws. Use self tapping screws, 3.2mm is OK, bigger may require drilling the holes. Regular M3 or M4 are OK too, not really needed to tap, just drill as required before tapping (diam minus pitch).

No messy lubrication required. Note that you need to properly align the bushings. Use the smooth rod to help. This is always true. The way LM8 are installed in most 3D printers is just the opposite of good engineering practice (split housing, tiewrap) but required because of poor design and alignment. The elasticity of the assembly will cope with it.

On the pictures, you can see them installed on my Geetech Prusa Al Y table (the housing is a previous non press fit design) and integrated in the X carriage of my own. For the X, I used two, one at each end.

To get a pretty good alignment, you can heat the housings once installed with a heat gun to relieve the stress. I did it for the Y table. Not required for the X carriage as I reamed the two bushings in one go with a long reamer once installed.

You can see the grooves left by the LM bearings ! Was time to phase them out.

They have been running for a few months now, a couple 1kg spool.

The Y table is more than 150g lighter than the original and my X carriage plus extruder, hot end etc is about 250 g, less than the weight of just the supplied MK8 Nema 17 motor !

Note that an added advantage of these bearings is they somewhat dampen vibration and are silent contrary to the LM bearings that rattle so much they can drive people crazy. (if they don't rattle it means they are stressed because of misalignment and will soon fail :) )

PS:

-Igus supplies drop in bearings (Drylin) similar to the LM, SC series used in 3D printer. They are fine but lead to bigger, heavier parts. Longer too wich is unnecessary here due to the light loads and they have therefore more friction. And what about the fun to do your own ?

-Standard bronze bushing (8X12X12) can be used instead of the printed Igus bearing.

For linear motion, the bushing with groves works best.

They are smaller, shorter, lighter than the chinese LM8UU series yet are better and can be used with cheap SS rods. These don't last long with ball bearings as they are too soft.

The housing is compatible with the SC8UU, just shorter, only two screws. Use self tapping screws, 3.2mm is OK, bigger may require drilling the holes. Regular M3 or M4 are OK too, not really needed to tap, just drill as required before tapping (diam minus pitch).

No messy lubrication required. Note that you need to properly align the bushings. Use the smooth rod to help. This is always true. The way LM8 are installed in most 3D printers is just the opposite of good engineering practice (split housing, tiewrap) but required because of poor design and alignment. The elasticity of the assembly will cope with it.

On the pictures, you can see them installed on my Geetech Prusa Al Y table (the housing is a previous non press fit design) and integrated in the X carriage of my own. For the X, I used two, one at each end.

To get a pretty good alignment, you can heat the housings once installed with a heat gun to relieve the stress. I did it for the Y table. Not required for the X carriage as I reamed the two bushings in one go with a long reamer once installed.

You can see the grooves left by the LM bearings ! Was time to phase them out.

They have been running for a few months now, a couple 1kg spool.

The Y table is more than 150g lighter than the original and my X carriage plus extruder, hot end etc is about 250 g, less than the weight of just the supplied MK8 Nema 17 motor !

Note that an added advantage of these bearings is they somewhat dampen vibration and are silent contrary to the LM bearings that rattle so much they can drive people crazy. (if they don't rattle it means they are stressed because of misalignment and will soon fail :) )

PS:

-Igus supplies drop in bearings (Drylin) similar to the LM, SC series used in 3D printer. They are fine but lead to bigger, heavier parts. Longer too wich is unnecessary here due to the light loads and they have therefore more friction. And what about the fun to do your own ?

-Standard bronze bushing (8X12X12) can be used instead of the printed Igus bearing.

Similar models

thingiverse

free

8mm Self aligning Igus bearing by MKSA

...ww.thingiverse.com/thing:1828789

see also : http://www.thingiverse.com/thing:2108914 that is suitable for radial and axial mount.

thingiverse

free

SC8UU IGUS-profiled bushing by kaa_

...e standard bearing sc8uu.

the bushing has original igus profile (rj4jp-01-08)

the inner diameter of the hole in the model - 8.1mm

grabcad

free

Drill Press

...drill press

grabcad

for drilling holes; can also be used for enlarging holes with a boring tool or finishing holes with a reamer

thingiverse

free

Prusa MK3(S) Improved Y-Carriage

... that are not threaded are the ones for the u-bolts that hold the bearings. all other holes should be drilled/tapped for m3x0.5.

thingiverse

free

Prusa MK2S X-Carriage for Igus RJ4JP by iancun

...older. i have reduced the bushing spacing and added a divider so that there is no slop, particularly between the top two bushings

thingiverse

free

lm10uu sc8uu adapter bushing by kwm

...d original bushing stl file and scad file that alters it. thingiverse does not show the scad correctly, ignore the scad preview.

