Thingiverse

Filament Enclosure Tap (1.75mm) by dottom22

by Thingiverse

Last crawled date: 3 years ago

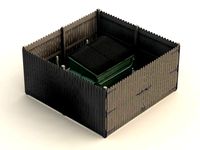

This part was inspired by the many filament cleaners that use a hollow chamber filled with some pliable porous material. However the intent of this was to allow the spool and spool holder remain in a moisture resistant container while in use by the printer. This is my second rendition so far and am still working out some of the kinks.

Instructions:

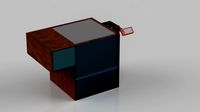

Your container that holds the spool and spool holder must have a 22mm whole drilled out to fit the threaded portion through. Then an equal sized O-Ring or gasket between the NUT and inner side of the case. Tighten the Nut until the Tap is firmly in place.

The inside of the Tap will allow any soft sponge or foam material and the filament to punch through, creating a semi moisture resistant seal as well as cleaning the filament. This model allows for 1.75mm filament.

For all other Non-Bowden Taps:

Your tap (when mounted to a case) must be in a relatively parallel position to the extruders path or it will snag and cause some drag on the extruder motor.

For Bowden Tap:

The bowden version, which uses PTFE tubing from Tap to extuder can follow relatively radical paths (within reason) as the tube and pneumatic fittings help to guide the filament.

New Bowden Style Fitting (4mm, M6)

Please use the following pneumatic fittings for the new Taphttps://www.amazon.com/TOOTO-Straight-Pneumatic-Connect-Extruder/dp/B019RQ5EYE/ref=pd_sim_328_32?_encoding=UTF8&pd_rd_i=B019RQ5EYE&pd_rd_r=8A6CF1XWP8R05W7GZTW3&pd_rd_w=NASUx&pd_rd_wg=uru9m&psc=1&refRID=8A6CF1XWP8R05W7GZTW3

The port on the front of the tap is designed so the threads of the fitting "bite" into the plastic. Thus far it hasn't given me issues when attaching one.

Construction Tips:

I used a thin sheet of craft foam to make my own gasket.

Be careful when cutting the hole out of the box as it cracks easily. I used an exacto knife.

Trouble notes:

When the filament pulled through the tap, it may feel snug. That's because the tolerance's are .25mm. However I have never had a snagging issue or problems with the extruder not getting enough filament.

If however the filament is TOO snug and hard to pull through due to the whole not printing perfectly round I recommend using a small Needle File (The rat tail style, looks like the pointy end of a chopstick) and gently spinning it in the opening. Then test a piece of filament. Don't do it too much or you'll loose the Tap's ability to keep a seal from the outside moisture.

Update Log:

3/12/17 - I have added two new NUT files. One that is 98% and one that is 96% the size of the tap. If your printer is NOT precise and has issues with accurate prints, use the 98%. If your printer is precise and is able to print tight tolerances, print the 96% nut for a snug fitting part.

3/3/17 - I have added a new version that accepts the 5mm PTFE fitting for "Bowden" style systems.

Fitting can be found here:https://www.amazon.com/TOOTO-Straight-Pneumatic-Connect-Extruder/dp/B019RQ5EYE/ref=pd_sim_328_32?_encoding=UTF8&pd_rd_i=B019RQ5EYE&pd_rd_r=8A6CF1XWP8R05W7GZTW3&pd_rd_w=NASUx&pd_rd_wg=uru9m&psc=1&refRID=8A6CF1XWP8R05W7GZTW3

The port on the front is friction or tension based so it is dependent upon the threads cutting into the plastic to hold tight. It works so far but let me know if you all have issues.

Instructions:

Your container that holds the spool and spool holder must have a 22mm whole drilled out to fit the threaded portion through. Then an equal sized O-Ring or gasket between the NUT and inner side of the case. Tighten the Nut until the Tap is firmly in place.

The inside of the Tap will allow any soft sponge or foam material and the filament to punch through, creating a semi moisture resistant seal as well as cleaning the filament. This model allows for 1.75mm filament.

For all other Non-Bowden Taps:

Your tap (when mounted to a case) must be in a relatively parallel position to the extruders path or it will snag and cause some drag on the extruder motor.

For Bowden Tap:

The bowden version, which uses PTFE tubing from Tap to extuder can follow relatively radical paths (within reason) as the tube and pneumatic fittings help to guide the filament.

New Bowden Style Fitting (4mm, M6)

Please use the following pneumatic fittings for the new Taphttps://www.amazon.com/TOOTO-Straight-Pneumatic-Connect-Extruder/dp/B019RQ5EYE/ref=pd_sim_328_32?_encoding=UTF8&pd_rd_i=B019RQ5EYE&pd_rd_r=8A6CF1XWP8R05W7GZTW3&pd_rd_w=NASUx&pd_rd_wg=uru9m&psc=1&refRID=8A6CF1XWP8R05W7GZTW3

The port on the front of the tap is designed so the threads of the fitting "bite" into the plastic. Thus far it hasn't given me issues when attaching one.

