Thingiverse

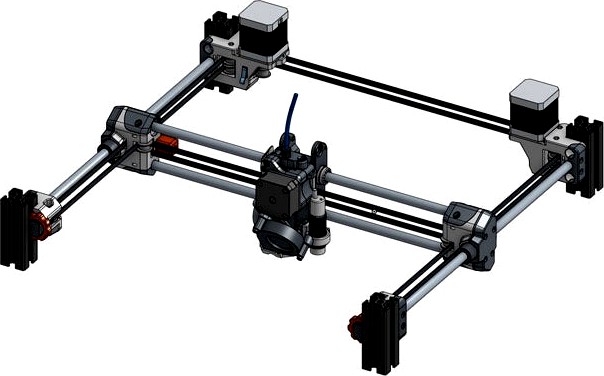

Hevo corexy system

by Thingiverse

Last crawled date: 4 years, 2 months ago

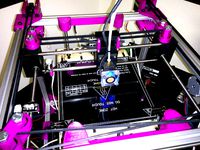

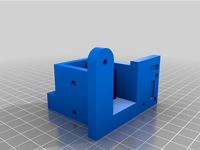

This is a part of my build of Hypercube evolution. This is complete corexy system. Motors are moved on the back, front idlers support belt tensioning using red nuts.

Features:

Belt tensioning on the front of the printer

Motors on the back

Belts flipped so only 2 toothed idlers used per belt (probably reduce ringing)

Probably useless because it is too specific for my build. My dimensions:

420mm x extrusion

410mm y extrusion

400mmx10mm y axis rod

450mmx10mm x axis rod

It is designed for 10mm rods for Y axis and 10mm rods for X axis.

You will need:

LM10LUU Bearings x2

LM10UU Bearings/IGUS Bushings/Printed bearings (I use 10mm bronze bushings with LM10UU adapter) x3

20T toothlesss idler 3mm bore x 12

20T toothed idler 3mm bore x 2

20T pulley for nema17 x2

nema17 x2

Bare microswitch as endstop x2 (since i am using duet that works for me)

Mostly m3 screws, nuts

M5x10mm screws for mounting + T nuts

Usage options:

You can use only front idlers and back motor mounts + default hypercube evolution Y carriage and X assembly

My Y carriage and X axis assembly + hypercube evolution adapter

My Y carriage and X axis assembly + my BMG direct extruder (https://www.thingiverse.com/thing:3518138)

Back motor mounts can be swapped, so motors will face down.

Optional:

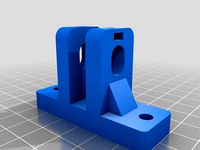

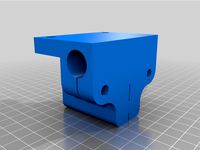

This thing designed to use piezo bed leveling. There is piezo disc housing bolted to x carriage. You can put small springs between carriage and mouting plate. You also need m3 screw (button head or grub screw) in mounting plate to push into the disc.

Source:https://cad.onshape.com/documents/fe7ef93aeb21687c26dace27/w/ac0cc948d4102d237be16f5c/e/cda881af6fa70062f4562796

Features:

Belt tensioning on the front of the printer

Motors on the back

Belts flipped so only 2 toothed idlers used per belt (probably reduce ringing)

Probably useless because it is too specific for my build. My dimensions:

420mm x extrusion

410mm y extrusion

400mmx10mm y axis rod

450mmx10mm x axis rod

It is designed for 10mm rods for Y axis and 10mm rods for X axis.

You will need:

LM10LUU Bearings x2

LM10UU Bearings/IGUS Bushings/Printed bearings (I use 10mm bronze bushings with LM10UU adapter) x3

20T toothlesss idler 3mm bore x 12

20T toothed idler 3mm bore x 2

20T pulley for nema17 x2

nema17 x2

Bare microswitch as endstop x2 (since i am using duet that works for me)

Mostly m3 screws, nuts

M5x10mm screws for mounting + T nuts

Usage options:

You can use only front idlers and back motor mounts + default hypercube evolution Y carriage and X assembly

My Y carriage and X axis assembly + hypercube evolution adapter

My Y carriage and X axis assembly + my BMG direct extruder (https://www.thingiverse.com/thing:3518138)

Back motor mounts can be swapped, so motors will face down.

Optional:

This thing designed to use piezo bed leveling. There is piezo disc housing bolted to x carriage. You can put small springs between carriage and mouting plate. You also need m3 screw (button head or grub screw) in mounting plate to push into the disc.

Source:https://cad.onshape.com/documents/fe7ef93aeb21687c26dace27/w/ac0cc948d4102d237be16f5c/e/cda881af6fa70062f4562796

Similar models

thingiverse

free

hevo coreXY system afterburner compatible by Gavitka

...f15789d99bc53ebbehttps://cad.onshape.com/documents/9c5314387703df90f304bd28/w/f12398f04381c0cceb291134/e/6466d9f70d85fc78756084c4

thingiverse

free

XY idler 10mm Y 20T Pulley

...back and forward work during print moves.

suitable for :

gt2 20t pulleys

10mm y axis

i'm also update the version for 8mm rods

thingiverse

free

Hypercube Evolution Mods by Syngenta

... parts:

x carriage with endstop mount ( no brass inserts)

stronger belt clamps

improved belt idler

motor mount with endstop mount

thingiverse

free

Hypercube Evolution X-Carriage for 10mm rods by trevor185

... fiber 10mm rods with ptfe bearings from mcmaster:https://www.mcmaster.com/#2685t13

my printer is assembled, but not running yet.

thingiverse

free

Motormount for Y-Axis - 10mm threaded rods by benzed78

...e of the motor is not moving away, if you tension the belt

27.10.2015:

i modified the design, a bit, so it looks nicer for me. ;)

thingiverse

free

HyperCube XY Joiner LM10UU by erdemerciyas

...x axis 10.25mm rods etc.

x axis 8.25mm rods etc.

