Thingiverse

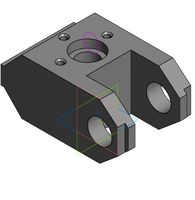

Flying Clamp for Tennis stringing - IMPROVED CLAMPING by sashalex007

by Thingiverse

Last crawled date: 3 years, 3 months ago

Yet another remix of edo_mae's excellent design. With this design I have eliminated the need for eyebolts with a fully 3D-printed shaft & threaded stopper. This mechanism is loosely based on the Stringway design providing improved clamping, and improved ergonomics. I have tested these designs with over 70lbs of tension.

With this remix I am also introducing a triple flying clamp (see Stringway clamps) for minimal tension loss due to drawback. Very useful for tie-offs.

PRINTING

It is important to note, that this design is intended for printing with carbon-fibre nylon, however I suspect ABS and PETG might work if all parts are printed at 90-100% density (lines). Recommended densities (%) are for CF nylon, 4 walls.

DOUBLE FLYING CLAMP

side_hexNut.stl -- 50%

side_noHexNut.stl --50%

2x middle_doubleClamp.stl --50%

shaft_doubleClamp --90%

lever.stl --90%

stopper.stl --90%

washer.stl --90%

guide.stl -- 50%

1/4 hex bolt 1.5 inch

1/4 lock nut

3/16 bolt 1 inch

8x 6x3mm round neodymium magnets

TRIPLE FLYING CLAMP

side_hexNut.stl -- 50%

side_noHexNut.stl --50%

2x middle_tripleClamp_outer.stl --50%

middle_tripleClamp_inner1.stl --50%

middle_tripleClamp_inner2.stl --50%

shaft_tripleClamp --90%

lever.stl --90%

stopper.stl --90%

washer.stl --90%

guide.stl -- 50%

1/4 hex bolt 2 inch (I didn't have one so there is an eye bolt in the image)

1/4 lock nut

3/16 bolt 1 inch

12x 6x3mm round neodymium magnets

ASSEMBLY

Assembly is generally the same for both clamp types, other than the extra middle pieces for the triple clamp.

Superglue middle pieces

Install magnets with correct polarity (opposing)

Cut 180grit sandpaper with guide.stl and superglue onto sides and middle pieces

Slightly sand mating protrusions for smooth insertion

Install bottom hex bolt

Install shaft, lever & washer, thread the stopper (threading this thing can be a challenge, but it works). Future iterations of the stopper will have textured grip...meanwhile we will have to make do...use channel locks or clamps to turn this thing.

NOTE1: You may need the enlarge to hole on the shaft with an allan key or something to get the desired feel. Ideally, the shaft should be a little loose on the bolt. If its not, this won't affect the functionality but ideally, the lever is pushed up into fully open position solely by magnetic force. It's more of an ergonomics feature, if its important to you, you might need to tune that hole size a little.

NOTE2: The bolt requirements are not strict, if you find metric bolts (or whatever else) that are in the ball-park, it will probably work fine. Also, every hole can be enlarged by quite a bit with a set of Allen keys

With this remix I am also introducing a triple flying clamp (see Stringway clamps) for minimal tension loss due to drawback. Very useful for tie-offs.

PRINTING

It is important to note, that this design is intended for printing with carbon-fibre nylon, however I suspect ABS and PETG might work if all parts are printed at 90-100% density (lines). Recommended densities (%) are for CF nylon, 4 walls.

DOUBLE FLYING CLAMP

side_hexNut.stl -- 50%

side_noHexNut.stl --50%

2x middle_doubleClamp.stl --50%

shaft_doubleClamp --90%

lever.stl --90%

stopper.stl --90%

washer.stl --90%

guide.stl -- 50%

1/4 hex bolt 1.5 inch

1/4 lock nut

3/16 bolt 1 inch

8x 6x3mm round neodymium magnets

TRIPLE FLYING CLAMP

side_hexNut.stl -- 50%

side_noHexNut.stl --50%

2x middle_tripleClamp_outer.stl --50%

middle_tripleClamp_inner1.stl --50%

middle_tripleClamp_inner2.stl --50%

shaft_tripleClamp --90%

lever.stl --90%

stopper.stl --90%

washer.stl --90%

guide.stl -- 50%

1/4 hex bolt 2 inch (I didn't have one so there is an eye bolt in the image)

1/4 lock nut

3/16 bolt 1 inch

12x 6x3mm round neodymium magnets

ASSEMBLY

Assembly is generally the same for both clamp types, other than the extra middle pieces for the triple clamp.

