Thingiverse

Grass Trimmer Part V2 by wisestone

by Thingiverse

Last crawled date: 3 years ago

My grass trimmer has a third party head attachment fitted. I much prefer a fixed head to the original spool tap approach. I often found that the filament broke at the spool opening, which meant opening the spool to rethread before I could continue with my lawn duties.

The third party trimmer head is a Saber Cut UN-59K 3 Blade/Line Heavy Duty. I have this head attached to my Makita DUR368LZ 18Vx2 Line Trimmer.

After 2 years, one of the filament holders on the third party head broke. This broken part is not available as a spare part, so it was either buy a whole new head or 3D print a new holder. Here is my 3D replacement part.

I used PETG filament to make the part. I found that an exact size part copy was not durable in PETG and soon broke. My part version has been strengthened by increasing some of the dimensions and with some subtle design improvements appears to make the part more resilient. Fortunately the 3D part is cheap and easy to replace, so should the other holders break, too, I can replace them, too.

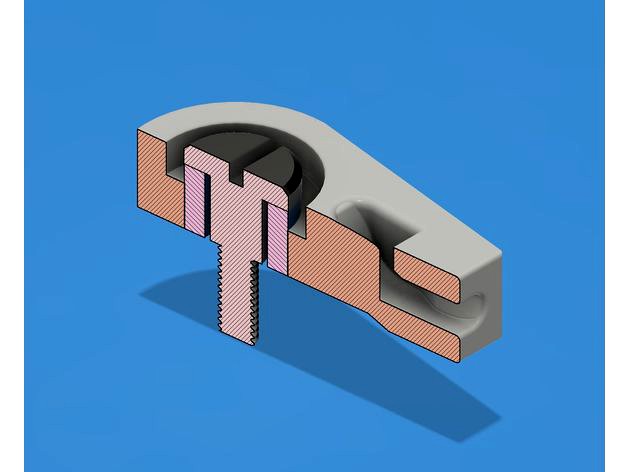

During normal use, friction heats the metal screw holding the mount in place. The hot metal screw is sufficient to raise the PETG in contact with it above it's "glass" temperature and will deform, eventually failing.

I introduced a LLDPE bush between the metal screw and the PETG mount. The Linear low-density polyethylene (LLDPE) has a melting point of 122°C, providing a heat barrier. LLDPE tubing is commonly used in plumbing applications, so is readily available for others to do the same.

The aim of the LLDPE is to separate the hot metal screw, heated by friction from the PETG. Cut the LLDPE tube section of sufficient length to also provide a heat separation from the screw head, too (see included images). With the LLDPE tube section, the PETG deformation is signficiantly reduced, with no noticeable deformation after two 30min sessions of use.

My print is made in PETG 1.75mm 3DFillies black filament, with 0.2mm layer height and 100% infill on a PRUSA I3 MK3S printer.

I hope that you can find this print useful, too.

Remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

UPDATES

V1.0f

To overcome excess heat melting the part, include a cut of LLDPE bush over the screw. Mount mounting hole adjusted to allow for the LLDPE bush.

The third party trimmer head is a Saber Cut UN-59K 3 Blade/Line Heavy Duty. I have this head attached to my Makita DUR368LZ 18Vx2 Line Trimmer.

After 2 years, one of the filament holders on the third party head broke. This broken part is not available as a spare part, so it was either buy a whole new head or 3D print a new holder. Here is my 3D replacement part.

I used PETG filament to make the part. I found that an exact size part copy was not durable in PETG and soon broke. My part version has been strengthened by increasing some of the dimensions and with some subtle design improvements appears to make the part more resilient. Fortunately the 3D part is cheap and easy to replace, so should the other holders break, too, I can replace them, too.

During normal use, friction heats the metal screw holding the mount in place. The hot metal screw is sufficient to raise the PETG in contact with it above it's "glass" temperature and will deform, eventually failing.

I introduced a LLDPE bush between the metal screw and the PETG mount. The Linear low-density polyethylene (LLDPE) has a melting point of 122°C, providing a heat barrier. LLDPE tubing is commonly used in plumbing applications, so is readily available for others to do the same.

The aim of the LLDPE is to separate the hot metal screw, heated by friction from the PETG. Cut the LLDPE tube section of sufficient length to also provide a heat separation from the screw head, too (see included images). With the LLDPE tube section, the PETG deformation is signficiantly reduced, with no noticeable deformation after two 30min sessions of use.

My print is made in PETG 1.75mm 3DFillies black filament, with 0.2mm layer height and 100% infill on a PRUSA I3 MK3S printer.

I hope that you can find this print useful, too.

Remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

UPDATES

V1.0f

To overcome excess heat melting the part, include a cut of LLDPE bush over the screw. Mount mounting hole adjusted to allow for the LLDPE bush.

