Thingiverse

Huge Cheap Home CNC (#hchcnc) by Enic

by Thingiverse

Last crawled date: 3 years ago

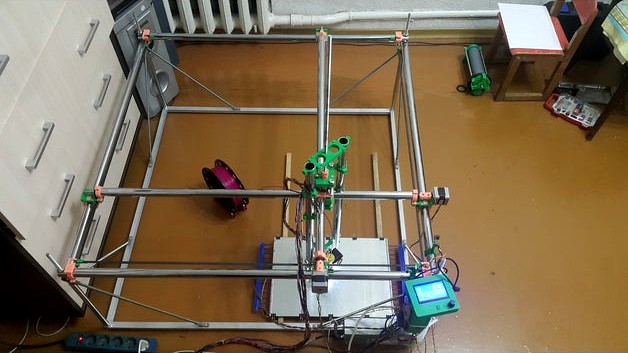

Project: Huge Cheap Home CNC (#hchcnc)

(continue of my Project: https://www.thingiverse.com/thing:2781630

some files listed can be found there)

The best guide for beginners: just start already ;-)

..and don't forget to press Like button ;-)

Design advantages:

Only 3 Steppers for XYZ

Strong construction (almost no plastic parts for frame and legs)

Small number of parts and parts types

Really small parts size, print time, filament amount

Small and cheap bollbearings

Less screws and nuts

Balanced Head Mount

Universal Head Mount

Mobility

Self designed hotbed from scratch

... ets.

Possibilities / features

New: MIG Welding !!!https://youtu.be/7JIfTCqgZAc

New: Foam cutting operationhttps://youtu.be/GZXX6x-DWQc

Foam Cutting Head: https://www.thingiverse.com/thing:3339841

3D Printing:https://youtu.be/j36U9geLij4https://youtu.be/kaJyCJsM_6M (all parts are visible here i hope ;-)

Laser Engravinghttps://youtu.be/N4sjGfpQQ8g

Drilling by Dremel 4300https://youtu.be/VoB-7SFKuH0

Wood Engraving by Dremel 4300https://youtu.be/m8kS548m90w

Wood Milling by Dremel 4300https://youtu.be/IL2M5LSuGdYhttps://youtu.be/nneKpp0wLkA

The Idea:

The Idea is based on

C-23.5mm OD https://www.thingiverse.com/thing:724999

F-25mm OD https://www.thingiverse.com/thing:790533

Borrowed parts, solutions and Thankses

Quick fit carriage systemhttps://www.thingiverse.com/thing:1670305

Thanks to Lukas https://www.thingiverse.com/lukie80/about

Dasaki Ramps 1.4 Enclosure / Box / Casehttps://www.thingiverse.com/thing:761806

Thanks to David Sanz Kirbis https://www.thingiverse.com/dasaki/about

Case for the Full Graphic Smart LCD Controllerhttps://www.thingiverse.com/thing:87250

Thanks to Michael Christou https://www.thingiverse.com/wersy/about

Parametric Z-axis coupler (stepper and threaded rod coupling) https://www.thingiverse.com/thing:1329750

Thanks to Lorenzo Aspesi https://www.thingiverse.com/aspesilorenzo/about

Printrbot Simple Metal GT2 Belt Cliphttps://www.thingiverse.com/thing:746423

Thanks to Spanner Hands https://www.thingiverse.com/SpannerHands/about

MiniDrill Mountingshttps://www.tinkercad.com/things/kVAEjzTXiO7#/

Thanks to Miguel Braidot https://www.thingiverse.com/mabraidot/about

TUSH - The Ultimate Spool Holderhttps://www.thingiverse.com/thing:2047554

Thanks to Vassil Gounev https://www.thingiverse.com/filamentry/about

UPGRADING YOUR RAMPS WITH HIGH POWER COMPONENTShttp://www.instructables.com/id/Upgrading-Your-RAMPS-With-High-Power-Components/

Thanks to AndJoeG http://www.instructables.com/member/AndJoeG/

INCREASING VOLTAGE SERVER SWITCHED POWER SUPPLYhttps://pa0fri.home.xs4all.nl/Diversen/DPS-800GB%20A%20Server%20sypply/DPS-800GB%20A%20PSU%20eng.htm

Thanks to Frits, PAØFRI https://pa0fri.home.xs4all.nl/

The DESIGN & CONSTRUCTION

All parts design was made by myself from scratch with OpenSCAD.

Designed Parts (0x04..0x19):

Part 04: 3xBearing_Ring

cnc_laser_04_3xBearing_Ring.scad

cnc_laser_04_3xBearing_Ring.stl

Quantity: 12 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 30 min Weight: 4.45 g Length 1.75: 1480.6mm

Purpose: Main housing for MR83ZZ bearing to slide over d25 tubes

Assemble guide: Push 3 x MR83ZZ bearing into the holes, fix with M3 screw and nut gently. Put 2x on every of 6x d25 1 meter tubes.