thingiverse

free

Printed double IGUS Bearing block for E3D baseplate by bipsen

...he diameter, if it is too loose or tight when printed on your own printer - or send me a message, if you need a custom sized stl.

thingiverse

free

IGUS RJMP-01-08 Bearing Block by Lay3rWorks

...://www.thingiverse.com/goerke/ created a version to fit the igus rjm-01-08 bearings here http://www.thingiverse.com/thing:2052556

thingiverse

free

8mm Self aligning Igus bearing type 2 by MKSA

...a spherical sanding tip of about 12mm or something similar do the same on the igus sphere outside with...

thingiverse

free

Igus 10mm Bushing Holder for LM8LUU by superjamie

...d or tube on the x axis, or just allows to not use a noisy metal linear bearing on a 10mm steel rod.

openscad source is included.

Mksa

thingiverse

free

Dremel universal holder by MKSA

...ith a small c clamp. cut or stop the print if you want partial or no protection.

100% infill makes it strong enough without bulk.

thingiverse

free

Sako 300 Win magazine follower by MKSA

... smooth where required for smooth operation.

print in red if you have the filament for. will help see when the magazine is empty.

thingiverse

free

Torque measurement by MKSA

...t your motot can deliver and adjust its current accordingly.

ok, its static, keep that in mind when adjusting your motor current.

thingiverse

free

Silentblock SC8UU by MKSA

...d is not comparable to what i am now getting. biggest gain due to replacing the z lead screws and one motor. see my other things.

thingiverse

free

NO SCREW, Hot glue hook by MKSA

...lue gun put a big blob of glue on them and immediately apply to the wall. the glue will go through the 4 holes securing the bond.

thingiverse

free

Micro switch bracket for smooth rod. by MKSA

...se petg or abs as it is strong and won't break.

suitable for x and y, for z you need something that provides fine adjustment.

thingiverse

free

Dremel protection by MKSA

...t publishing real working things even remixes i won't have to criticize ? some jerks even have nothing to show, just insults.

thingiverse

free

GT2 Belt tension adjustement by MKSA

...se crappy ones made out of acrylic sheets watch out that it may bend and even break so you now have an excuse to get rid of it :)

thingiverse

free

Simple glass plate holder by MKSA

...p edges that can lead to injury to the eyes or make you bleed ! too much bleeding will cause death. proceed at your own risk. :)

thingiverse

free

Extruder push measurement. by MKSA

...because of thinkverse, not used.

plenty more things to write about but. anyone knowledgeable can fill in the blanks or comment :)

Sc8Uu

thingiverse

free

SC8UU by Flox

...sc8uu by flox

thingiverse

new style sc8uu. good work.

thingiverse

free

SC8UU by DevCorp

...sc8uu by devcorp

thingiverse

sc8uu and sc16uu cartridge with tightening element

thingiverse

free

Connector for SC8UU and SK8

...connector for sc8uu and sk8

thingiverse

mount adapter for sc8uu and sk8. enables connecting x and y axis.

thingiverse

free

SC8UU Bushing by AxMod3DPrint

... untested currently. sc8uu dimensions taken from cad drawing at http://www.wedo3dprinting.uk/411-large_default/lm8uu-bearing-.jpg

thingiverse

free

SC8UU by Tijnv

...ith no nuts needed (m4)

the bearings click/clamp in tightly

also added 2 versions for the slightly bigger rjmp-01-08 and similar

thingiverse

free

sc8uu+8mm-thread by mriv

...sc8uu+8mm-thread by mriv

thingiverse

version 2. a simple thing to put together two sc8uu linear bearings and a 8mm screw and nut

thingiverse

free

Linear bearing LM8UU (Twisted) and SC8UU by InfusionKRD

... and sc8uu by infusionkrd

thingiverse

linear bearing lm8uu and sc8uu

blue - nylon = lm8uu (twisted)

white - hips or abs = sc8uu

thingiverse

free

sk8 sc8uu by linkasum

...sk8 sc8uu by linkasum

thingiverse

this model for the unification of the two linear bearings and racks

thingiverse

free

Bushing Block-SC8UU-M8 by Pmturiel

...m8 by pmturiel

thingiverse

this is a block for the self lubricated brushes 8x11x22mm

it is designed to fit like the sc8uu one.

thingiverse

free

SC8UU linear bearing stabilizer by sjr

...c8uu linear bearing stabilizer by sjr

thingiverse

stabilize your 8mm linear bearings type sc8uu

to improve your printing quality

Igus

3d_export

$5

Christmas ball

...print, a christmas flower files types include: obj, 3dv, igus step and...

archive3d

free

Sconce 3D Model

...lantern

sconce igu wall up-down n040214 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

AC-DC power supply

...the marking on the top for printed circuit boards. igus and step file format for importing into ecad...