Construction Tips:

I used a thin sheet of craft foam to make my own gasket.

Be careful when cutting the hole out of the box as it cracks easily. I used an exacto knife.

Trouble notes:

When the filament pulled through the tap, it may feel snug. That's because the tolerance's are .25mm. However I have never had a snagging issue or problems with the extruder not getting enough filament.

If however the filament is TOO snug and hard to pull through due to the whole not printing perfectly round I recommend using a small Needle File (The rat tail style, looks like the pointy end of a chopstick) and gently spinning it in the opening. Then test a piece of filament. Don't do it too much or you'll loose the Tap's ability to keep a seal from the outside moisture.

Update Log:

3/12/17 - I have added two new NUT files. One that is 98% and one that is 96% the size of the tap. If your printer is NOT precise and has issues with accurate prints, use the 98%. If your printer is precise and is able to print tight tolerances, print the 96% nut for a snug fitting part.

3/3/17 - I have added a new version that accepts the 5mm PTFE fitting for "Bowden" style systems.

Fitting can be found here:https://www.amazon.com/TOOTO-Straight-Pneumatic-Connect-Extruder/dp/B019RQ5EYE/ref=pd_sim_328_32?_encoding=UTF8&pd_rd_i=B019RQ5EYE&pd_rd_r=8A6CF1XWP8R05W7GZTW3&pd_rd_w=NASUx&pd_rd_wg=uru9m&psc=1&refRID=8A6CF1XWP8R05W7GZTW3

The port on the front is friction or tension based so it is dependent upon the threads cutting into the plastic to hold tight. It works so far but let me know if you all have issues.

Similar models

thingiverse

free

Toothbrush Holder by Jonathan_K1906

...d_rd_i=b000hhi6ma&pd_rd_r=1f1sg7rjj4c2dq6v42e1&pd_rd_w=efebp&pd_rd_wg=dm20z&psc=1&refrid=1f1sg7rjj4c2dq6v42e1

thingiverse

free

Center finder by casadefadi

...d_rd_i=b00861dh1o&pd_rd_r=cbpkvwcqwv39gdwd3kag&pd_rd_w=nzbn4&pd_rd_wg=pf1ro&psc=1&refrid=cbpkvwcqwv39gdwd3kag

thingiverse

free

Keyboard and Mouse Wall Holder by doke01

...d_rd_i=b0746fmns1&pd_rd_r=8knm732wzhhpb5c5psp4&pd_rd_w=cqis5&pd_rd_wg=q2y2n&psc=1&refrid=8knm732wzhhpb5c5psp4

thingiverse

free

Anycubic i3 Mega Filament Dispenser by Bursaton88

...46851949&pf_rd_r=856n0rkde7mw36hndttb&pf_rd_s=desktop-dp-sims&pf_rd_t=40701&psc=1&refrid=856n0rkde7mw36hndttb

thingiverse

free

Syma X8 Re-imagined as a Fire Wheel 450! by DIY3DTech

...ruction and use of this model is at your own risk with no warranties made or implied and always fly safe and never over people...

thingiverse

free

Cargo Container (Large) by yuriysklyar

...wg=flyrx&psc=1&refrid=64fkchypjnpt1wphbyx1&linkcode=sl1&tag=i08bdb-20&linkid=7b832ff89da8ecf1ed9c9c3f60793119

thingiverse

free

Qi Charging Dock for Phablet by mrjohns42

...=eelw3&psc=1&refrid=8srb77yrt41fxd7jxrrj

inspired by: https://www.thingiverse.com/thing:1921330

but created from scratch.

thingiverse

free

5 x AA Battery Holder by cameroncox

...d_rd_i=b00o9xve2m&pd_rd_r=r6f9pb8nvm93ttf6vp4n&pd_rd_w=wu17f&pd_rd_wg=c23ra&psc=1&refrid=r6f9pb8nvm93ttf6vp4n

grabcad

free

DJI_F330_QUADROTOR FRAME

...d_rd_i=b0072aey5i&pd_rd_r=jp3nyxrw321e67g9fm3v&pd_rd_w=yz70o&pd_rd_wg=wnegd&psc=1&refrid=jp3nyxrw321e67g9fm3v

thingiverse

free

Monstera Coasters by Stillash

...zkx&linkcode=sl1&tag=chippedbuil0e-20&linkid=ba1524c7771fd5265a160849449037a4&language=en_us&ref_=as_li_ss_tl

Dottom22

thingiverse

free

Cyclone Mini (Spinner) by dottom22

... changes i have made to my cyclone micro. divots to replace the nubs on the arms and a 3-armed version for extra weight and grip.

thingiverse

free

Micro Lamda (Fidget Spinner) by dottom22

...the straight sides make it easier to spin with on finger. the size has also increased slightly to accommodate the straight sides.

thingiverse

free

Pee-Wee Spinner (Fidget Spinner) by dottom22

... standard 608zz skateboard bearings. model bore is 22.3mm and should fit the 8x22x7 bearing dimensions depending on your printer.