Part 05: hole_helper (not a permanent part, used only during building)

cnc_laser_05_hole_helper.scad

cnc_laser_05_hole_helper.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 15 min Weight: 2.41 g Length 1.75: 802.1mm

Purpose: To achieve exactly parallel holes on both ends of a tubes

Assemble guide: Measure and cut d25 tube first. Fit 2 hole helpers on the both ends of the tube. The end of each tube shuld exectly match with hole helper. Put a tube an a horizontal surface. Drill first upper hole with 2mm drill. Insert a short 2mm nail in a hole (don’t remove hole helper). Drill the second upper hole on another end of a tube. Insert a short 2mm nail in a hole (don’t remove hole helper). Accuratly turn the tube upside down and drill both end bottom holes (currently they are on the top) with 2mm drill. Remove both nails. Remove both hole helpers. Drill a holes smoothly increasing drill sizes until you got ~10.5mm holes.

Part 06: BaseGasket

cnc_laser_06_BaseGasket.scad

cnc_laser_06_BaseGasket.stl

Quantity: 4 pcs

Params/1: Supports: No Layer: 0.2 Infill 100% Time: 1 min Weight: 0.09 g Length 1.75: 31.5mm

Purpose: To fill clearance between aluminum u-profiles of the base

Assemble guide: Сombine a holes in an aluminum u-profiles of a base, insert gasket and then insert M10 threaded rod from top. Fix with M10 nut from bottom.

Part 07: FixtureRing

cnc_laser_07_FixtureRing.scad

cnc_laser_07_FixtureRing.stl

Quantity: 8 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 31 min Weight: 5.00 g Length 1.75: 1661.8mm

Purpose: 1)To fix 2 moving tubes and 2) fix rubber belts

Assemble guide: 1) Fix 4 pcs to StepperFrame_v3a (after complete assemble of GuideRoller_v3 and Stepper fixture) with M3 screws and nuts then fix to the tube with upper holes M3 screw and nut. 2) Fix to the front and back tubes near each end with upper holes M3 screw and nut.

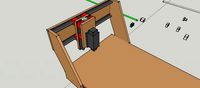

Part 08: StepperFrame

cnc_laser_08_StepperFrame_v3a.gcode

cnc_laser_08_StepperFrame_v3a.scad

cnc_laser_08_StepperFrame_v3a.stl

Quantity: 4 pcs

Params/1: Supports: Yes, Brim: Yes (included in provided .gcode file) Layer: 0.2 Infill 20% Time: 57 min Weight: 10.12 g Length 1.75: 3366.2mm

Purpose: To fix steppers and free ends of moving tubes

Assemble guide: Insert assembled GuideRoller_v3 screws. Fix stepper on stepper end only. Fix FixtureRing.

Part 09: GuideRoller

cnc_laser_09_GuideRoller_v3.scad

cnc_laser_09_GuideRoller_v3.stl

Quantity: 8 pcs

Params/1: Supports: No Layer: 0.15 Infill 100% Time: 14 min Weight: 0.37 g Length 1.75: 123.2mm

Purpose: To hold and guide a belts to GT2 timing pulley

Assemble guide: Fix a MR83ZZ bearing on a 32mm M3 screw with two M3 nuts. Push GuideRoller on a MR83ZZ bearing gently until stop. Insert two assembled Rollers into StepperFrame_v3a according a picture provided.

Part 0A: FixtureFrame

cnc_laser_0A_FixtureFrame.scad

cnc_laser_0A_FixtureFrame.stl

Quantity: 12 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 13 min Weight: 2.25 g Length 1.75: 746.9mm

Purpose: 1)To fix a space between each pair of 3xBearing_Rings on a static tubes 2) To hold ends of front and back rubber belts.

Assemble guide: 1)Attach two of FixtureFrame to the both bottom MR83ZZ bearing “ears” of the 3xBearing_Rings on a static tubes.2) Push FixtureFrame on the top of each FixtureRing on a ends of front and back static tubes.

Part 0B: HeadPlate (middle)

cnc_laser_0B_HeadPlate.scad

cnc_laser_0B_HeadPlate.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 1h 9 min Weight: 11.22 g Length 1.75: 3730.5 mm

Purpose: Head middle plate.

Assemble guide: Insert 4 M8 threaded rods into the bottom HeadPlate. Collect all 4 3xBearing_Ring symmetrically add four HeadFixers (two 2a and two 2b). Insert M8 threaded rods of bottom plate into four HeadFixers holes from bottom. Attach middle HeadPlate and then top the top. Fix with M8 nuts from both sides. Look at the pictures provided.

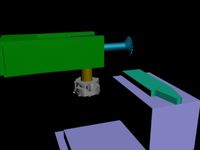

Part 0C: LaserMount

cnc_laser_0C_LaserMount.scad

cnc_laser_0C_LaserMount.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 1h 26 min Weight: 14.31 g Length 1.75: 4760.7 mm

Purpose: Mount Laser on a Head.

Assemble guide: Attach Laser with M3 screws. Attach LaserMount on two diagonal M8 threaded rods and fix with M8 nuts.

Part 0D: OptSensorFixture

cnc_laser_0D_OptSensorFixture.scad

cnc_laser_0D_OptSensorFixture.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 27 min Weight: 2.87 g Length 1.75: 953.9 mm

Purpose: Mount Optical Endstop Sensor to M10 threaded rod.

Assemble guide: Attach Sensor with M3 screw and nut. Attach OptSensorFixture to the M10 threaded rod with two M10 nuts. According to the picture.

Part 0E: OptSensorFlag

cnc_laser_0E_OptSensorFlag.scad

cnc_laser_0E_OptSensorFlag.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 7 min Weight: 0.40 g Length 1.75: 133.1 mm

Purpose: Cover IR beam of Optical Endstop sensors.

Assemble guide: Paint with black nail polish from both sides! Attach to Stepper with M3 screw Adjust to be in a middle of Optical Sensor in a zero position.

Part 0F: HeadFixer

cnc_laser_0F_HeadFixer_v2a.scad

cnc_laser_0F_HeadFixer_v2a.stl

cnc_laser_0F_HeadFixer_v2b.scad

cnc_laser_0F_HeadFixer_v2b.stl

Quantity: 4 pcs (2a + 2b)

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 35 min Weight: 5.89 g Length 1.75: 1958.3 mm

Purpose: Fix .four 3xBearing_Rings together

Assemble guide: Insert 4 M8 threaded rods into the bottom HeadPlate. Collect all 4 3xBearing_Ring symmetrically add four HeadFixers (two 2a and two 2b). Insert M8 threaded rods of bottom plate into four HeadFixers holes from bottom. Attach top HeadPlate on the top. Fix with M8 nuts from both sides. Look at the pictures provided.

Part 10: StepperPlate (top)

cnc_laser_10_StepperPlate1.scad

cnc_laser_10_StepperPlate1.stl

Quantity: 1 pcs

Purpose: Fix Z-axis Stepper

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 1h 45 min Weight: 26.43 g Length 1.75: 8789.2 mm

Assemble guide: Attach Z-axis Stepper with 4 M3 screews. Insert 4 M8 threaded rods into the bottom HeadPlate. Collect all 4 3xBearing_Ring symmetrically add four HeadFixers (two 2a and two 2b). Insert M8 threaded rods of bottom plate into four HeadFixers holes from bottom. Attach middle HeadPlate and then top the top. Fix with M8 nuts from both sides. Look at the pictures provided.

Part 11: HeadPlate_Bottom

cnc_laser_11_HeadPlate_Bottom.scad

cnc_laser_11_HeadPlate_Bottom.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 2h 34 min Weight: 33.35 g Length 1.75: 11092.4 mm

Assemble guide: Insert 4 M8 threaded rods into the bottom HeadPlate. Collect all 4 3xBearing_Ring symmetrically add four HeadFixers (two 2a and two 2b). Insert M8 threaded rods of bottom plate into four HeadFixers holes from bottom. Attach middle HeadPlate and then top the top. Fix with M8 nuts from both sides. Look at the pictures provided.

Part 12: Z_Plate

cnc_laser_12_Z_Plate.scad

cnc_laser_12_Z_Plate.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 1h 4 min Weight: 15.70 g Length 1.75: 5220.5 mm

Assemble guide: Insert M8 nut in a hole. Wind on Z-axis threaded rod. Fit tight on Z-axis d25 tubes with 4x M3 nuts and 4x M3 screws.

Part 13: SplittedFixture (for optical X,Y endstop sensors)

cnc_laser_13_SplittedFixture.scad

cnc_laser_13_SplittedFixture.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 26 min Weight: 5.76 g Length 1.75: 1917.3 mm

Assemble guide: Insert 2 x M3 nuts in a holes. Put parts from both sides of d25 tube near 0.0 by XY coords and fix with 2 x M3 screws. Attach optical endstop sensor.

Part 14: EndStopZ (fixture for Z Endstop)

cnc_laser_14_EndStopZ.scad

cnc_laser_14_EndStopZ.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 11 min Weight: 0.81 g Length 1.75: 269.0 mm

Assemble guide: use one of Z stepper screw to fix EndStopZ holder. Attach Z Endstop Optical sensor with m3 screw and nut. Use a piece of insulation tape to prevent electrical contacts.

Part 15: SpindleFixture (Optional: to fix custom 12v motor spindle)

cnc_laser_15_SpindleFixture.scad

cnc_laser_15_SpindleFixture.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 31 min Weight: 6.79 g Length 1.75: 2258.4 mm

Part 16: DremelFlexibleFixture (Optional: to fix Dremel flex shaft)

cnc_laser_16_DremelFlexibleFixture.scad

cnc_laser_16_DremelFlexibleFixture.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 17 min Weight: 3.43 g Length 1.75: 1141.8 mm

Assemble guide: Attach to the custom plate from "Quick fit carriage system" with pair of M3 screws and nuts

Part 17: marker (Optional: to fix pencil or marker)

cnc_laser_17_marker.scad

cnc_laser_17_marker.stl

Quantity: 1 pcs (3 sizes)

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 9 min Weight: 1.74 g Length 1.75: 579.7 mm

Assemble guide: use acetone as a glue to glue to the custom plate from "Quick fit carriage system"

Part 18.3: coupler3 top M10 to 2x M8 threaded rod ridgepole fixtures

cnc_laser_18_coupler3_ok.scad

cnc_laser_18_coupler3.stl

Quantity: 4 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 22 min Weight: 3.04 g Length 1.75: 1010.8 mm

Assemble guide: cut the internal thread with a tap on M8. Screw M8 threaded rod into 18.3 on the top and 18.4 at the bottom. Drill a M3 hole in the base in place. Fix with M3 screw and nut.

