Thingiverse

Hydra Fan Duct & Tool Change System for CR10S PRO with MicroSwiss Hotend (REMIX) by registeredthing

by Thingiverse

Last crawled date: 3 years, 4 months ago

THIS IS A WORK IN PROGRESS AND NOT YET TESTED

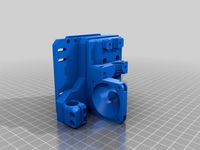

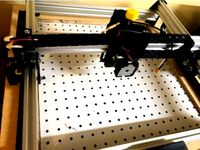

This is a remix of BoothyBoothy's awesome Hydra Fan Duct, and is designed for the CR10S Pro V1 (which is what I have), with a MicroSwiss Hotend. I have printed several prototypes of this design but have not yet tested this due to a seemingly constant stream of new projects and not enough time (but I will update this when I do test it). For now, if you do print this, it is at your own risk, however feedback is welcome.

This was designed with the additional help of the following:

The 3D model of the CR10S Pro x-gantry by PolygonHell who posted it here (https://a360.co/2BOAdnS).

Ookamii's Heatfixer to fit the taller MicroSwiss Hot end I use on my CR10S Pro (https://www.thingiverse.com/thing:4457658). Once Thingiverse fixes the ability to add multiple remix sources I will add this as a source.

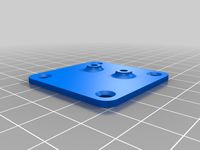

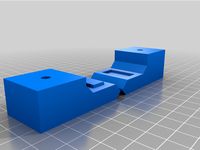

I designed this to use a front mounted inductive probe similar to the EZABL (18mm diameter). I also designed a side mounted bracket for it, however I felt the offset was too far out so did not test print it and am not including it here.

I did not include the files for the fan ducts, or the extruder mounts, please get them from the original Hydra design linked below. The fans I am using are 5010 fans.

https://www.thingiverse.com/thing:4062242

This uses M3 screws and locknuts as the original. It will require mostly M3x10mm screws but two M3x16mm screws will be necessary if using a direct drive extruder.

I will update the description here when everything is tested.

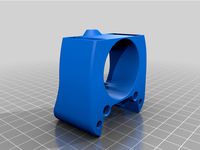

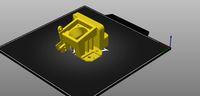

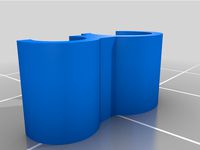

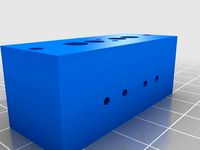

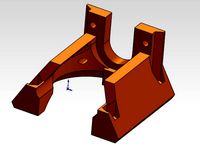

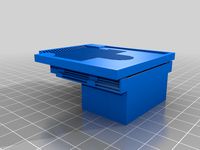

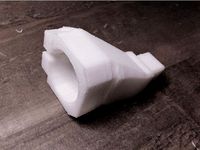

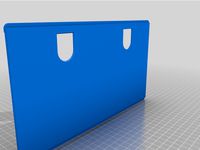

Parts are not oriented for printing (see the pics for a suggested orientation). Supports are optional, though I did use them on the fan guard and the Cable Management bracket. I used the following settings when printing the test parts:

0.16 layer height

50% infill (gyroid)

3 walls

I used PETG for the fan guard, and the heatfixer, as well as the extruder mount and the fan ducts. I used PLA on the other parts.

STEP file included for easy remixing.

This was designed using ViaCAD V12 Pro.

This is a remix of BoothyBoothy's awesome Hydra Fan Duct, and is designed for the CR10S Pro V1 (which is what I have), with a MicroSwiss Hotend. I have printed several prototypes of this design but have not yet tested this due to a seemingly constant stream of new projects and not enough time (but I will update this when I do test it). For now, if you do print this, it is at your own risk, however feedback is welcome.

This was designed with the additional help of the following:

The 3D model of the CR10S Pro x-gantry by PolygonHell who posted it here (https://a360.co/2BOAdnS).

Ookamii's Heatfixer to fit the taller MicroSwiss Hot end I use on my CR10S Pro (https://www.thingiverse.com/thing:4457658). Once Thingiverse fixes the ability to add multiple remix sources I will add this as a source.

I designed this to use a front mounted inductive probe similar to the EZABL (18mm diameter). I also designed a side mounted bracket for it, however I felt the offset was too far out so did not test print it and am not including it here.

