Thingiverse

Geeetech g2s Pro Frame Upgrade- Enclosure by NiklasF

by Thingiverse

Last crawled date: 3 years ago

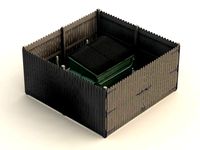

For a university project we upgraded the frame of the Geeetech g2s Pro Delta Printer. The main goal was to make the frame more stable and enclose the print area to increase the quality of the prints. For materials we mostly used aluminium and acrylic plates and item profiles. Water-jet/laser cutting has been used for tooling.

The original 8mm acrylic plates have been replaced by larger 4mm aluminium plates. All major holes and slots have been copied. In addition to that another aluminium plate has been added at the bottom which incorporates three adjustable feet. These three 4mm aluminium plates are connected through 6x570mm item aluminium profiles. The joints have been further tightened with 12 item angle brackets around the middle and bottom plate. In case you want to use 4mm plates as well you need to tighten the steel rods with 4mm washers as listed in the bill of materials below.

The shorts sides are enclosed with 2mm aluminium sheets and the long sides with 5mm acrylic sheets. From the front the built area can be accessed through an acrylic door and from the sides through two sliding doors which can be locked in place with a self-designed 3D-printed knob at the upper acrylic panel.

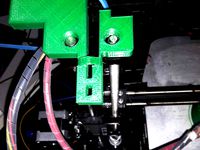

The bottom compartment is easy to access and offers plenty of space and mounts for cable management and electronics including the Raspberry Pi for Octoprint.

Overall from all these measures the printer became extremely stable and keeps the print area protected and noticeably warmer. Moreover, the printer looks even better now.

Besides the frame, work has been done as well in regards to temperature control, wifi connectivity and filament extrusion control. For this reason, at this point plenty of cables are still hanging around as it can be seen in the pictures. The holes for the top fan as well as the door magnet are not included in the drawings as you probably find your individual solutions for that.

This project is work in process. However, all files uploaded here already include the latest updates. Nevertheless, if you plan on doing the same just double check the most important holes and slots before cutting to avoid any waste material. If you find any mistakes or improvements do not hesitate to write it in the comments. In addition to that, if you need any other files I will try my best to catch up with that.

Have fun building and printing!

The original 8mm acrylic plates have been replaced by larger 4mm aluminium plates. All major holes and slots have been copied. In addition to that another aluminium plate has been added at the bottom which incorporates three adjustable feet. These three 4mm aluminium plates are connected through 6x570mm item aluminium profiles. The joints have been further tightened with 12 item angle brackets around the middle and bottom plate. In case you want to use 4mm plates as well you need to tighten the steel rods with 4mm washers as listed in the bill of materials below.

The shorts sides are enclosed with 2mm aluminium sheets and the long sides with 5mm acrylic sheets. From the front the built area can be accessed through an acrylic door and from the sides through two sliding doors which can be locked in place with a self-designed 3D-printed knob at the upper acrylic panel.

The bottom compartment is easy to access and offers plenty of space and mounts for cable management and electronics including the Raspberry Pi for Octoprint.

Overall from all these measures the printer became extremely stable and keeps the print area protected and noticeably warmer. Moreover, the printer looks even better now.

Besides the frame, work has been done as well in regards to temperature control, wifi connectivity and filament extrusion control. For this reason, at this point plenty of cables are still hanging around as it can be seen in the pictures. The holes for the top fan as well as the door magnet are not included in the drawings as you probably find your individual solutions for that.

This project is work in process. However, all files uploaded here already include the latest updates. Nevertheless, if you plan on doing the same just double check the most important holes and slots before cutting to avoid any waste material. If you find any mistakes or improvements do not hesitate to write it in the comments. In addition to that, if you need any other files I will try my best to catch up with that.

Have fun building and printing!

Similar models

thingiverse

free

Geeetech Y belt tensioner by Tijnv

...nter

you need a m4x30 bolt + nut (may need to dril the hole in the acrylic frame to 4mm)

and a pulley with 5mm bore + m5x20 bolt

thingiverse

free

Geeetech G2S Pro Stabilizer by Sokailu

...ch pylon an there you have it.

its a litle bit material expensive...

for the enclosure you can clide 4mm acrylic in from the top.

thingiverse

free

Geeetech G2s bearing plate upgrade mod by philbool

...he plate to attach the bearings are smaller than the stock plates this is because they are designed to be threaded with a m5 tap.

thingiverse

free

Tool Holder for Geeetech G2s Delta 3D Printer by DS_Desgin

...op.

...have fun :)

also check out my blue tape holder for the geeetech 3d printer:http://www.thingiverse.com/thing:1711845/#files

thingiverse

free

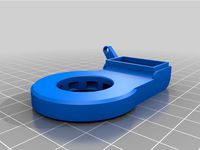

Chimera/Cyclops mount plate for Geeetech G2S Pro by martinengstrom

...der of the geeetech g2s pro delta printer. the small loop on the side is for a cable tie so that you can keep the wires in place.

thingiverse

free

Blue Tape Holder for Geeetech G2S Delta 3D-Printer by DS_Desgin

... or on the top.

...have fun :)

also check out my tool holder for the geeetech 3d printer:http://www.thingiverse.com/thing:1711895

thingiverse

free

Acrylic Enclosure's Printed Pieces

...ith less worry, but it will deter unwarranted hands from the printer as well. we're looking at you, middle school students ;)

thingiverse

free

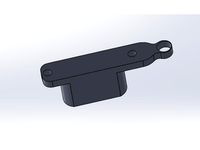

Geeetech Printer PSU Cover & Clamps by bernbout

... over the psu and are a tight fit. then they are fixed to the frame and tightened in place with an m3 screw in the hole provided.

thingiverse

free

Geeetech I3 aluminium

...geeetech i3 aluminium

thingiverse

this is upgraded printer shaft and threaded shaft holder for better quality printing

thingiverse

free

![AC Power Jack Bracket [C14 etc.] by Nleinad](/t/8811158.jpg)

AC Power Jack Bracket [C14 etc.] by Nleinad

...for an ac power jack of type c14 or similar i designed it specifically to be used om my...

G2S

3ddd

$1

Stand G2

..., stand , ar3

комод-паттерн (g2) design by ar3+

turbosquid

$25

Ring G2

...turbosquid

royalty free 3d model ring g2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1215199)

turbosquid

$19

FAMAS G2

...urbosquid

royalty free 3d model famas g2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1537479)

3d_ocean

$14

Mobile phone LG G2

... animation and rendering was done in softimage 2013. i am uploading obj. file with textures as well as softimage 2013 file whi...

turbosquid

$29

Pindad G2 Elite

...ree 3d model pindad g2 elite for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1446515)

3d_export

$99

FAMAS G2 3D Model

...ic famas g2 france french fully gun mas rifle semi weapon 3d models assault weapon gun

famas g2 3d model humster3d 94303 3dexport

3d_export

$49

LG G2 3D Model

...g 3g android droid smartphone cell phone mobile cellular tft lcd touchscreen touch screen

lg g2 3d model humster3d 85156 3dexport

turbosquid

$100

Canon PowerShot G2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$49

TMobile G2 3D Model

...se gingerbread 233 droid cell phone mobile cellular tft lcd touchscreen touch screen

tmobile g2 3d model humster3d 51180 3dexport

3ddd

$1

Ковёр G2

...ковёр g2

3ddd

ковёр

форматы в архиве:

max.2014

max.2011

obj

fbx

все текстуры присутствуют

Geeetech

3d_export

free

part right for geeetech acrylic i 3

...part right for geeetech acrylic i 3

3dexport

the engine can be shifted

3d_export

free

cable holder

...cable holder 3dexport for geeetech acrylic i...

thingiverse

free

geeetech a10 by Igor_garbuz

...geeetech a10 by igor_garbuz

thingiverse

model geeetech a10 ( solidworks).

thingiverse

free

geeetech calibration by muffler1979

...geeetech calibration by muffler1979

thingiverse

just a calibration test for the bed on a geeetech

thingiverse

free

Fan for Geeetech proB

...fan for geeetech prob

thingiverse

this is my fan for the geeetech pro b i3.

thingiverse

free

Chain for Geeetech A30

...chain for geeetech a30

thingiverse

this is my personal review of chain for geeetech a30.

thingiverse

free

Zugentlastung Hotend Geeetech A30T / Strain relief Geeetech A30T by 3DDennis1983

...zugentlastung hotend geeetech a30t / strain relief geeetech a30t by 3ddennis1983

thingiverse

zugentlastung hotend geeetech a30t

thingiverse

free

Kettenhalter i3x geeetech by Autark

...kettenhalter i3x geeetech by autark

thingiverse

geeetech i3x

thingiverse

free

Geeetech A10 Fanduct by stefan177gr

...geeetech a10 fanduct by stefan177gr

thingiverse

fanduct for geeetech a10

thingiverse

free

Geeetech filament guide by RicardoZ2018

...geeetech filament guide by ricardoz2018

thingiverse

desing for geeetech i3x

Upgrade

turbosquid

$15

Upgraded Glock

...e 3d model upgraded glock for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1185950)

3ddd

$1

Calligaris / UPGRADE

...calligaris / upgrade

3ddd

calligaris

c материалом

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

turbosquid

$80

Custer Tank upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Domestos 1 upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Upgraded tea cup

...upgraded tea cup

3dexport

a cup with an unusual design and a unique shape for a more enjoyable tea experience

3d_export

$8

dixy outlander classic style upgraded poplar wood lounge chair

...utlander classic style upgraded poplar wood lounge chair

3dexport

dixy outlander classic style upgraded poplar wood lounge chair

turbosquid

free

AK-12 + Upgrades low-poly 3D model

...ow-poly 3d model for download as fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1501145)

evermotion

$700

Upgrade from V-ray 1.5 to 3.5 for 3ds max

...here is no need to purchase a new dongle - your current dongles will be reprogrammed to carry v-ray 3. evermotion 3d models shop.

evermotion

$300

Upgrade from V-Ray 2.0 to V-ray 3.5 for 3ds Max

... interface (gui) for editing settings on one machine and one render node for rendering on one machine. evermotion 3d models shop.

Enclosure

3d_export

free

electrical enclosure

...l enclosure where electrical devices like (relays, contactors, busbars ) are kept in order to protect from hazardous environment.

turbosquid

$100

GPU Enclosure

...yalty free 3d model gpu enclosure for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1381061)

3d_export

$5

Electrical Enclosure

...ed. also has tower lights attaced on the top.<br>file format that are available:<br>.step<br>.obj<br>.stl

archive3d

free

Enclosure 3D Model

...closure 3d model

archive3d

shower enclosure-acquarius- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-omega- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-vega - 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-zenith - 3d model for interior 3d visualization.

turbosquid

$20

shower enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Dumpster Enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

3d printer enclosure

... model 3d printer enclosure for download as ipt, skp, and fbx on turbosquid: 3d models for games, architecture, videos. (1634310)

Pro

turbosquid

$29

Pro

...ree 3d model mac pro for download as obj, c4d, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1505782)

turbosquid

$15

Apple Mac Pro and Pro Display

...ee 3d model apple mac pro and pro display for download as max on turbosquid: 3d models for games, architecture, videos. (1417078)

3d_export

$5

iphone 13 pro max and pro

...3 pro max and 13 pro the model is made in four colors (graphite, gold, silver, and blue), all of which are attached in the files.

3d_export

free

sapphire pro

...sapphire pro

3dexport

sapphire pro 3d printer head mask

3d_export

$4

macbook pro

...macbook pro

3dexport

macbook pro 13" inch 2020 years model

3ddd

free

GentleLase Pro

... syneron , candela

gentlelase pro аппарат для лазерной эпиляции

turbosquid

$25

PRO frame

...rbosquid

royalty free 3d model pro frame for download as max on turbosquid: 3d models for games, architecture, videos. (1148329)

turbosquid

$5

Alien pro

...osquid

royalty free 3d model alien pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1678446)

turbosquid

$5

iphone11 pro

...uid

royalty free 3d model iphone11 pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1562707)

3ddd

$1

Mac Pro (appel)

...mac pro (appel)

3ddd

компьютер , apple

mac pro

Frame

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame n071113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Frame

...frame

3ddd

frame

3ddd

free

Frame

...frame

3ddd

frame

archibase_planet

free

Frame

...frame

archibase planet

frame mirror frame ornament

frame n260113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame photo frame

frame photo n190813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window frame window

frame 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame wall frame decoration

frame 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Frame

...frame

archibase planet

frame window window frame

frame 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.