Thingiverse

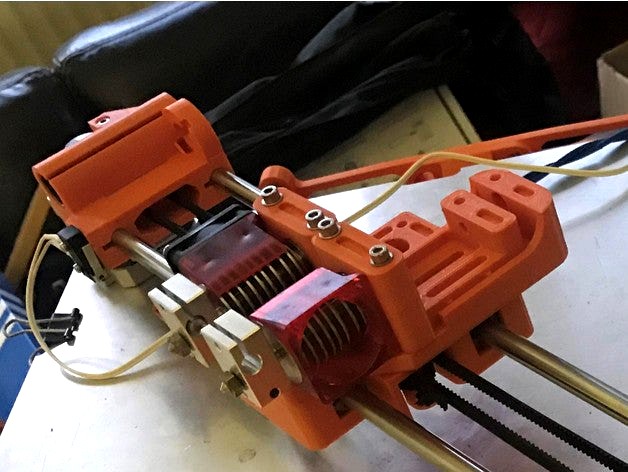

Hictop / Prusa i3 Z Axis adjustable tool offset mount - Dual E3D - Precision Ver 3.0 by Blade893_uk

by Thingiverse

Last crawled date: 3 years ago

If you like my work and would like me to develop more feel free to donate anything you can.

https://www.paypal.me/Blade893

13/10/2017.

Added right slide mount for 18mm sensor (Cap / Ind) if you are only using one hotend.

X offset from hotend is +32, Y is 0.

Ver 3.0. Requires M3 expanding inserts for assembly.

Principle design criteria is use of Drylin bearings, left hotend for part production and right hotend for soluble (PVA) support material.

X rod pitch is 45mm, please make sure this is compatible with your other components (this is Pursa spacing).

Print with at least 3 shells for the bearing block as lateral force on this part is high.

Infill should be at least 25% and up to 33% for strong parts.

PETG is best at 0.2 height.

See ordinal design:-https://www.thingiverse.com/thing:2290564

Printed bearing block saves two thirds the x axis weight and greatly assists in bearing alignment for use with Drylin bearings. Fine spacing is done using folded cigarette papers around the bearings.

Ensure your printer is calibrated in all axis as the tolerances are quite fine. If you are out by as little as 3% the bearings will bind if using Drylin, normal bearings are more forgiving.

Extruder mount plate use standard mounting holes, can be used with pillow bearings used on many 3d printer kits.

Any questions message me.

Please like so I will continue to develop.

https://www.paypal.me/Blade893

13/10/2017.

Added right slide mount for 18mm sensor (Cap / Ind) if you are only using one hotend.

X offset from hotend is +32, Y is 0.

Ver 3.0. Requires M3 expanding inserts for assembly.

Principle design criteria is use of Drylin bearings, left hotend for part production and right hotend for soluble (PVA) support material.

X rod pitch is 45mm, please make sure this is compatible with your other components (this is Pursa spacing).

Print with at least 3 shells for the bearing block as lateral force on this part is high.

Infill should be at least 25% and up to 33% for strong parts.

PETG is best at 0.2 height.

See ordinal design:-https://www.thingiverse.com/thing:2290564

Printed bearing block saves two thirds the x axis weight and greatly assists in bearing alignment for use with Drylin bearings. Fine spacing is done using folded cigarette papers around the bearings.

Ensure your printer is calibrated in all axis as the tolerances are quite fine. If you are out by as little as 3% the bearings will bind if using Drylin, normal bearings are more forgiving.

Extruder mount plate use standard mounting holes, can be used with pillow bearings used on many 3d printer kits.

Any questions message me.

Please like so I will continue to develop.