Superglue middle pieces

Install magnets with correct polarity (opposing)

Cut 180grit sandpaper with guide.stl and superglue onto sides and middle pieces

Slightly sand mating protrusions for smooth insertion

Install bottom hex bolt

Install shaft, lever & washer, thread the stopper (threading this thing can be a challenge, but it works). Future iterations of the stopper will have textured grip...meanwhile we will have to make do...use channel locks or clamps to turn this thing.

NOTE1: You may need the enlarge to hole on the shaft with an allan key or something to get the desired feel. Ideally, the shaft should be a little loose on the bolt. If its not, this won't affect the functionality but ideally, the lever is pushed up into fully open position solely by magnetic force. It's more of an ergonomics feature, if its important to you, you might need to tune that hole size a little.

NOTE2: The bolt requirements are not strict, if you find metric bolts (or whatever else) that are in the ball-park, it will probably work fine. Also, every hole can be enlarged by quite a bit with a set of Allen keys

Similar models

thingiverse

free

wondershade 1/4 in bolt adaper square to hex bolt carriage bolt adapter by SevenCornersWorkshop

...by sevencornersworkshop

thingiverse

this adapts a 1/4 inch carriage bolt to fit in the hex cutout on the stands leg locking bolt

thingiverse

free

Flying Clamp for Tennis stringing IMPERIAL REMIX by sashalex007

...to cut your sandpaper.

usage:

these need to be clamped tight. if your clamp isn't holding tension, tighten the eyebolt more.

thingiverse

free

Celestron PowerSeeker 70EQ Dovetail Clamp by dkrnet

...ex head of the m6 x 70mm bolt is completely pressed into the hex-shaped recess

loosen the wing nut to permit attaching a dovetail

grabcad

free

Michael Engineering Clamp

...michael engineering clamp

grabcad

a clamp for 1/2 inch hex shafts.

thingiverse

free

Shuriken magnet by grim86

...shuriken magnet by grim86

thingiverse

it needs a 6x3mm neodymium magnet.

thingiverse

free

Coupler, 5 mm to 1/4 inch, for Printrbot Simple All-Metal Z-Axis by Altan

... 4 pcs of 12 mm long m3 hex screws and nuts.

print conditions:

layer height: 0.1 mm

fill: 30%

wall thickness: 1 mm

brim: 20 mm

grabcad

free

MIGE Shaft Clamp

...o the motor shaft. you may have to adjust the size of the keyway for the optimal fit.

compatible with the amstudio bolt pattern.

thingiverse

free

Refrigerator Magnet by hjelle

...ts-inch-cylinder-n48/dp/b001kv9raw/ref=sr_1_46?ie=utf8&qid=1394664231&sr=8-46&keywords=1%2f4+x+1%2f4+neodymium+magnet

thingiverse

free

Camera Mount 90 degree adapter by spudinator

...works with standard 1/4 - 20 unc threads found on most cameras, gopros, webcams.

use a 3/4 inch or 1 inch 1/4 - 20 bolt and nut.

thingiverse

free

1/4 inch compatible Minature Vice 2.0 by cyron52

...re:

the thingiverse post (doesn't have all the files)

the vice v2.0

the table clamp

hope this makes it easier for some folks.

Sashalex007

thingiverse

free

Skr 1.3 case-lid remix (for extra fan) by sashalex007

...ould repurpose it for better cooling for my drivers.

print the body from the original. https://www.thingiverse.com/thing:3688484

thingiverse

free

Elegoo Mars 2 filter & heater by sashalex007

...ilterbody.

super-glue the heater to heatermount.

super-glue the filtermount to the heatermount.

assemble filter (1/8x1/2 bolts)

thingiverse

free

Flying Clamp for Tennis stringing IMPERIAL REMIX by sashalex007

...to cut your sandpaper.

usage:

these need to be clamped tight. if your clamp isn't holding tension, tighten the eyebolt more.

thingiverse

free

Elegoo Mercury Plus - Magnetic Stirrer conversion by sashalex007

...he sensor-facing side.

video:https://www.reddit.com/r/elegoomars/comments/nz9r24/converted_my_mercury_into_a_magnetic_stirrer_uv/

thingiverse

free

Ender 5 Direct Drive linear rail mount

...speeddrive v1 - ender 3 direct drive mount by sashalex007 to fit ender 5 linear rails mod by...

thingiverse

free

SpeedDrive For TronXY Pro 2 by marcdraco

...by marcdraco thingiverse this is (yet another) remix of sashalex007#39;s rather super direct drive mod but this time for...

thingiverse

free

SpeedDrive v1 - Ender 3 direct drive mount remix for dual drive extruder

...a remix of the excellent direct drive update by sashalex007 to make it work with the cr-10s pro extruder....

thingiverse

free

SpeedDrive for E3D V6 + BMG extruder + Cable clip

...speeddrive v1 - ender 3 direct drive mount by sashalex007 (https://www.thingiverse.com/thing:3816051) speeddrive for e3d v6 + bmg extruder by...

thingiverse

free

Ender 3 Pro Chimera Mount for Fan Forced Air Convection by CrazyBucketMan

...crazybucketman thingiverse this is my remix of speeddrive by sashalex007 and the "ender 3 chimera aqua half direct mount"...

Tennis

3d_ocean

$3

Tennis Ball

...tennis ball

3docean

ball tennis tennis ball

a gorgeous red and yellow seamless tennis ball

turbosquid

$29

Tennis Racket and Tennis Ball

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Tennis

...oyalty free 3d model tennis for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1480642)

turbosquid

$30

Tennis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

TENNIS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$10

![[Tennis series] Low-poly tennis court](/t/579509.jpg)

[Tennis series] Low-poly tennis court

... texture detail. it has the precise measurements of a real tennis court and net. the polygon count is just 856! all the elemen...

turbosquid

$98

Sports Tennis Girl Model with Tennis Court

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$19

tennis ball

...tennis ball

3dexport

3d_export

$12

tennis shoes

...tennis shoes

3dexport

turbosquid

free

Tennis Ball

...all

turbosquid

free 3d model tennis ball for download as max on turbosquid: 3d models for games, architecture, videos. (1482300)

Stringing

3ddd

$1

String W1

...string w1

3ddd

светильник string w1

turbosquid

$25

String

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$13

String Chair

...string chair

designconnected

magis string chair computer generated 3d model. designed by azumi, shin.

3ddd

$1

String Rack

...string rack

3ddd

декоративный набор

string rack is purpose for decorative object in living room or in study room.

turbosquid

$10

String bikini

...bosquid

royalty free 3d model string bikini for download as on turbosquid: 3d models for games, architecture, videos. (1559187)

3ddd

$1

String F1

...string f1

3ddd

rotaliana

rotaliana

string f1

design dante donegani, giovanni lauda (2011)

lower arm 80 cm

upper arm 46 cm

turbosquid

$62

Chill String

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

On-A-String-Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Elixer strings

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Dunlop Strings

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Flying

design_connected

$13

Fly-Fly

...fly-fly

designconnected

foscarini fly-fly computer generated 3d model. designed by palomba, ludovica.

3ddd

$1

Foscarini FLY-FLY

...foscarini fly-fly

3ddd

foscarini , fly-fly

foscarini fly-fly

полигонов: 73 022

3ddd

$1

Foscarini Fly-Fly

...foscarini fly-fly

3ddd

foscarini

люстра fly-fly

3d_export

free

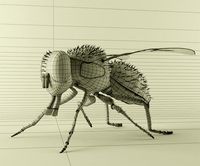

fly

...fly

3dexport

fly

turbosquid

$15

fly fishing fly

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

free

Fly

...fly

designconnected

free 3d model of fly by alias designed by acerbis, marco.

turbosquid

$49

Fly Fly Maya Rig

...turbosquid

free 3d model fly fly maya rig for download as ma on turbosquid: 3d models for games, architecture, videos. (1182393)

design_connected

$13

Fly

...fly

designconnected

zanotta fly computer generated 3d model. designed by robson , mark .

design_connected

$13

Fly

...fly

designconnected

kartell fly computer generated 3d model. designed by laviani, ferruccio.

3d_ocean

$10

3D Fly

...3d fly

3docean

3d fly 3ds max fly

this is a 3d fly model.

Clamping

3d_export

$11

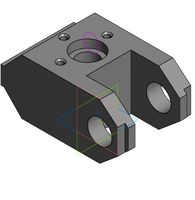

clamp

...clamp

3dexport

clamp

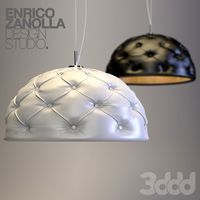

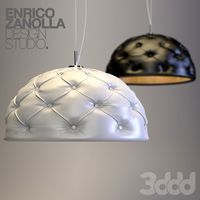

3ddd

free

Clamp

... enricо zanolla , капитоне

дизайнерenrico zanollмодель clamp

3ddd

$1

Clamp

...ricо zanolla , капитоне

дизайнеры

enrico zanolla

andrea di filippo

модель clamp

dzstudio

3d_export

free

clamp

...clamp

3dexport

simple clamp model, more free 3d models here:

3d_export

$5

clamping handle

...clamping handle

3dexport

clamping handle

3ddd

$1

Clamp / DZstudio

... dzstudio , капитоне

люстра clamp от dzstudio/enrico zanolla(италия).

3ddd

$1

Светильник Clamp

...светильник clamp

3ddd

clamp

стеганый светильник clamp в двух цветах в черном и белом.

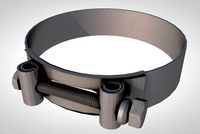

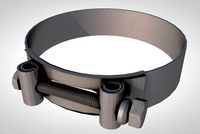

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442049)

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442041)

3d_export

$5

Clamp-14

...clamp-14

3dexport

3d model of clamp name 14

Clamp

3d_export

$11

clamp

...clamp

3dexport

clamp

3ddd

free

Clamp

... enricо zanolla , капитоне

дизайнерenrico zanollмодель clamp

3ddd

$1

Clamp

...ricо zanolla , капитоне

дизайнеры

enrico zanolla

andrea di filippo

модель clamp

dzstudio

3d_export

free

clamp

...clamp

3dexport

simple clamp model, more free 3d models here:

3d_export

$5

clamping handle

...clamping handle

3dexport

clamping handle

3ddd

$1

Clamp / DZstudio

... dzstudio , капитоне

люстра clamp от dzstudio/enrico zanolla(италия).

3ddd

$1

Светильник Clamp

...светильник clamp

3ddd

clamp

стеганый светильник clamp в двух цветах в черном и белом.

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442049)

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442041)

3d_export

$5

Clamp-14

...clamp-14

3dexport

3d model of clamp name 14

Improved

cg_studio

$49

Robot Z300 (improved version)3d model

...o

.3ds .fbx .max .obj - robot z300 (improved version) 3d model, royalty free license available, instant download after purchase.

3d_export

$39

Robot Z300 improved version 3D Model

...fantasy sci-fi robots bot humanoid droid sci fi materials character

robot z300 improved version 3d model alekrazum 55067 3dexport

3d_export

$75

CV-90 Improved

...nnon. export versions are fitted with hägglunds e-series turrets, armed with either a 30 mm mk44 or a 35 mm bushmaster autocannon

turbosquid

$55

(Important textures coming back soon after improvements)Cuboid gazebo bench area

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

COMPLETE AUDI 80-100 SHIFT LEVER REPAIR KIT WITH IMPROVED BUSHING

...dexport

• sleeve - 1 pc. • elastic band - 1 pc. • hinge - 1 pc. audi 100c3 audi 100 c4 audi 80 b3 (checked) audi 80 b4 (checked)

3d_export

$7

REPAIR KIT FOR GEARSHIFT LEVER AUDI 80-100 IMPROVED

...ar of the gum is excluded. - rusk - 1 pc. - elastic band - 1 pc. audi 100c3 audi 100 c4 audi 80 b3 (checked) audi 80 b4 (checked)

3d_export

$30

cup mask machine front section stereo mask manufacturing machine improved version

...ing rack cad outsourcing list. the drawings are mature drawings that have been produced.<br>drawing version solidworks 2018

3d_export

free

oven - forno

...oven - forno

3dexport

gradually i'm trying to improve my 3d.

3d_export

$75

T-55

...nally, but these improvements made the tank more efficient and lethal. the t-55 was officially adopted by the soviet army in 1958

3d_export

$5

civil registration authorities

...civil registration authorities

3dexport

city wedding square. the model can be used for projects, to improve the project, etc.