Thingiverse

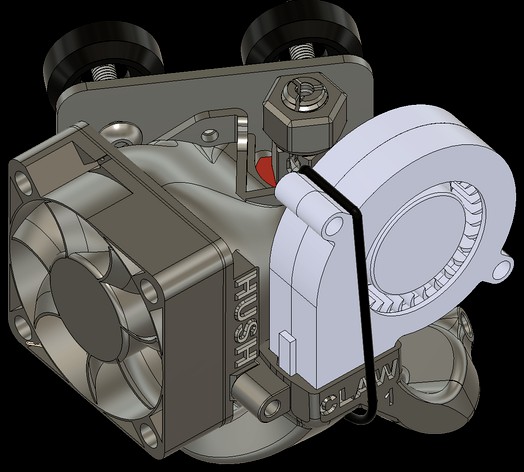

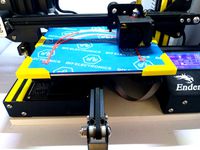

HUSH! Quiet cooler for Ender 2 / 3 / 3V2 by Mikael70

by Thingiverse

Last crawled date: 3 years, 3 months ago

Design goals:

Quiet!

Better part cooler

Better hotend cooling

Low weight

Easy access to nozzle

Good visibility of nozzle with LED

Compact

Modular

No supports

Compatible with my Direct Drive solution EDLhttps://www.thingiverse.com/thing:4642537

Design choices hotend cooler:

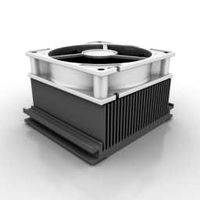

50x50x15mm axial fan + resistor (quiet)

Pressure booster (axial fan has low pressure)

Adjust fan speed to same or better performance as original

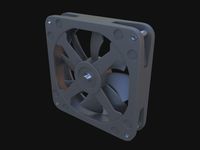

Design choices part cooler (Claw 1):

Single radial fan 5015

Cooling from two directions

CFD calculations with Simscale. Note that the flow from a radial fan is not pedicular to the fan outlet (~20 degrees) and the flow is much higher on one side. Water test was needed to balance flow in right and left channel.

Result:

Noise reduced 11dB!

Same hotend cooling performance as original (measured inside heat brake)

5015 can be removed in 2 sec (hold in place with elastic band)

Part cooler is mounted with two M3x12 screws.

Everything can be removed with the two original screws

Parts:

Gelid 5 (50x50x15) fan (spec 12.9CFM/4000rpm@12v)

Resistor hotend fan 36ohm (I used 18+18ohm on positive led)

JST XH 2.5-2 connectors (for connecting fan to motherboard). Check polarity of connector.

Hair rubber band for 5015

Two screw M3x12 2 for part cooler

Two 5 mm LED + resistor 330 ohm

Radial fan 5015

Note on material:

I used both PLA and ABS. ABS is recommended.

Part cooler in PLA may deform if part cooler fan is turned off. Aluminum tape might help.

Note on axil fan:

Actual voltage at HE fan with 2x18ohm was 8.6v and speed 3630rpm

Pressure booster on HE increased airflow ~8%

Spire 50x50x15 4800rpm@12v did not work well. Rattling noise when mounted on x-axis (bearings can’t handle vibrations from X stepper motor)

Gelid 5 (50x50x15) worked fine. Start duty cycle ~20%

Note on radial fan:

NoName 5015 fan didn’t sound good at any PWM speed than 0% or 100% so I changed Marlin firmware to software PWM.

Note on pressure booster:

The wings is only one wall thick so make sure to use "Print Thin Walls" in Cura.

How to measure static pressure: https://www.thingiverse.com/thing:4401775

2020-12-10: Minor update

Reinforcement at coupling moved (for more space)

Ender-3 V2 support added (not tested)

2020-12-12 update:

EZABL 18mm mount (and 12mm with EZABLMini_18mmAdapter) added on request (not tested).

Distance from nozzle x=43 y=-2

BLTouch v3.1 mount added on request (not tested).

Distance from nozzle x= 24 y= 3

Distance heater block to Bltouch side 7.5mm (to close?)

Quiet!

Better part cooler

Better hotend cooling

Low weight

Easy access to nozzle

Good visibility of nozzle with LED

Compact

Modular

No supports

Compatible with my Direct Drive solution EDLhttps://www.thingiverse.com/thing:4642537

Design choices hotend cooler:

50x50x15mm axial fan + resistor (quiet)

Pressure booster (axial fan has low pressure)

Adjust fan speed to same or better performance as original

Design choices part cooler (Claw 1):

Single radial fan 5015

Cooling from two directions

CFD calculations with Simscale. Note that the flow from a radial fan is not pedicular to the fan outlet (~20 degrees) and the flow is much higher on one side. Water test was needed to balance flow in right and left channel.