Similar models

thingiverse

free

Hictop i3 Z Axis adjustable tool offset mount - Dual E3D - Precision by Blade893_uk

...panding inserts.

hotend x offset in your slicer / marlin should be 32mm as a starting point before tuning.

please like / comment.

thingiverse

free

Wanhao i3 offset Y axis Bearing Block by Prometheus-3D

...he 45mm lm8luu bearings

**make sure to install the 2 m4 nuts under the bearing before you secure the bearing down with a ziptie..

thingiverse

free

Leapfrog creatr uppgrade for bigger build volume by teneopreto

...xis carriage or it can jam when printing in the rear right hand corner of the printer

https://www.youtube.com/watch?v=pix-zybjpkq

thingiverse

free

K8200 - E3D Titan Mount by o_liviu

...ages (own) also benefit from other improvements:

gt2 belts on x and y axis

k8204 on z axis

drylin linear bearings on x and y axis

thingiverse

free

X Axis mounts by dragon8220

...t works fine. you need to flip /mirror the right hand mount. the x mount wide slot has a 9mm slot so you can use a wider bearing.

thingiverse

free

Cyrus V2 Spare; E3D V6 hotend holder by Cyrus3D

...u have a cyrus 3d printer with the v5 hotend, please use this link;http://www.thingiverse.com/thing:228608

please print it in abs

thingiverse

free

Ender 3 X axis sensor mount by DickShaydle

... dickshaydle

thingiverse

untested

x sensor can be mounted with a little offset, so there is more space for the carriage to move.

thingiverse

free

Wanhao i3 Double Bearing Clip by dumbcomputers

... but it would work with the stock roller bearings as well if you wanted to drop the weight of one aluminum bearing block.

cheers.

thingiverse

free

3d printer carriage by Jmulalley

...o mount the hotend and stepper assembly. using plastic to mount the hotend is not ideal. https://www.thingiverse.com/thing:821066

thingiverse

free

Cyrus V2 Spare; E3D V6 hotend holder by Cyrus3D

...m of 25% infill

if you have a cyrus 3d printer with the v5 hotend, please use this link;http://www.thingiverse.com/thing:228608

Blade893

thingiverse

free

Kitchen Roll Holder by Blade893_uk

... 44mm.

if you like my work and would like me to develop more feel free to donate anything you can.

https://www.paypal.me/blade893

thingiverse

free

Dell Small Form Factor Mount by Blade893_uk

...or pc.

if you like my work and would like me to develop more feel free to donate anything you can.

https://www.paypal.me/blade893

thingiverse

free

Window shop open sign by Blade893_uk

... it down when not.

use double sided tape to fix the mounts to the inside of window.

if you download, print & use please like.

thingiverse

free

HP Server PSU Mount - 2020 by Blade893_uk

...r is dimensional accurate, tolerance is less then 1.0mm.

if you download, print, use please like and add to 'i made one'.

thingiverse

free

Freezer Door latch by Blade893_uk

...low for curved freezer doors, adjust the z height in your slicer to get the correct radius for your freezer door.

like and print.

thingiverse

free

Wade Extruder 2020 mount by Blade893_uk

...s designed to flex a little to damp transition of motion to the print but you may need to adjust infill for your print settings.

thingiverse

free

E3D V6 Water Cooling Jacket by Blade893_uk

...art is water tight press fit.

if you require a safety factor then glue parts / hotend together with epoxy.

please like / comment.

thingiverse

free

Simple Core XY Parts by Blade893_uk

...u

and you are going to need gt2 belts x2 5m length.

also, your frame needs to be stiff as possible if you want to print at speed.

thingiverse

free

Hictop i3 Z Axis adjustable tool offset mount - Dual E3D - Precision by Blade893_uk

...panding inserts.

hotend x offset in your slicer / marlin should be 32mm as a starting point before tuning.

please like / comment.

Hictop

thingiverse

free

Hictop - Adjustable z Endstop by ptk21

...hictop - adjustable z endstop by ptk21

thingiverse

adjustable z endstop for hictop

thingiverse

free

Hictop 3d LCD Befestigung by festus402

...hictop 3d lcd befestigung by festus402

thingiverse

hictop 3d lcd befestigung

thingiverse

free

Cable chain HICTOP by Insani3D

...cable chain hictop by insani3d

thingiverse

iniciando la modificación de nuestra hictop, se diseña una eslabón a medida.

