GrabCAD

food dispenser in all this diversity

by GrabCAD

Last crawled date: 1 year, 3 months ago

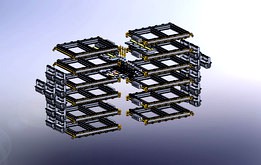

....here we have the first attempt to depict our food dispenser in all its diversity

due to the size of the working memory, i can only show it schematically, fragmented, so to speak - the whole thing in parts only. it is not possible for me to show all groups with their individual parts here.

to the food dispenser:

we have a device here with a large number of interchangeable, automatically interchangeable lines.

That means - the actual composition can change at any time - depending on the requirements!

I have simply concentrated the choice on the baguette route here:

- baguette-bread halves- become both bottom and top

baked

- the warm, fresh baguette is then filled - that means: we drive

the individual lines off and get fresh there

sliced placed on the baguette

the lines:

- above (1) is the die-cast production of our required

packaging form

- underneath (2) is a baking pan for schnitzel, backfissh, egg dishes

- down there (3) is the baking section for our baguettes

- there below (4) is the first cutting section for the lower support

the baguette- a slice (!!) with a firm sauce mass

- there below (5) is a cut for the second edition on the

baguette - that would be a firm tomato sauce

- Nothing is planned underneath (6): after the second edition

the output form up to (2) and gets the main product

a schnitzel, a breaded fish, an egg preparation.

- then now we continue with the edition above the third

edition: that means: the form of our baguette must be from

move up (2) down to the corresponding top picks,

to get conditions.

- once this has been done - the baguette upper part must be put on in (3).

- and that's it - the finished baguette goes whole

up and gets (1) its cover put on there.

- then the finished baguette moves all the way down and is

spent!

always six at a time.

what sounds complicated here is simple and quite fast

and implemented quickly.

the well-known boiled ham press mold is required for the production of boiled ham, cheese and all firm sauces and is housed in a continuously circulating water bath tower.

the cutting device for cutting the demoulded constructs from the boiling mold of the pressing mold is not included here!

the die-cast mold and the translator are also missing here!

so far everything works - despite endless attempts to permanently prevent me from doing everything - unfortunately this is still the case in the most massive way - by the German state of terror, quite well: e

due to the size of the working memory, i can only show it schematically, fragmented, so to speak - the whole thing in parts only. it is not possible for me to show all groups with their individual parts here.

to the food dispenser:

we have a device here with a large number of interchangeable, automatically interchangeable lines.

That means - the actual composition can change at any time - depending on the requirements!

I have simply concentrated the choice on the baguette route here:

- baguette-bread halves- become both bottom and top

baked

- the warm, fresh baguette is then filled - that means: we drive

the individual lines off and get fresh there

sliced placed on the baguette

the lines:

- above (1) is the die-cast production of our required

packaging form

- underneath (2) is a baking pan for schnitzel, backfissh, egg dishes

- down there (3) is the baking section for our baguettes

- there below (4) is the first cutting section for the lower support

the baguette- a slice (!!) with a firm sauce mass

- there below (5) is a cut for the second edition on the

baguette - that would be a firm tomato sauce

- Nothing is planned underneath (6): after the second edition

the output form up to (2) and gets the main product

a schnitzel, a breaded fish, an egg preparation.

- then now we continue with the edition above the third

edition: that means: the form of our baguette must be from

move up (2) down to the corresponding top picks,

to get conditions.

- once this has been done - the baguette upper part must be put on in (3).

- and that's it - the finished baguette goes whole

up and gets (1) its cover put on there.

- then the finished baguette moves all the way down and is

spent!

always six at a time.

what sounds complicated here is simple and quite fast

and implemented quickly.

the well-known boiled ham press mold is required for the production of boiled ham, cheese and all firm sauces and is housed in a continuously circulating water bath tower.

the cutting device for cutting the demoulded constructs from the boiling mold of the pressing mold is not included here!

the die-cast mold and the translator are also missing here!

so far everything works - despite endless attempts to permanently prevent me from doing everything - unfortunately this is still the case in the most massive way - by the German state of terror, quite well: e

Similar models

grabcad

free

cooked ham press mold

...the number of parts - our computer blocks due to the size of the files generated, so we are no longer able to act.

step, igs, stl

grabcad

free

new process for the production-both of sausages

...take over. we fill in the sausages into devices similar to the ham press molds which, for example, give...

grabcad

free

bread wreath

...s in oil - instead of butter - then as dandelion leaves, ham and cheese as toppings .....

solidworks 2013 data formats igs, step

cg_trader

$2

Bread

...bread

cg trader

lov poly bread bread bakery food baguette baked breakfast baking pastry other miscellaneous

grabcad

free

milk-bread-line

...k - the whole thing in parts only. it is not possible for me to show all groups with their individual parts here.

step, igs, stl

grabcad

free

bottle twister

...ed and gratinated rye baguettes - we also need a filling machine at the front and back and a bottle twister each!

step, igs, stl

grabcad

free

mold for the mechanical production of press ham

...he mechanical production of press ham in roll form for the autonomous food processor, the autonomous steam cooker

step, igs, stl

cg_trader

$19

Baguette or cut French bread with seeds and spices

...make sure you didn't miss collections and assets with similar type of objects to get better price offer with...

cg_trader

$10

Bread Tableware

...ncluded

low poly , game ready bread food baking bakery baguette toast breakfast lunch baked tableware kitchen other miscellaneous

cg_trader

$9

burger

...t salad tomato cucumber sauce bread hamburger sandwich fastfood food burger lunch dinner cheeseburger miscellaneous other ketchup

Diversity

turbosquid

$9

Diverse Deberenn screen

...del diverse deberenn screen for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1499832)

turbosquid

$4

Diverse Custom Chocolate Bars

... 3d model diverse custom chocolate bars for download as blend on turbosquid: 3d models for games, architecture, videos. (1667373)

humster3d

$75

3D model of Yamaha XJ6 Diversion F 2014

... 3d model of yamaha xj6 diversion f 2014 in various file formats. all our 3d models were created maximally close to the original.

turbosquid

$5

Stairs Set 01 - Marble Stairs in diverse shapes

...3d model stairs 01-2 for download as blend, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1650988)

3d_export

$7

sky dragon

...tol with rockets, with high maneurobility, and access to hard places, that can do an expected landing operations, and diversions.

3ddd

$1

Desk Finn

...inn

3ddd

стол

designed a diverse range of furniture with frames of steel pipe during his working life.

style: scandinavian design

3d_ocean

$5

National Trust Colour Set - Texturemap

...and is inspired and informed by the extraordinarily rich diversity of...

3d_ocean

$2

Happy Valentine´s Day

...

3docean

3dimage 3ds bg1440 c4d cinema4d day fbx happy lovers new obj valentines

happy valentine´s day / 3d art / diverse formats

3d_export

$15

Texture Greek Key Pattern 3D Model

...iquity tileable pattern diverse multiple square old video game seamless

texture greek key pattern 3d model dlhinds 36289 3dexport

3d_export

$7

Vibrant Facades

...se facades can be used for vibrant and active urban spaces. file export: obj & fbx<br>thanks for choosing this product.

Dispenser

archibase_planet

free

Dispenser

...dispenser

archibase planet

soap dispenser sanitary ware

soap dispenser - 3d model for interior 3d visualization.

archibase_planet

free

Dispenser

...dispenser

archibase planet

toilet paper dispenser sanitary ware

toilet paper dispenser - 3d model for interior 3d visualization.

archibase_planet

free

Dispenser

...hibase planet

dispenser water cooler cooler water

dispenser n040815 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3d_export

$10

soap dispenser

...soap dispenser

3dexport

soap liquid dispenser for top.

3ddd

$1

soda dispenser

...soda dispenser

3ddd

бар , кафе

soda dispenser

turbosquid

$5

dispenser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$12

Water Dispenser

...dispenser furnishings lowpoly water

this is a water dispenser hot water for tea is winter and summer is cold for souls. have fun!

archive3d

free

Dispenser 3D Model

...aper towel dispenser mediclinics n280116 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Dispenser 3D Model

...ater t6 purifier water dispenser n260216 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Soap dispenser

...ser

3dexport

soap dispenser for your bathroom interior design<br>include:<br>- pbr-materials<br>- 2 dispensers

Food

archibase_planet

free

Food

...food

archibase planet

food fires fast food

food fires n180614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$10

food

...food

3dexport

this is a table with food.

turbosquid

$10

canteen food, fast food

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$6

Food Truck

...oly low poly food truck truck

low poly food truck for games or animation. it contains of rack, ventilation, stairs, and umbrella.

turbosquid

$3

Food

...osquid

royalty free 3d model food for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1443013)

3d_export

$5

Food container

...food container

3dexport

food container

3d_export

$5

food box

...food box

3dexport

it is box for food with a cover.

turbosquid

$5

food

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Foods

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

food

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

All

turbosquid

$20

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$29

All-Two

...all-two

designconnected

bonaldo all-two computer generated 3d model. designed by bicego, sergio.

design_connected

$29

All-One

...all-one

designconnected

bonaldo all-one computer generated 3d model. designed by bicego, sergio.

design_connected

$16

Holly All

...holly all

designconnected

serralunga holly all computer generated 3d model. designed by starck, philippe.

3d_export

$15

all terrain

...all terrain

3dexport

turbosquid

$29

Holly All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.