GrabCAD

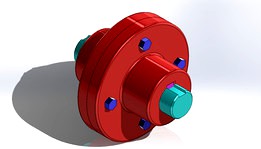

Flange Coupling Type 1

by GrabCAD

Last crawled date: 5 months ago

A flange coupling is a type of coupling device used to connect two shafts at their ends for the purpose of transmitting power. It is a common method of joining pipes, valves, pumps, and other equipment in various industries. The primary function of a flange coupling is to provide a secure and rigid connection between the shafts while allowing for some degree of misalignment.

Here are some key features and aspects of flange couplings:

1. Design:

i. Flange couplings typically consist of two flanges, each attached to the end of the shaft to be connected.

ii. The flanges are then bolted together, creating a strong and stable connection.

2. Types of Flange Couplings:

i. There are different types of flange couplings, such as rigid flange couplings, flexible flange couplings, and grid couplings.

ii. Rigid flange couplings provide a fixed connection between the shafts, while flexible flange couplings incorporate elements like rubber or elastomeric material to allow for some misalignment and flexibility.

3. Bolting:

i. The flanges are typically joined together using bolts, creating a robust and durable connection.

ii. The number and size of bolts depend on the size and load requirements of the coupling.

4. Alignment:

i. Flange couplings can accommodate angular, parallel, and axial misalignment between the connected shafts.

ii. This feature is crucial for compensating for any slight misalignments that may occur during operation.

5. Materials:

i. Flange couplings are commonly made of materials such as steel, stainless steel, or cast iron, depending on the application and environmental conditions.

6. Applications:

i. Flange couplings are widely used in industries like manufacturing, power generation, petrochemicals, and more.

ii. They are employed in various types of machinery, including pumps, compressors, generators, and other rotating equipment.

7. Maintenance:

i. Regular inspection and maintenance are important to ensure the proper functioning of flange couplings.

ii. Bolts should be checked for tightness, and any signs of wear or damage should be addressed promptly.

8. Advantages:

i. Flange couplings provide a strong and rigid connection.

ii. They are relatively easy to install and dismantle.

iii. They can accommodate different types of misalignments.

9. Disadvantages:

i. Rigid flange couplings do not allow for as much misalignment as flexible couplings.

ii. Regular maintenance is essential to prevent issues like bolt loosening or wear.

Here are some key features and aspects of flange couplings:

1. Design:

i. Flange couplings typically consist of two flanges, each attached to the end of the shaft to be connected.

ii. The flanges are then bolted together, creating a strong and stable connection.

2. Types of Flange Couplings:

i. There are different types of flange couplings, such as rigid flange couplings, flexible flange couplings, and grid couplings.

ii. Rigid flange couplings provide a fixed connection between the shafts, while flexible flange couplings incorporate elements like rubber or elastomeric material to allow for some misalignment and flexibility.

3. Bolting:

i. The flanges are typically joined together using bolts, creating a robust and durable connection.

ii. The number and size of bolts depend on the size and load requirements of the coupling.

4. Alignment:

i. Flange couplings can accommodate angular, parallel, and axial misalignment between the connected shafts.

ii. This feature is crucial for compensating for any slight misalignments that may occur during operation.

5. Materials:

i. Flange couplings are commonly made of materials such as steel, stainless steel, or cast iron, depending on the application and environmental conditions.

6. Applications:

i. Flange couplings are widely used in industries like manufacturing, power generation, petrochemicals, and more.

ii. They are employed in various types of machinery, including pumps, compressors, generators, and other rotating equipment.

7. Maintenance:

i. Regular inspection and maintenance are important to ensure the proper functioning of flange couplings.

ii. Bolts should be checked for tightness, and any signs of wear or damage should be addressed promptly.

8. Advantages:

i. Flange couplings provide a strong and rigid connection.

ii. They are relatively easy to install and dismantle.

iii. They can accommodate different types of misalignments.

9. Disadvantages:

i. Rigid flange couplings do not allow for as much misalignment as flexible couplings.

ii. Regular maintenance is essential to prevent issues like bolt loosening or wear.

Similar models

grabcad

free

Flexible coupling

...angular movement between the axes of two waveguides.

a coupling used to connect two shafts and to accommodate their misalignment.

grabcad

free

Flange Coupling

...r of power and torque between shafts in machinery and industrial applications, offering a sturdy and easily assembled connection.

grabcad

free

Parallelogram Coupling Design

...le the couplings accommodate a small amount of angular and axial misalignment, useful in applications with parallel misalignment.

grabcad

free

Flexible Coupling

...lexible coupling

grabcad

this coupling allows some amount of misalignment while transmitting motion and power between two shafts

grabcad

free

Oldham Coupling with Ring

...misalignment, they are especially useful in applications with parallel misalignment. this design uses ring as the axis alignment.

grabcad

free

JAW COUPLING

...ps, and gearboxes. they typically accommodate angular shaft misalignment up to 1 degree and parallel misalignment up to 0.015 in.

grabcad

free

Oldham Coupling with Cross

...t, they are especially useful in applications with parallel misalignment. this design uses cross component as the axis alignment.

grabcad

free

FLEXIBLE COUPLING M 28 GEARED TYPE

...es, sometimes of considerable magnitude, which arise from unavoidable misalignment usually associated with rigid shaft couplings.

grabcad

free

Flange Coupling

...as pumps, compressors, and generators, and are designed to transmit power while accommodating shaft misalignment and shock loads.

grabcad

free

Oldham Coupling

...aft couplings are used to counter parallel misalignment that occurs between connected shafts and, in some cases, to absorb shock.

Flange

turbosquid

$15

flange

...urbosquid

royalty free 3d model flange for download as sldas on turbosquid: 3d models for games, architecture, videos. (1341096)

3d_export

$5

Flanged mace

...flanged mace

3dexport

flanged mace after battle

turbosquid

$10

Flange

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Flange

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Flange

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Flange

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Turlet flange

...quid

royalty free 3d model turlet flange for download as stl on turbosquid: 3d models for games, architecture, videos. (1371282)

turbosquid

$40

Flanged Mace

... free 3d model flanged mace for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301562)

turbosquid

$1

Flanged Mace

...d model flanged mace for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1264668)

turbosquid

$17

Flat flange

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Coupling

3d_export

$5

coupling

...coupling

3dexport

coupling.

3d_export

$5

coupling

...coupling

3dexport

coupling.

3d_export

$5

elastic coupling

...elastic coupling

3dexport

elastic coupling.

3d_export

$5

periflex coupling

...periflex coupling

3dexport

periflex coupling.

3ddd

$1

COUPLE STATUE

...couple statue

3ddd

статуэтка

couple statue

turbosquid

$2

coupling

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$9

seahorse couple

...seahorse couple

3dexport

semi low poly seahorse couple

3d_export

$5

half-coupling

...g is a part of the gearbox. it is used to connect gearboxes to shafts. also, the half-coupling connects the motors to the shafts.

3d_export

$5

Coupling 3D Model

...coupling 3d model

3dexport

coupling torque

coupling 3d model fau 71173 3dexport

turbosquid

$44

Pigs Couple

...urbosquid

royalty free 3d model pigs couple for download as on turbosquid: 3d models for games, architecture, videos. (1584901)

Type

3d_export

$5

s type

...s type

3dexport

s type formats max 3ds obj stl

3d_export

$5

l-type conveyor

...l-type conveyor

3dexport

l-type conveyor

3d_export

$5

volkswagen type 2

...volkswagen type 2

3dexport

volkswagen type 2

turbosquid

$150

RBC types

...osquid

royalty free 3d model rbc types for download as blend on turbosquid: 3d models for games, architecture, videos. (1343563)

turbosquid

$1

B-Type

...urbosquid

royalty free 3d model b-type for download as blend on turbosquid: 3d models for games, architecture, videos. (1609608)

3ddd

$1

shoes type A

...shoes type a

3ddd

туфли

shoes

turbosquid

$39

R-type

...oyalty free 3d model r-type for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1303675)

turbosquid

$5

melon type

...ee 3d model melon galia type for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1557188)

3d_export

free

three different type

...three different type

3dexport

three different type: mace, axe, sword

turbosquid

$49

Types of Placentation

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)