Thingiverse

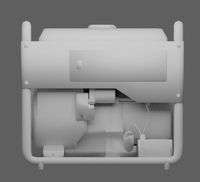

Generic car audio Tweeter mount 1" by David97

by Thingiverse

Last crawled date: 3 years, 1 month ago

This STL is a generic tweeter mount. Which serves as a useful way to mount tweeters to interior panels of cars.

They will need a lot of fitting, sanding, painting to get them looking good. But with enough time and patience, the results can look quite good.

I designed and built this to hold the tweeters provided in a alpine Alpine S-S65C kit. The tweeters are 1" driver, 2" mounting hole, and 17.6mm deep from the front lip. Given that these are designed around this set of tweeters, I would highly recommend doing some test prints and measurements, as the fit is quite tight. And they may not work well for every vehicle and tweeter combination. The vehicle I fitted these to was a 2004 ford courier.

Print in a material that will withstand the hot temperatures that the vehicle interior can reach. I recommend PETG, since it is easy to print, and withstands up to 80C

Assembly.

To position and fit the part I used Blu-Tack, or poster putty to position the mounts while the trims are in the vehicle. Using a dremil and grinding stone to shave down the tweeter pod. Getting it to fit well to the trim panel.

Once I had the fit correct and was happy with the position, I scribed around the part to mark the final position.

Scuff the surfaced that are to be glued together for good adhesion.Use super glue to hold hold it in the correct place.

Use epoxy resin to create a fillet between the parts.

I used fiberglass epoxy, WetSystem Z105 resin, 205 hardner, and 403 microfiber filler. No particular reason for using this stuff, other than that's what I had in my garage left over from other projects.

After mixing the resin, I added enough filler to make the resin fairly thick, so I could form a good bead between the printed part and plastic trim. Wetting a finger with rubbing alcohol to smooth out the bead and avoid the epoxy sticking to my finger helped create a smooth even fillet between both parts.

Using a sanding wheel on a dremel, I was able to sand the fillet, leaving a even radius all the way around. I used the dremel to cut out the back of the trim panel,, so I could fit the speaker and locking ring through.

Finish with hand sanding, and degreasing before applying primer filler. You may need to apply several coats of primer filler, depending on how good your sanding was. I used arcrylic based primer fill. After the primer filler drys, use wet sanding to remove any small imperfections or marks, starting at 600 grit, and progressively working up to finer sandpapers.

Finish by thoroughly washing and de-greasing. Wait for the part to dry, before applying a top coat of paint.

For my trim panel, I decided to use a satin black acrylic based rattle can. Since the color and shine closely resembled the original plastic. I'm no expert in whats the best paints to use, so use, but acrylic based paints seems to bind well with the plastics.

Unfortunately, I could not find any photos of the epoxy filling process. However will upload if I find them.

They will need a lot of fitting, sanding, painting to get them looking good. But with enough time and patience, the results can look quite good.

I designed and built this to hold the tweeters provided in a alpine Alpine S-S65C kit. The tweeters are 1" driver, 2" mounting hole, and 17.6mm deep from the front lip. Given that these are designed around this set of tweeters, I would highly recommend doing some test prints and measurements, as the fit is quite tight. And they may not work well for every vehicle and tweeter combination. The vehicle I fitted these to was a 2004 ford courier.

Print in a material that will withstand the hot temperatures that the vehicle interior can reach. I recommend PETG, since it is easy to print, and withstands up to 80C

Assembly.

To position and fit the part I used Blu-Tack, or poster putty to position the mounts while the trims are in the vehicle. Using a dremil and grinding stone to shave down the tweeter pod. Getting it to fit well to the trim panel.

Once I had the fit correct and was happy with the position, I scribed around the part to mark the final position.

Scuff the surfaced that are to be glued together for good adhesion.Use super glue to hold hold it in the correct place.

Use epoxy resin to create a fillet between the parts.

I used fiberglass epoxy, WetSystem Z105 resin, 205 hardner, and 403 microfiber filler. No particular reason for using this stuff, other than that's what I had in my garage left over from other projects.

After mixing the resin, I added enough filler to make the resin fairly thick, so I could form a good bead between the printed part and plastic trim. Wetting a finger with rubbing alcohol to smooth out the bead and avoid the epoxy sticking to my finger helped create a smooth even fillet between both parts.

Using a sanding wheel on a dremel, I was able to sand the fillet, leaving a even radius all the way around. I used the dremel to cut out the back of the trim panel,, so I could fit the speaker and locking ring through.

Finish with hand sanding, and degreasing before applying primer filler. You may need to apply several coats of primer filler, depending on how good your sanding was. I used arcrylic based primer fill. After the primer filler drys, use wet sanding to remove any small imperfections or marks, starting at 600 grit, and progressively working up to finer sandpapers.

Finish by thoroughly washing and de-greasing. Wait for the part to dry, before applying a top coat of paint.

For my trim panel, I decided to use a satin black acrylic based rattle can. Since the color and shine closely resembled the original plastic. I'm no expert in whats the best paints to use, so use, but acrylic based paints seems to bind well with the plastics.

Unfortunately, I could not find any photos of the epoxy filling process. However will upload if I find them.

Similar models

thingiverse

free

Necklace & Bracelet Tree Holder

...fit on my printer but may need to add epoxy to make it a nice fit. i finished the parts with spray filler primer and spray paint.

thingiverse

free

Millennium Puzzle - Yu-Gi-Oh! by MechDezignGuy

...d and paint it. going to use a glow in the dark paint for the cracks and around the eye. i'll update when i'm finished.

thingiverse

free

Mercedes Benz SL500 Convertible Top Flap Replacement Hinge by jtenkely

...ed part can lie flat on the underside of the cover.

3) epoxy the new part in place and let dry before replacing cover on the car.

thingiverse

free

Frankford Vibra Primer Tube Filler Adapter and Cap (small primer) by kkrebs76

...riction fit so adhesive is not required. i used tpu material though pla or abs could be used as well. the gcode is set for tpu.

thingiverse

free

Volvo 940 Window Crank Lid by xluccianox

...ssembling the door panel. good fit, sanded it gave base of primer, some stone textured paint and then a layer of dark grey paint.

thingiverse

free

Indiana Pacers by TrendyTrioLabs

...hem off with cork on the bottom. also, acetone vapor bathed the coaster holder before pouring resin in it for strength and shine.

thingiverse

free

BMW E30 tweeter pods speaker mounts by renglish

...r the tweeter.

i have also uploaded .step files for each part and a solidworks file so feel free to make changes if you need to.

thingiverse

free

Bear Filler Mount Remix by dirtsky

...me and modified the filler guide to make it a little easier to print (fillet's are just not good for fdm for some materials).

thingiverse

free

L.A. Lakers Coaster set by TrendyTrioLabs

...hem off with cork on the bottom. also, acetone vapor bathed the coaster holder before pouring resin in it for strength and shine.

thingiverse

free

Chicago Bulls Coaster set by TrendyTrioLabs

...hem off with cork on the bottom. also, acetone vapor bathed the coaster holder before pouring resin in it for strength and shine.

David97

thingiverse

free

Switch holder for Traxxas ERevo ESC by David97

...switch holder for traxxas erevo esc by david97

thingiverse

holds the esc power switch on traxxas erevo brushless edition

thingiverse

free

Prusa i3 mk2 level bed test by David97

...prusa i3 mk2 level bed test by david97

thingiverse

prusa i3 mk2 bed leveling test.

thingiverse

free

Defy DXR XT60 holder by David97

...quad frame.

ideal for pdb boards where the battery connectors are directly above and below each other, such as the betaflightf3.

thingiverse

free

Prusa i3 mk2 SD card holder. by David97

... behind the multi-sensory interface assembly.

stores up to three pieces of encapsulated silicone wafer.

*batteries not included

thingiverse

free

Defy DXR 30 degree mount for foxeer mini by David97

...tom plate using double sided servo tape, and run a ziptie over top to secure.

also allows you to reduce standoff length to 25mm.

thingiverse

free

Hakko toroidal transformer mount (80VA 230V conversion) by David97

... printed in abs, and used acetone to glue parts together.

don't attempt conversion unless you really know what you are doing!

thingiverse

free

Mini Servo operated Claw Machine Claw Grabber by David97

...acking out, and secured the cables to it with a zip tie.

here is a short video of the claw in actionhttps://youtu.be/higzmmk-rgw

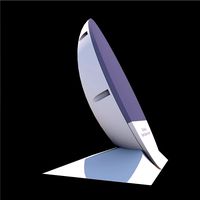

Tweeter

turbosquid

$75

tweeter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tweeter(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

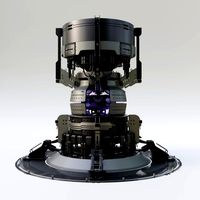

Speaker with one Subwoofer and a Tweeter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Tweeter Speaker 02 - Blender 3d

...r speaker 02 - blender 3d for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1678793)

turbosquid

free

Tweeter- Driver cornet - 02 Blender 3d

...er cornet - 02 blender 3d for download as blend, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1674965)

turbosquid

free

BOX Woofer Tweeter Cornet Blender 3D

...ver - cornet - blender 3d for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1676141)

3d_export

$15

E30 tweeter pods speaker mounts

...possible. printed with a layer of 0.2, a nozzle of 0.4. printed with abs plastic, interlayer adhesion is poor, i want to try petg

3d_ocean

$2

Tweet Tweet Bird

...tweet bird 3docean bird cartoon twitter a simple cartoon “tweeter bird. low polygon model perfect for any twitter related...

3d_export

$50

Bookshelf Speaker 3D Model

...speakers audio sound entertainment hifi home theater sub woofer tweeter vray bass treble music bookshelf speaker 3d model plutonius...

3d_export

$45

Speaker Set 3D Model

...speakers audio sound entertainment hifi home theater sub woofer tweeter vray bass treble music speaker set 3d model plutonius...

Audio

archibase_planet

free

Audio

...audio

archibase planet

home equipment audio

audio n170109 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Beats Audio

...beats audio

3ddd

наушники

наушники beats audio

3ddd

$1

колонки Monitor Audio

...колонки monitor audio

3ddd

monitor audio , monitor

колонки monitor audio - platinum

3d_ocean

$7

Audio speaker

...peakers stereo studio sub sub-woofer

high quality audio speakers. created in cinema4d but comes in various other formats as well.

3ddd

free

Clear Audio / Innovation

...clear audio / innovation

3ddd

clear audio / innovation

archive3d

free

Audio 3D Model

...ve3d

home equipment audio

audio n170109 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Vita Audio R4i

...vita audio r4i

3ddd

радио

vita audio r4i

turbosquid

$10

Audio Spectrum

...d

royalty free 3d model audio spectrum for download as blend on turbosquid: 3d models for games, architecture, videos. (1568428)

turbosquid

free

Audio Speaker

...quid

royalty free 3d model audio speaker for download as max on turbosquid: 3d models for games, architecture, videos. (1405286)

3d_export

$9

vintage audio cassette

...vintage audio cassette

3dexport

vintage audio cassette 3d model

Generic

3d_export

$17

Generator

...generator

3dexport

generator

archibase_planet

free

Generator

...base planet

generator electric generator

generator electric n300715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

design_connected

$20

Generation

...generation

designconnected

knoll generation computer generated 3d model. designed by formway design.

3d_export

$8

generator

...generator

3dexport

generator - obj, 3ds, fbx.

3d_export

$7

generator

...generator

3dexport

generator extures 4k resolution, basecolor -normal -metallic -ao-roughness-height tris:3084

turbosquid

free

generator

...rator

turbosquid

free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1492909)

3ddd

$1

general

...general

3ddd

генерал

turbosquid

$99

generator

...urbosquid

royalty free 3d model generator for download as ma on turbosquid: 3d models for games, architecture, videos. (1514125)

turbosquid

$20

Generator

...rbosquid

royalty free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1244841)

turbosquid

$2

Generator

...rbosquid

royalty free 3d model generator for download as fbx on turbosquid: 3d models for games, architecture, videos. (1245541)

Car

3d_export

$5

car

...car

3dexport

luxury car high quality car

3d_export

$5

car

...car

3dexport

luxury car high quality car

3d_export

$5

car

...car

3dexport

luxury car high quality car

3d_export

$5

car

...car

3dexport

luxury car high quality car

3d_export

$5

car

...car

3dexport

luxury car high quality car

archibase_planet

free

Car

...

archibase planet

car sports car motor-car sportster

car nascar#1 n300114 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Car

...ibase planet

car motor-car sportster sports car

car gablota xform n190214 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Car

...car

archibase planet

car motor car transport

car vaz 2104- 3d model for interior 3d visualization.

3d_export

$15

car

...car

3dexport

car

3d_export

free

car

...car

3dexport

car

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)