Thingiverse

![[idbox] Secondary Extruder by mrm64](/previews/8757582.jpg)

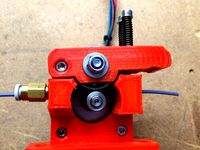

[idbox] Secondary Extruder by mrm64

by Thingiverse

Last crawled date: 3 years ago

This is a direct drive bowden extruder remodeled for deagostini idbox.

It is assumed to be used as a secondary extruder, but it can also be used as a primary extruder.

Remixed from: Compact Bowden extruder by scarou

Merged from: [idbox] Filament Funnel Set, Pacman Helper Disk V2 by midniteandy

Updates

2017-01-29 Added Spring_Compressor.stl

2017-03-02 Added SecondaryExtruder_Body_Disks_SupportV2.stl

2017-12-21 Added Spring_Compressor_V2.stl and Washer_Board.stl

2017-12-28 Added Spring_Compressor_V2.1.stl

Requirements

Use for extruder

1 x NEMA17 stepper motor

1 x MK8 drive gear

Outer diameter: 9mm

Length: 11mm

Hob diameter: 7mm

Bore: 5mm

1 x PC4-M6 connector

1 x PTFE tube

Outer diameter: 4mm

Inner diameter: 2mm

1 x 625ZZ bearing (or 625-2RS bearing)

1 x 608ZZ bearing (or 608-2RS bearing)

2 x M3x8mm pan head screws

2 x M3x10mm pan head screws

2 x M3x15mm pan head screws

2 x M3x40mm any screws

If you use a spring compressor, you may choose a flat head screws.

Truss head screws are not suitable for spring compressor.

2 x Compression springs

Wire diameter: 0.5‒1mm (0.0197‒0.0394")

Outer diameter: 5‒7mm (0.1969‒0.2756")

Free length: 10‒15mm (0.3937‒0.5905")

4 x M3 nuts

12 x M3 washers

Use for mount

2 x M3x14mm truss head screws

2 x M3 nuts

2 x M3 washers

Other requirements

1 x Dual print head

1 x Hotend kit

Print Settings

Body settings

Resolution: 0.2mm

Perimeter count: 4

Infill: 30%

Rafts: Yes

Supports: Yes

Supports everywhere: No

Idler settings

Resolution: 0.2mm

Perimeter count: 4

Infill: 60% (or higher)

Supports: Yes

Spring compressor settings

Resolution: 0.2mm

Supports: No

Marlin Firmware Settings

Configuration.h

Invert the direction of motor rotation#define INVERT_E1_DIR true

E steps per mm

Hob effective diameter: 7mm#define DEFAULT_AXIS_STEPS_PER_UNIT {71.1111,71.1111,3200,145.5131}

Hob effective diameter: 6.9mm#define DEFAULT_AXIS_STEPS_PER_UNIT {71.1111,71.1111,3200,147.6212}

Hob effective diameter: 6.8mm#define DEFAULT_AXIS_STEPS_PER_UNIT {71.1111,71.1111,3200,149.7929}

Hob effective diameter: 6.7mm#define DEFAULT_AXIS_STEPS_PER_UNIT {71.1111,71.1111,3200,152.0286}

Reference

Triffid Hunter's Calibration Guide - RepRapWiki

e_steps_per_mm = (motor_steps_per_rev * driver_microstep) * (big_gear_teeth / small_gear_teeth) / (hob_effective_diameter * pi)

Spring Compressor

Insert the spring compressor between the screw head and the washer, you can increase the pressure on the spring.

When 3D printing is finished, pulling out the spring compressor from the screw head can reduce the burden on the idler and the spring.

Washer Board

The washer board makes it easy to insert the spring compressor.

Attach to the screw head protruding from the idler.

It is assumed to be used as a secondary extruder, but it can also be used as a primary extruder.

Remixed from: Compact Bowden extruder by scarou

Merged from: [idbox] Filament Funnel Set, Pacman Helper Disk V2 by midniteandy

Updates

2017-01-29 Added Spring_Compressor.stl

2017-03-02 Added SecondaryExtruder_Body_Disks_SupportV2.stl

2017-12-21 Added Spring_Compressor_V2.stl and Washer_Board.stl

2017-12-28 Added Spring_Compressor_V2.1.stl

Requirements

Use for extruder

1 x NEMA17 stepper motor

1 x MK8 drive gear

Outer diameter: 9mm

Length: 11mm

Hob diameter: 7mm

Bore: 5mm

1 x PC4-M6 connector

1 x PTFE tube

Outer diameter: 4mm

Inner diameter: 2mm

1 x 625ZZ bearing (or 625-2RS bearing)

1 x 608ZZ bearing (or 608-2RS bearing)

2 x M3x8mm pan head screws

2 x M3x10mm pan head screws

2 x M3x15mm pan head screws

2 x M3x40mm any screws

If you use a spring compressor, you may choose a flat head screws.

