Thingiverse

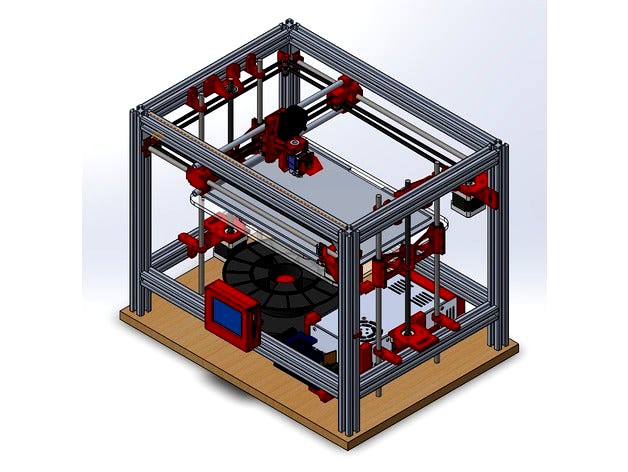

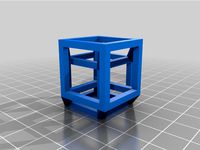

HyperCube 3D printer (2525 Aluminum) by brspartan

by Thingiverse

Last crawled date: 3 years ago

Modified parts from either the Hypercube or Hypercube Evolution for:

-2525 Aluminum Tslot

-3/8 Anodized Aluminum Rod or 8mm steel rods

-Z axis design: Acrylic Base or 2020 Aluminum Tslot

-Dual Z axis motors

-Larger Print Area: 200x300x160mm

-Compact Base Design: Power Supply, Ramps, Bowden Extruder, and Filament all sit below the printer

This printer includes things from:

-Brspartan's Horizontal Spool Mount

-Tom114's E3D fan

-Dintid's MKS TFT28 Case

-Dasaki's Ramps Case

-ProtoBuild's PSU Mounts

This printer modified things from:

-Schlotzz's Bowden Extruder

Change Log:

11.21.18: Uploaded all parts from V1 and V2 of my 2525 Hypercube/Hypercube Evolution. Includes solidworks models and STLs

09.07.18: Uploaded modified 2525 parts from the Hypercube Evolution. I've discovered that some of the original Hypercube parts had design flaws that I wanted to address. This version uses 2020 aluminum Tslot for the base which is much more rigid than my previously used acrylic. This also improved the rigidity of the x axis by switching from the 3/8in aluminum tube to 8mm steel rods. These parts have been modified for 8mm steel rods on all axis and to fit 2525 aluminum Tslot for the printer frame. The z axis base is still 2020.

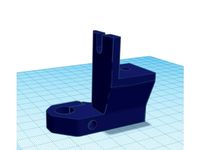

25.05.17: Added/modified PSUFanDuct QTY1.stl, Tool Holder QTY1.stl, bracket_no_notch_v2 QTY2.stl, and Filament Spool Mount v2 QTY1.stl. The PSU Fan Duct will prevent the air from cooling down your heated bed, the spool mount is now a tighter fit and the spool will no longer be able to slide around, the modified bracket_no_notch_v2 is an option that will drop down the height of the PSU mount and gave me more clearance, tool holder is just for fun!

BOM

Frame:

T-Slot 2525 Aluminium Extrusion Profiles for X200 x Y300 x Z155 print bed area

4 x 340mm (X)

4 x 440mm (Y)

4 x 350mm (Z) (longer if you would like a build height greater than my current 160mm)

Fixings:

100 x M5 x 12mm button head screws (for plastic parts)

50 x M5 x 10mm button head screws (for corner brackets)

2 x 100pcs 2525 T-Slot M5 hammer nuts

3 x 10pcs Aluminium Corner Brackets

CoreXY + Z + Bowden Drive System:

2 x 8mmx440mm Hardened Steel smooth rod (choose 500mm length) for Y axis

4 x 8mmx350mm Hardened Steel smooth rod (choose 350mm length) for Z axis

1 x 3/8"x6' Anodised Aluminium Rod/Tube for X axis

4 x 1pcs Self Lubricating 3/8" ID Bronze Bushing

8 x LM8UU linear bearing for Z axis

4 x LM8UU linear bearing for Y axis

2 x 10pcs F623ZZ Flange Bearing

1 x 5M GT2 Belt and 2 x 20 Tooth Pulleys

1 x Teflon PTFE Tube

1 x MK7 Extruder Gear

1 x Push Fit Connector M5

Fixings:

45 x M3 x 10mm pan head screws

45 x M3 x 20mm pan head screws

2 x M3 x 6mm pan head screws

2 x M3 x 35mm pan head screws

35 x M3 Nyloc nuts

35 x M3 Hex nuts

Motors, Electronics and Accessories:

3 x NEMA17 Stepper Motor

2 x Lead Screw NEMA17 Stepper Motor

1 x 2pcs Endstop Switch

1 x RAMPS 1.4 + MEGA2560 R3 + LCD&SD + A4988 With Heat Sink Kit

1 x 12V DC 50mm Blow Radial Cooling Fan

1 x Heatbed Aluminium MK3 12V 24V

1 x 12V 30A 360W Switching Power Supply

1 x Thermistor 100K With 1M Cable for Heat Bed

1 x DC power wire (choose 14AWG)

1 x 10M Tinned Copper 22AWG 2 Pin Red Black

1 x 5pcs Bed levelling screw/spring/knob

1 x Genuine E3Dv6 or Clone (1.75mm long) with optional Block & Sock v6 Upgrade

1 x Inductive Proximity Sensor - PNP

Print settings:

3 Perimeters

3 top/bottom layers

0.25mm layer height (or better)

50% infill

Print 1 of everything except below:

2 x Bed_Mount_v3

2 x XY_Clamp_v1.1

2 x XY_Joiner_v1.1

2 x XY_Idler

3 x Y_Shaft_Clamp

2 x Dual_Bushing_Holder

Laser Cut:

1 x Acrylic Bed (249mm x 349mm)

Follow Tech2C's build log for detailed instructions on how to build this printer! Be sure to follow them all the way through before you start your build.

-2525 Aluminum Tslot

-3/8 Anodized Aluminum Rod or 8mm steel rods

-Z axis design: Acrylic Base or 2020 Aluminum Tslot

-Dual Z axis motors

-Larger Print Area: 200x300x160mm

-Compact Base Design: Power Supply, Ramps, Bowden Extruder, and Filament all sit below the printer

This printer includes things from:

-Brspartan's Horizontal Spool Mount

-Tom114's E3D fan

-Dintid's MKS TFT28 Case

-Dasaki's Ramps Case

-ProtoBuild's PSU Mounts

This printer modified things from:

-Schlotzz's Bowden Extruder

Change Log:

11.21.18: Uploaded all parts from V1 and V2 of my 2525 Hypercube/Hypercube Evolution. Includes solidworks models and STLs

09.07.18: Uploaded modified 2525 parts from the Hypercube Evolution. I've discovered that some of the original Hypercube parts had design flaws that I wanted to address. This version uses 2020 aluminum Tslot for the base which is much more rigid than my previously used acrylic. This also improved the rigidity of the x axis by switching from the 3/8in aluminum tube to 8mm steel rods. These parts have been modified for 8mm steel rods on all axis and to fit 2525 aluminum Tslot for the printer frame. The z axis base is still 2020.

25.05.17: Added/modified PSUFanDuct QTY1.stl, Tool Holder QTY1.stl, bracket_no_notch_v2 QTY2.stl, and Filament Spool Mount v2 QTY1.stl. The PSU Fan Duct will prevent the air from cooling down your heated bed, the spool mount is now a tighter fit and the spool will no longer be able to slide around, the modified bracket_no_notch_v2 is an option that will drop down the height of the PSU mount and gave me more clearance, tool holder is just for fun!

BOM

Frame:

T-Slot 2525 Aluminium Extrusion Profiles for X200 x Y300 x Z155 print bed area

4 x 340mm (X)

4 x 440mm (Y)

4 x 350mm (Z) (longer if you would like a build height greater than my current 160mm)

Fixings:

100 x M5 x 12mm button head screws (for plastic parts)

50 x M5 x 10mm button head screws (for corner brackets)

2 x 100pcs 2525 T-Slot M5 hammer nuts

3 x 10pcs Aluminium Corner Brackets

CoreXY + Z + Bowden Drive System:

2 x 8mmx440mm Hardened Steel smooth rod (choose 500mm length) for Y axis

4 x 8mmx350mm Hardened Steel smooth rod (choose 350mm length) for Z axis

1 x 3/8"x6' Anodised Aluminium Rod/Tube for X axis

4 x 1pcs Self Lubricating 3/8" ID Bronze Bushing

8 x LM8UU linear bearing for Z axis

4 x LM8UU linear bearing for Y axis

2 x 10pcs F623ZZ Flange Bearing

1 x 5M GT2 Belt and 2 x 20 Tooth Pulleys

1 x Teflon PTFE Tube

1 x MK7 Extruder Gear

1 x Push Fit Connector M5

Fixings:

45 x M3 x 10mm pan head screws

45 x M3 x 20mm pan head screws

2 x M3 x 6mm pan head screws

2 x M3 x 35mm pan head screws

35 x M3 Nyloc nuts

35 x M3 Hex nuts

Motors, Electronics and Accessories:

3 x NEMA17 Stepper Motor

2 x Lead Screw NEMA17 Stepper Motor

1 x 2pcs Endstop Switch

1 x RAMPS 1.4 + MEGA2560 R3 + LCD&SD + A4988 With Heat Sink Kit

1 x 12V DC 50mm Blow Radial Cooling Fan

1 x Heatbed Aluminium MK3 12V 24V

1 x 12V 30A 360W Switching Power Supply

1 x Thermistor 100K With 1M Cable for Heat Bed

1 x DC power wire (choose 14AWG)

1 x 10M Tinned Copper 22AWG 2 Pin Red Black

1 x 5pcs Bed levelling screw/spring/knob

1 x Genuine E3Dv6 or Clone (1.75mm long) with optional Block & Sock v6 Upgrade

1 x Inductive Proximity Sensor - PNP

Print settings:

3 Perimeters

3 top/bottom layers

0.25mm layer height (or better)

50% infill

Print 1 of everything except below:

2 x Bed_Mount_v3

2 x XY_Clamp_v1.1

2 x XY_Joiner_v1.1

2 x XY_Idler

3 x Y_Shaft_Clamp

2 x Dual_Bushing_Holder

Laser Cut:

1 x Acrylic Bed (249mm x 349mm)

Follow Tech2C's build log for detailed instructions on how to build this printer! Be sure to follow them all the way through before you start your build.

Similar models

thingiverse

free

HyperCube 3D Printer/CNC by Tech2C

..._motor_v1.1 easier to print (62deg overhang)

enjoy this design? consider supporting me on patreon: https://www.patreon.com/tech2c

thingiverse

free

Prusa i3 3D Printer Anti Backlash v2.0 by StevenQ-NE-UK

...screw, you will need,

2 x m5 hex nuts

1 x spring with a 5mm bore

1 x m3 hex nut

1 x m3 bolt (i used an m3 x 10mm socket cap head)

thingiverse

free

Creality Ender 3 Z axis threaded rod spacer by lac826

...d 2x m5 t nuts + 2 pieces m5*6 mm screw (flat head) bolt

important!

if the z axis goes up to 240mm, you'll be caught in this.

thingiverse

free

support bed cr10 310x310 for hypercube by ngandalf

... is optionnal if you added 4.4cm on the aluminium tube on the middle.

need :

4 x m5 x 50 (for cale)

4 x m4 x 40 (bed)

4 x nut m4

thingiverse

free

Hypercube EVO z-max sensor mount by rjcuomo1

...0 screws

(2) m5 t-nuts for 3030 extrusion

(2) m5 t-nuts for 2020 extrusion

(1) optical endstop (this style: http://a.co/4d1igfr )

thingiverse

free

Z axis 12mm rod 3030 hypercube remix by dakarx

... frame and m3 screw for tension. i printed at 80% infill for added strength and rigidity. this is for my hypercube 500 project

thingiverse

free

HyperCube Reinforced 12mm Z-Axis Rod Bracket by Nase00

...e bed to have room for the rear m5 mounting screws. otherwise, there is an additional m5 screw hole in the middle of the bracket.

thingiverse

free

HyperCube Z axis Alignment Tool by wsolstice69

...e them and properly center the z screw.

note: if you are having trouble fitting this on your bed to print, rotate it 45 degrees.

thingiverse

free

HyperCube XY Joiner LM10UU by erdemerciyas

...x axis 10.25mm rods etc.

x axis 8.25mm rods etc.

20t tooth pulley

need to m3 screw... some size

updated!

add new x axis to 8.25mm

thingiverse

free

BLV Ender 3 Pro Sensorless Homing Endstops by 13Ender123Pro19

... for use with ender-3 pro with blv upgrade.

x-axis hardware:

m3 x 8 mm pan head screws

y-axis hardware:

m3 x 6 mm pan head screws

Brspartan

thingiverse

free

Viper Hitch Cover by brspartan

...viper hitch cover by brspartan

thingiverse

multi extruder viper remix of stimpy's hitch cover.

thingiverse

free

Rigid Shop Vacuum to PVC Adapter by brspartan

... & ridgid vac cart.

this part is the adapter to the 1 1/2in pvc pipe. it sits in the spare components location on the vacuum.