thingiverse

free

hictop y belt mount by polpetras

...hictop y belt mount by polpetras

thingiverse

hictop aluminum prusa y belt mount

thingiverse

free

Pen Holder for Hictop ender by basolur

...pen holder for hictop ender by basolur

thingiverse

this is a simple pen holder to use a hictop ender as a plotter.

thingiverse

free

remix for hictop mount by chibi_hero

...iverse

edit. made recesses for mounting deeper.

remixed this with http://www.thingiverse.com/thing:1323225

for my hictop 3dp-11.

thingiverse

free

Hictop 3DP-17 Parts by Adranovik

...hictop 3dp-17 parts by adranovik

thingiverse

printed parts for the hictop prusa eds-17 with auto level

thingiverse

free

Hictop xaxis clamp by Gen0idea

...oken x-axis belt clamp on the hictop printer.

printed in a different colour to the original to differentiate it as a replacement.

thingiverse

free

Hictop xaxis clamp by Gen0idea

...oken x-axis belt clamp on the hictop printer.

printed in a different colour to the original to differentiate it as a replacement.

thingiverse

free

Hictop i3 RAMPS Board Cover

...hictop i3 ramps board cover

thingiverse

cover for the stock ramps 1.3 board on the hictop i3 clone (2015 model).

Offset

turbosquid

$20

Armchair Offset

...ee 3d model armchair offset for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1593561)

3ddd

$1

Комод Madia Offset

...комод madia offset

3ddd

oro-milano

комод madia offset. бренд oro-milano

3ddd

$1

Столик Offset (Bonaldo)

...aldo (италия)

артикул: c3596

модель предоставляется в форматах: max(2010), fbx, obj, 3ds, с материалами, текстурами и размерами.

turbosquid

free

Wooden Barrel - Offset

...alty free 3d model wooden barrel - offset for download as fbx on turbosquid: 3d models for games, architecture, videos. (1184305)

turbosquid

$14

Offset Armchair by Menu

...ffset armchair by menu for download as max, 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1681480)

turbosquid

$65

Small Offset Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Offset floor lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Roche Bobois / Offset

...roche bobois / offset

3ddd

стеллаж

линейка мебели offset.roche-bobois.desing sacha lakic.

3d_export

$65

Small Offset Printer 3D Model

...dustrial production equipment tool small offset machine machinery plotter

small offset printer 3d model dropassets 54178 3dexport

turbosquid

$5

MIRROR---Half moon offset

...ror---half moon offset for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1525571)

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

Ver

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

кресло ver design

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

диван ver design

3ddd

free

VER DESIGN

...ver design

3ddd

ver design , стеллаж

полка ver design

3ddd

$1

VER DESIGN

...ver design , лежак , шезлонг

шезлонг ver design

3ddd

$1

Ver Design стол

...ver design стол

3ddd

ver design

...

3ddd

$1

Ver Design / NOTTURNA

...ver design / notturna

3ddd

ver design

http://www.verdesign.it

3d_export

$6

Old book ver 2

...old book ver 2

3dexport

old book ver. 2 pbr unwrap

3d_export

$6

Old book ver 3

...old book ver 3

3dexport

old book ver. 3 pbr unwrap

3d_export

$6

Old book ver 5

...old book ver 5

3dexport

old book ver. 5 pbr unwrap

turbosquid

free

plant ver 02

...2

turbosquid

free 3d model plant ver 0.2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1491580)

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

Uk

turbosquid

$40

UK sockets

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Uk Map

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

UK Spitfire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

UK Flag

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Диван Chesterfield UK flag

...диван chesterfield uk flag

3ddd

chesterfield

диван chesterfield uk flag

cg_studio

$15

UK Phonebooth3d model

...phonebooth3d model

cgstudio

.lws .lwo - uk phonebooth 3d model, royalty free license available, instant download after purchase.

turbosquid

$39

Woman Shoe UK

...quid

royalty free 3d model woman shoe uk for download as max on turbosquid: 3d models for games, architecture, videos. (1462477)

turbosquid

$1

UK Pound Symbol

...id

royalty free 3d model uk pound symbol for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560784)

turbosquid

$19

Manhole Covers UK

...y free 3d model manhole covers uk for download as max and max on turbosquid: 3d models for games, architecture, videos. (1575421)

turbosquid

$9

UK Torpedo MarkXII

...3d model uk torpedo markxii for download as xsi, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1523738)

