Thingiverse

Flap sanding attachment for rotary tool - smaller versions by Ziddan

by Thingiverse

Last crawled date: 3 years, 3 months ago

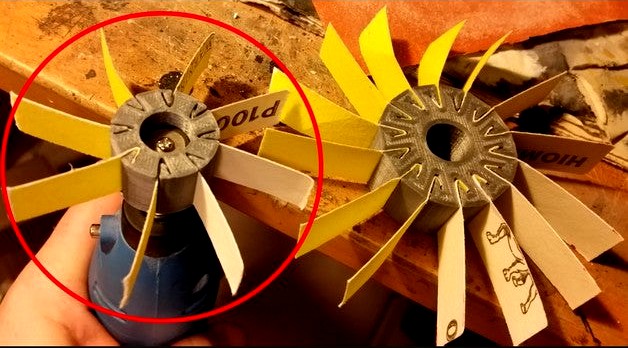

Remixed the Dremel Rotary Sander V2 by OldGaf into a smaller version with fewer flaps to allow my weak no-brand rotary tool to be able to spin it up properly.

It still uses the same attachment system, ie one of those tighten-screw-to-expand-rubber-thingies meant for the little sandpaper tubes.

Use jig2 from https://www.thingiverse.com/thing:3017214 to properly size and bend the sandpaper strips, after marking the width i cut the sandpaper with an hobby knife and a steel ruler.

ADDITION: Went ahead and made a micro version too, it requires the sand paper strips to be bent the other way.

Designed it so that the paper is leaning back from the direction of rotation since i figure that will give less drag and possibly hit whatever is being sanded with larger area of the paper but i wont know before ive tested it.

Since there is less paper it will obviously wear out quicker but should allow for getting into even tighter places and possibly also work with lower power rotary tools.

Will test print it as soon as the stuff currently on the printer is done.

ADDITION2:

The micro works but i still wasnt happy with it so i made a bench sander from left over RC parts, added versions with the hole to changed to 3.5mm in order to fit the output axle on a hexTronik DT750.

Also added air scoops to the large version to cool to motor, dont think its necessary tho, it doesnt get hot at all and the flaps are moving a lot of air out from the attachment and that is being pulled in from the two sides of the attachment, ie over the motor.

Also added bevels so the paper doesnt bend as sharply and and works for longer.

Table sander built from a motor, esc, servo tester and the power brick left over from an old LCD screen, took the motor pod off an old Flitetest Explorer i havnt flown in years, put a failed flat 3d print in the bottom of it, cut a hole for the clamp and it was done.

It still uses the same attachment system, ie one of those tighten-screw-to-expand-rubber-thingies meant for the little sandpaper tubes.

Use jig2 from https://www.thingiverse.com/thing:3017214 to properly size and bend the sandpaper strips, after marking the width i cut the sandpaper with an hobby knife and a steel ruler.

ADDITION: Went ahead and made a micro version too, it requires the sand paper strips to be bent the other way.

Designed it so that the paper is leaning back from the direction of rotation since i figure that will give less drag and possibly hit whatever is being sanded with larger area of the paper but i wont know before ive tested it.

Since there is less paper it will obviously wear out quicker but should allow for getting into even tighter places and possibly also work with lower power rotary tools.

Will test print it as soon as the stuff currently on the printer is done.

ADDITION2:

The micro works but i still wasnt happy with it so i made a bench sander from left over RC parts, added versions with the hole to changed to 3.5mm in order to fit the output axle on a hexTronik DT750.

Also added air scoops to the large version to cool to motor, dont think its necessary tho, it doesnt get hot at all and the flaps are moving a lot of air out from the attachment and that is being pulled in from the two sides of the attachment, ie over the motor.

Also added bevels so the paper doesnt bend as sharply and and works for longer.

Table sander built from a motor, esc, servo tester and the power brick left over from an old LCD screen, took the motor pod off an old Flitetest Explorer i havnt flown in years, put a failed flat 3d print in the bottom of it, cut a hole for the clamp and it was done.

Similar models

thingiverse

free

Jobmax Multi-Tool Micro Sanders

...ax multi-tool micro sanders

thingiverse

i needed some small sanding attachments. i use sticky back sandpaper and it works well.

thingiverse

free

Matrix Tool System Sander Attachment by sjdennis

...nted to make an attachment so i didn't have to buy the velcro sanding paper, i could just glue any piece to my matrix sander.

thingiverse

free

Sandpaper Helper for BOSCH Orbital Sander by Wherzog

...little helper to fixate the sanding paper on a bosch gex150/125.

should also work with other models of bosch 150mm orbital sander

thingiverse

free

Orbital Sander - Paper aligner by chrismolloy

...the step file to accommodate different spacings if required.

here is a link to the fusion 360 design file http://a360.co/2haqklj

thingiverse

free

Dremel Bit by Muthinor

...other one is the brand new v3, which has a smaller hole diameter so the screw doesnt wiggle, and a bigger hole for the screw head

thingiverse

free

Mini TOOL Sand Paper Grip by Magliettaro

...mini tool sand paper grip by magliettaro

thingiverse

sand paper grip

bioadhesive stick with sandpaper

thingiverse

free

Delta Sander attachment by focussys

... it just needs some velcro© loops to allow the sandpaper to attach. this part can also act as a template to cut sandpaper to fit.

thingiverse

free

Lasercut Detail sanders by patsakorn

... patsakorn

thingiverse

my design detail sanders tools for the makers.

used for sanding small details with sandpaper.

watch video

thingiverse

free

Sander tool for modellers by Odassyn

...to the tool.

you can find two sizes. i use the smallest one to fine sanding and the biggest one to pre-sanding.

use it. enjoy it.

thingiverse

free

Easy loading Sanding Block / Detail Sander by Joew1120

... screw for the original version, you'll only need to print the main body and top piece, since the screws are interchangeable.

Ziddan

thingiverse

free

Handyman by Ziddan

...erse

handyman by reddit request.

includes rigged blend file, automatic weight paint but should be ok unless doing extreme poses.

thingiverse

free

Knifing Goose. by Ziddan

...end is unmerged for easier reposing if anyone is interested.

just for fun as a response to an image posted on a discord server :)

thingiverse

free

Sometimes you get what you ask for. by Ziddan

...sometimes you get what you ask for. by ziddan

thingiverse

yup

thingiverse

free

Flexitracks for model vehicles by Ziddan

... treads that one just cuts to length and glues on.

ive also started on some wheels that go inside as well, will put them up soon.

thingiverse

free

Mars Moon Magic Man by Ziddan

...w an option available.

big thanks to don dave/miru8112, cornivius, mrmcangry and andrewmracette from whose models i remixed this.

thingiverse

free

Arm resting on sheathed sword by Ziddan

...g thank you!

styled on the bit out of the sternguard box.

changed out the ultra icon to a winged skull to be chapter independent.

thingiverse

free

Kunai - Split with alignment holes fit for easy assembly. by Ziddan

...

added a split of this with alignment holes for someone on reddit.

the holes are sized so lengths of filament should fit easily.

thingiverse

free

Remixed screen bracket by Ziddan

...reen slide into the mount, holds with enough holding force that the tx/screen can be shaken upside down without coming apart off.

thingiverse

free

Octawheel Bombsquig by Ziddan

...poikilos https://www.thingiverse.com/thing:3985624

heroquest squig 4 by ninjawolfhybrid https://www.thingiverse.com/thing:4362164

thingiverse

free

Contemptor foot remix - squarey version. by Ziddan

...ho initially made it.

big props to the original creator anyhow!

if told of who it was i will gladly update the attribution here.

Flap

thingiverse

free

Flap by emepaulino

...flap by emepaulino

thingiverse

flap.

thingiverse

free

Sand Flap Flap! by Coolcrawler_

...the sandpaper is secure.

please post your makes!

photos and videos by evanandkatelyn

https://www.youtube.com/watch?v=q2ddjzz0qjw

thingiverse

free

scuba flap by fablabkvadrat2020

...scuba flap by fablabkvadrat2020

thingiverse

scuba flap for divers

thingiverse

free

Flap sander by gazbot

...flap sander by gazbot

thingiverse

3d printed flap sander

thingiverse

free

FLAPS by Data2k7

...k7

thingiverse

flaps para b58 necesita de un interruptor de dos circuitos y tres led, para configurar para simvim, mobyflight...

thingiverse

free

Enclosure flap Cablemanagement

...enclosure flap cablemanagement

thingiverse

this is a cablemanagement flap for my ender 3 enclosure.

thingiverse

free

Split Flap Mini - 12 Flap Display by _AlexY

...per motor. ideal for displaying digits and 2 additional symbols (decimal point, percent, etc).

video:https://youtu.be/0e8yn0dbwrk

thingiverse

free

Lift Flap

...ft flap for fire call point. i use a 2.4 x 10 mm rivet to connect the lid to the box.

https://www.youtube.com/watch?v=lztvcqan5ec

thingiverse

free

Noquet Lodge Flap

...noquet lodge flap

thingiverse

this file was created to create a 3d version of the noquet lodge flap

thingiverse

free

Flap Runner Part for B-24 Fowler flap by MakerMark5000

...s b-24 to replace the lite ply pieces imbedded in the flaps that break too easily from normal use. six are required for each flap

Rotary

thingiverse

free

Rotary dial by nukaboy

...rotary dial by nukaboy

thingiverse

a simple rotary dial for mounting on a rotary switch

thingiverse

free

rotary / kreisel by Syzguru11

...rotary / kreisel by syzguru11

thingiverse

rotary / kreisel

thingiverse

free

rotary scruntchy holder

...rotary scruntchy holder

thingiverse

rotary scruntchy holder

thingiverse

free

Rotary Viçosa by marciommr

...rotary viçosa by marciommr

thingiverse

rotary club viçosa

thingiverse

free

Rotary-Clamp by VolkerB

...ngiverse

this clamp fits the object to the rotary-wheel.

tested with:

morn-laser rotary

this part is for non-comercial use only!

thingiverse

free

Rotary lenses by JayJo

...rotary lenses by jayjo

thingiverse

focusing pair of reflecting lenses, rotary formation, caged, in line

thingiverse

free

ROTARY TABLE by Arduinoklg

...rotating table

this video i show you how make rotary table this 3d model box and motor from microwavehttps://youtu.be/lohjewb6dqc

thingiverse

free

Rotary shelf

...rotary shelf

thingiverse

keep general screws. anything...

thingiverse

free

Knob for rotary encoder / potmeter

...ry encoder / potmeter

thingiverse

knob for a rotary encoder/potmeter. fits the standard size potentiometer/rotary encoder (6mm).

thingiverse

free

Rotary Knobs by scarou

...rotary knobs by scarou

thingiverse

rotary knobs for 6 mm shaft with flat or without.

cursor - 10 bumps.

Sanding

thingiverse

free

sand by beyouem

...sand by beyouem

thingiverse

sand

thingiverse

free

Cup of sand

...cup of sand

thingiverse

that at cup of sand

thingiverse

free

Sanding Block

...sanding block

thingiverse

simple sanding block

thingiverse

free

Sand pile for Faller #120146 sand house by dasbert33

... dasbert33

thingiverse

sand pile for faller sand house, as no sand pile was supplied with the model (only a bag of actual sand).

thingiverse

free

Sand Cluster

...sand cluster

thingiverse

my spin on the sand cluster object from the heavy object anime.

thingiverse

free

Sand Dune Sand Box Mold by plaroach

...iverse

here's a sand box mold that lets you make your own sand dunes.

it fits together to make a tessellated set of dunes.

thingiverse

free

Sanding block

...sanding block

thingiverse

another sanding block. you will need 2x m3 screws and 2x m3 nuts

thingiverse

free

sanding block by glukofinder

...sanding block by glukofinder

thingiverse

sanding block

thingiverse

free

Sanding Block by legion80g

...sanding block by legion80g

thingiverse

sanding block

thingiverse

free

Sanding block by slpaddler

... by slpaddler

thingiverse

this is a radiused sanding block used to sand fingerboards on violin family instruments after planing.

Smaller

thingiverse

free

Smaller Mustang by JoelNail

...smaller mustang by joelnail

thingiverse

smaller mustang car file

thingiverse

free

Caddyrack smaller by rielygamer

...caddyrack smaller by rielygamer

thingiverse

just cut the thing in half for smaller printers

thingiverse

free

Smaller Bearing by bobj3382

...smaller bearing by bobj3382

thingiverse

this is a work in progress for a slightly smaller giant spinner.

thingiverse

free

smaller xmas tree by lokilaufeysen

...smaller xmas tree by lokilaufeysen

thingiverse

smaller tree

thingiverse

free

Capri Pipe Stem (Smaller)

...capri pipe stem (smaller)

thingiverse

another pipe stem, a smaller pipe

thingiverse

free

Heart Spinner (smaller) by DallasA56

...heart spinner (smaller) by dallasa56

thingiverse

spinner, but 1/2 inch smaller

thingiverse

free

Devin Emblem (smaller)

...devin emblem (smaller)

thingiverse

car badge

thingiverse

free

smaller panda footstopper

...smaller panda footstopper

thingiverse

longboard footstopper

thingiverse

free

Spinner Smaller 8 by k3usr

...se

for smaller hands. 608 bearing and 8 1/2in steel ball bearings. smaller but a fair amount of weight so it spins pretty good

thingiverse

free

smaller mug by lokilaufeysen

...smaller mug by lokilaufeysen

thingiverse

make out of ceramics

Tool

thingiverse

free

Tool holder tool box

...tool holder tool box

thingiverse

!

thingiverse

free

Teng Tools tool set hinge

...teng tools tool set hinge

thingiverse

hinge for teng tools tool set.

thingiverse

free

Tool holder for 8mm lathe tools

... holder for 8mm lathe tools

thingiverse

tool holder for 8mm lathe tools.

there is 11 slots because i have 11 tools in my pack :)

thingiverse

free

Tool Holder for Small Tools by Darak_Chen

...tool holder for small tools by darak_chen

thingiverse

a little tool holder witch fits on you desk for small tools!

thingiverse

free

Tool Holder For various Tools by Nhcraig01

...tools by nhcraig01

thingiverse

this is just a simple tool holder for various tools i found useful for tinkering on a 3d printer.

thingiverse

free

Tool Box Tool Holder by FPVITALL

...tool box tool holder by fpvitall

thingiverse

a simple and spacesafing tool stand or desktop organizer

thingiverse

free

tools by kallik

...tools by kallik

thingiverse

tools

thingiverse

free

TOOLS by kallik

...tools by kallik

thingiverse

tools

thingiverse

free

TOOLS by kallik

...tools by kallik

thingiverse

tools

thingiverse

free

Tool by nagato

...tool by nagato

thingiverse

tool

Attachment

thingiverse

free

Attachment by serteserselim

...attachment by serteserselim

thingiverse

elastic attachment 30x15 mm and 40x15 mm

thingiverse

free

Drill Attachment by alm865

...drill attachment by alm865

thingiverse

drill attachment for attaching things such as a scourer or sponge to a drlll

thingiverse

free

Bed Attachment

...achment

thingiverse

i making this to attach a 310 x 310 heated bed to 2020 aluminum extrusion. using the oversized screw wheels.

thingiverse

free

Pipe attachment by swehugin

...pipe attachment by swehugin

thingiverse

pipe attachment.

thingiverse

free

Dozerbot attachment - Torrey

...dozerbot attachment - torrey

thingiverse

dozerbot attachment

thingiverse

free

Attache Casquette by bainge

...attache casquette by bainge

thingiverse

attache casquette

thingiverse

free

VACUuM ATtACHMENT by theecokid

...vacuum attachment by theecokid

thingiverse

vacuum attachment

thingiverse

free

Wheel Attachment by JessicaFoster6998

...wheel attachment by jessicafoster6998

thingiverse

wheel attachment

thingiverse

free

Vacuum Attachment by JamCav

...vacuum attachment by jamcav

thingiverse

vacuum attachment

thingiverse

free

Attachment to bike by bIGCARL33

...attachment to bike by bigcarl33

thingiverse

you attach to bike

Versions

thingiverse

free

Shocker Hand Final Version.. New Full version !! ...KEYCHAIN Version Final by marc_1988

...!! ...keychain version final by marc_1988 thingiverse now 2 versions !! .... new full.... keychain version of shocker hand...

thingiverse

free

beafy version by Bemothelaiemo

...beafy version by bemothelaiemo

thingiverse

beafy version for fanless psu

thingiverse

free

Pumpkin Version 2

...pumpkin version 2

thingiverse

version 2 of my pumpkin.

thingiverse

free

Poro (Ekko version)

...poro (ekko version)

thingiverse

warlock3dmodels poro, but as an ekko version.

thingiverse

free

Better version by AlexMaker816

...better version by alexmaker816

thingiverse

better version of heart box

thingiverse

free

lite version by Mitche11S

...lite version by mitche11s

thingiverse

i built this model by analogy with the simplified version.

thingiverse

free

5015Blowerduct Inverted version

...5015blowerduct inverted version

thingiverse

inverted version of 5015blowerduct.

the spacer is used to prevent deflection.

thingiverse

free

Repaired version by Snake83

...repaired version by snake83

thingiverse

repaired version of the a https://www.thingiverse.com/thing:841122/#comments

thingiverse

free

thicker version by Finch666

...thicker version by finch666

thingiverse

thicker version, my original got warped under tension.

thingiverse

free

2016 version by totof60

...2016 version by totof60

thingiverse

just add the 2016 version

from http://www.thingiverse.com/thing:193755