GrabCAD

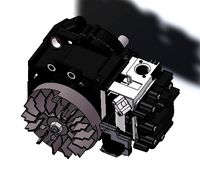

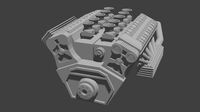

Free piston double acting diesel engine

by GrabCAD

Last crawled date: 1 year, 11 months ago

https://pocharitechnologies.com/2020/01/01/worlds-only-dual-chamber-two-stroke-stoichiometric-diesel-engine/

Pochari Technologies has invented a revolutionary new type of diesel engine for use in current diesel propulsion applications with hugely improved power density and dramatically improvement emission control. The engine is a conventional piston engine where a single-cylinder serves as two separate combustion chambers. A single-piston reciprocates in a two-stroke cycle providing compression in the opposing chamber each power stroke in the opposite chamber. A single-cylinder, with the same stroke length as a conventional engine, can provide the equivalent amount of power as two cylinders. By eliminating one set of connecting rods, crankshaft, piston and cylinder we can reduce engine weight significantly.

The engine is free of a camshaft, valvetrain and crankshaft, radically improving reliability.

As a two-cycle cannot provide vacuum, air must be forced in at high pressure. Electrically driven high speed 4:1 pressure ratio turbochargers are used. In a two-stroke diesel engine, the “blower” or turbo helps in removing as much exhaust as possible at the end of each power stroke and provides the pressure necessary to fill the chamber with enough oxygen.

The injection system is a conventional common rail.

The engine block is 351 high-temperature Aluminum Alloy. This invention allows for increased volumetric power density, and most importantly, a gravimetric power density increase by a factor of 170%.

This technology will be most attractive for weight and volume sensitive applications, such as marine propulsion. As the engine is a “free piston”, rather than using a hydraulic piston, a permanent magnet motor linear generator is used to directly power electric motors which can be connected to each drive axle eliminating the transmission and providing instant torque at low speed.

The lubrication system is proprietary but provides greatly enhanced lubrication over conventional crankcase fed cylinder lubrication as oil is injected directly underneath the oil ring through multiple small orifices at a constant rate and pressure.

Targeted BSFC is below 0.35 lbs/hp/hr. Power density is estimated to be approximately 2 hp/lb.

CR is 17:1.

No EGR and SCR is needed thanks to the stoichiometric operation enabling conventional platinum monolith TWC technology to reduce by up to NOx 99.95% with the addition of a small amount of hydrogen gas as a reducing agent. The use of synthetic fuel eliminates the need for a DPF, since the absence of sulfur and nitrates in the synthetic natural gas-based fuel result in little to no PM being generated.

Since emissions do not dictate the design as in the case for conventional diesel engines, we can design the engine for power density and efficiency only.

This engine will greatly exceed all modern diesel emission standards while providing efficient trouble-free service to operators. For those interested, Please contact Christophe Pochari.

Pochari Technologies has invented a revolutionary new type of diesel engine for use in current diesel propulsion applications with hugely improved power density and dramatically improvement emission control. The engine is a conventional piston engine where a single-cylinder serves as two separate combustion chambers. A single-piston reciprocates in a two-stroke cycle providing compression in the opposing chamber each power stroke in the opposite chamber. A single-cylinder, with the same stroke length as a conventional engine, can provide the equivalent amount of power as two cylinders. By eliminating one set of connecting rods, crankshaft, piston and cylinder we can reduce engine weight significantly.

The engine is free of a camshaft, valvetrain and crankshaft, radically improving reliability.

As a two-cycle cannot provide vacuum, air must be forced in at high pressure. Electrically driven high speed 4:1 pressure ratio turbochargers are used. In a two-stroke diesel engine, the “blower” or turbo helps in removing as much exhaust as possible at the end of each power stroke and provides the pressure necessary to fill the chamber with enough oxygen.

The injection system is a conventional common rail.

The engine block is 351 high-temperature Aluminum Alloy. This invention allows for increased volumetric power density, and most importantly, a gravimetric power density increase by a factor of 170%.

This technology will be most attractive for weight and volume sensitive applications, such as marine propulsion. As the engine is a “free piston”, rather than using a hydraulic piston, a permanent magnet motor linear generator is used to directly power electric motors which can be connected to each drive axle eliminating the transmission and providing instant torque at low speed.

The lubrication system is proprietary but provides greatly enhanced lubrication over conventional crankcase fed cylinder lubrication as oil is injected directly underneath the oil ring through multiple small orifices at a constant rate and pressure.

Targeted BSFC is below 0.35 lbs/hp/hr. Power density is estimated to be approximately 2 hp/lb.

CR is 17:1.

No EGR and SCR is needed thanks to the stoichiometric operation enabling conventional platinum monolith TWC technology to reduce by up to NOx 99.95% with the addition of a small amount of hydrogen gas as a reducing agent. The use of synthetic fuel eliminates the need for a DPF, since the absence of sulfur and nitrates in the synthetic natural gas-based fuel result in little to no PM being generated.

Since emissions do not dictate the design as in the case for conventional diesel engines, we can design the engine for power density and efficiency only.

This engine will greatly exceed all modern diesel emission standards while providing efficient trouble-free service to operators. For those interested, Please contact Christophe Pochari.

Similar models

grabcad

free

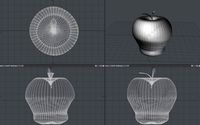

Free piston engine

...n standards while providing efficient trouble-free service to operators. for those interested, please contact christophe pochari.

grabcad

free

Dual-chamber two-stroke engine

...se contact christophe pochari at christophe.pochari@yandex.com.

credit to kuba záhora for the crankshaft and piston rod modeling.

grabcad

free

Dual chamber four-stroke engine

...general aviation aircraft. for those interested in licencing, please contact christophe pochari at christophe.pochari@yandex.com.

grabcad

free

Two-stroke supercharged engine

...power density, the simplicity of the concept, the lubrication similar with four stroke engine and the fact that the...

grabcad

free

Two stroke apposed pistons parallel cylinders internal combustion engine

...ankshafts, which rotate in the same direction, are linked by rods to respective pistons. wrist pins link the rods to the pistons.

grabcad

free

Design Of Single Cylinder Engine

...o rotary motion. a flywheel is generally connected to the crankshaft to reduce the vibrating characteristic of four stroke cycle.

cg_trader

$10

Two Stroke Engine

...ngine motorcycle engine two story internal combustion camshaft crankshaft cylinder exhaust intake piston cycle vehicle motorcycle

grabcad

free

Cylinder (two-cycle engine)

...engine that completes a power cycle with two strokes (up and down movements) of the piston during only one crankshaft revolution.

3dwarehouse

free

Sanko Engine revised(again)

...#innovation #inovative #invention #power #powerhouse #revolutionary #sanko #sanko_cycle #super #supercharger #turbo #turbocharger

cg_trader

$35

Single cylinder 4-stroke engine

...r motorcycle piston valve motorbike automobile crankshaft camshaft combustion fourstroke 4stroke singlecylinder motorcycle engine

Diesel

3ddd

$1

Diesel chair

...diesel chair

3ddd

diesel

моя интерпретация кресла diesel.

polys: 88 895

3d_export

$15

diesel generator

...diesel generator

3dexport

generator diesel

3ddd

$1

Diesel by Moroso

...й

diesel by moroso

размеры: 400х400х h750http://www.architonic.com/pmsht/bar-stud-stool-diesel-by-moroso_proref/1076262

3ddd

$1

Кровать Diesel

... diesel

кровать moroso "diesel"

размеры: 2140х1900х1000

материал оббивки: ткань

turbosquid

$12

Diesel

...d model diesel for download as ma, c4d, max, ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1705708)

3ddd

$1

Diesel / Mic

...diesel / mic

3ddd

diesel , foscarini

cage mic nero

diesel.foscarini.com

3ddd

free

Diesel / Stud

... foscarini

фабрика: diesel (with foscarini)

коллекция: stud

модели: stud grande, stud piccola

www.diesel.foscarini.com

3ddd

$1

Diesel - Cloudscape

...diesel - cloudscape

3ddd

diesel

100 х 100 х 104 см.

3ddd

$1

DIESEL CAGE LIGHT

...diesel cage light

3ddd

diesel , cage

diesel cage light by foscarini

3ddd

$1

Diesel / Cage Mic

...carini , diesel , подвесной

design: diesel 2011

Acting

3d_export

$99

star wars at-act walker

...rogue one: a star wars story<br>v-ray render and materials (1.50 sp4a)<br>lighting setup is not included in the file!

3d_export

$5

zerglingmodelling rig ani

...zerglingmodelling rig ani 3dexport i have implemented starcraft2 juggling. acting is also...

3d_export

$5

balloon with material imitating transparency

...terial imitating transparency

3dexport

balloon with a material simulating transparency. vertex color acts as a transparency map.

3d_export

$30

Cute anthropomorphic robot

...a cute robot is suitable as an assistant character or bot guide. he can act as a butler, janitor or protector/nanny for children.

3ddd

free

Nowodvorski. Bubble black. Bubble white.

...ww.nowodvorski.com/oferta?category=9668&act;=listcategory=9668&act;=list

в архиве файлы 2010,1012 макса, fbx.

cg_studio

$39

David Beckham acting3d model

... model

cgstudio

.3ds .max .obj - david beckham acting 3d model, royalty free license available, instant download after purchase.

cg_studio

$39

Brad Pitt acting3d model

...ng3d model

cgstudio

.3ds .max .obj - brad pitt acting 3d model, royalty free license available, instant download after purchase.

3d_export

$15

Maverick REV-6

...n act as the main blaster of a nerfer, but due to the short range, it is recommended to use it as a secondary, additional weapon.

3d_export

$5

donut and cup of coffee

...of coffee. the stage also has a wall, marble (acting as a marble table) and...

cg_studio

$39

Robert De Niro acting3d model

...model

cgstudio

.3ds .max .obj - robert de niro acting 3d model, royalty free license available, instant download after purchase.

Piston

3d_ocean

$4

Piston

...rmats included: .c4d, .obj – the model contains 5130 polygons – not rigged, scene setup / lighting / environments from the pre...

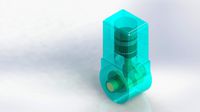

3d_export

$3

piston

...piston

3dexport

3d design piston (solidworks)

3d_export

free

piston

...piston

3dexport

piston model, more files here:

3d_export

$5

piston

...piston

3dexport

3d drawing of a piston of an automotive combustion engine.

3d_export

$12

piston

...piston

3dexport

piston models are modelled in max and riged with manuel technics. animated as eternal loop.

3d_export

$5

piston

...ne, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod.

3d_ocean

$20

Piston Engine

...ax 2011 with rig set up and animation loop if you have some questions, please contact me through my profile page. render versi...

turbosquid

free

Piston

...piston

turbosquid

free 3d model piston for download as obj on turbosquid: 3d models for games, architecture, videos. (1320057)

3d_export

$5

piston

...piston

3dexport

поршень

turbosquid

$15

Piston

...

turbosquid

royalty free 3d model piston for download as dwg on turbosquid: 3d models for games, architecture, videos. (1323338)

Double

3ddd

free

Double

...double

3ddd

double , sicis

диван double от итальянской фабрики sicis next art

3d_ocean

$5

double stairs

...double stairs

3docean

double stairs

double stairs

3d_export

$5

double handle

...double handle

3dexport

double handle

3d_export

$5

double fastener

...double fastener

3dexport

double fastener

3ddd

$1

double bed

...double bed

3ddd

двуспальная

double bed

design_connected

free

Chair Double

...chair double

designconnected

free 3d model of chair double

3ddd

$1

Double Leaves

...double leaves

3ddd

double leaves

кресло китайской фабрики double leaves. vray, 3dmax 2013, гамма 2.2, текстуры в комплекте.

3ddd

free

Люстра Double

...люстра double

3ddd

double , david chipperfield

2004

размеры в архиве

3d_export

free

couch - double

...couch - double

3dexport

couch double with texture and .psd files for personal customization

3d_export

$10

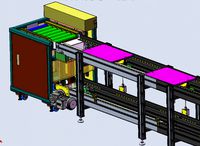

double layer double speed chain

...d chain

3dexport

double layer speed chain (design very detailed) 3d model drawing model file reference using solidworks software

Engine

3d_export

$5

engine

...engine

3dexport

engine

3d_export

free

Engine

...engine

3dexport

engine

archibase_planet

free

Engine

...engine

archibase planet

motor engine

engine - 3d model for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

motor engine mover

engine n170708 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

engine locomotive train

locomotive - 3d model for interior 3d visualization.

turbosquid

$1

ENGINE

...osquid

royalty free 3d model ic engine for download as sldas on turbosquid: 3d models for games, architecture, videos. (1382781)

3d_export

$5

engine

...engine

3dexport

3d_export

free

engine

...engine

3dexport

turbosquid

$7

Engine

...d model animated engine mograph element3d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1380716)

turbosquid

$1

ENGINE

...y free 3d model engine for download as max, 3ds, stl, and fbx on turbosquid: 3d models for games, architecture, videos. (1673703)

Free

design_connected

$13

Free

...free

designconnected

parri design free armchairs computer generated 3d model. designed by marco maran.

turbosquid

$5

free

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Free

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Free

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

free

Free barstool

...free barstool

designconnected

free 3d model of free barstool by kristalia designed by graffeo, monica.

3d_export

$5

free mixamo

...free mixamo

3dexport

free mixamo

3d_export

free

free rocks

...free rocks

3dexport

free price rock

turbosquid

free

Free Free Standing Punching Bag

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

character free

...urbosquid

free 3d model character free for download as blend on turbosquid: 3d models for games, architecture, videos. (1321193)

turbosquid

free

Hamburger Free

...urbosquid

free 3d model hamburger free for download as blend on turbosquid: 3d models for games, architecture, videos. (1592262)