Thingiverse

Helical Gear Fidget Toy by spingoogL

by Thingiverse

Last crawled date: 3 years, 1 month ago

Now has a little sibling at http://www.thingiverse.com/thing:2105705.

!!!DEBURR THE GEARS AND REMOVE SHARP EDGES FROM THE GEAR TEETH!!!

Do not put anything that can get hurt in to mesh point of gears!

Not for young children. If not assembled correctly, ball bearings can fall out.

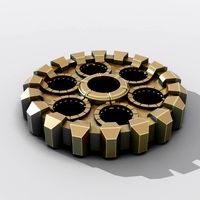

Meshing helical gear fidget toy with through hole for finger.

Printing two of the same gears will make them mesh at 90 degrees.

Printing one right hand and one left hand gear will mesh straight on same plane.

Same housing for both straight and perpendicular planes assemblies.

Included is an STL for a bearing race dressing tool.

I passed some 180 grit sand paper through the slots.

Pushed it in the the half toroids and rotated back,

and forth to help smooth out ball bearing grooves.

I used PLA for the gears, and ABS for the housings.

The little holes in the housing are meant to receive short pieces of filament.

Cemented together using acetone on the ABS housings and inner cylinder.

Epoxy or any decent glue can be used to assemble the housing pieces as well.

There are a few versions of the inner cylinder.

I had delamination issues when removing it from the printing bed.

A little acetone on a paint brush re-enforced the laminations fairly well.

Spherical 4.5mm(0.177") BB ammunition is used for the ball bearings.

Contained with this package is an OpenSCAD script for generating metric helical gear blanks.

Written by yours truly, is being released under and besides this fidget toy under the GNU GPLv3 license.

I exported the gear to an STL. I then imported the STL in to TurboCAD, and carved out the rest.

If the assembly meshes a little tight, you might try

1. Scaling a difference of up to 0.5% between housing and the gear(make the housing bigger).

More than that, and housing might "rock" over the ball bearings.

2. Printing shim to your desired thickness, and adding to the housing assembly.

In CURA the shim can be cut off to the desired thickness.

Something is very wrong if you need more than 1mm.

3. Included are two gears. One is to spec with no backlash.

The other has 5% of the CP removed from the gear profile for added

backlash(clearance on the gear tooth flank). This one is loose.

If anyone wants a copy of the original TurboCAD files, or an export to AutoCAD DWG,

please make your request in the comment section. I'll zip it up and post it.

Bill Of Materials for pair of meshing gears

4 housings

2 inner cylinders

2 gears

4 short pieces of filament ~9mm long.

BB Balls to fill grooves

Glue or Acetone(ABS)

!!!DEBURR THE GEARS AND REMOVE SHARP EDGES FROM THE GEAR TEETH!!!

Do not put anything that can get hurt in to mesh point of gears!

Not for young children. If not assembled correctly, ball bearings can fall out.

Meshing helical gear fidget toy with through hole for finger.

Printing two of the same gears will make them mesh at 90 degrees.

Printing one right hand and one left hand gear will mesh straight on same plane.

Same housing for both straight and perpendicular planes assemblies.

Included is an STL for a bearing race dressing tool.

I passed some 180 grit sand paper through the slots.

Pushed it in the the half toroids and rotated back,

and forth to help smooth out ball bearing grooves.

I used PLA for the gears, and ABS for the housings.

The little holes in the housing are meant to receive short pieces of filament.

Cemented together using acetone on the ABS housings and inner cylinder.

Epoxy or any decent glue can be used to assemble the housing pieces as well.

There are a few versions of the inner cylinder.

I had delamination issues when removing it from the printing bed.

A little acetone on a paint brush re-enforced the laminations fairly well.

Spherical 4.5mm(0.177") BB ammunition is used for the ball bearings.

Contained with this package is an OpenSCAD script for generating metric helical gear blanks.

Written by yours truly, is being released under and besides this fidget toy under the GNU GPLv3 license.

I exported the gear to an STL. I then imported the STL in to TurboCAD, and carved out the rest.

If the assembly meshes a little tight, you might try

1. Scaling a difference of up to 0.5% between housing and the gear(make the housing bigger).

More than that, and housing might "rock" over the ball bearings.