Precision

turbosquid

$40

Precision Screwdriver

...model precision screwdriver for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301545)

cg_studio

$59

Precision mountain3d model

...n mountain3d model

cgstudio

.max - precision mountain 3d model, royalty free license available, instant download after purchase.

turbosquid

$10

Lazer Precision rifle

...lty free 3d model lazer precision rifle for download as blend on turbosquid: 3d models for games, architecture, videos. (1313439)

3d_export

$7

Precision Indicator

...includes all scene, lighting, cameras, materials and textures. many file formats are available. the visuals are in 4k resolution.

turbosquid

$59

Dell Precision 7510 Laptop

... dell precision 7510 laptop for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1678133)

turbosquid

$45

11 Precision Metals Bldg03

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$37

Kelly Wearstler Precision bench

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$18

Kelly Wearstler Precision table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$60

Fender Precision Bass 3D Model

...uitar frets instrument electric bassguitar 4string rock blues pop music

fender precision bass 3d model rendersteel 86834 3dexport

3d_export

$5

precision centrifugal pump

...ceed 180℃ and the inlet pressure does not exceed 0.8mpa.<br>drawings can only be used as a reference for mechanical design!

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

0

turbosquid

$12

Calligraphic Digit 0 Number 0

...hic digit 0 number 0 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389318)

3d_export

$6

set-0

...set-0

3dexport

turbosquid

$6

hedge 0

...yalty free 3d model hedge 0 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1450353)

turbosquid

$5

Nuber 0

...oyalty free 3d model nuber 0 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1564674)

turbosquid

$22

0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Steam Locomotive Fowler 4F 0-6-0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Liquid Number 0

... model liquid number 0 for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1689919)

turbosquid

$45

Dragon360_perspShape_tmp.0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Rocks Debris 0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

wood-guardrail-fence 0

...wood-guardrail-fence 0

3dexport

wood-guardrail-fence 0<br>3ds max 2015

Adjustable

3d_ocean

$7

Adjustable Wrench

...adjustable wrench

3docean

adjustable wrench highly detailed wrench

highly detailed adjustable wrench.

3ddd

$1

Adjustable Stool

...adjustable stool

3ddd

табурет

wooden adjustable stool.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$16

Adjustable Weight Bench

...arbell bench black equipement gym gymnastic indoor sport weight workout

3d model of black adjustable weight bench with a barbell.

turbosquid

$5

Adjustable wrench

...

royalty free 3d model adjustable wrench for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313414)

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$1

Adjustable Wrench

...free 3d model adjustable wrench for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1446736)

turbosquid

$1

Adjustable Wrench

...y free 3d model adjustable wrench for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1379022)

3d_export

$5

Adjustable key

...adjustable key

3dexport

Tool

turbosquid

$21

Tool box with tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archibase_planet

free

Tools

...tools

archibase planet

tools instruments implements

tools n070114 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3d_ocean

$12

Tools

...tools

3docean

hammer metal old screw tools wrench

maya

turbosquid

$6

Tool Cart / Tool Box

...

royalty free 3d model tool cart / tool box for download as on turbosquid: 3d models for games, architecture, videos. (1241859)

3d_ocean

$15

crimp tool

... tool copper cutter crimp crimp tool electrical electrical tools press tools pressing tool tools wire cutter

created in maya 2013

3d_ocean

$5

Tools

...tools

3docean

3d models paint tools work

3d,models,works,paint,art,create,working,

3d_export

free

tools

...tools

3dexport

coldsteel

turbosquid

$15

Tools

...turbosquid

royalty free 3d model tools for download as blend on turbosquid: 3d models for games, architecture, videos. (1331352)

3ddd

$1

bar tool

...bar tool

3ddd

барный

bar tool

turbosquid

$35

tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$29

Books 150 pieces 3-3-3

...books 150 pieces 3-3-3 for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1384033)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder