GrabCAD

Gundrills, Reamers, Rifling Buttons, and Toolpost Holder for: 556NATO (223 remington), and 762NATO (308 Winchester)

by GrabCAD

Last crawled date: 1 year, 11 months ago

Gundrills, Reamers, Rifling Buttons, and Toolpost Holder for: 556NATO (223 remington), and 762NATO (308 Winchester).

In making the barrel; Heattreat the blank to 27-32 HRC, gundrill, than ream with the rough reamer, than the finishing reamer, turn the outside diameter of the blank to get a true to boore outside diameter, than button rifle, than stress relief the barrel again to 27-32 HRC. You now can profile the barrel how you want on the outside without ruining the rifling and boore dimensions.

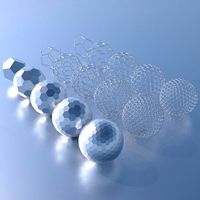

I did a lot of research on the correct sizes of the parts. The thickness of the gundrill shanks however, the only reference i have got is from the modern gunsmith file: "(.281-.218)/2=.0315 thick walls, or .0315*25.4= .8001mm thick." Use the picture of the mcmaster catalog to get an idea what kind of steel tubes are around, from these sizes you should make your pick (there are more sizes around, keep that in mind).

The reamers are the newest addition to my uploads, these do need some explanation: The reamers need unevenly spaced flutes because otherwise they will cause chatter! Chatter is a very destructive phenomenon that will destroy gundrills and reamers alike.

Division on the flutes in degrees:

4 fluted reamer 1st 0

2nd 88.1538

3rd 180.9231

4th 268.6154

6 fluted reamer 1st 0

2nd 59.0769

3rd 121.1538

4th 178.8462

5th 241.3846

6th 298.8462

The right fluid pressure, right angles on the tools when making/resharpening, and feed rate, are essential in keeping these tools from catastrophically failing and destroying the barrel and the tools itself (that is the worst case scenario). See the ReportGundrilling file for examples. Figures on the oil pump? If you run up to .50 CAL, 7 gallons per minute, pressure 525 psi, 2.5 hp. With smaller calibers the psi rating goes up and the hp and gpm goes down. 700psi/4gpm/2hp 30 cal, 1000psi/2gpm/1.5hp for 22 cal. Other sources: 700psi for drilling, 200psi for reaming. You want a low volume high hydraulic pressure pump with at least 1000psi force. Get a 1.5hp low volume high pressure hydraulic pump and it should be fine.....

I added some books by Harold Hoffman that go into detail on making barrels and tools. I also added some pictures of home made toolpost grinders (some of the easiest ones looked like wood routers in a frame). If you want to make gundrills, reamers and buttons yourself, it is essential that you have this tool for your lathe.

A lathe with a spindle bore no less than 1.5" is essential for drilling barrels for the button rifling method. Up to 50 bmg barrels can be made with this. I have seen some table top models that can do this. You also need a vertical milling machine to make the reamers. But basically you want a milling machine that is big enough to mill your receiver or pistol part, and also has room for a dividing head to make your barrel making tools in.

I also have added a toolpost holder for the gundrill, and reamer.

The reamers, buttons, and adapters are inductions brazed onto each other. As can be seen in some of the pictures and videos. Also the video shows a gundrill shank being heated by induction, formed and heat treated at the same time. Very interesting to see induction again, just as we saw in the bullet factory upload. I am still looking for a book that has all the answers about induction in it. So i can design my own induction apparatus.

I added 2 more books, one about metal working, and another one about welding. Check out page 260 of the welding book, and page 230, and 313 of the machining book. Check page 833 of the Machinery handbook. Check jigs and fixtures for ideas on how to build them for holding your tools and parts for machining.

It is best to read and make both the welding and the machining book, an keep all the other books i give you a read. Keep the Machining book for reference when you try to build something.

Next upload: Probably the 6.5 creemoor, 300 blackout, 300 HAM'R, and 22TCM.. Or maybe the heattreatment oven module 15 amp 230 volt, 3 modules.. I guess we will see...

Please press the like button when downloading!

For now the upload is a bit of a mess, i will clean this up tomorrow. Some shanks and other parts files/ assemblies got uploaded.

NOTES:

223 Remington Barrel (.219 bore, .224 groove)

-Barrel blank 1.125"-1.250" diameter (drilled and reamed before turning outside diameter)

-HRC (rockwell C) 27-32 HRC

-Drill .213"

-Gundrill shank .198" OD, .152" ID (This may be to thin (!!!) so: .120" ID if it f*cks up)

-Reamer 1 .217"

-Reamer 2 (bore dia.) .2195"

-Land on reamer 1/64"

-Rake angle reamer 5 degree

-Relief angle reamer 13 degree

-Flutes 6

-Flute width .044

-Reamer rod .202" OD, .120" ID

-Button rifler/reamer .2278/.2202"

-Button pull rod .208"

308 Winchester Barrel (.300 bore, .308 groove)

-Barrel blank 1.125"-1.250" diameter (drilled and reamed before turning)

-HRC (rockwell C) 27-32 HRC

-Drill .294"

-Gundrill shank .281" OD, .218" ID (or 7mm (.276") OD and 5mm (.197") ID)

-Reamer 1 .298"

-Reamer 2 .3005"

-Land on reamer 15/704"

-Rake angle reamer 5 degree

-Relief angle reamer 13 degree

-Flutes 6

-Flute width .060

-Reamer rod .277" OD

-Button rifler/reamer .3132"/.3012"

-Button pull rod .290"

Button rifle and then stress relief to 27-32 HRC, it makes the bore and rifling spring back to SAAMI specification. (.219 boore and .224 rifling, and .300 boore, and .308 rifling, for 556NATO and 762NATO accordingly)

In making the barrel; Heattreat the blank to 27-32 HRC, gundrill, than ream with the rough reamer, than the finishing reamer, turn the outside diameter of the blank to get a true to boore outside diameter, than button rifle, than stress relief the barrel again to 27-32 HRC. You now can profile the barrel how you want on the outside without ruining the rifling and boore dimensions.

I did a lot of research on the correct sizes of the parts. The thickness of the gundrill shanks however, the only reference i have got is from the modern gunsmith file: "(.281-.218)/2=.0315 thick walls, or .0315*25.4= .8001mm thick." Use the picture of the mcmaster catalog to get an idea what kind of steel tubes are around, from these sizes you should make your pick (there are more sizes around, keep that in mind).

The reamers are the newest addition to my uploads, these do need some explanation: The reamers need unevenly spaced flutes because otherwise they will cause chatter! Chatter is a very destructive phenomenon that will destroy gundrills and reamers alike.

Division on the flutes in degrees:

4 fluted reamer 1st 0

2nd 88.1538

3rd 180.9231

4th 268.6154

6 fluted reamer 1st 0

2nd 59.0769

3rd 121.1538

4th 178.8462

5th 241.3846

6th 298.8462

The right fluid pressure, right angles on the tools when making/resharpening, and feed rate, are essential in keeping these tools from catastrophically failing and destroying the barrel and the tools itself (that is the worst case scenario). See the ReportGundrilling file for examples. Figures on the oil pump? If you run up to .50 CAL, 7 gallons per minute, pressure 525 psi, 2.5 hp. With smaller calibers the psi rating goes up and the hp and gpm goes down. 700psi/4gpm/2hp 30 cal, 1000psi/2gpm/1.5hp for 22 cal. Other sources: 700psi for drilling, 200psi for reaming. You want a low volume high hydraulic pressure pump with at least 1000psi force. Get a 1.5hp low volume high pressure hydraulic pump and it should be fine.....

I added some books by Harold Hoffman that go into detail on making barrels and tools. I also added some pictures of home made toolpost grinders (some of the easiest ones looked like wood routers in a frame). If you want to make gundrills, reamers and buttons yourself, it is essential that you have this tool for your lathe.

A lathe with a spindle bore no less than 1.5" is essential for drilling barrels for the button rifling method. Up to 50 bmg barrels can be made with this. I have seen some table top models that can do this. You also need a vertical milling machine to make the reamers. But basically you want a milling machine that is big enough to mill your receiver or pistol part, and also has room for a dividing head to make your barrel making tools in.

I also have added a toolpost holder for the gundrill, and reamer.

The reamers, buttons, and adapters are inductions brazed onto each other. As can be seen in some of the pictures and videos. Also the video shows a gundrill shank being heated by induction, formed and heat treated at the same time. Very interesting to see induction again, just as we saw in the bullet factory upload. I am still looking for a book that has all the answers about induction in it. So i can design my own induction apparatus.

I added 2 more books, one about metal working, and another one about welding. Check out page 260 of the welding book, and page 230, and 313 of the machining book. Check page 833 of the Machinery handbook. Check jigs and fixtures for ideas on how to build them for holding your tools and parts for machining.

It is best to read and make both the welding and the machining book, an keep all the other books i give you a read. Keep the Machining book for reference when you try to build something.

Next upload: Probably the 6.5 creemoor, 300 blackout, 300 HAM'R, and 22TCM.. Or maybe the heattreatment oven module 15 amp 230 volt, 3 modules.. I guess we will see...

Please press the like button when downloading!

For now the upload is a bit of a mess, i will clean this up tomorrow. Some shanks and other parts files/ assemblies got uploaded.

NOTES:

223 Remington Barrel (.219 bore, .224 groove)

-Barrel blank 1.125"-1.250" diameter (drilled and reamed before turning outside diameter)

-HRC (rockwell C) 27-32 HRC

-Drill .213"

-Gundrill shank .198" OD, .152" ID (This may be to thin (!!!) so: .120" ID if it f*cks up)

-Reamer 1 .217"

-Reamer 2 (bore dia.) .2195"

-Land on reamer 1/64"

-Rake angle reamer 5 degree

-Relief angle reamer 13 degree

-Flutes 6

-Flute width .044

-Reamer rod .202" OD, .120" ID

-Button rifler/reamer .2278/.2202"

-Button pull rod .208"

308 Winchester Barrel (.300 bore, .308 groove)

-Barrel blank 1.125"-1.250" diameter (drilled and reamed before turning)

-HRC (rockwell C) 27-32 HRC

-Drill .294"

-Gundrill shank .281" OD, .218" ID (or 7mm (.276") OD and 5mm (.197") ID)

-Reamer 1 .298"

-Reamer 2 .3005"

-Land on reamer 15/704"

-Rake angle reamer 5 degree

-Relief angle reamer 13 degree

-Flutes 6

-Flute width .060

-Reamer rod .277" OD

-Button rifler/reamer .3132"/.3012"

-Button pull rod .290"

Button rifle and then stress relief to 27-32 HRC, it makes the bore and rifling spring back to SAAMI specification. (.219 boore and .224 rifling, and .300 boore, and .308 rifling, for 556NATO and 762NATO accordingly)

Similar models

grabcad

free

Floating reamer holder

...the bronze body - and yet there is no lost motion is the axial direction.

the 1/2" shank fits in a collet or a drill chuck.

grabcad

free

TOOL NO. C18

...tool no. c18

grabcad

hardinge turret top plate tooling

2-bolt drill and shank tool holder 5/8" bore

grabcad

free

Drill Press

...drill press

grabcad

for drilling holes; can also be used for enlarging holes with a boring tool or finishing holes with a reamer

grabcad

free

100 Degree 3 Flute Countersink

...ameter hss, 100 degree, 3 flute rh countersink tool, 2-5/8" oal. used for 100 degree fhcs flat head cap screws to lie flush.

grabcad

free

boor met cilindrische schacht, drill bit with cylindrical shank

...ll bit with cylindrical shank

grabcad

boor met een correct gemodelleerde punt 118 graden.

drill bit with a correctly modeled tip

thingiverse

free

Drill trays for 1/2" reduced shank (Silver & Deming) drills, flute sizes 1/2" to 1" by caveduck

...of size parameters, and then make multiple trays that subtract different groups of tools to accommodate your subset of the tools.

thingiverse

free

Bore guide .308 hunting rifle by ShaneeRabie

...08 hunting rifle by shaneerabie

thingiverse

i printed this bore guide to help my brother clean his .308 hunting rifle with ease.

grabcad

free

AXA - R8 Tool holder

...l become indexable because they remain in the tormach collet when mounted on the lathe.

the files were created in inventor 2015.

grabcad

free

.308 / 762x51mm automatic rifle homemade with mill and latch

...that to allow fabrication with a simple latch and a mill machine (you need a special tool to make the rifle twist in the barrel).

thingiverse

free

.308 / 7.62 NATO bore guide by gingerbearded84

...er or 7.62x51mm nato to prevent unnecessary internal barrel throat wear from use of cleaning rod. may or may not fit other rifles

Gundrills

762Nato

thingiverse

free

(AT1-762NATO) TRAY CASE ASS'Y, AMMUNITION 7.62 NATO by SBSExtensions

...g orientation options.

all four (4) trays were revised for external uniformity

added at1-5a-762nato.

removed at1-6-762nato.

grabcad

free

M855A1 62gr 556NATO, M80A1 130gr 762NATO, M80A1 derived 150gr

...://youtu.be/ah_gijsxr9e

note: these rounds still perform subsonic, and thus at extended ranges if shot supersonic at full speed.

3dwarehouse

free

762NATO 7.62×51mm NATO 7.62

...

draft model! sizes from c.i.p. (permanent international commission for the proof of small arms) #ammo #762nato #nato #cartridges

3dwarehouse

free

x100 762NATO in MTM RM-100 16T

...t

3dwarehouse

dynamic! draft model! !!warning!!! size \approx the original product may be larger #ammo #ammobox #ammunition #mtm

3dwarehouse

free

original guns

...acc, 20in 7.62 nato ver. included #556mm #556mmnato #762mm #762nato #assault_rifle #assault_rifles #cad #firearm #firearms #gun #guns #homemade #original...

556Nato

thingiverse

free

(AT1-556NATO) TRAY CASE ASS'Y, AMMUNITION 5.56 NATO by SBSExtensions

...but have not been tested.

update: (2016-06-27)

at1-5-556nato: width of strap increased by 0.8mm, to compensate for abs shrinkage.

thingiverse

free

Open source case feeder - 223R/556Nato or 308W (Dillion 650, Hornady L&L etc) by gzcwnk

...use aliexpress? and not say amazon or ebay?

because i am not in the usa and shipping hurts.

please note this is gpl2/3 licenced.

grabcad

free

M855A1 62gr 556NATO, M80A1 130gr 762NATO, M80A1 derived 150gr

...://youtu.be/ah_gijsxr9e

note: these rounds still perform subsonic, and thus at extended ranges if shot supersonic at full speed.

cg_trader

$10

AR15 Drum Mag

...hp lp mesh:- wpn _ mag _ ar15 _ 556nato _ name material:- m _ mag _ ar15 _...

3dwarehouse

free

556NATO 5.56×45mm NATO 5.56

...

draft model! sizes from c.i.p. (permanent international commission for the proof of small arms) #ammo #556nato #nato #cartridges

3dwarehouse

free

original gun(black model)

...can disassemble to parts from this object #556cal #556mm #556nato #arm #arms #army #assault_rifle #assaultrifle #combat #dotsight #fiearms #fight...

Toolpost

thingiverse

free

toolpost dial guage mount for Emco compact 5 quick change toolpost by stillcool40

... emco compact 5 quick change toolpost by stillcool40

thingiverse

could be modified to take other gadgets. good fit on toolpost!

thingiverse

free

emco toolpost dremel 8200 mount by iainanderson

...emco toolpost dremel 8200 mount by iainanderson

thingiverse

mounts a dremel 8200 cordless to an emco compact 5

thingiverse

free

Lathe Drill guide for 1" toolpost by Gagdet

...ws creations such as theo haralampou's holey bauble.

this is for a 1" diameter toolpost as found on the axminster lathe.

thingiverse

free

Indicator holder for AXA toolpost by moonismyhome

...dovetail. i will try to add the corrected file this summer if i have time, and i'll try to upload the original files as well.

thingiverse

free

6 in 1 lathe quick change toolpost adapter by LarryStein

...o make it, believe it or not, only just compatible with 12mm tools. i'm loving the finish carbide inserts gives on aluminium.

thingiverse

free

Lathe drill guide for 1" toolpost by Gagdet

... from axminster.

printed with 10 shells to allow for strong wall for banjo clamping. i used a jubilee clip to set centre height.

thingiverse

free

Sieg SC4 Toolpost Dial Gauge Holder

...post holder.

v1 needed a 3mm shim in order to place the centre of the gauge at the correct height.

v2 holds the gauge 4mm higher.

thingiverse

free

Simple toolpost grinder for 10" lathe by leadinglights

...

pictures show grinder in use as a cutter, grinding a 4mm tap and 3mm copper and aluminium 'o' rings cut from stock tube

thingiverse

free

T2 Lathe Toolpost Toolholder by johnpanter

... in the 4 jaw chuck. needed a bit of fettling to slot onto the post but does a fine job and saves paying £40 for a metal holder.

thingiverse

free

dial indicator for axa toolpost for a smaller lathe by magiva

...it is now a few mm low)

the dial is mounted with a m6 screw, threaded inteo the plastic. i use a thread tap to clear the threads.

Reamers

turbosquid

$20

Bone Reamer

...bosquid

royalty free 3d model bone reamer for download as ma on turbosquid: 3d models for games, architecture, videos. (1223049)

turbosquid

$5

Lemon Reamer

...el lemon reamer for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1457677)

3d_ocean

$3

Peeler Reamer 3D Model Low - High Poly

... / images and read description carefully before you buy. thanks. created 100% quad faces. render system, materials and environ...

thingiverse

free

reamer holder by Mictnt

...reamer holder by mictnt

thingiverse

10pc reamer holder 3mm to 12mm

thingiverse

free

Reamer Holder (Metric) by PotatoX

...reamer holder (metric) by potatox

thingiverse

a simple reamer holder.

thingiverse

free

SphereHandle for reamer ф6mm by Andrew1978

...spherehandle for reamer ф6mm by andrew1978

thingiverse

just 30mm handle for reamer 6mm

thingiverse

free

Reamer Cover by owlfab

...epairman's reamer that snaps onto the reamer end. i printed it in petg so it's tough and the snap end has a little flex.

thingiverse

free

Metric Reamer Index by urw

...a quick index for my cheap set of metric reamers ...

thingiverse

free

Reamer handles by mgg942

...a selection of ebay and other on-line sourced hand reamers and now i've made handles for them which is...

thingiverse

free

Hand reamers set box by ToFe

...et:https://www.aliexpress.com/item/3mm-4mm-5mm-6mm-7mm-8mm-9mm-10mm-11mm-12mm-10pcs-set-hand-reamers-hand-reamer/32620425303.html

Winchester

turbosquid

$49

Winchester

...lty free 3d model winchester for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1293904)

turbosquid

$1

Winchester

... free 3d model winchester for download as 3ds, obj, and blend on turbosquid: 3d models for games, architecture, videos. (1362082)

turbosquid

$1

Winchester

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

308 Winchester

...r

turbosquid

free 3d model 308 winchester for download as ma on turbosquid: 3d models for games, architecture, videos. (1181654)

turbosquid

$19

winchester 1866

...

royalty free 3d model winchester 1866 for download as blend on turbosquid: 3d models for games, architecture, videos. (1190998)

turbosquid

$19

winchester 1894

...

royalty free 3d model winchester 1894 for download as blend on turbosquid: 3d models for games, architecture, videos. (1190990)

turbosquid

free

WInchester 1866

... 3d model winchester 1866 for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1463107)

turbosquid

$3

Winchester 12

...3d model winchester 12 for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1384349)

3d_ocean

$10

Low Poly Winchester Rifle

...low poly winchester rifle

3docean

low poly rifle winchester

low poly winchester rifle 313 polys

turbosquid

$35

Winchester Rifle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Remington

3ddd

free

дробовик Remington

...дробовик remington

3ddd

дробовик

дробовик remington

3ddd

$1

Remington

...ремингтон, делался для игры, так что в архиве присутствуют 2 модели, с оптикой высокополигональная, без оптики низкополигональная

turbosquid

$25

Remington ACR

...bosquid

royalty free 3d model remington acr for download as on turbosquid: 3d models for games, architecture, videos. (1316834)

turbosquid

$40

Remington 1858

...uid

royalty free 3d model remington 1858 for download as obj on turbosquid: 3d models for games, architecture, videos. (1427579)

turbosquid

$20

Remington 1100

...uid

royalty free 3d model remington 1100 for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1272874)

3ddd

$1

Shootgun Remington R12

...shootgun remington r12

3ddd

ремингтон , ружье

гладкоствольное ружье remington r12

3d_ocean

$9

Remington Shotgun

...s: -.blend; rendered in the internal render engine -.obj; with applied materials -.fbx; with applied materials the model was o...

3d_ocean

$8

Low Poly Remington 1866

...low poly remington 1866

3docean

low poly remington

low poly remington 1866

turbosquid

$16

Remington chair

...ee 3d model remington chair for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1296647)

turbosquid

$20

Remington ACR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

223

turbosquid

$18

plants 223

...

royalty free 3d model plants 223 for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1468325)

turbosquid

free

223-AMMOBOX

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Fallout Pistol 223

...bosquid

royalty free 3d model 223 for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1482082)

3d_export

$5

223 Ammo Bullets 3D Model

...223 ammo bullets 3d model

3dexport

223 ammo // bullets

223 ammo bullets 3d model nick2012 62621 3dexport

turbosquid

$7

Rug Set 223

...y free 3d model rug set 223 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1497443)

turbosquid

$17

Coffee Table_ 223

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Geometric Shape 223

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Gervasoni InOut 223

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

223 Calhoon Round

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

LowPoly Character Male 223

...223

turbosquid

royalty free 3d model 223 for download as obj on turbosquid: 3d models for games, architecture, videos. (1242232)

308

3d_export

$5

dino 308 gt4

...dino 308 gt4

3dexport

ferrari dino 308 gt4

turbosquid

free

308 Winchester

...r

turbosquid

free 3d model 308 winchester for download as ma on turbosquid: 3d models for games, architecture, videos. (1181654)

3d_export

$10

peugeot 308 t7

...peugeot 308 t7

3dexport

peugeot 308 t7 (2008-2011) premium pack

turbosquid

$50

KT-308

...y free 3d model kt-308 for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1441452)

3d_export

$19

Peugeot 308 3D Model

...peugeot 308 3d model

3dexport

peugeot 308

peugeot 308 3d model ones 58833 3dexport

3d_ocean

$89

Peugeot 308 2012

...www.youtube.com/watch?v=28iaxsjgaxy with its new lines, the peugeot 308 subtly incorporates the marque’s latest stylistic code...

turbosquid

$1

Cartridge .308 Winchester

...y free 3d model cartridge .308 winchester for download as fbx on turbosquid: 3d models for games, architecture, videos. (1521053)

design_connected

$13

Wireflow 306 & 308

...hoto-realistic 3d models of the wireflow 306 & 308 pendant from vibia for 3d architectural and interior design presentations.

3d_ocean

$89

Peugeot 308 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

turbosquid

$17

Nokia Asha 308

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Rifling

3d_ocean

$9

rifle

...rifle

3docean

gun low poly rifle soldier weapon

rifle model max 2013 and obj 1024×1024 texture lowpoly

turbosquid

$30

Rifle

...le

turbosquid

royalty free 3d model rifle for download as ma on turbosquid: 3d models for games, architecture, videos. (1161496)

turbosquid

$1

rifle

...turbosquid

royalty free 3d model rifle for download as blend on turbosquid: 3d models for games, architecture, videos. (1344661)

3d_export

$5

longfire rifle

...longfire rifle

3dexport

longfire rifle

3d_export

free

butt of the rifle

...butt of the rifle

3dexport

butt of the rifle

3d_export

free

repeater rifle

...repeater rifle

3dexport

repeater rifle

3d_export

$15

Rifle v2

...rifle v2

3dexport

assault rifle, designed for the protection and storming of objects. the rifle has a paralytic function.

turbosquid

$20

Rifle

...quid

royalty free 3d model rifle for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1301083)

3d_export

$5

rifle sks

...rifle sks

3dexport

rifle sks simonov

turbosquid

$49

Rifle

...

royalty free 3d model rifle for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1582428)

Buttons

archibase_planet

free

Buttons

...buttons

archibase planet

lift elevator call buttons

elevator call buttons - 3d model for interior 3d visualization.

3ddd

$1

Button

... button , john reeves

набор мебели button от дизайнера john reeves

3d_export

$5

Button

...button

3dexport

smd button<br>verts 2.180<br>faces 3.848

turbosquid

$4

Button

...

turbosquid

royalty free 3d model button for download as fbx on turbosquid: 3d models for games, architecture, videos. (1297941)

turbosquid

$1

Button

...

turbosquid

royalty free 3d model button for download as fbx on turbosquid: 3d models for games, architecture, videos. (1392935)

turbosquid

$9

buttons

...id

royalty free 3d model buttons for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1404875)

turbosquid

$6

button

...uid

royalty free 3d model button for download as 3dm and max on turbosquid: 3d models for games, architecture, videos. (1669204)

turbosquid

$5

Button

...uid

royalty free 3d model button for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1710868)

turbosquid

$3

Button

...quid

royalty free 3d model button for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1510524)

turbosquid

$3

Button

...quid

royalty free 3d model button for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1509961)

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.