Thingiverse

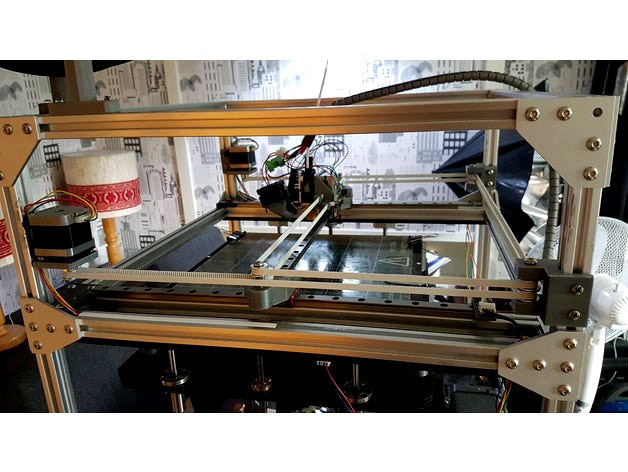

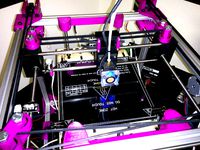

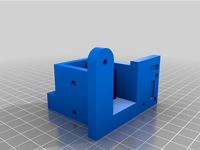

FT5 CoreXY Conversion by Rajaa

by Thingiverse

Last crawled date: 3 years ago

Important update: Don't use steel-core belts, they'll cause wrong print dimensions after a while.

-Replaced the files with the new V2 files. 27/07/2017

-New little adjustments made toady 1/08/2017

-Lowered (1.5mm) the high idler of the left carriage (because the toothless idler height is 10mm, not 9mm like the toothed one), changed Y endstop holes, and corrected a small error in Extruder mount tensioner holes. 2/08/2017

-Corrected the holes position in the parts "Right idlers mount 2" and "Left idlers mount 2" (they were off by like 0.5mm). 3/8/2017

-Uploaded Fan Mount v2. 6/08/2017

-Changed stepper mounts. 19/9/2017

-Updated belt tensioner. 30/11/2017

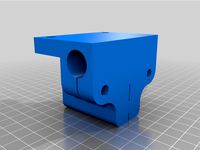

-Added letters (L&R) to the parts to indicate left and right. Updated the left and right carriages to use M5 nuts instead of using the carriage itself as a nut for the idlers screws (easier to work with) and slightly adjusted their design. check the last rendering picture. Changed all the idlers to F695zz Flanged Bearing 5x13x4mm and updated almost all the parts to fit the new idlers. 26/01.2018

-Added the files in STEP format. 3/04/2018

-Edited Extruder Mount so you can use regular nozzle/heat block or Volcano setup (but if you will not use Volcano, you have to modify the part cooling fan design so it becomes shorter otherwise it'll hit the bed). 2018/06/23.

Now you can 3D view or download the raw design in multiple formats to edit it easily (if you want to).http://a360.co/2Bv5o4T

Video about all the changes I made to my FT-5:https://youtu.be/JWi-ZnHx8co

FT5 Accurate Adjustable Z Endstop:https://www.youtube.com/watch?v=tF2z4EKhI4I

13X M5*10mm screws and T-nuts (to hold mounts on 2020 profiles).

1X M3*8mm screw (for X Endstop).

X16 Idlers F695zz Flanged Bearing 5x13x4mm.

Carriages screws: 8X M310mm for Y and 4X M38mm for X. 2X M3*20mm screws and nylon lock nuts (to hold the X rail).

4X M3*30mm screws and nuts (for belts tensioners).

6X M5*45mm and 8X M5 nuts (for idlers).

For the back M5 idler screw holes, I drilled them with 4.5mm drilling bit, so I can use the screws without nuts (so the plastic will be the nut) but you can drill them with 5mm bit and use M5 nuts.

The extruder mount got 4 holes in case you want to make adapters for something like BLtouch or cables box etc..

The motors side is the front side! Use support for the part "belt tensioner/mount" but don't use support for its belt teeth. When inserting the belts into the tensioners, be gentle with the little lever, open it very slightly to insert the belt or you might break it. This design requires a long nozzle or Volcano setup (see updates section). Use high quality idlers!! I tried the cheap ones, and they are not spinning 100% in center, and that leads to print quality issues! No need to extend any wires for the motors or X endstop, the stock wires are long enough. I used 3X M360mm screws with nuts to hold the extruder assembly all the way from the back of the short stepper to the Aero heatsink (I removed 3 screws from the stepper). Make sure to orient the parts to the proper orientation before printing (depends on how the part is stressed). I'll change the orientations later for you. I used 4 walls, 4 top, 4 bottom, 50% infill. Don't forget to remove the "//" before "#define COREXY" to enable CoreXY kinematics. Make sure all idlers/belts are in their correct height, the belts should always be horizontal at any point! If you are going to use high bed temps, don't use PLA for the part "bed spacer", you can also ignore this part and use m360mm screw as a bed spacer as shown in the picture (I used 80mm screws temporarily).

** Use a stiff material, preferably heat resistance like CF-PETG, CF-nylon CF-ABS. Anything could work tho even PLA.

Idlers F695zz Flanged Bearing 5x13x4mm X16 :https://goo.gl/Wfv45t

Recommended pulleys: https://goo.gl/XntrST

Let me know if I forgot something. Good luck! :)

-Replaced the files with the new V2 files. 27/07/2017

-New little adjustments made toady 1/08/2017

-Lowered (1.5mm) the high idler of the left carriage (because the toothless idler height is 10mm, not 9mm like the toothed one), changed Y endstop holes, and corrected a small error in Extruder mount tensioner holes. 2/08/2017

-Corrected the holes position in the parts "Right idlers mount 2" and "Left idlers mount 2" (they were off by like 0.5mm). 3/8/2017

-Uploaded Fan Mount v2. 6/08/2017

-Changed stepper mounts. 19/9/2017

-Updated belt tensioner. 30/11/2017

-Added letters (L&R) to the parts to indicate left and right. Updated the left and right carriages to use M5 nuts instead of using the carriage itself as a nut for the idlers screws (easier to work with) and slightly adjusted their design. check the last rendering picture. Changed all the idlers to F695zz Flanged Bearing 5x13x4mm and updated almost all the parts to fit the new idlers. 26/01.2018

-Added the files in STEP format. 3/04/2018

-Edited Extruder Mount so you can use regular nozzle/heat block or Volcano setup (but if you will not use Volcano, you have to modify the part cooling fan design so it becomes shorter otherwise it'll hit the bed). 2018/06/23.

Now you can 3D view or download the raw design in multiple formats to edit it easily (if you want to).http://a360.co/2Bv5o4T

Video about all the changes I made to my FT-5:https://youtu.be/JWi-ZnHx8co

FT5 Accurate Adjustable Z Endstop:https://www.youtube.com/watch?v=tF2z4EKhI4I

13X M5*10mm screws and T-nuts (to hold mounts on 2020 profiles).

1X M3*8mm screw (for X Endstop).

X16 Idlers F695zz Flanged Bearing 5x13x4mm.

Carriages screws: 8X M310mm for Y and 4X M38mm for X. 2X M3*20mm screws and nylon lock nuts (to hold the X rail).

4X M3*30mm screws and nuts (for belts tensioners).

6X M5*45mm and 8X M5 nuts (for idlers).

For the back M5 idler screw holes, I drilled them with 4.5mm drilling bit, so I can use the screws without nuts (so the plastic will be the nut) but you can drill them with 5mm bit and use M5 nuts.

The extruder mount got 4 holes in case you want to make adapters for something like BLtouch or cables box etc..

The motors side is the front side! Use support for the part "belt tensioner/mount" but don't use support for its belt teeth. When inserting the belts into the tensioners, be gentle with the little lever, open it very slightly to insert the belt or you might break it. This design requires a long nozzle or Volcano setup (see updates section). Use high quality idlers!! I tried the cheap ones, and they are not spinning 100% in center, and that leads to print quality issues! No need to extend any wires for the motors or X endstop, the stock wires are long enough. I used 3X M360mm screws with nuts to hold the extruder assembly all the way from the back of the short stepper to the Aero heatsink (I removed 3 screws from the stepper). Make sure to orient the parts to the proper orientation before printing (depends on how the part is stressed). I'll change the orientations later for you. I used 4 walls, 4 top, 4 bottom, 50% infill. Don't forget to remove the "//" before "#define COREXY" to enable CoreXY kinematics. Make sure all idlers/belts are in their correct height, the belts should always be horizontal at any point! If you are going to use high bed temps, don't use PLA for the part "bed spacer", you can also ignore this part and use m360mm screw as a bed spacer as shown in the picture (I used 80mm screws temporarily).

** Use a stiff material, preferably heat resistance like CF-PETG, CF-nylon CF-ABS. Anything could work tho even PLA.

Idlers F695zz Flanged Bearing 5x13x4mm X16 :https://goo.gl/Wfv45t

Recommended pulleys: https://goo.gl/XntrST

Let me know if I forgot something. Good luck! :)

Similar models

thingiverse

free

Anet A6 X Axis Half-slit Carriages by kaa_

...ioner and counterbalance mount (optional).

z-endstop justification

use this simple part to adjust vertical position of z-endstop.

thingiverse

free

Prusa Steel X axis with tensioner and 8mm leadscrew support by fedewolfie

...ner and a m5 screw and nut for the toothed idler, i use a cheap aliexpress toothed idler with a m5 bore.

prints without supports.

thingiverse

free

Kossel carriage with implant screw support for belt tension and endstop trigger adjustable by 3DPW

...ll circle on belt, insert the circle to be belt holder. pull belt then the belt will be tighted. use zip tie to tighten the belt.

thingiverse

free

Anet A8 Y-belt Toothed Idler Tensioner by butchja

...ter

9mm thickness

m3 or m5 screw (30mm)

m3 or m5 nut

m3 screw (30mm)

m3 nut

you still need part 1 and 2 of yoshi's tensioner.

thingiverse

free

XL Belt Clamp by scharkalvin

...it the xl belts i'm using. i've left the original source code intact, and i'm only using part of it for this design.

thingiverse

free

CTC I3 Belt Tensioner by Xynter

...a bit slimmer since i've noticed that the previous version was a bit to wide so that the pulley wasn't perfectly aligned.

thingiverse

free

Carriage Fan mount Combo by blacklyquid

...truder. tried to work in a belt tension on the carriage but it was easier to just to pull , zip tie, and add a belt tension clip.

thingiverse

free

Endstop Mount for MakerBot Mecanical Endstop. by nka

...v-slots carriage.

endstop is screw with m3 (8mm) tapped hole and the endstop hold on the extrusion using a m5 (8mm) and t-nuts.

grabcad

free

CoreXY Belt Tensioner Update v.2

...r all corexy printers with v-profiles and 6-slot

update v.2

redesigned pusher left & right

inserted bom & hex screw knob

thingiverse

free

Micromake C1 belt tensioner by vasco1814

...at least 3 m5 nuts

an m3 screw, m3 nut

a gt2 idler pulley 16 teeth or the two small bearings that were used in the original part.

Rajaa

thingiverse

free

Trium3D zip tie mount by Rajaa

...ie mount by rajaa

thingiverse

mount for zip tie to mount rubber instead of springs for the effector, and mount flying extruders.

thingiverse

free

Mixer coupler by Rajaa

...while printing). you can modify the part to fit your needs (i provided the step file as well).

material i used taulman nylon 910.

thingiverse

free

Harmony's Dish by Rajaa

...ch! the parts should move freely.

use support.

the orientation is up to you, depends on what surface you want it to look nicer :)

thingiverse

free

3 Spools Holder For Trium3D by Rajaa

...iverse

5mm/361mm axis. m3 screws and nuts.100% infill.

if the holes came out tight for the screws, just drill them with 3mm bit.

thingiverse

free

3D Printed Speaker by Rajaa

...holes with m3 screws to connect the wires, if you want.

no support.

0.2mm layer hight.https://www.youtube.com/watch?v=soe3phicem4

thingiverse

free

DIY Microscope Using Your Mobile Camera! by Rajaa

...utube.com/watch?v=s5khfwf5lng

watch the video to see how it works in action.

v2 is coming later.

the size i made is for galaxy s5

thingiverse

free

170mm spacer for FT-5 3D printer by Rajaa

...h the supports to the vertical beams so the spacer is 100% vertical, then tighten your screws :)

no support needed when printing.

thingiverse

free

Belt tensioner for Trium3D printer by Rajaa

...-m5 screw and nut, 40mm.

-if the screw didn't fit freely, just drill the holes with 5mm bit (for the small hole use 4mm bit).

thingiverse

free

DIY Magnetic Jack/Plug For Any Purpose (No Soldering) by Rajaa

...video to see how it works in action.

this is version 1.1

version 2 is coming soon ;)

use m3 screws and nuts.

5mm dia, 1mm magnets

thingiverse

free

2020 multi-size spool(s) holder by Rajaa

...s.

can take big size spools of 2.3kg each.

15mm m3 screws with t-nuts.

supports only needed for the axis slot on the two columns.

Ft5

thingiverse

free

Tmotor FT5 by JUNG_HY

...tmotor ft5 by jung_hy

thingiverse

tmortor ft5 frame 3dpart. build & test flight

thingiverse

free

FT5 spool holder by Joe558

...ft5 spool holder by joe558

thingiverse

spool holder for the ft5

thingiverse

free

Folgertech FT5 Cooler by the0ry

... mount.

this is a sloppy remix/edit of the ciiicooler done in tinkercad to fit the ft5, https://www.thingiverse.com/thing:2004629

thingiverse

free

FT5 Spool Holder by deuel18

...ft5 spool holder by deuel18

thingiverse

this is an alternative solution for ft5 users who wanted a better spool holder set up.

thingiverse

free

Ft10 and FT5 / FT7 and FT5 merged with a 7mm drop to level the pulley and stepper

...0 and ft5 / ft7 and ft5 merged with a 7mm drop to level the pulley and stepper

thingiverse

print at 100% infill and rock it out.

thingiverse

free

FT5 bed corner hold-down by Joe558

...ft5 bed corner hold-down by joe558

thingiverse

hold downs for the corners of the aluminum bed on the ft5

thingiverse

free

FT5 with centered Y belt holes by NEMS3D

... the folgertech ft5 printer. original parts didn't have the belt holes centered causing the belt to pop off the idler pulley.

thingiverse

free

FT5 Vista Base by HirschJunge

...e ft5 60% build

to mount you the vista you additionally need 4x m2 - 25mm screws

pictures of the newest version are gonna follow.

thingiverse

free

Fan and sensor mount for stock FT5 by Joe558

... for stock ft5 by joe558

thingiverse

this uses the small induction sensor and a 40mm fan for cooling on the stock ft5 equipment.

thingiverse

free

FT5 Chain Guide

...work with any 2020 extrusion

the open cable chain link i'm using are from ramonseda https://www.thingiverse.com/thing:2802560

Corexy

thingiverse

free

CoreXY by Kaz_tech

...corexy by kaz_tech

thingiverse

this is the model of corexy platform. i separately put the parts on this place.

thingiverse

free

corexy plotter by tjwan

...corexy plotter by tjwan

thingiverse

parts for corexy mill inspired by http://der-frickler.net/technik/corexyportal

thingiverse

free

ScribbleJ CoreXY Beta by ScribbleJ

...j/corexy-v1https://github.com/scribblej/corexy-v1#corexy-beta

full gallery of development photos here: http://imgur.com/a/donun

thingiverse

free

CoreXY Emblem by emkajot

...by emkajot

thingiverse

an emblem for your corexy printer.

size: 100mm x 38mm x 2mm.

update: added a version with a proper mount.

thingiverse

free

SolidCore CoreXY Carriage by shanehooper

...olidcore 3d printer. this design could be used in other corexy 3d printers.

also see:https://3ddistributed.com/corexy-3d-printer/

thingiverse

free

CoreXY 3D Printer Model by ReginaFabricam

...bricam

thingiverse

this is an original design of a corexy printer.https://www.tinkercad.com/things/jggr9qk4s4p-3d-printer-corexy

thingiverse

free

coreXY Upper structure Left

...corexy upper structure left

thingiverse

my customized corexy 3d printer upper left parts

thingiverse

free

CoreXY by frankie

...ing machines, etc. the design is described in greater detail at http://www.corexy.com . a video is at http://vimeo.com/40914530 .

thingiverse

free

Endstop block for CoreXY carriage by svkeulen

...endstop block for corexy carriage by svkeulen

thingiverse

endstop for corexy carriage

thingiverse

free

X carriage for the CoreXY MGN12 by hackerbijay

...x carriage for the corexy mgn12 by hackerbijay

thingiverse

x carriage for the corexy frame

Conversion

3ddd

$1

Conversation Seat

...шетка

the conversation seat made in englandhttp://www.squintlimited.com/products/the_conversation_seat/gold

+ max 2011

3d_export

$10

Converse 3D Model

...converse 3d model

3dexport

converse shoe pc unix mac

converse 3d model electropainter17075 38067 3dexport

turbosquid

$100

converse-shoe

...quid

royalty free 3d model converse-shoe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1398427)

turbosquid

$10

Conversation Furniture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Converse Allstars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Conversation Club Chair

...conversation club chair

designconnected

donghia conversation club chair chairs computer generated 3d model. designed by n/a.

design_connected

$27

Hemicycle Conversation Chair

...rsation chair

designconnected

ligne roset hemicycle conversation chair computer generated 3d model. designed by nigro, philippe.

3d_export

$24

Converse keds 3D Model

...converse keds 3d model

3dexport

converse all star ked shoe clothes sports

converse keds 3d model vermi1ion 26201 3dexport

3ddd

$1

Converse All-Star Shoes

...converse all-star shoes

3ddd

кеды , обувь

converse all-star shoes

design_connected

$18

CONVERSE Jack Purcell Sneakers

...converse jack purcell sneakers

designconnected

converse jack purcell sneakers computer generated 3d model.