3d_export

$5

Picto toilet directions

...directions. include 3d files next to rhino6: x3dv, step, igus obj and stl. double-sided, flipping changes the gender directions...

3d_export

$5

LED Right Angled PCB Mounting

...3dexport right angled pcb mounting ø3.0mm led. step and igus files. multiple led colors: blue, purple, red, green, and...

3d_export

$5

USB Micro B connector

...usb mirco connector. two type of files step and igus for 3d import into ecad tools, pcb footprints. added...

thingiverse

free

LMH8LUU Igus style by NitzscheModellbau

...lmh8luu igus style by nitzschemodellbau

thingiverse

lmh8luu igus style

thingiverse

free

Printed Igus bushing by MikeDX

...gus bushings whilst building my prusa air, so i designed and printed these.

http://czechreprap.eu/reprap-parts/igus-bushing.html

thingiverse

free

igus slide by arbib

...igus slide by arbib

thingiverse

team 1577 frc

thingiverse

free

IGUS Bushing finishing tool by jpasternack

...igus bushing finishing tool by jpasternack

thingiverse

igus bushing finishing tool

8Mm

turbosquid

$50

8MM CAMERA.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

kodak 8mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Brass Bush Bearing 8mm ID

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

wrench big collection from 8mm to 32mm

...llection from 8mm to 32mm for download as obj, fbx, and sldas on turbosquid: 3d models for games, architecture, videos. (1438111)

turbosquid

$1

Flexible Shaft Coupling 6mm x 8mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Flexible shaft coupling 5mm x 8mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

German WWII Breda MG-8mm Ammo Box (Low Poly)

...g-8mm ammo box (low poly) for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1395526)

3ddd

free

Treasures of the Sea

...treasures of the sea 3ddd бижутерия d=8mm ...

3d_export

$5

double thread screw

...thread length: 10 mm total length: 41 mm diameter: 8mm ...

3d_export

$5

large double thread screw

...thread length: 10 mm total length: 115 mm diameter: 8mm ...

Bushing

3d_ocean

$9

Bush

...bush

3docean

bush pink plant white

a bush with white pink leaves

archibase_planet

free

Bush

...bush

archibase planet

bush plant shrub

bush n300813 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bush

...bush

archibase planet

bush plant shrub

bush n180614 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bush

...bush

archibase planet

bush plant shrub

bush 5 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bush

...bush

archibase planet

bush plant shrub

bush 2 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bush

...bush

archibase planet

bush plant shrub

bush 4 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bush

...bush

archibase planet

bush plant shrub

bush 1 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bush

...bush

archibase planet

bush plant shrub

bush 3 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bush

...bush

archibase planet

bush plant stones shrub

bush stones n230814 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Bush

...bush

archibase planet

bush grass plant shrub

bush and grass n230714 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

Compatible

turbosquid

$3

Genesis 8 Clothing 1 dForce Compatible

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Genesis 8 Clothing Top 1 dForce Compatible

...nesis 8 clothing top 1 dforce compatible (2) for download as on turbosquid: 3d models for games, architecture, videos. (1217671)

turbosquid

$50

Screwdriver Latch Type CSC Torx compatible with Straumann

...sc torx compatible with straumann for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1370064)

3d_export

$9

cad compatible casual woman hand model f1p3d1v1hand

...s: stl, obj, fbx<br>models with quad-topology (1100 quads) are also included (f1p3d1v1hand_quad.obj, f1p3d1v1hand_quad.fbx)

3d_export

$38

uzaki rigify

...uzaki rigify 3dexport compatible-blender ...

3d_export

$5

cloud lowpoly 3d

...cloud lowpoly 3d 3dexport lowpoly 3d format fbx compatible with unreal and...

3d_export

$5

flower lowpoly 3d

...flower lowpoly 3d 3dexport lowpoly 3d format fbx compatible with unreal and...

3d_export

$5

rocks lowpoly 3d

...rocks lowpoly 3d 3dexport lowpoly 3d format fbx compatible with unreal and...

3d_export

$10

pots

...pots

3dexport

pots<br>modeled in blender<br>compatable with evee and cycels

3d_ocean

$95

Mr Techny

...for 3ds max 2010 and later – biped (2010 compatible and cat (2011 compatible) versions incluided. for maya 2012...

Housing

archibase_planet

free

House

...t

house residential house private house wooden house

house wooden n290815 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...use residential house private house wooden house

house wood stone n140815 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n050615 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n030615 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n230715 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n240615 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n290815 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n110915 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n120915 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n210915 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.