20t tooth pulley

need to m3 screw... some size

updated!

add new x axis to 8.25mm

thingiverse

free

Hictop 3dp11 Adjustable Y Idler Mount by SaberShip

...rts:

x1 stock 608zz idler bearing

x1 stock m3 bolt and nut

x2 stock m5 bolts

x2 stock m5 t-slot nuts

x2 m3 x 10 screws

x2 m3 nuts

thingiverse

free

Igus 10mm Bushing Holder for LM8LUU by superjamie

...d or tube on the x axis, or just allows to not use a noisy metal linear bearing on a 10mm steel rod.

openscad source is included.

thingiverse

free

Hypercube evolution Y Carriage with M3 nuts and bushings by Otomar

...i am able to do derivates for your bearings, just ask in comments...!

first picture is not updated, it is old version for lm10uu.

thingiverse

free

Hypercube Evolution LMLUU10mm Carriage for Stock Hotend Mount

...on for 10mm rods. it is plug and play, all things can be used from the 8mm rod model...

it is not a remix, it is self createtd...

Hevo

thingiverse

free

powerunit HEVO by Ploegie

...by ploegie

thingiverse

this thing is made for the backside of my hevo and works great

i used neutrik usb and ethernet connectors

thingiverse

free

HEVO Spool Holder by theredguy

...hevo spool holder by theredguy

thingiverse

parts will require gluing

thingiverse

free

HEVO to HevORT 12mm Smooth Rod holder by Rippernz

...older by rippernz

thingiverse

hevo to hevort 12mm smooth rod holder

3030 extrusion

bed 12mm smooth rod holder for hevo to hevort

thingiverse

free

Hevo SupCRprobe Hotendaufnahme by lordduplo

...:https://www.thingiverse.com/thing:2254103

hotendaufnahme + retainer für den hevo mit 12mm bohrung für eine supcrprobe von cr-3d.

thingiverse

free

30x30 Extrusion Foot (HEVO) by brainchecker

...se

a foot which attachs securely to a 30x30mm extrusion. i designed it to give my hevo a little bit of clearance from the floor.

thingiverse

free

Hevo BLV Fusion - Hevo MGN Linear Rail Conversion Kit

...al conversion kit for my hypercube evolution to use mgn12h linear rail, inspired by blv mgn cube, as a replacement for rod shaft.

thingiverse

free

Hypercube Evolution (HEVO) Prusa Mk3s Hotrend mount

... customised for the hypercube evolution (hevo) with a bl-touch probe. this fits the standard hevo plate and bowden configuration.

thingiverse

free

Hevo Double Z Center Bed Support by groovydude1981

...hevo double z center bed support by groovydude1981

thingiverse

this is a simplified center bed support for my double z hevo.

thingiverse

free

hevo wobble wing remix by warham

...hevo wobble wing remix by warham

thingiverse

work in progress

thingiverse

free

HEVO COVER by heisenberg333

...se

this cover is adapted for original hypercube evolution head , no need to modify other part .

protect and hold properly cables

Corexy

thingiverse

free

CoreXY by Kaz_tech

...corexy by kaz_tech

thingiverse

this is the model of corexy platform. i separately put the parts on this place.

thingiverse

free

corexy plotter by tjwan

...corexy plotter by tjwan

thingiverse

parts for corexy mill inspired by http://der-frickler.net/technik/corexyportal

thingiverse

free

ScribbleJ CoreXY Beta by ScribbleJ

...j/corexy-v1https://github.com/scribblej/corexy-v1#corexy-beta

full gallery of development photos here: http://imgur.com/a/donun

thingiverse

free

CoreXY Emblem by emkajot

...by emkajot

thingiverse

an emblem for your corexy printer.

size: 100mm x 38mm x 2mm.

update: added a version with a proper mount.

thingiverse

free

SolidCore CoreXY Carriage by shanehooper

...olidcore 3d printer. this design could be used in other corexy 3d printers.

also see:https://3ddistributed.com/corexy-3d-printer/

thingiverse

free

CoreXY 3D Printer Model by ReginaFabricam

...bricam

thingiverse

this is an original design of a corexy printer.https://www.tinkercad.com/things/jggr9qk4s4p-3d-printer-corexy

thingiverse

free

coreXY Upper structure Left

...corexy upper structure left

thingiverse

my customized corexy 3d printer upper left parts

thingiverse

free

CoreXY by frankie

...ing machines, etc. the design is described in greater detail at http://www.corexy.com . a video is at http://vimeo.com/40914530 .

thingiverse

free

Endstop block for CoreXY carriage by svkeulen

...endstop block for corexy carriage by svkeulen

thingiverse

endstop for corexy carriage

thingiverse

free

X carriage for the CoreXY MGN12 by hackerbijay

...x carriage for the corexy mgn12 by hackerbijay

thingiverse

x carriage for the corexy frame

System

archibase_planet

free

System

...m

archibase planet

fire alarm system fire alarm box

security light system - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Euforia System

...euforia system

3ddd

euforia

euforia system

3d_export

$50

Roof system Truss system 3D Model

...oof system truss system 3d model

3dexport

roof system truss truss stage

roof system truss system 3d model aleksbel 38970 3dexport

3ddd

$1

DVD System

...dvd system

3ddd

dvd , schneider

dvd system

design_connected

free

Seating system

...seating system

designconnected

free 3d model of seating system

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3ddd

$1

Quanta System

...quanta system

3ddd

медицина

quanta system.

лазерное оборудование для медицинских центров

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3d_export

$14

missile system

...missile system

3dexport