Truss head screws are not suitable for spring compressor.

2 x Compression springs

Wire diameter: 0.5‒1mm (0.0197‒0.0394")

Outer diameter: 5‒7mm (0.1969‒0.2756")

Free length: 10‒15mm (0.3937‒0.5905")

4 x M3 nuts

12 x M3 washers

Use for mount

2 x M3x14mm truss head screws

2 x M3 nuts

2 x M3 washers

Other requirements

1 x Dual print head

1 x Hotend kit

Print Settings

Body settings

Resolution: 0.2mm

Perimeter count: 4

Infill: 30%

Rafts: Yes

Supports: Yes

Supports everywhere: No

Idler settings

Resolution: 0.2mm

Perimeter count: 4

Infill: 60% (or higher)

Supports: Yes

Spring compressor settings

Resolution: 0.2mm

Supports: No

Marlin Firmware Settings

Configuration.h

Invert the direction of motor rotation#define INVERT_E1_DIR true

E steps per mm

Hob effective diameter: 7mm#define DEFAULT_AXIS_STEPS_PER_UNIT {71.1111,71.1111,3200,145.5131}

Hob effective diameter: 6.9mm#define DEFAULT_AXIS_STEPS_PER_UNIT {71.1111,71.1111,3200,147.6212}

Hob effective diameter: 6.8mm#define DEFAULT_AXIS_STEPS_PER_UNIT {71.1111,71.1111,3200,149.7929}

Hob effective diameter: 6.7mm#define DEFAULT_AXIS_STEPS_PER_UNIT {71.1111,71.1111,3200,152.0286}

Reference

Triffid Hunter's Calibration Guide - RepRapWiki

e_steps_per_mm = (motor_steps_per_rev * driver_microstep) * (big_gear_teeth / small_gear_teeth) / (hob_effective_diameter * pi)

Spring Compressor

Insert the spring compressor between the screw head and the washer, you can increase the pressure on the spring.

When 3D printing is finished, pulling out the spring compressor from the screw head can reduce the burden on the idler and the spring.

Washer Board

The washer board makes it easy to insert the spring compressor.

Attach to the screw head protruding from the idler.

Similar models

thingiverse

free

![[idbox] Primary Extruder by mrm64](/t/8757992.jpg)

[idbox] Primary Extruder by mrm64

...

washer board

the washer board makes it easy to insert the spring compressor.

attach to the screw head protruding from the idler.

thingiverse

free

Compact Bowden Extruder Plus by mrm64

...m previous version

made left and right idlers the same thickness

reduced cylinder size

related thing

1.5 axis gimbal for nema 17

thingiverse

free

Compact extruder for Prusa i3 and 42YF22GN050R (2engineers) geared motor with shaft support by denisc

... ...300

#define default_retract_acceleration 300

update 13-sep-2014

added long screws, springs, washers, nuts for idler.

thingiverse

free

LMK8UU and LMK8LUU Hybrid PTFE bearing by mrm64

...print settings

printer: deagostini idbox

filament material: pla

nozzle diameter: 0.4mm

resolution: 0.2mm

supports: no

infill: 90%

thingiverse

free

Compact Direct Drive MK8 Bowden Extruder for 1.75mm Filament by 0110-M-P

...625zz bearing (1) mk8 hobbed pulley (tri-d printing or similar (2) springs | recommend ultibots wades idler spring (same...

thingiverse

free

Mini Kossel 1.75mm extruder by wallie

...et head cap screw

2x spring

1x m5 pneumatic straight threaded-to-tube adapter, push in 4 mm 4mm male

tools

m5 manual screw tap

thingiverse

free

Compact Bowden extruder, direct drive, bearing bloc, auto load 1.75mm filament by scarou

... pushfit_builtin support.stl

update 25-06-2016 : as requested, added c_b_e_mk8 - 2 pushfit - no braket - with builtin support.stl

thingiverse

free

Cetus MK3 adjustable extruder idler holder. by Sergey_77

...flush with the bearing. and 14mm screw to set pressure on the filament. bearing and m2.5x8 screws are from the original extruder.

thingiverse

free

NSTT Extruder by Paciente8159

...gure the e steps/mm to about 440. test it and adjust.

enjoy your new geared extruder. the printing quality on this is worth it!!!

thingiverse

free

idbox! extruder enhanced arm "Beetle" by MA_SA

...4nut x1

9.m3spacer l=5 x3(idbox genuine parts)

10.624zz bearing x1(idbox genuine parts)

11.tension spring x1(idbox genuine parts)

Mrm64

thingiverse

free

Simple S-Hook by mrm64

...simple s-hook by mrm64

thingiverse

simple s-hook

thingiverse

free

Chef's Knife Holder by mrm64

...chef's knife holder by mrm64

thingiverse

supports: no

thingiverse

free

![[idbox] Mini Hook by mrm64](/t/8746867.jpg)