Part 18.4: coupler4 bottom M8 threaded rod ridgepole fixtures

cnc_laser_18_coupler4.scad

cnc_laser_18_coupler4.stl

Quantity: 8 pcs

Params/1: Supports: Yes Layer: 0.2 Infill 20% Time: 23 min Weight: 2.77 g Length 1.75: 922.6 mm

Assemble guide: cut the internal thread with a tap on M8. Screw M8 threaded rod into 18.3 on the top and 18.4 at the bottom. Drill a M3 hole in the base in place. Fix with M3 screw and nut.

Part 19: heated_table_connector_strip1

cnc_laser_19_heated_table_connector_strip1.scad

cnc_laser_19_heated_table_connector_strip1.stl

Quantity: 4 pcs

Params/1: Supports: Yes Layer: 0.2 Infill 20% Time: 31 min Weight: 5.89 g Length 1.75: 1959.1 mm

Assemble guide: Use a kitchen cutting board from strained glass. Remove a picture with hot air gun. (Don't remove glue). Attach to 1-1.2 mm alluminium plate. Cover alluminium with 2-3 layers of captone tape. Use nichrome wires. Look at a pictures for detailes ;-)

Firmware:

Marlin_1.1.8_Configuration.zip - My Configuration files for Marlin Firmware

Laser PWM control is attached to D6 at Servos ramps 1.4 connector.

Laser power is controlled by:

M3 Sxxx - Laser On: xxx=0..255, 255 - max

M5 - Laser Off

Test code:

PowerTestCode.zip - Code to generate Laser power test .gcode files (windows)

TestGcode.zip - Test files to start with

CAM Software Used:

Laser GRBL 2.8.35: Vectorize mode only (without filling).

Postprocess:

Replace:

"M5 S255" -> "M3 S0"

"M3" -> "M3 S255"

"M5" -> "M3 S0"

Rename: .nc -> .gcode

Av's SVG to GCODE v 1.2.6

Preprocess:

check initial svg units (Marlin works in mm only):

Replace 'width="4in" height="3in"'

(continue of my Project: https://www.thingiverse.com/thing:2781630

some files listed can be found there)

The best guide for beginners: just start already ;-)

..and don't forget to press Like button ;-)

Design advantages:

Only 3 Steppers for XYZ

Strong construction (almost no plastic parts for frame and legs)

Small number of parts and parts types

Really small parts size, print time, filament amount

Small and cheap bollbearings

Less screws and nuts

Balanced Head Mount

Universal Head Mount

Mobility

Self designed hotbed from scratch

... ets.

Possibilities / features

New: MIG Welding !!!https://youtu.be/7JIfTCqgZAc

New: Foam cutting operationhttps://youtu.be/GZXX6x-DWQc

Foam Cutting Head: https://www.thingiverse.com/thing:3339841

3D Printing:https://youtu.be/j36U9geLij4https://youtu.be/kaJyCJsM_6M (all parts are visible here i hope ;-)

Laser Engravinghttps://youtu.be/N4sjGfpQQ8g

Drilling by Dremel 4300https://youtu.be/VoB-7SFKuH0

Wood Engraving by Dremel 4300https://youtu.be/m8kS548m90w

Wood Milling by Dremel 4300https://youtu.be/IL2M5LSuGdYhttps://youtu.be/nneKpp0wLkA

The Idea:

The Idea is based on

C-23.5mm OD https://www.thingiverse.com/thing:724999

F-25mm OD https://www.thingiverse.com/thing:790533

Borrowed parts, solutions and Thankses

Quick fit carriage systemhttps://www.thingiverse.com/thing:1670305

Thanks to Lukas https://www.thingiverse.com/lukie80/about

Dasaki Ramps 1.4 Enclosure / Box / Casehttps://www.thingiverse.com/thing:761806

Thanks to David Sanz Kirbis https://www.thingiverse.com/dasaki/about

Case for the Full Graphic Smart LCD Controllerhttps://www.thingiverse.com/thing:87250

Thanks to Michael Christou https://www.thingiverse.com/wersy/about

Parametric Z-axis coupler (stepper and threaded rod coupling) https://www.thingiverse.com/thing:1329750

Thanks to Lorenzo Aspesi https://www.thingiverse.com/aspesilorenzo/about

Printrbot Simple Metal GT2 Belt Cliphttps://www.thingiverse.com/thing:746423

Thanks to Spanner Hands https://www.thingiverse.com/SpannerHands/about

MiniDrill Mountingshttps://www.tinkercad.com/things/kVAEjzTXiO7#/

Thanks to Miguel Braidot https://www.thingiverse.com/mabraidot/about

TUSH - The Ultimate Spool Holderhttps://www.thingiverse.com/thing:2047554

Thanks to Vassil Gounev https://www.thingiverse.com/filamentry/about

UPGRADING YOUR RAMPS WITH HIGH POWER COMPONENTShttp://www.instructables.com/id/Upgrading-Your-RAMPS-With-High-Power-Components/

Thanks to AndJoeG http://www.instructables.com/member/AndJoeG/

INCREASING VOLTAGE SERVER SWITCHED POWER SUPPLYhttps://pa0fri.home.xs4all.nl/Diversen/DPS-800GB%20A%20Server%20sypply/DPS-800GB%20A%20PSU%20eng.htm

Thanks to Frits, PAØFRI https://pa0fri.home.xs4all.nl/

The DESIGN & CONSTRUCTION

All parts design was made by myself from scratch with OpenSCAD.

Designed Parts (0x04..0x19):

Part 04: 3xBearing_Ring

cnc_laser_04_3xBearing_Ring.scad

cnc_laser_04_3xBearing_Ring.stl

Quantity: 12 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 30 min Weight: 4.45 g Length 1.75: 1480.6mm

Purpose: Main housing for MR83ZZ bearing to slide over d25 tubes

Assemble guide: Push 3 x MR83ZZ bearing into the holes, fix with M3 screw and nut gently. Put 2x on every of 6x d25 1 meter tubes.

Part 05: hole_helper (not a permanent part, used only during building)

cnc_laser_05_hole_helper.scad

cnc_laser_05_hole_helper.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 15 min Weight: 2.41 g Length 1.75: 802.1mm

Purpose: To achieve exactly parallel holes on both ends of a tubes

Assemble guide: Measure and cut d25 tube first. Fit 2 hole helpers on the both ends of the tube. The end of each tube shuld exectly match with hole helper. Put a tube an a horizontal surface. Drill first upper hole with 2mm drill. Insert a short 2mm nail in a hole (don’t remove hole helper). Drill the second upper hole on another end of a tube. Insert a short 2mm nail in a hole (don’t remove hole helper). Accuratly turn the tube upside down and drill both end bottom holes (currently they are on the top) with 2mm drill. Remove both nails. Remove both hole helpers. Drill a holes smoothly increasing drill sizes until you got ~10.5mm holes.

Part 06: BaseGasket

cnc_laser_06_BaseGasket.scad

cnc_laser_06_BaseGasket.stl

Quantity: 4 pcs

Params/1: Supports: No Layer: 0.2 Infill 100% Time: 1 min Weight: 0.09 g Length 1.75: 31.5mm

Purpose: To fill clearance between aluminum u-profiles of the base

Assemble guide: Сombine a holes in an aluminum u-profiles of a base, insert gasket and then insert M10 threaded rod from top. Fix with M10 nut from bottom.

Part 07: FixtureRing

cnc_laser_07_FixtureRing.scad

cnc_laser_07_FixtureRing.stl

Quantity: 8 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 31 min Weight: 5.00 g Length 1.75: 1661.8mm

Purpose: 1)To fix 2 moving tubes and 2) fix rubber belts

Assemble guide: 1) Fix 4 pcs to StepperFrame_v3a (after complete assemble of GuideRoller_v3 and Stepper fixture) with M3 screws and nuts then fix to the tube with upper holes M3 screw and nut. 2) Fix to the front and back tubes near each end with upper holes M3 screw and nut.

Part 08: StepperFrame

cnc_laser_08_StepperFrame_v3a.gcode

cnc_laser_08_StepperFrame_v3a.scad

cnc_laser_08_StepperFrame_v3a.stl

Quantity: 4 pcs

Params/1: Supports: Yes, Brim: Yes (included in provided .gcode file) Layer: 0.2 Infill 20% Time: 57 min Weight: 10.12 g Length 1.75: 3366.2mm

Purpose: To fix steppers and free ends of moving tubes

Assemble guide: Insert assembled GuideRoller_v3 screws. Fix stepper on stepper end only. Fix FixtureRing.

Part 09: GuideRoller

cnc_laser_09_GuideRoller_v3.scad

cnc_laser_09_GuideRoller_v3.stl

Quantity: 8 pcs

Params/1: Supports: No Layer: 0.15 Infill 100% Time: 14 min Weight: 0.37 g Length 1.75: 123.2mm

Purpose: To hold and guide a belts to GT2 timing pulley

Assemble guide: Fix a MR83ZZ bearing on a 32mm M3 screw with two M3 nuts. Push GuideRoller on a MR83ZZ bearing gently until stop. Insert two assembled Rollers into StepperFrame_v3a according a picture provided.

Part 0A: FixtureFrame

cnc_laser_0A_FixtureFrame.scad

cnc_laser_0A_FixtureFrame.stl

Quantity: 12 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 13 min Weight: 2.25 g Length 1.75: 746.9mm

Purpose: 1)To fix a space between each pair of 3xBearing_Rings on a static tubes 2) To hold ends of front and back rubber belts.

Assemble guide: 1)Attach two of FixtureFrame to the both bottom MR83ZZ bearing “ears” of the 3xBearing_Rings on a static tubes.2) Push FixtureFrame on the top of each FixtureRing on a ends of front and back static tubes.

Part 0B: HeadPlate (middle)

cnc_laser_0B_HeadPlate.scad

cnc_laser_0B_HeadPlate.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 1h 9 min Weight: 11.22 g Length 1.75: 3730.5 mm

Purpose: Head middle plate.

Assemble guide: Insert 4 M8 threaded rods into the bottom HeadPlate. Collect all 4 3xBearing_Ring symmetrically add four HeadFixers (two 2a and two 2b). Insert M8 threaded rods of bottom plate into four HeadFixers holes from bottom. Attach middle HeadPlate and then top the top. Fix with M8 nuts from both sides. Look at the pictures provided.

Part 0C: LaserMount

cnc_laser_0C_LaserMount.scad

cnc_laser_0C_LaserMount.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 1h 26 min Weight: 14.31 g Length 1.75: 4760.7 mm

Purpose: Mount Laser on a Head.

Assemble guide: Attach Laser with M3 screws. Attach LaserMount on two diagonal M8 threaded rods and fix with M8 nuts.

Part 0D: OptSensorFixture

cnc_laser_0D_OptSensorFixture.scad

cnc_laser_0D_OptSensorFixture.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 27 min Weight: 2.87 g Length 1.75: 953.9 mm

Purpose: Mount Optical Endstop Sensor to M10 threaded rod.

Assemble guide: Attach Sensor with M3 screw and nut. Attach OptSensorFixture to the M10 threaded rod with two M10 nuts. According to the picture.

Part 0E: OptSensorFlag

cnc_laser_0E_OptSensorFlag.scad

cnc_laser_0E_OptSensorFlag.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 7 min Weight: 0.40 g Length 1.75: 133.1 mm

Purpose: Cover IR beam of Optical Endstop sensors.

Assemble guide: Paint with black nail polish from both sides! Attach to Stepper with M3 screw Adjust to be in a middle of Optical Sensor in a zero position.

Part 0F: HeadFixer

cnc_laser_0F_HeadFixer_v2a.scad

cnc_laser_0F_HeadFixer_v2a.stl

cnc_laser_0F_HeadFixer_v2b.scad

cnc_laser_0F_HeadFixer_v2b.stl

Quantity: 4 pcs (2a + 2b)

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 35 min Weight: 5.89 g Length 1.75: 1958.3 mm

Purpose: Fix .four 3xBearing_Rings together

Assemble guide: Insert 4 M8 threaded rods into the bottom HeadPlate. Collect all 4 3xBearing_Ring symmetrically add four HeadFixers (two 2a and two 2b). Insert M8 threaded rods of bottom plate into four HeadFixers holes from bottom. Attach top HeadPlate on the top. Fix with M8 nuts from both sides. Look at the pictures provided.

Part 10: StepperPlate (top)

cnc_laser_10_StepperPlate1.scad

cnc_laser_10_StepperPlate1.stl

Quantity: 1 pcs

Purpose: Fix Z-axis Stepper

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 1h 45 min Weight: 26.43 g Length 1.75: 8789.2 mm

Assemble guide: Attach Z-axis Stepper with 4 M3 screews. Insert 4 M8 threaded rods into the bottom HeadPlate. Collect all 4 3xBearing_Ring symmetrically add four HeadFixers (two 2a and two 2b). Insert M8 threaded rods of bottom plate into four HeadFixers holes from bottom. Attach middle HeadPlate and then top the top. Fix with M8 nuts from both sides. Look at the pictures provided.

Part 11: HeadPlate_Bottom

cnc_laser_11_HeadPlate_Bottom.scad

cnc_laser_11_HeadPlate_Bottom.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 2h 34 min Weight: 33.35 g Length 1.75: 11092.4 mm

Assemble guide: Insert 4 M8 threaded rods into the bottom HeadPlate. Collect all 4 3xBearing_Ring symmetrically add four HeadFixers (two 2a and two 2b). Insert M8 threaded rods of bottom plate into four HeadFixers holes from bottom. Attach middle HeadPlate and then top the top. Fix with M8 nuts from both sides. Look at the pictures provided.

Part 12: Z_Plate

cnc_laser_12_Z_Plate.scad

cnc_laser_12_Z_Plate.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 1h 4 min Weight: 15.70 g Length 1.75: 5220.5 mm

Assemble guide: Insert M8 nut in a hole. Wind on Z-axis threaded rod. Fit tight on Z-axis d25 tubes with 4x M3 nuts and 4x M3 screws.

Part 13: SplittedFixture (for optical X,Y endstop sensors)

cnc_laser_13_SplittedFixture.scad

cnc_laser_13_SplittedFixture.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 26 min Weight: 5.76 g Length 1.75: 1917.3 mm

Assemble guide: Insert 2 x M3 nuts in a holes. Put parts from both sides of d25 tube near 0.0 by XY coords and fix with 2 x M3 screws. Attach optical endstop sensor.

Part 14: EndStopZ (fixture for Z Endstop)

cnc_laser_14_EndStopZ.scad

cnc_laser_14_EndStopZ.stl

Quantity: 1 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 11 min Weight: 0.81 g Length 1.75: 269.0 mm

Assemble guide: use one of Z stepper screw to fix EndStopZ holder. Attach Z Endstop Optical sensor with m3 screw and nut. Use a piece of insulation tape to prevent electrical contacts.