2525

turbosquid

free

Miami 2525

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ALMA DESIGN / 2525

... барный

кресло: alma design / 2525

производитель: alma design

страна:италия

коллекция:barstools

3ddd

free

Бра Odeon Light 2525/1W Garden

...бра odeon light 2525/1w garden

3ddd

odeon light

бра odeon light 2525/1w garden

3ddd

$1

HTC Touch HD

...touch hd 3ddd htc , телефон смартфон htc touch hdинфо:http://www.gsmarena.com/htc_touch_hd-2525php фото:http://i.smartphone.ua/img/phones/htc-touch-hd/foto_001.jpg ...

3d_export

$10

beard v16

...: 2228 - tris : 3920 - uvs : 2525 file format: - maya 2018 (.ma .mb) - fbx...

3d_export

$7

Base Hair for girl V43

...much more.<br>you can view in my profile.<br>features:<br>- verts : 2525lt;br>- edges : 5133<br>- faces : 2610<br>- tris : 5046<br>-...

3dfindit

free

2525

...2525

3dfind.it

catalog: rábalux

3dfindit

free

25-2525, 25-2525-Black

...25-2525, 25-2525-black

3dfind.it

catalog: 80/20

3d_sky

$8

el 2525

...el 2525

3dsky

decor

free3d

free

Miami 2525

...miami 2525

free3d

by herminio

Hypercube

turbosquid

free

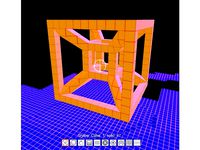

HyperCube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Hypercube 3D Model

...hypercube 3d model

3dexport

cube hypercube four-dimensional space side geometry edge

hypercube 3d model dmitry87 54991 3dexport

3d_export

$5

tesseract hypercube

...t it. moreover different textures and materials can be added and tesseract can be set in any scene. dimensions: x: 4m y: 4m z: 4m

thingiverse

free

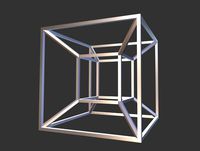

Hypercube

...hypercube

thingiverse

hypercube projected into three dimensional space.

thingiverse

free

Hypercube by alpheccar

...hypercube by alpheccar

thingiverse

projection of an hypercube on an hypersphere.

thingiverse

free

Hypercube by BorisBlavasky

...hypercube by borisblavasky

thingiverse

hypercube. testing the tool.

thingiverse

free

Hypercube by Christian42

...hypercube by christian42

thingiverse

i made a hypercube using rhino3d

thingiverse

free

Hypercube by Christian42

...hypercube by christian42

thingiverse

i made a hypercube using rhino3d

thingiverse

free

HyperCube by wwebber

...hypercube by wwebber

thingiverse

this is the standard perspective projection of the hypercube from 4d to 3d

thingiverse

free

HyperCube scaled by Muzeem

...hypercube scaled by muzeem

thingiverse

customized hypercube

Aluminum

3d_export

$5

aluminum crutch

...aluminum crutch

3dexport

aluminum crutch

3d_export

free

aluminum cane

...aluminum cane

3dexport

aluminum cane

3d_export

$5

the aluminum canister

...

3dexport

the aluminum canister is designed for storing and transporting liquids( water), fuels and lubricants (gasoline, oils).

turbosquid

$2

Aluminum Wheel

...uid

royalty free 3d model aluminum wheel for download as fbx on turbosquid: 3d models for games, architecture, videos. (1371918)

turbosquid

$2

aluminum pulley

...

royalty free 3d model aluminum pulley for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1671716)

turbosquid

$40

Aluminum Can

... free 3d model aluminum can for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301606)

turbosquid

$15

Curved aluminum

...ee 3d model curved aluminum for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1260293)

turbosquid

$12

Aluminum pot

... free 3d model aluminum pot for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1653492)

3d_export

$5

Aluminum Bottle

... for shampoo, conditioner or any liquids (500ml 17floz) separated all parts, able to customize any color, material and finishing.

turbosquid

$19

Aluminum windows

...model aluminum windows for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1646740)

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.