Thingiverse

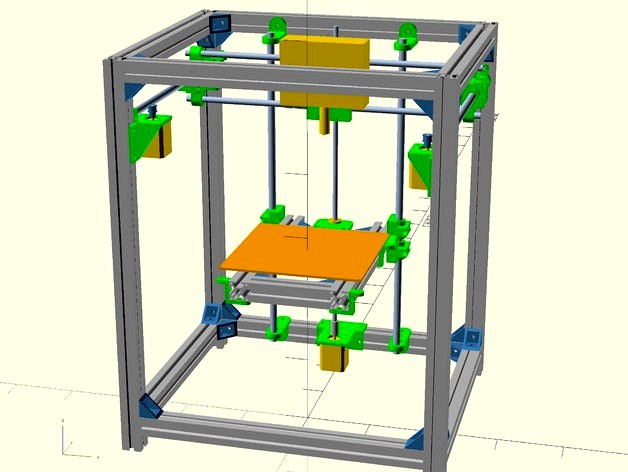

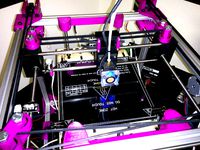

Fully Parametric 3D Printer CoreXY "HyperQbert" by projunk

by Thingiverse

Last crawled date: 3 years ago

Fully Parametric 3D Printer CoreXY "HyperQbert".

BACKGROUND:

The idea of designing an own printer comes from the Hypercube project by tech2c.http://www.thingiverse.com/thing:1752766

Many idea's from that printer have been incorporated into this fully parametric design.

OPENSCAD:

The printer has been fully designed in OpenSCAD. This has the great advantage that parts of the objects can be changed and the complete printer can be recalculated to determinate the new dimensions of all the related parts. The OpenSCAD console log summarizes the dimensions of the required extrusions, rods and lead screw.

The printer can also be fully visualized by compiling:

drawTotalAssembly()

or

drawTotalAssembly(true)

to visualize the printer including the enclosure.

MODIFYING THE PRINTER:

The most interesting parameters to change are the following:

1) The buildsize:

maxBuildHeight = 300.0; (maximum height of printed object)

wHeatedBedX = 213; (width of heated bed)

wHeatedBedY = 213; (depth of heated bed)

2) The extrusion profile type:

//include "ALU_PROFILE_15x15.inc"

//include "ALU_PROFILE_20x20.inc"

include "ALU_PROFILE_30x30.inc"

//include "ALU_PROFILE_40x40.inc"

(remove the comment sign of the profile to be used)

3) The bearing sizes per axis (so enforcing the rod diameters)

BearingX = LM10UU;

BearingY = LM12UU;

BearingZ = LM12UU;

4) The motor types

motorXY = NEMA17; //NEMA23;

motorZ = NEMA17; //NEMA14;

5) The screw size used for connecting the parts:

//include "M3.inc"

include "M4.inc"

(remove the comment sign of the screw size to be used)

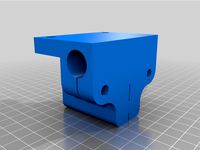

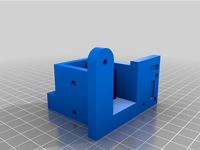

PRINTED PART LIST:

ZCarriage (2x)

ZCarriageClamp (4x)

ZMotorMount (1x)

ZRodMount (4x)

LeadScrewNutMount (1x)

BedClamp (4x)

YCarriage (2x)

YCarriageClamp (4x)

YRodMount (4x)

XYMotorMountLeft (1x)

XYMotorMountRight (2x)

XYIdler (2x)

XCarriage (1x)

XCarriageClamp (3x)

XCarriageBeltClamp (2x)

OPTIONAL PART LIST:

Optional parts (only needed when second ZMotor is used):

LeadScrewNutMount2 (or LeadScrewNutMountBigCoupler2) (1x)

ZMotorMount (1x)

Optional Parts (needed only for enclosing the printer):

HingeFixed (number dependent on height of printer; dimensions are dependent on thickness of front enclosing panel "tFrontEnclosingPanel", so rerendering required if different front panel thickness is being used!)

HingeMoving (same number as HingeFixed )

DoorKnop (1x)

DoorMagnetClamp (1x)

Optional Parts (needed for microswitch endstops X and Y):

XEndstopMount (1x)

XCarriageClampWithEndStopMount (1x), replaces one the 3 XCarriageClamps

YEndstopMount (1x)

Optional Parts (needed for organizing the electrical wires):

"WireHolderClip" (as many as required)

"WireHolderClipTieRap" (as many as required)

REMARKS:

All parts can be printed without use of support structures.

The attached STL's belong to the printer with all dimensions, extrusions, bearings, etc, set to the default values. If you decide to change those defaults, the STL's of course need to be re-rendered using OpenSCAD.

I would recommend to choose extrusionLengthBedY longer than the the calculated value. A larger length will give the option to move the heated bed more forward/backward to compensate for alternative extruder dimensions. (40 mm extra should be enough)

I recommend to use ABS as material for the printed parts, especially if one plans to build the enclosure around the printer. I printed most of the parts with 95% infill to avoid cracking of the plastic parts when strongly tightening the screws. For the dampening parts I used Ninja flex with 50% infill.

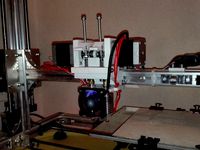

THE PRINTER IN ACTION:

https://youtu.be/3svdtzb3dgAhttps://youtu.be/MBuSbpBIuI8https://youtu.be/WVZtLoglih4

RELEASE NOTES:

Changes 17 December 2016

All bearing holders can now self align to ensure smooth traveling along the rods. To disable this feature one can set the variable useBearingSelfAlignment = false;.

Y Rod Mounts have now slot holes instead of the original round holes, to allow alignment of the Y-rods.

X-Carriage has now an integrated profile to fit the GT2 belt.

Changes 22 December 2016

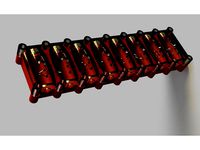

XCarriage and XCarriageBeltClamp now contain an exact imprint of the GT2 belt.

Changes 23 December 2016

increased thickness of XCarriageBeltClamp

Changes 26 December 2016

alternative Lead Screw Nut Mount called "LeadScrewNutMountBigCoupler" when the very big Z Coupler is to be used (the flexible coupler type with the plastic inserts)

mount for X Endstop microswitch : "XCarriageClampWithEndStopMount" + "XEndstopMount"

mount for Y Endstop microswitch: "YEndstopMount"

fix for XYIdler to avoid collision with the YRodMount in case the Aluminum profile 2020 is used

Changes 28 December 2016

support for NEMA14 and NEMA23 motors (not tested)

clip for holding electrical wires inside the aluminum profile "WireHolderClip"

clip for holding electrical wires with aid of a tie rap: "WireHolderClipTieRap"

Changes 29 December 2016

support for aluminum profiles 1515 and 4040 (not tested)

Changes 11 January 2017

fixes to ZBearingMount and YEndStopMount

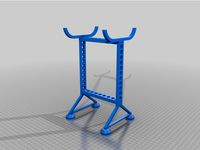

added Spoolholder to mount on top of printer (SpoolholderLeft, SpoolholderRight)

added ShockAbsorber (printed in Ninja flex) to put underneath the legs of the printer

added option to create an extra strong version of the ZCarriage

samples:

drawZCarriage(true);

drawZCarriage(true,45); // will create one arm extra long (can be used if a longer version of the extrusionLengthBedY is used). 45 mm is the extra length of the arm.

fixed ZRodMount and ZBearingMount in case aluminum 1515 profiles are used.

Changes 12 January 2017

added screw slot holes to ZMotorMount to allow for alignment in y-direction.

Changes 16 January 2017

added motor slot hole to ZMotorMount to allow for alignment in y-direction.

added camera mount for Logitech C270 webcam (CameraMount).

Changes 3 February 2017

added door magnet clamp holder DoorMagnetClamp

increased length of spool holder arms

closed hammer nut holes for XYMotorMountRight and XYMotorMountLeft

added shockabsorbers for XY steppers XYMotorMountShockAbsorber (ninja flex)

changed shape of hole in top enclosing panel TopPanel

Changes 17 February 2017

support for aluminum profile 2525 (not tested)

Changes 8 April 2017 (added optional X carriage extruder parts)

CoolingSystem_Probe_8mm_Offset10.stl

Gasket.stl (Ninja Flex)

FanDuct2.stl

BigGear_Nut.stl

SmallGear.stl

idler.stl

extruder.stl

FanSeal.stl (Ninja Flex)

Changes 11 September 2017

fixed water-tightness of the XYMotorMounts (both left and right). This issue caused the slicer to create a weaker part then expected.

Changes 24 September 2017

made XYMotorMounts (both left and right) much stronger (partially).

Changes 26 September 2017

made XYMotorMounts (both left and right) much stronger (the whole part).

Changes 11 November 2017

support for second Z-Motor. To enable this feature set variable useSecondZMotor=true. this option has not been tested yet in a real printer. It is on my to-do list to build a printer with a 300x300 build area and use the second Z-Motor for this printer.

markings have been put on Carriage clamps (X/Y/Z)

the bearing alignment feature can now be enabled/disabled via variable useBearingSelfAlignment

Changes 20 November 2017

bugfix undefined variable "correction_BearingRadius"

Changes 26 February 2018

added optional holder for LJ12A3-4-Z Proximity sensor (GregMountWithProbe.stl)

added support for bearing types: LM8LUU, LM10LUU,LM12LUU

removed "useBearingSelfAlignment" variable. This variable has now been defined in the BEARINGS.inc file. For all long bearing types, the self alignment has been disabled.

Changes 10 October 2018

added optional hinge where screw can be used as axle (HingeFixedWithScrewAsAxle.stl)

added optional XCarriage with hole for cable management (XCarriageWithCableHole.stl)

Changes 7 July 2019

updated the model to take into account length/width of hammernuts when calculating hole distance of XYIdler

Changes 31 August 2019

updated the model to take allow for a bigger distance between the micro switch mount holes (this concerns part "XCarriageClampWithEndStopMount.stl").

Changes 8 September 2019

added bearings LM6UU and LM6LUU

BACKGROUND:

The idea of designing an own printer comes from the Hypercube project by tech2c.http://www.thingiverse.com/thing:1752766

Many idea's from that printer have been incorporated into this fully parametric design.

OPENSCAD:

The printer has been fully designed in OpenSCAD. This has the great advantage that parts of the objects can be changed and the complete printer can be recalculated to determinate the new dimensions of all the related parts. The OpenSCAD console log summarizes the dimensions of the required extrusions, rods and lead screw.

The printer can also be fully visualized by compiling:

drawTotalAssembly()

or

drawTotalAssembly(true)

to visualize the printer including the enclosure.

MODIFYING THE PRINTER:

The most interesting parameters to change are the following:

1) The buildsize:

maxBuildHeight = 300.0; (maximum height of printed object)

wHeatedBedX = 213; (width of heated bed)

wHeatedBedY = 213; (depth of heated bed)

2) The extrusion profile type:

//include "ALU_PROFILE_15x15.inc"

//include "ALU_PROFILE_20x20.inc"

include "ALU_PROFILE_30x30.inc"

//include "ALU_PROFILE_40x40.inc"

(remove the comment sign of the profile to be used)

3) The bearing sizes per axis (so enforcing the rod diameters)

BearingX = LM10UU;

BearingY = LM12UU;

BearingZ = LM12UU;

4) The motor types

motorXY = NEMA17; //NEMA23;

motorZ = NEMA17; //NEMA14;

5) The screw size used for connecting the parts:

//include "M3.inc"

include "M4.inc"

(remove the comment sign of the screw size to be used)

PRINTED PART LIST:

ZCarriage (2x)

ZCarriageClamp (4x)

ZMotorMount (1x)

ZRodMount (4x)

LeadScrewNutMount (1x)

BedClamp (4x)

YCarriage (2x)

YCarriageClamp (4x)

YRodMount (4x)

XYMotorMountLeft (1x)

XYMotorMountRight (2x)

XYIdler (2x)

XCarriage (1x)

XCarriageClamp (3x)

XCarriageBeltClamp (2x)

OPTIONAL PART LIST:

Optional parts (only needed when second ZMotor is used):

LeadScrewNutMount2 (or LeadScrewNutMountBigCoupler2) (1x)

ZMotorMount (1x)

Optional Parts (needed only for enclosing the printer):

HingeFixed (number dependent on height of printer; dimensions are dependent on thickness of front enclosing panel "tFrontEnclosingPanel", so rerendering required if different front panel thickness is being used!)

HingeMoving (same number as HingeFixed )

DoorKnop (1x)

DoorMagnetClamp (1x)

Optional Parts (needed for microswitch endstops X and Y):

XEndstopMount (1x)

XCarriageClampWithEndStopMount (1x), replaces one the 3 XCarriageClamps

YEndstopMount (1x)

Optional Parts (needed for organizing the electrical wires):

"WireHolderClip" (as many as required)

"WireHolderClipTieRap" (as many as required)

REMARKS:

All parts can be printed without use of support structures.

The attached STL's belong to the printer with all dimensions, extrusions, bearings, etc, set to the default values. If you decide to change those defaults, the STL's of course need to be re-rendered using OpenSCAD.

I would recommend to choose extrusionLengthBedY longer than the the calculated value. A larger length will give the option to move the heated bed more forward/backward to compensate for alternative extruder dimensions. (40 mm extra should be enough)

I recommend to use ABS as material for the printed parts, especially if one plans to build the enclosure around the printer. I printed most of the parts with 95% infill to avoid cracking of the plastic parts when strongly tightening the screws. For the dampening parts I used Ninja flex with 50% infill.

THE PRINTER IN ACTION:

https://youtu.be/3svdtzb3dgAhttps://youtu.be/MBuSbpBIuI8https://youtu.be/WVZtLoglih4

RELEASE NOTES:

Changes 17 December 2016

All bearing holders can now self align to ensure smooth traveling along the rods. To disable this feature one can set the variable useBearingSelfAlignment = false;.

Y Rod Mounts have now slot holes instead of the original round holes, to allow alignment of the Y-rods.

X-Carriage has now an integrated profile to fit the GT2 belt.

Changes 22 December 2016

XCarriage and XCarriageBeltClamp now contain an exact imprint of the GT2 belt.

Changes 23 December 2016

increased thickness of XCarriageBeltClamp

Changes 26 December 2016

alternative Lead Screw Nut Mount called "LeadScrewNutMountBigCoupler" when the very big Z Coupler is to be used (the flexible coupler type with the plastic inserts)

mount for X Endstop microswitch : "XCarriageClampWithEndStopMount" + "XEndstopMount"

mount for Y Endstop microswitch: "YEndstopMount"

fix for XYIdler to avoid collision with the YRodMount in case the Aluminum profile 2020 is used

Changes 28 December 2016

support for NEMA14 and NEMA23 motors (not tested)

clip for holding electrical wires inside the aluminum profile "WireHolderClip"

clip for holding electrical wires with aid of a tie rap: "WireHolderClipTieRap"

Changes 29 December 2016

support for aluminum profiles 1515 and 4040 (not tested)

Changes 11 January 2017

fixes to ZBearingMount and YEndStopMount

added Spoolholder to mount on top of printer (SpoolholderLeft, SpoolholderRight)

added ShockAbsorber (printed in Ninja flex) to put underneath the legs of the printer

added option to create an extra strong version of the ZCarriage

samples:

drawZCarriage(true);

drawZCarriage(true,45); // will create one arm extra long (can be used if a longer version of the extrusionLengthBedY is used). 45 mm is the extra length of the arm.

fixed ZRodMount and ZBearingMount in case aluminum 1515 profiles are used.

Changes 12 January 2017

added screw slot holes to ZMotorMount to allow for alignment in y-direction.

Changes 16 January 2017

added motor slot hole to ZMotorMount to allow for alignment in y-direction.

added camera mount for Logitech C270 webcam (CameraMount).

Changes 3 February 2017

added door magnet clamp holder DoorMagnetClamp

increased length of spool holder arms

closed hammer nut holes for XYMotorMountRight and XYMotorMountLeft

added shockabsorbers for XY steppers XYMotorMountShockAbsorber (ninja flex)

changed shape of hole in top enclosing panel TopPanel

Changes 17 February 2017

support for aluminum profile 2525 (not tested)

Changes 8 April 2017 (added optional X carriage extruder parts)

CoolingSystem_Probe_8mm_Offset10.stl

Gasket.stl (Ninja Flex)

FanDuct2.stl

BigGear_Nut.stl

SmallGear.stl

idler.stl

extruder.stl

FanSeal.stl (Ninja Flex)

Changes 11 September 2017

fixed water-tightness of the XYMotorMounts (both left and right). This issue caused the slicer to create a weaker part then expected.

Changes 24 September 2017

made XYMotorMounts (both left and right) much stronger (partially).

Changes 26 September 2017

made XYMotorMounts (both left and right) much stronger (the whole part).

Changes 11 November 2017

support for second Z-Motor. To enable this feature set variable useSecondZMotor=true. this option has not been tested yet in a real printer. It is on my to-do list to build a printer with a 300x300 build area and use the second Z-Motor for this printer.

markings have been put on Carriage clamps (X/Y/Z)

the bearing alignment feature can now be enabled/disabled via variable useBearingSelfAlignment

Changes 20 November 2017

bugfix undefined variable "correction_BearingRadius"

Changes 26 February 2018

added optional holder for LJ12A3-4-Z Proximity sensor (GregMountWithProbe.stl)

added support for bearing types: LM8LUU, LM10LUU,LM12LUU

removed "useBearingSelfAlignment" variable. This variable has now been defined in the BEARINGS.inc file. For all long bearing types, the self alignment has been disabled.

Changes 10 October 2018

added optional hinge where screw can be used as axle (HingeFixedWithScrewAsAxle.stl)

added optional XCarriage with hole for cable management (XCarriageWithCableHole.stl)

Changes 7 July 2019

updated the model to take into account length/width of hammernuts when calculating hole distance of XYIdler

Changes 31 August 2019

updated the model to take allow for a bigger distance between the micro switch mount holes (this concerns part "XCarriageClampWithEndStopMount.stl").

Changes 8 September 2019

added bearings LM6UU and LM6LUU

Similar models

thingiverse

free

Print bed Frame for 2020 aluminium frame printer by Sjekkie

...cer m3x11

4x srew m3x40

4x m3 nuts

endstop parts

2x m3x25

1x m3x20

3x m3 nuts

all printed parts are printed with esum pla+ zilver

thingiverse

free

SpotMicroESP32 (using 623ZZ bearings) by projunk

...oint between bottom shells to avoid collision with 20a buckconverters (bottom_cover_split_front.stl, bottom_cover_split_rear.stl)

grabcad

free

3D Printer LCD Case

...

23.6.2019 - updated shape, dimensions

28.9.2019 - added screws, third rib to reinforce back plate, added hexagon hole for screws

thingiverse

free

Motorized barndoor tracker for astrophotography by elenhinan

...r

1x a4988 (or other stepper driver)

1x arduino nano

1x 1/4 inch 20 tpi screw for mounting camera

m3 screws for the laser pointer

thingiverse

free

OMG oh no yet another lack enclosure by kumekay

...al

1x spool rail extender (for large 2kg+ spools)

6x m3x20 bolts with nuts

nb: you should cut 50mm parts from bottom of legs (4x)

thingiverse

free

Dual Extruder by Psycho1981

...ng:

4x allen screw m5

4x square nut m5

4x washer m5

electronic:

-ramps 1.4 board

-atx power supply

-firmware "marlin"

thingiverse

free

Baseplate for spindle clamp (52/55mm), CNC3018/CNC3018 Pro

...sher

4x m6 spring ring

optional:

4x m2x14mm (allen) screw

2x micro switch (print)

1x anti backlash nut

2x 5x56mm rod

2x linelaser

thingiverse

free

Liner Arc Scriber by tot144

...g

4x m5 nuts

2x m3 by 12mm cap screws

1x m5 by 8mm cap screw

2x m5 by 30mm machine screws

4x bearings od: 11mm id: 5mm width: 4mm

thingiverse

free

K40 Bed angles with tensioner by carsi

...ng 22x8mm ( 608zz )

4x bearing 11x4mm

4x gt2 8mm pulley

1x gt2 belt 1350 mm

2x washer

2x m4 screws

1x bearing 22x5mm

1x m5 screw

thingiverse

free

XY_Plotter by modelatolyesi

...

1x ball-pen spring.

electronics:

arduino uno

cnc shield.

2x a4988 stepper driver.

9g. servo.

4x micro switch.

extension cables.

Projunk

thingiverse

free

Parametric Stand for SpotMicroESP32 by projunk

...f.stl and stand_bottomhalf.stl which should be glued together. these parts can be used if the stand.stl does not fit the printbed

thingiverse

free

Parametric Shoulder Joint for SpotMicroESP32 by projunk

... part limbtopshell.stl is the same as the original part "limb_top_shell.stl" except for the screw hole for the bearing.

thingiverse

free

Parametric LCD Display Box for Reprap Smart Controller by projunk

...m.stl (1x)

screw m3x12 (4x)

optional parts:

bracket.stl (1x)

bracketmirrored.stl (1x)

screw m3x10 (4x)

nut m3 (4x)

washer m3 (4x)

thingiverse

free

Parametric Prusa i3 Frame Stabilizer kit by projunk

...(2x) (back)

m10 threaded rod 394 mm (2x) (y-axis)

m10 threaded rod 385 mm (2x) (sloping)

m10 nuts (46x)

m10 washers (46x)

thingiverse

free

Projunk's Omniwheel Barrel Casting Form by MirecXP

...d put them on the axle on each side of the barrel to prevent unwanted friction between the barrel's sides and the wheel body.

thingiverse

free

SpotMicroESP32 (using 623ZZ bearings) by projunk

...oint between bottom shells to avoid collision with 20a buckconverters (bottom_cover_split_front.stl, bottom_cover_split_rear.stl)

thingiverse

free

Parametric Herringbone Differential for OpenRC F1 car by projunk

...arflataxle.stl (better fits the axle of the motor)

piniongearnuthole.stl (this requires a m3 nut and a small m3 screw, see photo)

thingiverse

free

Parametric Prusa i3 Stabilizer kit (Part 2) by projunk

... parts have been printed in abs (95% infill) except for the gasket and fanseal, which have been printed in ninjaflex (50% infill)

thingiverse

free

Barrel casting form for Projunk's Mecanum Wheel 82 mm by MirecXP

...d put them on the axle on each side of the barrel to prevent unwanted friction between the barrel's sides and the wheel body.

thingiverse

free

Parametric Hieroglyphic Alphabet (high resolution bitmaps) by projunk

... // determines the overall size of the character

pixelthickness = 2.0; // determines the thickness (z-direction) of the character

Corexy

thingiverse

free

CoreXY by Kaz_tech

...corexy by kaz_tech

thingiverse

this is the model of corexy platform. i separately put the parts on this place.

thingiverse

free

corexy plotter by tjwan

...corexy plotter by tjwan

thingiverse

parts for corexy mill inspired by http://der-frickler.net/technik/corexyportal

thingiverse

free

ScribbleJ CoreXY Beta by ScribbleJ

...j/corexy-v1https://github.com/scribblej/corexy-v1#corexy-beta

full gallery of development photos here: http://imgur.com/a/donun

thingiverse

free

CoreXY Emblem by emkajot

...by emkajot

thingiverse

an emblem for your corexy printer.

size: 100mm x 38mm x 2mm.

update: added a version with a proper mount.

thingiverse

free

SolidCore CoreXY Carriage by shanehooper

...olidcore 3d printer. this design could be used in other corexy 3d printers.

also see:https://3ddistributed.com/corexy-3d-printer/

thingiverse

free

CoreXY 3D Printer Model by ReginaFabricam

...bricam

thingiverse

this is an original design of a corexy printer.https://www.tinkercad.com/things/jggr9qk4s4p-3d-printer-corexy

thingiverse

free

coreXY Upper structure Left

...corexy upper structure left

thingiverse

my customized corexy 3d printer upper left parts

thingiverse

free

CoreXY by frankie

...ing machines, etc. the design is described in greater detail at http://www.corexy.com . a video is at http://vimeo.com/40914530 .

thingiverse

free

Endstop block for CoreXY carriage by svkeulen

...endstop block for corexy carriage by svkeulen

thingiverse

endstop for corexy carriage

thingiverse

free

X carriage for the CoreXY MGN12 by hackerbijay

...x carriage for the corexy mgn12 by hackerbijay

thingiverse

x carriage for the corexy frame

Parametric

turbosquid

$25

Parametric

...oyalty free 3d model parametric for download as blend and stl on turbosquid: 3d models for games, architecture, videos. (1683196)

3ddd

$1

Parametric Wall

...parametric wall

3ddd

панель

parametric wall with shelf

3d_export

$5

parametric table

...parametric table

3dexport

parametric table model created on rhinoceros 6. this 3d model includes: .gh, .3dm files

turbosquid

$2

parametrical chandelier

...lty free 3d model parametrical chandelier for download as dxf on turbosquid: 3d models for games, architecture, videos. (1257635)

turbosquid

$2

Parametric Seat

...id

royalty free 3d model parametric seat for download as max on turbosquid: 3d models for games, architecture, videos. (1691557)

turbosquid

$2

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1690373)

turbosquid

$1

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1691303)

turbosquid

$1

Parametric Wall

...id

royalty free 3d model parametric wall for download as max on turbosquid: 3d models for games, architecture, videos. (1691148)

turbosquid

$19

Parametric Bench

...ty free 3d model parametric bench for download as max and max on turbosquid: 3d models for games, architecture, videos. (1713396)

turbosquid

free

Parametric wall

...ee 3d model parametric wall for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1356869)

Fully

turbosquid

$50

Drone fully rigged

...

royalty free 3d model drone fully rigged for download as max on turbosquid: 3d models for games, architecture, videos. (1282280)

turbosquid

$12

FULLY PARAMETRIC CHAIR

...alty free 3d model fully parametric chair for download as rvt on turbosquid: 3d models for games, architecture, videos. (1280209)

turbosquid

$10

firetruck-fully-rigged

...yalty free 3d model firetruck-fully-rigged for download as ma on turbosquid: 3d models for games, architecture, videos. (1653811)

turbosquid

$6

Fully rigged character

...ty free 3d model fully rigged character for download as blend on turbosquid: 3d models for games, architecture, videos. (1486076)

turbosquid

$3

Fully Rigged shark

...ee 3d model fully rigged 3d shark model for download as blend on turbosquid: 3d models for games, architecture, videos. (1517695)

turbosquid

$75

Fully Customizable Hospital

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Fully Rigged Link

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Troy W Fully Covered

...troy w fully covered

designconnected

magis troy w fully covered computer generated 3d model. designed by wanders, marcel.

cg_studio

$99

Pepe fully rigged3d model

...ully rigged3d model

cgstudio

.max - pepe fully rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$60

Ankylosaur 8K - fully animated

...ankylosaur 8k - fully animated

3dexport

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.