Part 15: SpindleFixture (Optional: to fix custom 12v motor spindle)

cnc_laser_15_SpindleFixture.scad

cnc_laser_15_SpindleFixture.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 31 min Weight: 6.79 g Length 1.75: 2258.4 mm

Part 16: DremelFlexibleFixture (Optional: to fix Dremel flex shaft)

cnc_laser_16_DremelFlexibleFixture.scad

cnc_laser_16_DremelFlexibleFixture.stl

Quantity: 2 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 17 min Weight: 3.43 g Length 1.75: 1141.8 mm

Assemble guide: Attach to the custom plate from "Quick fit carriage system" with pair of M3 screws and nuts

Part 17: marker (Optional: to fix pencil or marker)

cnc_laser_17_marker.scad

cnc_laser_17_marker.stl

Quantity: 1 pcs (3 sizes)

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 9 min Weight: 1.74 g Length 1.75: 579.7 mm

Assemble guide: use acetone as a glue to glue to the custom plate from "Quick fit carriage system"

Part 18.3: coupler3 top M10 to 2x M8 threaded rod ridgepole fixtures

cnc_laser_18_coupler3_ok.scad

cnc_laser_18_coupler3.stl

Quantity: 4 pcs

Params/1: Supports: No Layer: 0.2 Infill 20% Time: 22 min Weight: 3.04 g Length 1.75: 1010.8 mm

Assemble guide: cut the internal thread with a tap on M8. Screw M8 threaded rod into 18.3 on the top and 18.4 at the bottom. Drill a M3 hole in the base in place. Fix with M3 screw and nut.

Part 18.4: coupler4 bottom M8 threaded rod ridgepole fixtures

cnc_laser_18_coupler4.scad

cnc_laser_18_coupler4.stl

Quantity: 8 pcs

Params/1: Supports: Yes Layer: 0.2 Infill 20% Time: 23 min Weight: 2.77 g Length 1.75: 922.6 mm

Assemble guide: cut the internal thread with a tap on M8. Screw M8 threaded rod into 18.3 on the top and 18.4 at the bottom. Drill a M3 hole in the base in place. Fix with M3 screw and nut.

Part 19: heated_table_connector_strip1

cnc_laser_19_heated_table_connector_strip1.scad

cnc_laser_19_heated_table_connector_strip1.stl

Quantity: 4 pcs

Params/1: Supports: Yes Layer: 0.2 Infill 20% Time: 31 min Weight: 5.89 g Length 1.75: 1959.1 mm

Assemble guide: Use a kitchen cutting board from strained glass. Remove a picture with hot air gun. (Don't remove glue). Attach to 1-1.2 mm alluminium plate. Cover alluminium with 2-3 layers of captone tape. Use nichrome wires. Look at a pictures for detailes ;-)

Firmware:

Marlin_1.1.8_Configuration.zip - My Configuration files for Marlin Firmware

Laser PWM control is attached to D6 at Servos ramps 1.4 connector.

Laser power is controlled by:

M3 Sxxx - Laser On: xxx=0..255, 255 - max

M5 - Laser Off

Test code:

PowerTestCode.zip - Code to generate Laser power test .gcode files (windows)

TestGcode.zip - Test files to start with

CAM Software Used:

Laser GRBL 2.8.35: Vectorize mode only (without filling).

Postprocess:

Replace:

"M5 S255" -> "M3 S0"

"M3" -> "M3 S255"

"M5" -> "M3 S0"

Rename: .nc -> .gcode

Av's SVG to GCODE v 1.2.6

Preprocess:

check initial svg units (Marlin works in mm only):

Replace 'width="4in" height="3in"'

Similar models

thingiverse

free

Just Another One Mostly Printed CNC (jaoMPCNC). Laser engraver cutter XY 1m x 1m x 0.5m d25 version. by Enic

...0 pcs ) abec-5 skate stroller miniature 608 zz ball bearings 608z 608 2z bearing https://www.aliexpress.com/item/*/549643998.html

thingiverse

free

Articulated arm by mroc

...figured it'd be fun to try to make something similar by 3d printing. i made three different versions with...

thingiverse

free

Prusa i3 Hephestos on M8 Threaded Rods by 3DIYOriginal

...al prusa i3 hephestos modified for m8 threaded rods with reinforced long m8 nut.

the m8 nut is the one in the picture.

enjoy !!!

thingiverse

free

![{[Fast Print]} Fillament Spool Holder with 608zz and M8 rod by mr2clean](/t/8983894.jpg)

{[Fast Print]} Fillament Spool Holder with 608zz and M8 rod by mr2clean

... placed on the back of my chassi.

but for now i am using it on my prusa i3 with m8 rod angles.

update 20140717: bowden_m5 fitting

thingiverse

free

Spool holder for HyperCube Evolution by Alderoth

...ted twice

assembly

you will need :

4 f628zz ball bearings

200mm m8 threaded rod

1 m8 butterfly nut

3 standard m8 nuts

4 m8 washer

thingiverse

free

Kossel Mini Spool Holder by mccarmo

...ce assembled in part 2;

fix the other piece of the spool holder;

fix the spool holder in the piece assempled in part 1.

enjoy! :)

thingiverse

free

Artillery Sidewinder X1 V4 Gantry Support by Minkio95

...olution, the top surface of the diagonal hole will be "stepped" and you will have more grip when you will fix the nuts.

thingiverse

free

CUBICON STYLE SPOOL-HOLDER, BEARINGS, M8 THREADED ROD by 77-17

... 130mm threaded rod (uxcell1.25mm pitch m8 x 130mm threaded rod bar)

3 of m8 nuts 13mm x 7mm

2 of 608zz bearings

thread locker

thingiverse

free

Underberg V8 by jaasball

...6 bolt for crank handle

a handfull of 8mm washers

you need to print:

8 pcs sylinder

2 pcs ende

1 piece sveiv

4 pcs kam.

good luck

thingiverse

free

M8 bolts, nuts, threaded rods, standoffs, spacers and washer by Hersheljr

... standoffs in case i need them later.

i printed them with 0.2 layer height, they aren't loose or tight and works quite well.

Enic

thingiverse

free

power supply stand by Enic

...upply stand by enic

thingiverse

stand for hitachi storage array power supply

abs 0.2 resolution 55% infill

no supports was used

thingiverse

free

Cat Dish Support (rubber replace) by Enic

...cat dish support (rubber replace) by enic

thingiverse

stainless steel cat dish support (rubber replace)

thingiverse

free

Aquarium Castle by Enic

... for your fish tank size:

$d=50; // tower tube diameter

$dw=4; // doubled wall width

$h=100; // tower height & tunnel length

thingiverse

free

Metric Square Tube 40x40 Plug end cover by Enic

...metric square tube 40x40 plug end cover by enic

thingiverse

metric square tube 40x40 plug end cover

thingiverse

free

HDD Spindle Mount for DIY by Enic

...lic domain.

can be used for futher development of any diy projects.

supports required.

brim is optional.

0.2mm layer

abs 110/225c

thingiverse

free

Jumping Bugs by Enic

...nd of the tip on the back of a bug and slide the stick backwards.

just look a video, print and enjoy.https://youtu.be/h-iabyb1cys

thingiverse

free

Bicycle bell 20mm gear by Enic

...elical gear and involute rack)

// version 1.1

// by leemon baird, 2011, leemon@leemon.com

//http://www.thingiverse.com/thing:5505

thingiverse

free

universal connector for aluminium profile system 32x32 mm by Enic

...is included)

.gcode files for 1psc and for 27pcs are also included

i use abs 110/225c 20% infill 0,2mm layer.

no supports needed.

thingiverse

free

Arduino+RFM69HW+MySensors IoT Home Node Boxes: Freezer node, Universal node by Enic

...giverse

arduino+rfm69hw+mysensors iot home node boxes: freezer node, universal node

thanks to mark gaffney for parametric box!!!

thingiverse

free

vacuum cleaner adapter (for hard to reach places) by Enic

...se (source file included)

use a glue gun to glue a bunch of plastic drinking straws together and then glue to the printed adapter

Huge

turbosquid

$4

Huge Fungus

...royalty free 3d model huge fungus for download as 3ds and max on turbosquid: 3d models for games, architecture, videos. (1310036)

3d_export

$5

Huge Treee 3D Model

...huge treee 3d model

3dexport

huge tree

huge treee 3d model nikkistinger19 38424 3dexport

turbosquid

$3

Sofa huge grey

...osquid

royalty free 3d model sofa huge grey for download as on turbosquid: 3d models for games, architecture, videos. (1526303)

turbosquid

$149

Huge City 03

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$70

Stillux GliOri Huge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Huge Dispenser

...huge dispenser

3ddd

диспенсер

designer: mr. jin-seok kwon

design type: public space design

launch year: 2013

turbosquid

$549

HUGE CUTE ROBOT II

...3d model huge cute robot ii for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1500470)

3ddd

$1

Stillux GliOri Huge Art. 7801 8

... huge

люстра итальянской фабрики stillux, коллекция gliori, серия huge арт. 7801

размеры: d78 h70

3ddd

$1

Stillux GliOri Huge Art. 8800 6

... huge

люстра итальянской фабрики stillux, коллекция gliori, серия huge арт.8800

размеры: d70 h60

turbosquid

$550

Huge Bridge Collection 1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Cheap

turbosquid

$10

Cheap Desk

...

royalty free 3d model cheap desk for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1602631)

turbosquid

$30

Cheap Apartment

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

CHEAP PEN.c4d

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Cheap terrain

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Cheap Baseball Bat

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Basic Cheap Cellphone

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Cheap Ballpoint Pen

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Cheap looking table and chair

...del cheap looking table and chair for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1439884)

3d_export

$5

Cheap laser sword 3D Model

...cheap laser sword 3d model

3dexport

star wars

cheap laser sword 3d model gettinqdown 79283 3dexport

turbosquid

$45

Cheap-A$$-Guitar II.3dm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

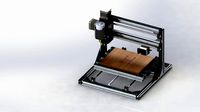

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)

Home

3d_export

$8

Home

...home

3dexport

home

3d_export

$8

Home

...home

3dexport

home

3d_export

$5

home

...home

3dexport

home

3d_export

free

Home

...home

3dexport

this is home.

3d_export

$5

home

...home

3dexport

home god izi

3d_export

$5

home

...home

3dexport

3d model home

3d_export

free

home

...home

3dexport

home. render and cycles

3ddd

free

Zara Home

...home , zara home , декоративный набор

zara home

3d_export

$5

Home sweet home 3D Model

...home sweet home 3d model

3dexport

home model made in google sketch up

home sweet home 3d model snakeplease 100984 3dexport

3ddd

$1

Ambella Home

...ambella home

3ddd

ambella home , консоль

ambella home