Similar models

grabcad

free

Grass Trimmer Part V2

...ess heat melting the part, include a cut of lldpe bush over the screw. mount mounting hole adjusted to allow for the lldpe bush.

thingiverse

free

Grass Trimmer Part by wisestone

...find this print useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

grabcad

free

Grass Trimmer Part

...ind this print useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

Ender 3 extended spool holder by Zvedak

..., because they are not necessary here.

i recommend to use nut_square because of easy tightening.

note: made for my 2018 ender 3.

thingiverse

free

CTC Replicator Overhead Spool Holder by OzJohnson

... inside diameter ptfe tube (see photo), i didn't realise that the slack in the filament only gets taken up when this is used.

thingiverse

free

Bowden extruder motor mount spool holder by ksevin

...uder motor on my spool holder. this way, the teflon tube is shorter thus minimizing the friction of the filament inside the tube.

thingiverse

free

Mount for low friction spool holder (608) by Dogm

...replace default duplicator spool tubes.

best for low friction spool holder (608 bearing)http://www.thingiverse.com/thing:235925

thingiverse

free

Hatchbox Bearing Holder V2 by phrogg111

...o plan to redesign this again at a later date to better work with the printrbot simple metal so the spool will sit sideways, too.

thingiverse

free

Husqvarna c122 trimmer customized bolt

...c122 trimmer customized bolt

thingiverse

this is a customized bolt to install a third party head on my husqvarna c122 trimmer...

thingiverse

free

Filament tube holder by DeepDiverDude

...filament tube holder by deepdiverdude

thingiverse

a holder for a 50mm pvc tube that i mount my filament spools on.

Wisestone

thingiverse

free

Ikea Hook by wisestone

...find this print useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

Mounting Brackets by wisestone

...find this print useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

Links Tray by wisestone

...find this print useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

Salt Meter by wisestone

...ind this design useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

35mm Clamp by wisestone

...find this print useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

Collet 42 to 35mm by wisestone

...find this print useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

5 Hooks Hanger by wisestone

...find this print useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

Potentiometer Knob 05 by wisestone

...find this print useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

Toggle Switch by wisestone

...ind this design useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

thingiverse

free

BNC Connector by wisestone

...ind this design useful, too.

remember to leave me some feedback or even a tip to keep me enthused to make more of these drawings.

Trimmer

3d_ocean

$15

Trimmer

...trimmer

3docean

beard cut electronic face hair head tool trim trimmer

electronic trimmer for hair and beard.

archive3d

free

Trimmer 3D Model

...rclipper trimmer

trimmer mosser n160910 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$2

Hair trimmer

...uid

royalty free 3d model hair trimmer for download as blend on turbosquid: 3d models for games, architecture, videos. (1382562)

turbosquid

$20

Trimmer, razor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Golden Nail Trimmers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$18

PANASONIC Trimmer

...

royalty free 3d model panasonic_trimmer for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313656)

cg_studio

$30

Grass trimmer - 013d model

...lwo .igs .dwg .c4d .max .3ds .3dm - grass trimmer - 01 3d model, royalty free license available, instant download after purchase.

3d_export

$8

hair trimmer 04

...& .obj. please rate, when you buy. thanks! :) also, please check out my other useful portfolio items that you may be missing!

3d_export

$8

hair trimmer 01

...& .obj. please rate, when you buy. thanks! :) also, please check out my other useful portfolio items that you may be missing!

3d_export

$25

Grass trimmer Villager ET 500 3D Model

...del

3dexport

grass trimmer villager et 500 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl pezon62 103467 3dexport

Grass

3d_export

free

Grass

...grass

3dexport

grass

3d_export

free

Grass

...grass

3dexport

grass

3d_ocean

$9

Grass

...grass

3docean

field foot gazon grass green nature

grass summer

3d_export

$5

grass

...grass

3dexport

the grass is green

3d_export

$5

grass

...grass

3dexport

9 models of grass

archibase_planet

free

Grass

...grass

archibase planet

grass herb sward

grass n230714 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$6

grass

...grass

3dexport

grass<br>blender 2.79

3d_export

$5

Grass

...grass

3dexport

realistic grass area, made by particle system.

3d_export

$5

Grass

...es grass 3: 682 faces, 658 vertices grass 4: 950 faces, 902 vertices .fbx files and texture maps included tested in unity and ue5

3d_export

$5

grass

... quality and realistic texture. in the .blend format, the customized material and ready-made grass are attached. .fbx .obj .blend

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

$20

Kitchen V2

...ty free 3d model kitchen v2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1155111)

turbosquid

$20

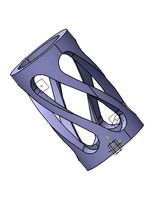

kengkod64-v2

... free 3d model kengkod64-v2 for download as 3dm, ztl, and stl on turbosquid: 3d models for games, architecture, videos. (1701415)

turbosquid

$19

Chair v2

...yalty free 3d model chair v2 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1693360)

turbosquid

$15

Table v2

...yalty free 3d model table v2 for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1688743)

Part

3d_export

$5

Parts

...parts

3dexport

parts

3d_export

$5

Part

...part

3dexport

part

3d_export

$5

Part

...part

3dexport

machine part

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$65

Part

...part

3dexport

simple rendering of the scene file

3d_export

$30

fan part

...fan part

3dexport

this is a part of fan of pedastal

3d_export

$10

machine parts

...machine parts

3dexport

3d part modeling work ,contact for 3d work

turbosquid

$17

Road parts

...bosquid

royalty free 3d model road parts for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1192967)

turbosquid

$9

Cutter Parts

...squid

royalty free 3d model cutter parts for download as stl on turbosquid: 3d models for games, architecture, videos. (1220010)

turbosquid

$8

Drum parts

...bosquid

royalty free 3d model drum parts for download as max on turbosquid: 3d models for games, architecture, videos. (1631178)