2. Printing shim to your desired thickness, and adding to the housing assembly.

In CURA the shim can be cut off to the desired thickness.

Something is very wrong if you need more than 1mm.

3. Included are two gears. One is to spec with no backlash.

The other has 5% of the CP removed from the gear profile for added

backlash(clearance on the gear tooth flank). This one is loose.

If anyone wants a copy of the original TurboCAD files, or an export to AutoCAD DWG,

please make your request in the comment section. I'll zip it up and post it.

Bill Of Materials for pair of meshing gears

4 housings

2 inner cylinders

2 gears

4 short pieces of filament ~9mm long.

BB Balls to fill grooves

Glue or Acetone(ABS)

Similar models

thingiverse

free

Helical gear fidget toy

...ar fidget toy

thingiverse

i made this thing to feel how helical gears feel. just a little toy that is fun to handle and look at.

thingiverse

free

6mm bb Bearing fidget spinner caps for m4 size inner. by riman7089

...size inner. by riman7089

thingiverse

bearing caps for a fidget spinner made using the 6mm bb ball bearing with the m4 size inner

thingiverse

free

Gear Fidget Toy by kgnglsn

...r fidget toy by kgnglsn

thingiverse

print 3 outer gears, 1 inner gear, 2 covers, and 2 caps. you will need 4 22mm ball bearings.

cg_trader

$3

Antikythera Mechanism helical Herringbone Gear Desk Fidget Toy | 3D

...op, ball bearings, interlocking gears, bits that spin, solid construction, striking visuals that intrigue the eye .

assemble with

thingiverse

free

BB Bearing Fidget Toy by spingoogL

...r printing, i tried putting the little retainer in the hole, but it broke. so far, the ball bearings have not fallen out for me.

cults

free

Gear Fidget Spinner (ABS)

...pink purple red time toy toys twiddle yellow

this is a basic fidget spinner. uses basic skate board bearing.

optimized for abs *

thingiverse

free

Ball Gear Bearing by Biscuit147

... without supports and it may take a little force to free the gear bearing in the center and to remove the supports at the bottom.

thingiverse

free

gear fidget toy by Geo_bot

...oy by geo_bot

thingiverse

a little stim and fidget toy i made using fusion 360 and the openscad file from the emmet gear bearing

thingiverse

free

Fidget Quintuple Spinner / 625 Bearing Holder by Inertie_3D

...ings for the outside.

i didn't printed it yet but i used the same ø tolerances for good bearing assembly/disassambly.

enjoy !

thingiverse

free

gear fidget by jesse3489

...thingiverse

just a little fidget toy i made there is a good size gap in the mesh of the gears so tolerances will not be an issue

Spingoogl

thingiverse

free

Hexagon Case by spingoogL

...hexagon case by spingoogl

thingiverse

hexagon case with twist on/off cap.

thingiverse

free

Nine Tails Spinner by spingoogL

...nine tails spinner by spingoogl

thingiverse

naruto themed nine tails spinner with leaf center button.

thingiverse

free

Coughin Nail by spingoogL

...se

holder for 7 king size cigarettes.

first print failed at about 95%. used a 10 line brim on the second attempt and it worked.

thingiverse

free

Golf Ball Fan Mod by spingoogL

...fan mod by spingoogl

thingiverse

golf ball inspired fan blade mod.

based on this mount:https://www.thingiverse.com/thing:4553248

thingiverse

free

Wire Nut by spingoogL

...i'm using it to distribute 5v to multiple components in an arduino project.

wire nut is a 9mm cube.

with shroud, 11.5mm cube.

thingiverse

free

Thread Spool/Bobbin Keeper by spingoogL

...se

place at the bottom of your spool of thread to prevent/reduce wrap around the stem. guides the thread back on to the bobbin.

thingiverse

free

Overlock Spool Adapter for Sewing Machine by spingoogL

...ng machine by spingoogl

thingiverse

sewing machine adapter for the much cheaper spools of thread intended for overlock machines.

thingiverse

free

Greedy Cup, Spilly Cup, Syphon Cup by spingoogL

...greedy cup, spilly cup, syphon cup by spingoogl

thingiverse

little greedy cup. the flow is a little slow, but it works.

thingiverse

free

Philip D Bird Business Card Holder by spingoogL

... by spingoogl

thingiverse

perfect accessory for the complaints department of any corporation, or a gift for the office sunshine.

thingiverse

free

EMT 90 - 1/2" by spingoogL

...le part. meant to hold 1/2" electrical metal tube (emt), at 90 degrees. meant to hold with a 1/4" or 6mm through bolt.

Helical

3d_export

$5

helical gear

...helical gear

3dexport

helical gear

3d_export

$5

Helical Gear

...l contact ratio which can improve vibration and noise. badly designed helical gears can be noisier than well designed spur gears.

turbosquid

$5

Helical Gear

...squid

royalty free 3d model helical gear for download as stl on turbosquid: 3d models for games, architecture, videos. (1502723)

turbosquid

$4

helical gears

...id

royalty free 3d model helical gears for download as blend on turbosquid: 3d models for games, architecture, videos. (1423917)

turbosquid

$40

Helical Stairs

...el helical stairs for download as 3ds, max, ige, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1422987)

turbosquid

$32

armchair-Helical

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

helical gear

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

helical gear

...cal gear for download as max, unitypackage, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1667275)

turbosquid

$4

Helical gear

... gear for download as sldpr, 3dm, 3ds, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1530622)

3d_export

$50

HELICAL BEVEL GEAR

...lel and perpendicular. in parallel-axis helical gears the two opposite-hand gears provide quiet operation and high load capacity.

Fidget

3d_export

$10

Fidget Cube

...fidget cube

3dexport

fidget cube 3d modeling<br>3d max<br>auto cad

turbosquid

free

Fidget Cube

...ube

turbosquid

free 3d model fidget cube for download as c4d on turbosquid: 3d models for games, architecture, videos. (1370283)

turbosquid

$20

Fidget Spinner

...squid

royalty free 3d model fidget snner for download as c4d on turbosquid: 3d models for games, architecture, videos. (1194595)

turbosquid

$20

fidget spinner

...uid

royalty free 3d model fidget spinner for download as c4d on turbosquid: 3d models for games, architecture, videos. (1168895)

turbosquid

$10

fidget Cube

...osquid

royalty free 3d model fidget cube for download as obj on turbosquid: 3d models for games, architecture, videos. (1173544)

turbosquid

$6

Fidget Cube

...osquid

royalty free 3d model fidget cube for download as max on turbosquid: 3d models for games, architecture, videos. (1205497)

turbosquid

$5

Fidget Cube

...osquid

royalty free 3d model fidget cube for download as c4d on turbosquid: 3d models for games, architecture, videos. (1287742)

turbosquid

$5

Fidget Spinner

...uid

royalty free 3d model fidget spinner for download as c4d on turbosquid: 3d models for games, architecture, videos. (1190870)

turbosquid

$5

Fidget spinner

...uid

royalty free 3d model fidget spinner for download as dwg on turbosquid: 3d models for games, architecture, videos. (1279860)

turbosquid

$2

Fidget cube

...quid

royalty free 3d model fidget cube for download as blend on turbosquid: 3d models for games, architecture, videos. (1488961)

Gear

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)

Toy

3d_export

$5

toys

...toys

3dexport

toys

archibase_planet

free

Toy

...toy

archibase planet

giraffe toy toy giraffe

toy giraffe n041010 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Toy

...toy

archibase planet

elephant toy toy plaything

toy elephant n131010 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Toy

...toy

archibase planet

toy deer

toy n061011 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Toy

...toy

archibase planet

nutcracker toy

toy n070111 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Toy

...toy

archibase planet

toy nutcracker

toy n190811 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Toy

...toy

archibase planet

toy snake serpent

toy n181112 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Toy

...toy

archibase planet

toy elephant

toy elephant n040112 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Toy

...toy

archibase planet

toy hare

toy a hare n311210 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Toy

...toy

archibase planet

toy rabbit

toy s n150412 - 3d model (*.3ds) for interior 3d visualization.