Result:

Noise reduced 11dB!

Same hotend cooling performance as original (measured inside heat brake)

5015 can be removed in 2 sec (hold in place with elastic band)

Part cooler is mounted with two M3x12 screws.

Everything can be removed with the two original screws

Parts:

Gelid 5 (50x50x15) fan (spec 12.9CFM/4000rpm@12v)

Resistor hotend fan 36ohm (I used 18+18ohm on positive led)

JST XH 2.5-2 connectors (for connecting fan to motherboard). Check polarity of connector.

Hair rubber band for 5015

Two screw M3x12 2 for part cooler

Two 5 mm LED + resistor 330 ohm

Radial fan 5015

Note on material:

I used both PLA and ABS. ABS is recommended.

Part cooler in PLA may deform if part cooler fan is turned off. Aluminum tape might help.

Note on axil fan:

Actual voltage at HE fan with 2x18ohm was 8.6v and speed 3630rpm

Pressure booster on HE increased airflow ~8%

Spire 50x50x15 4800rpm@12v did not work well. Rattling noise when mounted on x-axis (bearings can’t handle vibrations from X stepper motor)

Gelid 5 (50x50x15) worked fine. Start duty cycle ~20%

Note on radial fan:

NoName 5015 fan didn’t sound good at any PWM speed than 0% or 100% so I changed Marlin firmware to software PWM.

Note on pressure booster:

The wings is only one wall thick so make sure to use "Print Thin Walls" in Cura.

How to measure static pressure: https://www.thingiverse.com/thing:4401775

2020-12-10: Minor update

Reinforcement at coupling moved (for more space)

Ender-3 V2 support added (not tested)

2020-12-12 update:

EZABL 18mm mount (and 12mm with EZABLMini_18mmAdapter) added on request (not tested).

Distance from nozzle x=43 y=-2

BLTouch v3.1 mount added on request (not tested).

Distance from nozzle x= 24 y= 3

Distance heater block to Bltouch side 7.5mm (to close?)

Similar models

thingiverse

free

4010 5015 Hotend cooler for BMG / E3D V6

...tion from the two remixed authors to get a great hotend / part cooler for a standard v6 with a 4010 fan and a 5015 radial blower.

thingiverse

free

CR-10 / CR-10S Fan mount + BLTouch (PWM fan - 5015, 12V) by Genna1986

...0s fan mount + bltouch (pwm fan - 5015, 12v) by genna1986

thingiverse

fanmount for cr-10 / cr-10s + bltouch (pwm fan 5015, 12v)

thingiverse

free

Mini Hotend + BLTouch + Cooler Fan by karnhack

...dapter for effector. mini hotend + bltouch + cooler fan

this is a test: the bltouch is very close to hotend and can be damaged!!!

thingiverse

free

Universal Radial Fan 5015 for hotend by nirvana93

...radial fan 5015 for hotend by nirvana93

thingiverse

universal radial fan 5015 for hotend

you need m3 screws to mount the output

thingiverse

free

MutedVision Mashup Mount: CR10s, E3D V6 (With Stock Fan), 5015 Part Fan

...r -9 // y offset: -front +behind [the nozzle]

#define z_probe_offset_from_extruder -2 // z offset: -below +above [the nozzle]

thingiverse

free

OmniaDrop 5015 Adapter BLTouch Edition by Nusel

...module for super silent printing while still keeping the hotend cool.

the partcooler is a generic 24v fan. cooling is sufficient.

thingiverse

free

Diamond Hotend Fan Shroud by LHartmann

...diamond hotend fan shroud by lhartmann

thingiverse

part cooling fan mount and shroud for this mount, uses a 5015 radial fan.

thingiverse

free

e3d v6 extruder / print cooler both for 5015 radial fan by motosrac

...an duct for both the extruder fan and the layer cooling fan.

you can mount two 5015 radial fan to it.

this is for e3d v6 extruder

thingiverse

free

Sapphire Pro E3D V6 Volcano double 5015

...

m4x20 flat head x2 - for 5015 fan

unfortunately, the left fan should be secured with double-sided tape, so that it does not move

thingiverse

free

Ender 5 Plus Cooler - Only minimal modifications required by Dolugius

...rial

made the outlet walls thinner to get them a little further up

suggested fan guard: https://www.thingiverse.com/thing:4674297

Mikael70

thingiverse

free

PTFE Cable Clip 8mm by Mikael70

...ptfe cable clip 8mm by mikael70

thingiverse

orginal inside dia is 10mm. this one is 8mm.

thanks fiaskogaul for the original.

thingiverse

free

XL4015 DC-DC case by Mikael70

...ks yohabi for the idea.

3d model for xl4015 by dmytro shroamer:https://grabcad.com/library/xl4015-5a-dc-dc-cc-cv-buck-converter-1

thingiverse

free

Ethernet - RJ45 Secure clip, repair broken tab - remix by Mikael70

...emoved some material and added built in support (z=0.3).

update 2021-01-10: increased the cutout 0.5mm so it’s easier to install.

thingiverse

free

Eye Measuring Tool (IPD) for Quest 2 by Mikael70

...orrect after gluing. paper shrink and extend depending on moister.

i painted the arrow white on the eyefinder white with tipp-ex.

thingiverse

free

Ender-2 Bed leveling system by Mikael70

...r turn

each tick is 0.025mm

if the detent parts breaks because of poor layer adhesion then screw in a m3x8 screw as reinforcement

thingiverse

free

Drill / bit handle 1.5 - 6 mm total length 45mm by Mikael70

...cture but i doubt that i need them.

i noticed aynuz remix when i published this thing. i could just have used his part instead...

thingiverse

free

OctoPrint disconnect fix (SerialException) by Mikael70

...er, grym and gkar!

please leave a comment if you know more about this.

(i did this 2020-10-12 and it still works fine 2020-11-08)

thingiverse

free

Ender Direct Drive Light (EDL) by Mikael70

...e added to x-bar for stripes

tube cutter 1.0mm and 2.0mm removed. 1.5 mm is best.

removed fusion files. i can add them on request

Hush

3ddd

$1

Hush Chair from Naughtone

...hush chair from naughtone

3ddd

naughtone

hush chair from naughtone

turbosquid

$20

Herman Miller Hush Chair

...3d model herman miller hush chair for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1486684)

3ddd

$1

Neverending Glory

...like pavarotti’s closing vicerò from puccini’s aria, refusing to hush even years later… “we wanted to look at classical...

thingiverse

free

Batbomb (hush ver)

...batbomb (hush ver)

thingiverse

a bat bomb from the hush comics.

thingiverse

free

hush by speedtwin69

...hush by speedtwin69

thingiverse

i said i have an headache

3d_sky

free

Hush Chair from Naughtone

...hush chair from naughtone

3dsky

naughtone

hush chair from naughtone

thingiverse

free

Hush style batarang by aesrick

...hush style batarang by aesrick

thingiverse

batarang based on the hush batman version.

3dbaza

$4

Hush Low Armchair (137485)

... armchair (137485)

3dbaza

hush low armchair 3d model<br>dimensions width 72 cm depth 76 cm height 88 cm seat height 43 cm

sketchfab

$7

Greendesigngallery Hush Seating-Pod

...l density. element ids for easy shader customization - greendesigngallery hush seating-pod - buy royalty free 3d model by tmrwinc

3dbaza

$4

Naughtone Hush Sofa (138242)

...38242)

3dbaza

naughtone hush sofa 3d model<br>dimensions width 135 cm depth 76 cm height 88 cm<br>seat height 43 cm

3V2

thingiverse

free

ENDER 3V2 by DirksBastelbude

...ender 3v2 by dirksbastelbude

thingiverse

thingiverse

free

Display holder for Ender 3V2 by sveternik

...isplay holder for ender 3v2 by sveternik

thingiverse

this is holder for ender 3v2 display for mounting on iner side of box wall.

thingiverse

free

Ender-3v2 BLT Bracket by RedWhere2020

...2 blt bracket by redwhere2020

thingiverse

bltouch bracket for the ender-3v2. included 1mm packer.

allows for the x-axis endstop.

thingiverse

free

Ender 3v2 Filament hook by jason264235

...ender 3v2 filament hook by jason264235

thingiverse

this is a ender 3v2 indas wire hook

2020/11/08

add new version b

thingiverse

free

Ender 3v2 Switch cover by Fishing1969

...ender 3v2 switch cover by fishing1969

thingiverse

printed at 25% infill

thingiverse

free

Ender 3V2 bed leveling test by jakob_wieberneit

...ender 3v2 bed leveling test by jakob_wieberneit

thingiverse

thingiverse

free

Ender 3v2 screen cover by DMR11

...ender 3v2 screen cover by dmr11

thingiverse

this product is,designed to protect your screens.

thingiverse

free

Ender 3V2 Cable guide by Vonderwald

...ender 3v2 cable guide by vonderwald

thingiverse

cable guide to put under the extruder

thingiverse

free

Ender 3V2 LCD Cover with Ender Dragon by PhotoBud

...mplistic cover with extruded ender dragon and handle designed on fusion 360 to cover and protect the lcd screen of the ender 3v2.

thingiverse

free

Ender 3V2 Mount Direct Drive - BMG + E3D V6 + BLTouch by Chbko

...ender 3v2 mount direct drive - bmg + e3d v6 + bltouch by chbko

thingiverse

remixed to fit ender 3v2

Quiet

turbosquid

free

Quiet L.c4d

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Arketipo / Quiete

...rketipo , журнальный , круглый

www.arketipo.com

3d_export

$20

A Quiet Walkway 3D Model

...a quiet walkway 3d model

3dexport

room colums white quiet marble

a quiet walkway 3d model braproductions 6529 3dexport

turbosquid

$15

Leon quiet in Africa

...oyalty free 3d model leon quiet in africa for download as stl on turbosquid: 3d models for games, architecture, videos. (1303523)

3d_export

$8

Chinese style elegant and quiet yard landscape

...chinese style elegant and quiet yard landscape

3dexport

chinese style + elegant and quiet yard landscape

turbosquid

$5

Bernhardt Quiet Side Table

...t side table for download as max, max, 3ds, dwg, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1568821)

turbosquid

$5

Tonin Casa Quiet Coffee Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$9

Quiet and elegant natural art residential landscape SU model

...t and elegant natural art residential landscape su model

3dexport

quiet and elegant + natural art residential landscape su model

3d_export

$10

armchair roche bobois quiet life

...t

armchair roche bobois quiet life<br>formats:<br>3d max 2010<br>3d max 2011<br>3d max 2012<br>obj

3ddd

$1

Кресло roche bobois QUIET LIFE ARMCHAIR

...кресло roche bobois quiet life armchair

3ddd

roche bobois

roche bobois

Cooler

archibase_planet

free

Cooler

...hibase planet

wine-cooler wine cooler kitchen equipment

rk wine cooler uc - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cooler

...cooler

archibase planet

cooler

cooler seyedmms n271212 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cooler

...cooler

archibase planet

refrigerator cooler kitchen's technics

cooler - 3d model for interior 3d visualization.

archibase_planet

free

Cooler

...er

archibase planet

pc equipment cooler computer equipment

cooler n040908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cooler

...cooler

archibase planet

cooler cpu fan pc equipment

cooler asus n080211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Cooler

...cooler

3dexport

water cooler. program maya 2018. materials v-ray 3.6.

3d_export

$5

Juice cooler

...juice cooler

3dexport

juice cooler

turbosquid

$10

Cooler

...uid

royalty free 3d model cooler for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1478561)

turbosquid

$20

cooler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

cooler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Ender

3ddd

$1

Enders / Elegance

...enders / elegance

3ddd

обогреватель

уличный газовый обогреватель enders elegance

высота: 2200 мм

3d_export

free

ender 3 frame cavity covers

... of the creality ender 3 - makes it look a bit more attractive it just slides into the open channels of the aluminium framework

turbosquid

$1

pen support for ender 3

...y free 3d model pen support for ender 3 for download as blend on turbosquid: 3d models for games, architecture, videos. (1611282)

3d_ocean

$9

Ender Dragon Minecraft

...ojang obj poly videogames

ender dragon minecraft created with cinema 4d r15 formats included: max 2013 – fbx 2012 – c4d r15 – obj

3d_export

free

Creality ender enclosure webcam mount

...e creality enclosure. sure is better than a tripod. change it up if it helps. i printed pla with 50% infill on my dd ender 3 pro.

3d_export

free

ender 3 enclosure corners

...er corners and 4 upper corners, using 25mmx25mm angled aluminium pieces that gets covered on inside of the frame with plexiglass

3d_export

free

ender 3 3d print bed clips

...ed + normal aluminium bed frame of the creality ender 3 = 6mm (b) these clips are designed for glass plate + aluminium bed = 4mm

3d_export

$5

GRUMPY CAT

...grumpy cat 3dexport grumpy cat to print in ender ...

3d_export

$5

Logs fire

...with one multi material for corona and vray r ender. albedo, normal, uvmap, roughness format jpg 4096x4096 models:...

3d_export

$42

excavator

...is the original size. 0.12 mm printing surface creality ender5 ...

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$29

Books 150 pieces 3-3-3

...books 150 pieces 3-3-3 for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1384033)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$29

Book variation 2 2

...3d model book variation 2 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1366868)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур