Thingiverse

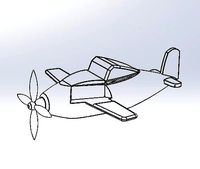

Flying Wing Buratinu by wersy

by Thingiverse

Last crawled date: 3 years ago

The Buratinu is a smaller derivate of the Buratino which was designed by Bil in St. Petersburg.

Thank you Bil for the great design.

With its pointed nose I was optimistic that I would manage the CG problem, which is always tricky with printed planes.

The original has a wingspan of 1800 mm. I designed it for a wingspan of 1300 mm with slightly more sweep back.

The video is on YouTube https://www.youtube.com/watch?v=HTmxjgw0Mq4&t=165s

Helmut uploaded a great video to show how to launch it by hand:

And this is the exciting maiden of Peter's Buratinu - inclusive stress test ;)

Detailed information about the development from the beginning and a lot pictures of the parts can be found on rc-networkhttp://www.rc-network.de/forum/showthread.php/682097-Drohne-aus-St-Petersburg-drucken

Recommended Print Settings

Attention

The wings are designed to print using 0.5 mm width, 4 bottom and 4 top

layers, no infill, 1 perimeter only.

Should you print thinner walls, the perimeter of the upper side will not stick well enough

to the perimeter of the inner stiffening construction.

If you apply thicker walls, the perimeters will not come out continuously in one

uninterrupted turn.

The layers must build up as if you were printing in spiral vase mode. Only then you get a

smooth surface on the upper side.

If unsatisfied with the results, try out 0.49 or 0.48 width in your slices settings. It

depends whether you use Cura, Slic3r, S3D or what you have. I suggest you experiment with

some tests before printing the whole thing.

The second point is: Should you print lesser layer heights, the inner stiffening

construction will not connect well to the top and bottom layers. You will suffer a gap inbetween.

All wing parts:

layer height =0,25mm, width =0.5 mm, 1 perimeter, no infill

W1, W2: 4 bottom layer, 4 top layer

W3 servo: 3 bottom layer, 4 top layer

W4, W5: 3 bottom layer, 3 top layer

W6: 3 bottom layer, 5 top Layer

winglet

2 perimeter, layer hight =0,2 mm, width =0,5 mm, 2 botton layer, 3 top layer, 25% infill

winglet slim

2 perimeter, layer hight =0,2 mm, width =0,5 mm, 1 botton layer, 2 top layer, 6% infill

elevon inner: 6 bottom layers, spiral vase mode, no top layer

elevon outer: 3 bottom layers, spiral vase mode, no top layer

elevon joint: no bottom/top layer, spiral vase mode

All fuselage parts: layer height =0,2mm, width =0.5 mm

fuselage 1: 3 perimeters, 12 bottom layers, 3 top layers, 40% infill

fuselage 2: 3 perimeters, 2 bottom layer, 3 top layer, no infill

fuselage 3: 2 perimeters, 2 bottom layers, 3 top layers, no infill

access panel and bracket

layer height =0.2 mm, width =0,5 mm

spiral vase, no top/bottom layer

Length of carbon tubes

Diameter 8 mm

fuselage/W1/W2 front: 305 mm

fuselage/W1/W2 rear: 400 mm

W2/W3/W4: 105 mm

W4/W5: 40 mm

Diameter 6 mm

W5/W6: 59 mm

Diametern 4 mm

elevons 420 mm

Specifications

airfoils: own design

wing span: 1300 mm

wing chord: 480/140 mm

CoG: 220 mm from the front of the fuselage

overall weight: 1245 g

wing weight one side complet: 342 g

wing area: 32 dm²

wing loading: 39 g/dm²

motor: Propdrive 28-36 1200KV

propeller: Aeronaut CAM Aeronaut Carbon Classic 10 x 6"

static thrust: 1300 g (3S Lipo)

battery: Turnigy 1800 mAh 3S 40~50C Lipo

motor camber: tilted -1.5 degrees

Update 16th April 2019

Uploaded elevon parts for smaller printer

elevon inner cut

elevon rudder horn

elevon joint inner

If you want to print the wingend with the winglet in one, you can now take the following part:

W6 incl. winglet

The base of the winglet is 1.5 mm thick.

This thickness must be completely filled with solid layer. E.g. 6 solid layers each 0.25 mm high.

Update 16th April 2019

Uploaded

fuselage front mc4 sp2 hd25

stop rib

It has a motor bulkhead with 4° motor camber, 2° side pull and 4 mm holes with hole circle 25 mm.

Instead of the front pass hole there are thin bars for a stop rib for the battery.

Update 17th May 2019

Uploaded fuselage 1 mc4

It has already integrated 4° motor camber.

The hole pattern is rotated 90°.

Update 7th October 2020

For those who have a rear-mounted motor, I have designed a special fuselage nose.

fuselage 1 rear-mounted mc3

firewall rear-mounted

It has already integrated 3° motor camber.

Thank you Bil for the great design.

With its pointed nose I was optimistic that I would manage the CG problem, which is always tricky with printed planes.

The original has a wingspan of 1800 mm. I designed it for a wingspan of 1300 mm with slightly more sweep back.

The video is on YouTube https://www.youtube.com/watch?v=HTmxjgw0Mq4&t=165s

Helmut uploaded a great video to show how to launch it by hand:

And this is the exciting maiden of Peter's Buratinu - inclusive stress test ;)

Detailed information about the development from the beginning and a lot pictures of the parts can be found on rc-networkhttp://www.rc-network.de/forum/showthread.php/682097-Drohne-aus-St-Petersburg-drucken

Recommended Print Settings

Attention

The wings are designed to print using 0.5 mm width, 4 bottom and 4 top

layers, no infill, 1 perimeter only.

Should you print thinner walls, the perimeter of the upper side will not stick well enough

to the perimeter of the inner stiffening construction.

If you apply thicker walls, the perimeters will not come out continuously in one

uninterrupted turn.

The layers must build up as if you were printing in spiral vase mode. Only then you get a

smooth surface on the upper side.

If unsatisfied with the results, try out 0.49 or 0.48 width in your slices settings. It

depends whether you use Cura, Slic3r, S3D or what you have. I suggest you experiment with

some tests before printing the whole thing.

The second point is: Should you print lesser layer heights, the inner stiffening

construction will not connect well to the top and bottom layers. You will suffer a gap inbetween.

All wing parts:

layer height =0,25mm, width =0.5 mm, 1 perimeter, no infill

W1, W2: 4 bottom layer, 4 top layer

W3 servo: 3 bottom layer, 4 top layer

W4, W5: 3 bottom layer, 3 top layer

W6: 3 bottom layer, 5 top Layer

winglet

2 perimeter, layer hight =0,2 mm, width =0,5 mm, 2 botton layer, 3 top layer, 25% infill

winglet slim

2 perimeter, layer hight =0,2 mm, width =0,5 mm, 1 botton layer, 2 top layer, 6% infill

elevon inner: 6 bottom layers, spiral vase mode, no top layer

elevon outer: 3 bottom layers, spiral vase mode, no top layer

elevon joint: no bottom/top layer, spiral vase mode

All fuselage parts: layer height =0,2mm, width =0.5 mm

fuselage 1: 3 perimeters, 12 bottom layers, 3 top layers, 40% infill

fuselage 2: 3 perimeters, 2 bottom layer, 3 top layer, no infill

fuselage 3: 2 perimeters, 2 bottom layers, 3 top layers, no infill

access panel and bracket

layer height =0.2 mm, width =0,5 mm

spiral vase, no top/bottom layer

Length of carbon tubes

Diameter 8 mm

fuselage/W1/W2 front: 305 mm

fuselage/W1/W2 rear: 400 mm

W2/W3/W4: 105 mm

W4/W5: 40 mm

Diameter 6 mm

W5/W6: 59 mm

Diametern 4 mm

elevons 420 mm

Specifications

airfoils: own design

wing span: 1300 mm

wing chord: 480/140 mm

CoG: 220 mm from the front of the fuselage

overall weight: 1245 g

wing weight one side complet: 342 g

wing area: 32 dm²

wing loading: 39 g/dm²

motor: Propdrive 28-36 1200KV

propeller: Aeronaut CAM Aeronaut Carbon Classic 10 x 6"

static thrust: 1300 g (3S Lipo)

battery: Turnigy 1800 mAh 3S 40~50C Lipo

motor camber: tilted -1.5 degrees

Update 16th April 2019

Uploaded elevon parts for smaller printer

elevon inner cut

elevon rudder horn

elevon joint inner

If you want to print the wingend with the winglet in one, you can now take the following part:

W6 incl. winglet

The base of the winglet is 1.5 mm thick.

This thickness must be completely filled with solid layer. E.g. 6 solid layers each 0.25 mm high.

Update 16th April 2019

Uploaded

fuselage front mc4 sp2 hd25

stop rib

It has a motor bulkhead with 4° motor camber, 2° side pull and 4 mm holes with hole circle 25 mm.

Instead of the front pass hole there are thin bars for a stop rib for the battery.

Update 17th May 2019

Uploaded fuselage 1 mc4

It has already integrated 4° motor camber.

The hole pattern is rotated 90°.

Update 7th October 2020

For those who have a rear-mounted motor, I have designed a special fuselage nose.

fuselage 1 rear-mounted mc3

firewall rear-mounted

It has already integrated 3° motor camber.

Similar models

thingiverse

free

Delta Wilde Hummel by wersy

...se no solid bottom/top layers

acces panel brackets: print width 0.5mm, layer height 0.2mm, spiral vase no solid bottom/top layers

thingiverse

free

Speedy "Red Midi Swept Wing" by wersy

...0 mah 3s 40~50c lipo

motor camber: tilted -4 degrees

side pull: none

propeller: aeronaut cam aeronaut carbon classic 10 x 6"

thingiverse

free

Speedy Red Midi Wing by wersy

... in the slicer.

the cylinder must be printed hollow, with only 2 or 3 perimeters.

then you have to re-cut the bushing with a tap.

thingiverse

free

Buratinu Midi 13000 by wersy

...perimeter_extrusion_width = 0.5

layer_height = 0.25

perimeters = 1

fill_density = 0%

bottom_solid_layers = 4

top_solid_layers = 4

cults

free

Speedy "Red Midi Swept Wing"

...0 mah 3s 40~50c lipo

motor camber: tilted -4 degrees

side pull: none

propeller: aeronaut cam aeronaut carbon classic 10 x 6"

thingiverse

free

Speedy "Red Swept Wing" RC by wersy

...after the other, and see that you can get them out again, if needed. if both pipes are inside, the wings can not be pulled apart!

thingiverse

free

Speedy "Red Mini Wing" RC Plane by wersy

....3 layer hight

0.5 width

3 solid bottom layer, spiral vase mode

the bigger fin plate:

3 solid bottom layer

1 perimeter

10% infill

thingiverse

free

Speedy "Red Swept Wing 2" RC by wersy

...ery: turnigy 1800 mah 3s 40~50c lipo

motor camber: -4°

side pull: no

propeller: aeronaut cam aeronaut carbon classic 10 x 6"

thingiverse

free

Cookie Cutter - Star With A Hole by RadekSlowik

...yers, 2 perimeters, at least 20% infill,

pusher: 0.2 mm layers, 4 top and bottom solid layers, 2 perimeters, at least 20% infill,

thingiverse

free

Maker Mining Rig by bytestrome

...: 10

infill: 30%

t-slot nut w/ fan mount:

layer: 0.1 mm

filament: pla

perimeters: 10

top layers: 10

bottom layers: 10

infill: 30%

Buratinu

thingiverse

free

Buratinu Midi 13000 by wersy

...perimeter_extrusion_width = 0.5

layer_height = 0.25

perimeters = 1

fill_density = 0%

bottom_solid_layers = 4

top_solid_layers = 4

thingiverse

free

Buratinu Maxi 2000 by wersy

...ng the construction of the 2000 (half-shell, skid reinforcement, extended fuselage) and the many helpful suggestions - thank you!

thingiverse

free

Buratinu Maxi 1600 by wersy

...perimeter_extrusion_width = 0.5

layer_height = 0.25

perimeters = 1

fill_density = 0%

bottom_solid_layers = 4

top_solid_layers = 4

thingiverse

free

Mini Buratinu LW PLA by wersy

...m for this if the rear tubes are shortened. therefore i upload a remix of the modified rear fuselage.

fuselage rear 860 lwpla.stl

Wersy

thingiverse

free

Fan 80 mm.stl by wersy

...fan 80 mm.stl by wersy

thingiverse

just a fan 80 mm for your planning.

thingiverse

free

LED Ring Mount for Printrbot by wersy

...led ring mount for printrbot by wersy

thingiverse

this mount can be fastened on one side of the extruder.

thingiverse

free

Penholder Tubes by wersy

...one for the kids with some more tubes.

it is by far not so artfully because i am just an engineer - though i hope you like it :-)

blendswap

free

WERSI Galaxis

...ocal z direction, the lights will switch on or of. for moving the hole organ there is a squared empty.

have fun with this peace.

thingiverse

free

Carrier to carry the Printrbot by wersy

...ty small and not so heavy it is a bit cumbersome to transport because the only stiff parts are the bases connected with the rods.

thingiverse

free

Prusa I2 holder for wersy's case for RRD full graphic LCD by byteborg

...i like the rrd smart lcd and have it integrated in wersy's case. i needed a way to mount it on my prusa i2, so here it is :)

thingiverse

free

Mount for the Full Graphic Smart LCD Controller Case by wersy 2020 3030

...ing for wersy's case holes... so i designed this mount parts for this great lcd case https://www.thingiverse.com/thing:87250.

thingiverse

free

Turbo Car RC (experimental) by wersy

...be/6tzpffwsd0q

tires:http://www.makeblock.com/tire-68-5x22mm-4-packhttps://www.kiwi-electronics.nl/band-68-5x22mm-4-stuks?lang=de

thingiverse

free

Case for the Full Graphic Smart LCD Controller by wersy

...is a case for the full graphic smart lcd controller. http://www.reprapdiscount.com/home/34-full-graphic-smart-lcd-controller.html

thingiverse

free

Mini Buratinu LW PLA by wersy

...m for this if the rear tubes are shortened. therefore i upload a remix of the modified rear fuselage.

fuselage rear 860 lwpla.stl

Flying

design_connected

$13

Fly-Fly

...fly-fly

designconnected

foscarini fly-fly computer generated 3d model. designed by palomba, ludovica.

3ddd

$1

Foscarini FLY-FLY

...foscarini fly-fly

3ddd

foscarini , fly-fly

foscarini fly-fly

полигонов: 73 022

3ddd

$1

Foscarini Fly-Fly

...foscarini fly-fly

3ddd

foscarini

люстра fly-fly

3d_export

free

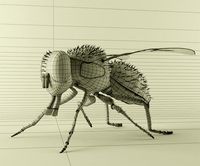

fly

...fly

3dexport

fly

turbosquid

$15

fly fishing fly

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

free

Fly

...fly

designconnected

free 3d model of fly by alias designed by acerbis, marco.

turbosquid

$49

Fly Fly Maya Rig

...turbosquid

free 3d model fly fly maya rig for download as ma on turbosquid: 3d models for games, architecture, videos. (1182393)

design_connected

$13

Fly

...fly

designconnected

zanotta fly computer generated 3d model. designed by robson , mark .

design_connected

$13

Fly

...fly

designconnected

kartell fly computer generated 3d model. designed by laviani, ferruccio.

3d_ocean

$10

3D Fly

...3d fly

3docean

3d fly 3ds max fly

this is a 3d fly model.

Wing

3ddd

$1

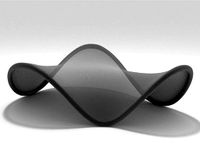

The Wing

...the wing

3ddd

wing , appledesign

the wing seating by appledesignstudio

3d_export

$5

wings

...wings

3dexport

beautiful wings model.

archibase_planet

free

Wing

...wing

archibase planet

wing decoration ornament

wing angel n180215 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3ddd

$1

Wing Chair

...wing chair

3ddd

baker , wing

wing chair

3ddd

$1

Диван WING

...диван wing

3ddd

flexform , wing

модель дивана wing

производитель: flexform

3ddd

$1

Диван WING

...диван wing

3ddd

flexform , wing

модель дивана wing

производитель: flexform

3ddd

$1

Кушетка WING

...кушетка wing

3ddd

flexform , wing

модель дкушетки wing

производитель: flexform

turbosquid

free

A-Wing

...id

free 3d model a-wing for download as fbx and unitypackage on turbosquid: 3d models for games, architecture, videos. (1164828)

3ddd

$1

Кресло Wing

...кресло wing

3ddd

wing

кресло wing из каталога в двух сочетаниях конфигурации.

3d_export

$5

wing nut

...wing nut

3dexport

wing nut