I did not include the files for the fan ducts, or the extruder mounts, please get them from the original Hydra design linked below. The fans I am using are 5010 fans.

https://www.thingiverse.com/thing:4062242

This uses M3 screws and locknuts as the original. It will require mostly M3x10mm screws but two M3x16mm screws will be necessary if using a direct drive extruder.

I will update the description here when everything is tested.

Parts are not oriented for printing (see the pics for a suggested orientation). Supports are optional, though I did use them on the fan guard and the Cable Management bracket. I used the following settings when printing the test parts:

0.16 layer height

50% infill (gyroid)

3 walls

I used PETG for the fan guard, and the heatfixer, as well as the extruder mount and the fan ducts. I used PLA on the other parts.

STEP file included for easy remixing.

This was designed using ViaCAD V12 Pro.

Similar models

thingiverse

free

CR10/Ender 3 MicroSwiss DirectDrive Dual 40mm Part Cooling Fan Duct by Print2Win

...ium plate from microswiss i recommend using two more m3 screws with m3 washers to better spread the force on the printed surface.

thingiverse

free

Upgraded V6 - Adapter - Hydra CR10 Fan Duct by dankaiser

... the hydra fan duct cr10.

this makes it possible to screw the round v6 hotend directly into the cr-10 receptacle on the ender 3.

thingiverse

free

Mendel90 x-carriage hotend fan duct (always on, for hexagon hotend) by Stemer114

...the fan duct (towards the hotend) is for the extruder mounting to still be accessible when the duct is mounted (see 3rd picture).

thingiverse

free

MicroSwiss DirectDrive AllMetalHotend CR10s Pro Fan Duct for 4010 fans (Alpha version for testing) by Print2Win

...d 2 m3 grub screws.

this version is still in alpha!!

as testing is still in progress please report any issues you're having!!

thingiverse

free

CR10s Pro direct drive conversion using stock extruder. by SilverPaul

...y attached to the carriage.)

i've yet to download an stl that didn't need tweaking so expect to have to do a little work!

thingiverse

free

Layer fan bracket/duct by jonahblackwell24

...hine or #8 wood screws to attach the 40x40mm fan to the bracket. the holes for mounting the fan are arranged in a 32x32mm square.

thingiverse

free

ender CR-10S PRO hotend model by edric4thingiverse

.... if you are designing a fan duct / mount related to the hotend, you will find it useful to have this model to orientate yourself

thingiverse

free

BIQU B1 Direct Drive mount for BMG Extruder by rannski

...sed m3x40 buttom hex screws and nyloks to mount it on top. the hotend fan have to be moved outside the case because of the screws

thingiverse

free

CR10 / Ender2 Microswiss Fangs removed by CHOPPER1066

...one of the chocolate screws out.

note: while the cr10 and ender2 are excellent machines, the screws and hex wrenches are garbage.

thingiverse

free

Sovol Sv01 5015 radial part cooling duct by trohn_javolta

...sure the airflow isn't that great but i just printed a bridging test and it turned out quite good.... if that says anything..

Registeredthing

thingiverse

free

Beads for a bracelet or whatever by registeredthing

...ot be needed. if you make one please post a make, if you have a suggestion please post a comment. good luck and happy printing!

thingiverse

free

Mini Magnet Hardware Pickup Tool by registeredthing

...net may also work. the magnet goes into the tool about 5mm.

part is not oriented for printing but should print without supports.

thingiverse

free

15/32" Drill Bit Case by registeredthing

...rs.

this was designed using viacad v12 pro

step file is included for easy remixing and the parts are not oriented for printing.

thingiverse

free

Under Desk Headphone Holder by registeredthing

...ut may help with positioning it under a desk.

if you print one, please post a make. step file is included for easy remix'in.

thingiverse

free

Number 8 Screw Cover or Cap by registeredthing

...t you will test the prototypes and provide feedback (i don't like to spend the pla on testing stuff i don't plan to use).

thingiverse

free

BLTouch Mount Ender 5

...cut a small hole in the bltouch mount by registeredthing to fit it on the creality ender 5 extruder...

thingiverse

free

Towel Holder | Handtuchhalter (REMIX) for 3M Command Strips by registeredthing

...a door it is placed next to).

step file is included, and the parts may need to be oriented for printing (no supports are needed).

thingiverse

free

Clorox Wipes Holder - Wall Mount (WORK IN PROGRSS) - With STEP file by registeredthing

... hurt. 2x mounting screws will also be needed.

if you make one and have feedback please let me know so i can improve this model.

thingiverse

free

Clorox Wipes Holder - Cube Mount for Haworth Compose (WORK IN PROGRSS) - With STEP file by registeredthing

...onal (to hold the nuts in) but can't hurt.

if you make one and have feedback please let me know so i can improve this model.

thingiverse

free

Sony Headphones Strain Relief Boot (Sony MDR-V6) by registeredthing

...erse.com/thing:4662709

part is not oriented for printing (rotate so the larger end is down).

if you make one, please post a make.

Microswiss

thingiverse

free

Microswiss Ender 3 by Joferval

...microswiss ender 3 by joferval

thingiverse

microswiss direct drive adapter for ender 3

thingiverse

free

Precision Piezo Orion Microswiss clamp by Moriquendi

...nted parts required to use the orion with a microswiss hotend.

i have not personally tested these parts with a microswiss hotend.

thingiverse

free

VORON printhead for MicroSwiss hotend by phil245

...3d v6 hotend but i do have the microswiss so i set to making it fit.

i hope this helps someone, if it does please post a make.

thingiverse

free

BLTouch adjuster for Ender 3 with MicroSwiss hotend

... adjuster for ender 3 with microswiss hotend

thingiverse

bl touch (creality version) adjuster for ender 3 with microswiss hotend

thingiverse

free

Microswiss X Axis Endstop for DirectDrive by ericthetazman

... by ericthetazman

thingiverse

i made this to account for new position of x endstop with microswiss direct drive on my longer lk4

thingiverse

free

microswiss dd cr10s pro by deshi

...thingiverse

modified for the ender 3 microswiss dd to fit cr10s pro.

had to raise bed 5mm set x axis off set to -35 and y to -25

thingiverse

free

CR-10S fan nozzle for microswiss hotendf by jfmvoers

...hotendf by jfmvoers

thingiverse

cooling nozzle for a creality cr10s with microswiss hotend.also fits on other creality printers.

thingiverse

free

Satsana Ender 3 v2 MicroSwiss 5010 by Annikamint

...giverse.com/thing:4787797/files

and

https://www.thingiverse.com/thing:4647053 to fit on ender 3 v2 with microswiss and 5010 fan

thingiverse

free

ender 3 v2 bltouch microswiss by Mampo112

...sured 1.4mm shorter than creality stock hotend.

use m3 screws to fit it.

thats my first post in thingiverse

sorry my poor english

thingiverse

free

CR10 / Ender2 Microswiss Fang by 2bedom

...all metall 300°c microswiss hotend.

(https://store.micro-swiss.com/products/all-metal-hotend-kit-for-cr-10)

the fang fits good ..

Hydra

thingiverse

free

hydra by aramisi

...hydra by aramisi

thingiverse

hydra

thingiverse

free

Hydra logo by LogoGuy

...hydra logo by logoguy

thingiverse

the hydra logo

hail hydra!

thingiverse

free

Merry Hydra by MNutt_STS

...merry hydra by mnutt_sts

thingiverse

a hydra-themed ornament. hail hydra!

thingiverse

free

Hydra

...s them in short order."

i am a beginner designer, i will be very grateful for a little tip! thank you in advance! good game!

thingiverse

free

HYDRA MARVEL by TFbio

...hydra marvel by tfbio

thingiverse

this is the logo of the hydra. the hydra is the enemy of s.h.i.e.l.d. in marvel comiscs

thingiverse

free

Hydra stencil by Longquang

...hydra stencil by longquang

thingiverse

hydra

thingiverse

free

Hydra pauldron

...n

thingiverse

this stylish hydra-themed shoulder pad signifies that the wearer is a true alpha among a legion of other warriors.

thingiverse

free

Hydra Worm

...hydra worm

thingiverse

a hydra worm.

you can support me on https://www.patreon.com/schlossbauer if you like my work.

thingiverse

free

Hydra Ring by BoyScout311

...hydra ring by boyscout311

thingiverse

hydra ring made of tinkercad

thingiverse

free

Hydra token by Axomir

...hydra token by axomir

thingiverse

hydra tokens to use in board games

Cr10S

thingiverse

free

Clips for Ender 3, CR10, CR10S

.... maybe others, but only been tested with these.

these clips makes a tight fit, so that the cable and bowden tube stays in place.

thingiverse

free

X-axis endstop offset for cr10 cr10s Ender 3

...x-axis endstop offset for cr10 cr10s ender 3

thingiverse

x-axis endstop offset for cr10 cr10s ender 3

thingiverse

free

Filament Sensor CR10

...to face directly the extruder and ptfe tube cr10, cr10s ...

thingiverse

free

Fan V4 CR10/CR10S Ender3 Versione 4 by creativesolutions-lab

...fan v4 cr10/cr10s ender3 versione 4 by creativesolutions-lab

thingiverse

fan v4 cr10/cr10s versione 4

thingiverse

free

CR10 Feet by Leighton417

...cr10 feet by leighton417

thingiverse

this is a cr10 feet for people who have short table width.

thingiverse

free

Dremel Attachment for CR10, Ender 3, Cr10s by Conn22_43

...verse

a bracket to hold a dremel onto any ender 3, cr10 bracket. i printed it in petg, but it can be made in any rigid material.

thingiverse

free

CR10S-Plus Hotend by scorpio_man30ro

...cr10s-plus hotend by scorpio_man30ro

thingiverse

cr10s-plus hotend

thingiverse

free

Leveling knob CR10 by JMJacques

...leveling knob cr10 by jmjacques

thingiverse

leveling knob cr10

thingiverse

free

Soporte Superior sensor filamento CR10 v2 - CR10 v3 by Guimir

...3 by guimir

thingiverse

soporte sensor de filamento guia superiror tipo cr10 v3 para convertir la cr10 v2 en extrusión directa.

thingiverse

free

Ultimate cr10/cr10s Bed Leveling Knob by neo42487

...so they remain where you set them indefinitely.

it s a remix of this piece https://www.thingiverse.com/thing:4743835 but for cr10

Hotend

thingiverse

free

hotend by fablab_lueneburg

...hotend by fablab_lueneburg

thingiverse

hotend model

thingiverse

free

Hotend for Graber

...hotend for graber

thingiverse

hotend complement pastes for graber printerhttps://youtu.be/0koxhnsuhdy

thingiverse

free

Hotend adapter by antaviana

...hotend adapter by antaviana

thingiverse

hotend adapter

thingiverse

free

hotend fan by mming1106

...hotend fan by mming1106

thingiverse

hotend fan

thingiverse

free

Hotend schema by ione

...hotend schema by ione

thingiverse

hotend project schema

thingiverse

free

Fabtotum XY Hotend holder for E3D Hotend

...s with integrated supports.

more for the project you can see here: https://kf-designs.com/2019/09/07/fabtotum-printer-conversion/

thingiverse

free

HotEnd Stand by onepointdiy

...tend, when you make your new hotend or repair your j-head or mg-plus hotend.

the hole of 16mm, please adjust using a reamer, etc.

thingiverse

free

fast magnetic hotend changer for Chimera Hotend by Draman

...chimera hotend !

and new basis (the hole from original is to small)

it is a remix form skimmy's fast magnetic hotend changer

thingiverse

free

Hotend Fan Adapter for MicroSwiss All Metal Hotend by jo_schi_man

...

thingiverse

little change for the hotend fan adapter to hold the microswiss all metal hotend (slightly longer and sharp edges).

thingiverse

free

Merlin Hotend by Alejanson

...merlin hotend by alejanson

thingiverse

this is a 1:1 drawing of the classic merlin hotend.

Duct

thingiverse

free

NACA Duct to 3inch Hose for duct & brakes

... & brakes

thingiverse

naca duct to 3inch hose for duct & brakes

as seen here:https://www.youtube.com/watch?v=nrv6kayzwkw

thingiverse

free

Donut duct

...donut duct

thingiverse

after breaking the original ducts, i developed my own, stronger

thingiverse

free

Duct-to-duct Adapter (4-inch to 6-inch)

...ry: 97.0 mm

outer diameter for 6inch duct entry: 156.0 mm

inner diameter for 6inch duct entry: 153.0 mm

enjoy printing!

curiousor

thingiverse

free

Fan Duct by JacobMakes

...fan duct by jacobmakes

thingiverse

a fan duct

thingiverse

free

Fan Duct by CodyG

...fan duct by codyg

thingiverse

fan duct

thingiverse

free

Fan Duct by CodyG

...fan duct by codyg

thingiverse

fan duct

thingiverse

free

5015 fan duct

...5015 fan duct

thingiverse

5015 fan duct

thingiverse

free

Duct Vortex V1

...duct vortex v1

thingiverse

duct vortex v1

thingiverse

free

ducted fan by LorenzjP

...ducted fan by lorenzjp

thingiverse

ducted fan assembly

thingiverse

free

Cable duct by prokazzza

...cable duct by prokazzza

thingiverse

cable duct for wire routing.

System

thingiverse

free

Coordinate system

...coordinate system

thingiverse

coordinate system

thingiverse

free

ACRO SYSTEMS DRAG CHAIN SYSTEM by dragonfire81m

...acro systems drag chain system by dragonfire81m

thingiverse

chain link mounting system for acro system openbuilds

thingiverse

free

Circulatory System

...circulatory system

thingiverse

made in a 3d design software

designed for students

circulatory system based on images

thingiverse

free

Clutch system

...clutch system

thingiverse

clutch system inspired from lego technics kit

print with default settings

thingiverse

free

Gear system test-Systeme d'engrenage Test by CPS007

...gear system test-systeme d'engrenage test by cps007

thingiverse

gear system test-systeme d'engrenage test

13cm7cm7cm

thingiverse

free

Pulley System by LeapFrog_3D

...pulley system by leapfrog_3d

thingiverse

pulley system

thingiverse

free

System Block by CryoShift

...system block by cryoshift

thingiverse

system block

thingiverse

free

System administrator by Diodmag

...system administrator by diodmag

thingiverse

system administrator, sculpting

thingiverse

free

L.A. Systems by Bjorn175

...l.a. systems by bjorn175

thingiverse

l.a. systems mold

thingiverse

free

Decken Montage-system

...decken montage-system

thingiverse

decken montage-system

Pro

thingiverse

free

Ender3 pro

...ender3 pro

thingiverse

a plastic cover for the ender3 pro power supply, 100% fit.

note: fits only on the ender3 pro.

thingiverse

free

sketchup pro by nagato

...sketchup pro by nagato

thingiverse

sketchup pro

thingiverse

free

sketchup pro by nagato

...sketchup pro by nagato

thingiverse

sketchup pro

thingiverse

free

sketchup pro by nagato

...sketchup pro by nagato

thingiverse

sketchup pro

thingiverse

free

sketchup pro by nagato

...sketchup pro by nagato

thingiverse

sketchup pro

thingiverse

free

sketchup pro by nagato

...sketchup pro by nagato

thingiverse

sketchup pro

thingiverse

free

sketchup pro by nagato

...sketchup pro by nagato

thingiverse

sketchup pro

thingiverse

free

sketchup pro by nagato

...sketchup pro by nagato

thingiverse

sketchup pro

thingiverse

free

sketchup pro by nagato

...sketchup pro by nagato

thingiverse

sketchup pro

thingiverse

free

sketchup pro by nagato

...sketchup pro by nagato

thingiverse

sketchup pro

Tool

thingiverse

free

Tool holder tool box

...tool holder tool box

thingiverse

!

thingiverse

free

Teng Tools tool set hinge

...teng tools tool set hinge

thingiverse

hinge for teng tools tool set.

thingiverse

free

Tool holder for 8mm lathe tools

... holder for 8mm lathe tools

thingiverse

tool holder for 8mm lathe tools.

there is 11 slots because i have 11 tools in my pack :)

thingiverse

free

Tool Holder for Small Tools by Darak_Chen

...tool holder for small tools by darak_chen

thingiverse

a little tool holder witch fits on you desk for small tools!

thingiverse

free

Tool Holder For various Tools by Nhcraig01

...tools by nhcraig01

thingiverse

this is just a simple tool holder for various tools i found useful for tinkering on a 3d printer.

thingiverse

free

Tool Box Tool Holder by FPVITALL

...tool box tool holder by fpvitall

thingiverse

a simple and spacesafing tool stand or desktop organizer

thingiverse

free

tools by kallik

...tools by kallik

thingiverse

tools

thingiverse

free

TOOLS by kallik

...tools by kallik

thingiverse

tools

thingiverse

free

TOOLS by kallik

...tools by kallik

thingiverse

tools

thingiverse

free

Tool by nagato

...tool by nagato

thingiverse

tool

Fan

thingiverse

free

Fan Duct 60mm fan

...fan duct 60mm fan

thingiverse

this a 60mm fan adaptor

thingiverse

free

Fan Stand 140mm Fan by Aron84

...fan stand 140mm fan by aron84

thingiverse

fan stand for 140x140x27mm fan

thingiverse

free

Fan wall for 40mm fan by Nule

...fan wall for 40mm fan by nule

thingiverse

fan aislator for 40mm fan with meshmixer support

thingiverse

free

Fan holder 40mm fan for V67

...n for v67

thingiverse

fan holder 40mm fan for v67

fan: https://www.amazon.de/dp/b07vhmv4dz/ref=cm_sw_r_other_apa_i_803cebwt8kvpe

thingiverse

free

Fan cover & fan grill to suit 50mm fan by Phil_Maddox

...fan cover & fan grill to suit 50mm fan by phil_maddox

thingiverse

simple fan cover for 50 x 50 x 10 fan

thingiverse

free

Fan grille for 50mm fan andE3D V6 Fan Duct for 50mm Fan V2 by vitaly12

...for 50mm fan ande3d v6 fan duct for 50mm fan v2https://www.thingiverse.com/thing:4662850

height:3.5mm

40mm fan grille coming soon

thingiverse

free

Fan Grid for 127mm Fan by MasterFX

...fan grid for 127mm fan by masterfx

thingiverse

just a simple fan grid for unusual 127mm fan

thingiverse

free

Fan Showdown fan submission by DAraymond

...fan showdown fan submission by daraymond

thingiverse

this is a fan i submitted for the youtube fan showdown series.

thingiverse

free

Fan Shroud

...fan shroud

thingiverse

this is a fan shroud for a 140mm fan

thingiverse

free

Mosaic Fan on Fan by bwevans

...a fan mount for the second fan that's included in the mosaic kit but is lacking any hardware. really useful for printing pla!

Change

thingiverse

free

Change

...change

thingiverse

"change"

thingiverse

free

Change Cup

...hingiverse

this is a change cup for my desk. can be used a pencil holder too.

used the spiralize outer contour in cura to print.

thingiverse

free

Change bin

...dicated place to store loose change, so designed this little bin. works great. i hope it can be useful for someone else as well.

thingiverse

free

Change Holder by Briare_hinton98

...change holder by briare_hinton98

thingiverse

change holder i designed for my cad class

thingiverse

free

Change Case by Ken579

...9

thingiverse

i need to have change on me for work because i park at meters a lot. so i made this little closeable change case.

thingiverse

free

Nozzle Change Tool

...nozzle change tool

thingiverse

a tool for changing nozzles. hex hole sized at 6.4 mm to allow for shrinkage.

thingiverse

free

Crystal Change Rod and Crystal Change Orbs

...four parts in order to get it to print on the lulzbot mini i was using. if you are interested in the split-up files, let me know!

thingiverse

free

Side Changing Snowflake by DOrtner01

...dortner01 thingiverse this is a snowflake that can easily change the number of sides or spokes by changing a...

thingiverse

free

Change Dish

... better luck with the priline rosewood pla. 2 perimeters, 4 layers top and bottom. 10 percent fill. support touching build plate.

thingiverse

free

Esther Chang by Afro-Punk

...esther chang by afro-punk

thingiverse

esther chang

Remix

thingiverse

free

Extruder Spinner Remix of Remix of Remix

...d

feel free to print or remix and don't forget to post it.

if you find it useful you can send tip or buy me a coffe. thanks.

thingiverse

free

Predator mask (remix of remix)

...predator mask (remix of remix)

thingiverse

just cool mask :)

thingiverse

free

REMIX by nbvgbbvv

...remix by nbvgbbvv

thingiverse

remix

thingiverse

free

remix by Alejandragr

...remix by alejandragr

thingiverse

remix

thingiverse

free

remixed by mkj

...remixed by mkj

thingiverse

this is remix comment

thingiverse

free

UK Remix of a Remix by ukcat

...for a big kentucky wildcats' fan birthday!

update 3/18/14: uploaded a version with the uk stuff, but no initials at bottom.

thingiverse

free

Remix Mystery

...remix mystery

thingiverse

this is for a class remix assignment.

thingiverse

free

Slight Remix of Tundra Remix by PyrOverkill

...pyroverkill

thingiverse

slight modification of the my remix of the bakflip handle. better resolution on the name plate and logo.

thingiverse

free

Arrowhead Remix

...arrowhead remix

thingiverse

remixing my og arrowhead

thingiverse

free

Remix Project

...remix project

thingiverse

this is my submission for the thingiverse remix project.