Thingiverse

Flow Calibration Cube by PrintsLeo3D

by Thingiverse

Last crawled date: 3 years ago

This is a very simple calibration cube, used to measure the thickness of all four walls.

I found this process from Tomb of 3D Printed Horrors (https://www.youtube.com/channel/UC5Lbnd97HV3rU98gcwHklzQ/featured)

There are two models, a cube with 0.8 thickness wall used to measure 0.4mm nozzles, and then a larger 1.6 thickness wall used to measure 0.8mm nozzles. The test would work as follows:

(0.4mm nozzle example in Cura)

-In your slicer make sure Wall Thickness is 0.8 and Wall Line Count is 2

-This will ensure that your cube will be printed with exactly 2 walls on each side (0.4mm nozzle = 0.4mm line width = 2 walls)

-Print your cube and then using calipers measure the thickness of each wall

-Each wall should measure 0.8mm thickness, if it does, you're done! If not, keep going

-Measure the thickness of each wall, then add them together and divide by 4 to get an average. We call this number 'X'

-Then divide the width of the model wall (0.8) we call this 'Y' by the average of all sides (X)

-Y / X = NEW FLOW %

I found this process is a great starting point but can also be built upon by using all the various flow settings in your given slicer.

I found this process from Tomb of 3D Printed Horrors (https://www.youtube.com/channel/UC5Lbnd97HV3rU98gcwHklzQ/featured)

There are two models, a cube with 0.8 thickness wall used to measure 0.4mm nozzles, and then a larger 1.6 thickness wall used to measure 0.8mm nozzles. The test would work as follows:

(0.4mm nozzle example in Cura)

-In your slicer make sure Wall Thickness is 0.8 and Wall Line Count is 2

-This will ensure that your cube will be printed with exactly 2 walls on each side (0.4mm nozzle = 0.4mm line width = 2 walls)

-Print your cube and then using calipers measure the thickness of each wall

-Each wall should measure 0.8mm thickness, if it does, you're done! If not, keep going

-Measure the thickness of each wall, then add them together and divide by 4 to get an average. We call this number 'X'

-Then divide the width of the model wall (0.8) we call this 'Y' by the average of all sides (X)

-Y / X = NEW FLOW %

I found this process is a great starting point but can also be built upon by using all the various flow settings in your given slicer.

Similar models

thingiverse

free

Extrusion multiplier calibration cube by hrishib

... the walls and take an average of all 4 sides. then divide 0.8 by this value and you'll have your exact extrusion multiplier.

thingiverse

free

Calibration cube for 0.8mm nozzle

...zzle calibration.

use a 0.8mm nozzle and single wall in shell settings.

edit: the caliper should measure it as 1.6mm at each wall

thingiverse

free

Calibration Cube 20mm by Skoopsy

... issues.

cube dimensions:

width = 20mm

depth = 20mm

height = 20mm

wall thickness = 0.8mm

this cube will work with a 0.4mm nozzle.

thingiverse

free

Flow Calibration Cube by humebeam

...available for easy editing.

if you enjoy this or any of my other designs, a small donation is not needed but welcome. thanks! :)

thingiverse

free

Flow Rate Calibration Cube by thumper06

...people use is that they print 1 cube and assume that the outer wall squish is 0, if this were true there would be no layer lines.

thingiverse

free

calibration flow 0.8mm wall

...0.8mm wall

thingiverse

this is a little wall calibration for pepole who want to use default settings of cura with a 0.4mm nozzle

thingiverse

free

20mm cube for walls test by pyroevil

...m

wall 3 = 0.34mm

wall 4 = 0.34mm

average = 0.35mm

nozzle size = 0.4mm

numbers of wall = 1

0.35 / 0.4 = 0.875

0.875 x 100 = 87.5%

thingiverse

free

0.8 fatwall for extrusion width calibrations by abear

...n 2 lines making up the wall width.

i also calibrate retraction and ooze control settings using two of these about an inch apart.

thingiverse

free

Calibration thicknesses 0.4mm nozzle by enricodare

...to calibrate the slicer settings according to the print thickness.

you can stop printing to check the printing of the outer walls

thingiverse

free

Thin Wall Calibration Cube by brianlow

...lls of this cube are 0.40mm thick to match a 0.40mm nozzle. use the customizer to change the wall thickness to match your nozzle.

Printsleo3D

thingiverse

free

Leveling Adjustable Square by PrintsLeo3D

... square that can used as a calibration/test print., the size can be adjusted in your slicer by changing the x y and z dimensions.

thingiverse

free

Aluminum Extrusion Inserts by PrintsLeo3D

...ou bring it into your slicer. just make sure you turn off uniform scaling and then just increase the length to whatever you need.

thingiverse

free

Aluminum Extrusion Inserts / V-Slot cover by PrintsLeo3D

... all play a role in printing and while these sizes work for me you may have to adjust them slightly up or down to fit your needs.

thingiverse

free

Ender 3 Side mount Filament Filter by PrintsLeo3D

...th(easyenter) for the filament to be inserted, and the other is a 90 degree angle path(slideenter). both have worked fine for me.

Calibration

turbosquid

$15

DEFIBRILLATOR CALIBRATORS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Calibration Test Benches

...libration test benches for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1355804)

turbosquid

$79

Tag Heuer Monaco Calibre 11

...free 3d model tag heuer monaco calibre 11 for download as max on turbosquid: 3d models for games, architecture, videos. (1634427)

turbosquid

$50

Smith & Wesson 50 Calibre Magnum

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Laboratory Calibration Weight Set 1 3D Model

... 3d model

3dexport

laboratory lab science equipment weight set

laboratory calibration weight set 1 3d model bessoo 88084 3dexport

3d_export

$15

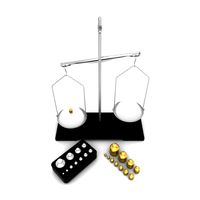

Laboratory Scale and Calibration Weight Set 3D Model

...port

laboratory lab science equipment weight set scale

laboratory scale and calibration weight set 3d model bessoo 88203 3dexport

3d_export

$5

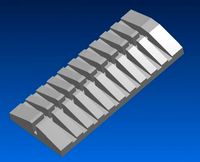

3D printer filament calibration tool 3D Model

...ernier

3d printer filament calibration tool 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl locoman 107942 3dexport

3d_export

$59

tag heuer link calibre 16 watch

...built to real-world scale. units used: centimeters. model is 18 centimeters tall.<br>scene objects are organized by groups.

3d_export

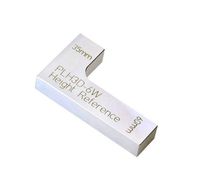

free

laser height reference calibration tool opt lasers

...ind out more about the engraving and cutting laser heads, this item was designed to work with, take a look at the following page:

3d_export

$99

Patek Philippe White Gold Calibre 89

...br>please note: this 3d model like all my other models cannot be used as nft, as is or modified<br>thank you for reading

Flow

turbosquid

free

Flow(Fluid/Flow)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Flow

...dd

flow , mdf italia , tessile

10 тыс.полигонов

turbosquid

$59

Blood Flow - Capilar flow

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

FLOW CHAIR and FLOW SLIM

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

FLOW CHAIR and FLOW SLIM

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

FLOW CHAIR and FLOW SLIM

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

FLOW CHAIR and FLOW SLIM

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

FLOW CHAIR and FLOW SLIM

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

FLOW CHAIR and FLOW SLIM

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Flow

...flow

3dexport

Cube

3d_ocean

$5

Cubes

...cubes

3docean

children cube cubes model paint toy toys wooden

old wooden children’s cubes.

3d_export

$5

cube

...cube

3dexport

cube

3d_export

$5

cube

...cube

3dexport

cube

3d_export

free

Chemistry cube - cube chimique

...chemistry cube - cube chimique

3dexport

chemistry cube - cube chimique

3d_export

$10

Cube

...cube

3dexport

cube deco

3d_export

free

cube

...cube

3dexport

invented the cube

archibase_planet

free

Cube

...cube

archibase planet

cube

g4 cube - 3d model for interior 3d visualization.

3d_export

$6

cube

...cube

3dexport

cube gamel location

archibase_planet

free

Cube

...cube

archibase planet

home furniture cube

cube - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cube

...cube

archibase planet

cube block die

cube eazelcom n050113 - 3d model (*.gsm+*.3ds) for interior 3d visualization.