[idbox] Mini Hook by mrm64

...[idbox] mini hook by mrm64

thingiverse

used to hang a binder clip.

thingiverse

free

Wire Shelving Safety Cap by mrm64

...wire shelving safety cap by mrm64

thingiverse

raft: yes

support: no

thingiverse

free

Cubic Filament Colorizer by mrm64

...cubic filament colorizer by mrm64

thingiverse

requirements

polyurethane foam sponge

refill ink for permanent marker

thingiverse

free

Tooth Brush Holder for Tray by mrm64

...tooth brush holder for tray by mrm64

thingiverse

tooth brush holder for tray

thingiverse

free

![[idbox] Top Corner Bracket by mrm64](/t/8779959.jpg)

[idbox] Top Corner Bracket by mrm64

...[idbox] top corner bracket by mrm64

thingiverse

[idbox] top corner bracket

thingiverse

free

![[idbox] Soft Pick Mount by mrm64](/t/8779355.jpg)

[idbox] Soft Pick Mount by mrm64

...[idbox] soft pick mount by mrm64

thingiverse

requirements: soft toothpick

support: no

thingiverse

free

Cone Head Spool Holder by mrm64

...cone head spool holder by mrm64

thingiverse

requirements: grease

resolution: 0.3mm-0.5mm

thingiverse

free

Melamine Foam Tool Holder by mrm64

...melamine foam tool holder by mrm64

thingiverse

requirements: melamine foam (30x30x30mm cube)

Idbox

thingiverse

free

idbox Base by Tanyichung

...idbox base by tanyichung

thingiverse

idbox

thingiverse

free

idbox! Z_Adjust_Set by nakarobo

...op plate and m3 nylon nut table adjuster.

caution:if your 3d printer is normal idbox then you're rescale 1.0038 x and y axis.

thingiverse

free

Display Holder for iDBOX by VirtualHours

...display holder for idbox by virtualhours

thingiverse

a simple display holder for idbox or other printers

first test release

thingiverse

free

![[idbox] Top Corner Bracket by mrm64](/t/8779959.jpg)

[idbox] Top Corner Bracket by mrm64

...[idbox] top corner bracket by mrm64

thingiverse

[idbox] top corner bracket

thingiverse

free

MKS_TFT28_V1.2_case_Kai(BS01+&idbox) by fumihiko1226

...1.2_case_kai(bs01+&idbox) by fumihiko1226

thingiverse

remake mks tft28 v1.2 case

fit lcd screen (front)

bs01+&idbox tray

thingiverse

free

Extruder S-tension adjuster for idbox by mittan

...extruder s-tension adjuster for idbox by mittan

thingiverse

extruder custom parts of idbox

thingiverse

free

![[idbox] Filament Funnel Set by mrm64](/t/8780408.jpg)

[idbox] Filament Funnel Set by mrm64

...ent funnel set by mrm64

thingiverse

remixed from: http://www.thingiverse.com/thing:554555

printer: deagostini idbox!

support: no

thingiverse

free

Table stopper for idbox! by ts2a

...haft with 5mm x12 bolts and nuts. this parts reduces to slip a table and table base of your idbox!.

2 : 5mm x 12mm bolts and nuts

thingiverse

free

![[idbox] Pull Ring for Extruder Spring by mrm64](/t/8779386.jpg)

[idbox] Pull Ring for Extruder Spring by mrm64

...[idbox] pull ring for extruder spring by mrm64

thingiverse

[idbox] pull ring for extruder spring

thingiverse

free

idbox! feeder by idbox325

...ciencies found have been updated.

we made to measure from "idbox!".

m3 bolt & nut 15-20mm x 4

m6 nut x 1

pc4-m6 x 1

Secondary

turbosquid

$149

Track Secondary Pulverizer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Chilled Water Secondary Pumps

...ee 3d model chilled water secondary pumps for download as max on turbosquid: 3d models for games, architecture, videos. (1270113)

turbosquid

$60

Secondary Atitude Indicator (AI, Artifical Horizon)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Modern style primary and secondary school architectural design SU model

... secondary school architectural design su model

3dexport

modern style primary and secondary school architectural design su model

3d_export

$8

transat bamboo

...3dexport diffuse and normal on primary uvmap ao on secondary :...

3d_export

$6

transat deauville

...3dexport diffuse and normal on primary uvmap ao on secondary :...

3d_export

$15

Maverick REV-6

...range, it is recommended to use it as a secondary additional...

3d_export

$10

maison du monde pinup stool

...diffuse texture on primary map : uvmap ao on secondary map : uvmap...

3d_export

$5

Scrap metal 3D Model

...spare object subject scrap metal iron breakage stuff waste secondary raw materials scrap metal 3d model talgat 39978...

3d_export

$15

insectoid monster

...insectoid mutant low poly<br>can be used in games as secondary character or enemy<br>created in blender 2.91<br>archive includes next...

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.