Thingiverse

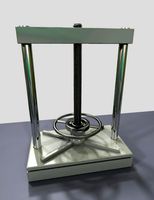

Heat Insert Press by air0n

by Thingiverse

Last crawled date: 3 years ago

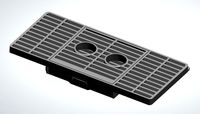

Gravity press for setting heat-set inserts in plastic parts.

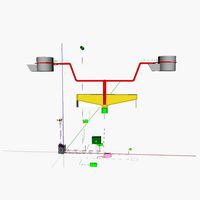

Fusion 360 model is here for reference:https://a360.co/3s0OgyT

Notes

You may need to adjust the brake plate spring retainers to accommodate your spring size. I found that putting a slightly heavier spring at the bottom of the brake assembly helped keep the arm in position best. Also, the spring retainers are not centered. This is intentional so make sure the spring aligns with the center of the wheel. If it does not, simply rotate the plate 180deg.

The arm assembly may need adjusting to fit up to your Iron diameter.

I also added an extra channel nut and screw at the bottom of the rail as a wheel stop to prevent the iron from slamming into the base plate. (shown in pictures but nut listed in parts list)

Non printed parts list:

(1) Variable temperature soldering iron

(1) 3/4" x 12" x 12" MDF

(1) 2040 450mm Aluminum Extrusion

(4) 24mm Plastic Pulley Wheel with Bearing Idler Pulley Gear

(2) 5mm bore, 8mm high, Hexagonal Eccentric Column

(2) Springs

(2) M5-0.8 Heat-set Insert Nuts

(6) M5-0.8 x 30mm Pam Head Machine Screws

(2) M5 Flat Washers

(4) M5-0.8 Lock Nuts

(2) #10 x 1/2" Pan Head Sheet Metal Screws

(2) #10 x 2" Flat Head Sheet Metal Screws

(2) M5-0.8 Channel Insertion Nuts

(2) M5-0.8 x 6mm Pam Head Machine Screws

*M5-0.8 hardware could be swapped for 10-32 or 10-24 hardware if preferred.

Fusion 360 model is here for reference:https://a360.co/3s0OgyT

Notes

You may need to adjust the brake plate spring retainers to accommodate your spring size. I found that putting a slightly heavier spring at the bottom of the brake assembly helped keep the arm in position best. Also, the spring retainers are not centered. This is intentional so make sure the spring aligns with the center of the wheel. If it does not, simply rotate the plate 180deg.

The arm assembly may need adjusting to fit up to your Iron diameter.

I also added an extra channel nut and screw at the bottom of the rail as a wheel stop to prevent the iron from slamming into the base plate. (shown in pictures but nut listed in parts list)

Non printed parts list:

(1) Variable temperature soldering iron

(1) 3/4" x 12" x 12" MDF

(1) 2040 450mm Aluminum Extrusion

(4) 24mm Plastic Pulley Wheel with Bearing Idler Pulley Gear

(2) 5mm bore, 8mm high, Hexagonal Eccentric Column

(2) Springs

(2) M5-0.8 Heat-set Insert Nuts

(6) M5-0.8 x 30mm Pam Head Machine Screws

(2) M5 Flat Washers

(4) M5-0.8 Lock Nuts

(2) #10 x 1/2" Pan Head Sheet Metal Screws

(2) #10 x 2" Flat Head Sheet Metal Screws

(2) M5-0.8 Channel Insertion Nuts

(2) M5-0.8 x 6mm Pam Head Machine Screws

*M5-0.8 hardware could be swapped for 10-32 or 10-24 hardware if preferred.

Similar models

grabcad

free

Unified Steel Phillips Rounded Head Screws for Sheet Metal

..., 1 1/2" long - 90935a365

• phillips rounded head screw for sheet metal, black-oxide steel, no. 14, 2" long - 90935a370

thingiverse

free

Heat-Set Insert Press with Spring Return

...providing a simpler solution. a constant force spring maybe similar to what is in a tape measure. it always...

thingiverse

free

Tiltable Camera Mount by Geldar0124

...crew 10mm

4 x m5 nut

1 x 1/4" to 3/8" reducer bushing screw

1 x 1/4'' male to 1/4'' male threaded screw

grabcad

free

Tiltable Camera Mount

...crew 10mm

4 x m5 nut

1 x 1/4" to 3/8" reducer bushing screw

1 x 1/4'' male to 1/4'' male threaded screw

thingiverse

free

3 Wheel X carriage attachment and X belt adjuster for the Tarrantula by jimwooly

...place the 20mm bolt and ensure all 3 wheels are making contact with the v channel.

9) the remaining assemble is straght foreward.

thingiverse

free

Openbuilds v-slot X axis for Lulzbot TAZ 6 printers by piercet

...head m5 bolts and nuts 30mm (standard bolts will not fit, need the flat ones. ). longer if you plan to add the cable chain pieces

thingiverse

free

CobbleBot Heatbed Table by FoL

...hi, this is a heatbed holder to cobblebot (or similar printer on 20mm profile). it fits to 2 mm...

thingiverse

free

Belt tensioner axis Y Prusa i3 by 3DWnico

...self-locking nut m5

4 m4 nuts

2 m4 screws

belt tensioner designed for prusa i3 hictop but extensible for all prusa i3 versions.

thingiverse

free

Adjustable cabinet foot for M5 screw

...with (4) #8x3/8" round head sheet metal screws or similar i printed them in carbon fiber pla for my...

thingiverse

free

Corner_clamp by oskr63

...nuts and standard screws 1/4 "2.5" long. it is ideal to add a spring to help separate the plate that presses the parts.

Air0N

thingiverse

free

HandSky by air0ne

...handsky by air0ne

thingiverse

just another print test

thingiverse

free

Toilet Sign by air0ne

...toilet sign by air0ne

thingiverse

classic toilet sign

thingiverse

free

C64 logo by air0ne

...c64 logo by air0ne

thingiverse

vintage commodore 64 logo

thingiverse

free

Space Invader Logo by air0ne

...space invader logo by air0ne

thingiverse

i created that for my office door

Press

archibase_planet

free

Press

...ibase planet

press squeezer masher

press garment heat press n131213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Press

...press

archibase planet

newspaper daily paper magazine

press - 3d model for interior 3d visualization.

archibase_planet

free

Press

...press

archibase planet

gymnastic apparatus gym

gym leg press - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Press bench

...press bench

archibase planet

bench press press bench gym

press bench - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$20

iron press

...iron press

3dexport

iron press

3d_export

$15

punch press

...punch press

3dexport

punch press

3d_export

$10

Grape press

...grape press

3dexport

grape press

3d_ocean

$9

Fruit Press

...fruit press

3docean

food and drinks fruit press furnishing

fruit press,food and drinks, furnishing

turbosquid

$20

Press

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Press

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Heat

3d_export

$5

heat

...heat

3dexport

heat tool

3ddd

$1

electric heating

...electric heating

3ddd

обогреватель

electric heating

3d_export

$6

The heating module

...any questions also you can email to me. designed with solidworks 2017, render with keyshot **************************************

turbosquid

$2

Heating Radiator

...

royalty free 3d model heating radiator for download as blend on turbosquid: 3d models for games, architecture, videos. (1561908)

3d_export

$35

heating instalation with heat pump and solar system

...el , please contact me. before buying a model, you can try to download one of my free models and testing. thank you for watching.

turbosquid

$29

Heating Mantle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Heating Radiator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

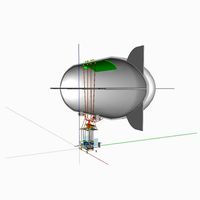

AT_airship_control_stand_(heated)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

AT_airship_(heated)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Heating radiator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Insert

turbosquid

$10

insert a bracelet

... 3d model the link element insert for download as max and max on turbosquid: 3d models for games, architecture, videos. (1609593)

turbosquid

$56

Threaded Inserts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Insert for eggs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$14

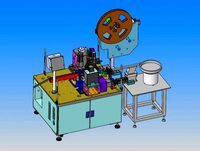

drawing of needle inserting machine

...lectronic manufacturers use pin machines to help customers to insert needles, so as to obtain processing costs and obtain wealth.

turbosquid

$5

IKEA Insert drawers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

IKEA insert with door

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Siemsn EQ 6 Inlet insert

...placed there without any problems. the insert is then straight for normal cups and a square insert can be removed for large cups.

turbosquid

$25

eagle insert on leather or rubber

...eagle insert on leather or rubber for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1342476)

turbosquid

$22

Fireplace Stovax - Knightsbridge Insert

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Fireplaces Stovax - Knightsbridge Insert

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.