thingiverse

free

Tweaked Bowden tap - Remix of Filament Enclosure Tap (1.75mm) by dottom22 by DougJoseph

...o make the sidewall thicker there.

i did the tweak work in sketchup, and i am providing both the .stl file and the sketchup file.

thingiverse

free

Cyclone Micro (Fidget Spinner) by dottom22

... textured bumps and replaced them with concaved divots. i have also added a 3-armed version that adds more weight and extra grip.

thingiverse

free

SD Card Reader Extension Holder (Anet A8, micro SD) by dottom22

...he anet a8. enjoy!

card reader link:https://www.amazon.com/gp/product/b01d9j8kqe/ref=oh_aui_detailpage_o09_s01?ie=utf8&psc=1

thingiverse

free

Graspable Filament Cap by Inquisitor720

...to open the moisture-tight box. these were modified using dottom22#39;s, "filament enclosure tap (1.75mm)". i started with his nut_96_tollerance...

thingiverse

free

Nickle Spinner Fidget by vandium

...i added a thicker version (+1mm) as suggested by dottom22 to better fit 4 nickles in each pocket. the...

thingiverse

free

Filament Enclosure Tap Cap Leash by nameek

...leash by nameek thingiverse this is an adaptation of dottom22#39;s "filament enclosure tap (1.75mm)https://www.thingiverse.com/thing:2139021 i designed this strap to...

75Mm

cg_studio

$79

75mm Pak 97/383d model

...rld ww2 wwii

.obj .jpg .max .fbx .3ds - 75mm pak 97/38 3d model, royalty free license available, instant download after purchase.

3d_export

$79

75mm Pak 97-38 3D Model

... pak tank war weapon world

75mm pak 97-38 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl graverino 108478 3dexport

3d_ocean

$79

75mm Pak 97/38

...el originally created with 3ds max and rendered with vray the model is easy to modify, the main parts can be easily moved as i...

cg_studio

$149

M4A3 Sherman - 75mm - Mid production3d model

... .c4d .lwo .obj - m4a3 sherman - 75mm - mid production 3d model, royalty free license available, instant download after purchase.

cg_studio

$139

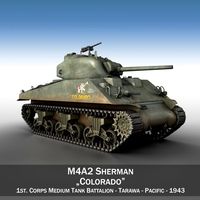

M4A2 Sherman - Colorado3d model

...m4a2 sherman colorado tank us marine corps pacific theatre 75mm m3 l/40 gun .c4d .obj .lwo .fbx .3ds -...

cg_studio

$139

M4A2 Sherman - Destroyer3d model

...m4a2 sherman destroyer tank us marine corps pacific theatre 75mm m3 l/40 gun .c4d .obj .lwo .fbx .3ds -...

cg_studio

$65

Pak 403d model

...pak 403d model cgstudio gun ww2 75mm artillery world war wwii 1943 army 1945 anti tank...

cg_studio

$125

Anti tank guns ww23d model

...anti tank guns ww23d model cgstudio gun ww2 75mm artillery wwii army 1945 antitank projectile weapon shell case...

3ddd

free

Indian vase

...311742 размеры: длинна маленькой вазы - 460mm, ширина - 75mm высота - 130mm длинна большой вазы - 600mm, ширина...

3d_export

$7

facemaskearloopweldingmachine

...the welding of one-time plane mask ear belt with 75mm standard ear band spacing. if you want to weld...

Enclosure

3d_export

free

electrical enclosure

...l enclosure where electrical devices like (relays, contactors, busbars ) are kept in order to protect from hazardous environment.

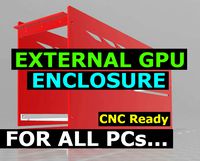

turbosquid

$100

GPU Enclosure

...yalty free 3d model gpu enclosure for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1381061)

3d_export

$5

Electrical Enclosure

...ed. also has tower lights attaced on the top.<br>file format that are available:<br>.step<br>.obj<br>.stl

archive3d

free

Enclosure 3D Model

...closure 3d model

archive3d

shower enclosure-acquarius- 3d model for interior 3d visualization.

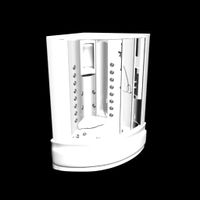

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-omega- 3d model for interior 3d visualization.

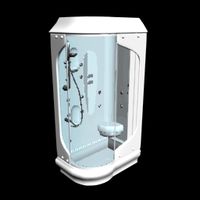

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-vega - 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-zenith - 3d model for interior 3d visualization.

turbosquid

$20

shower enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Dumpster Enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

3d printer enclosure

... model 3d printer enclosure for download as ipt, skp, and fbx on turbosquid: 3d models for games, architecture, videos. (1634310)

Tap

archibase_planet

free

Tap

...tap

archibase planet

tap stop-cock faucet

tap - 3d model for interior 3d visualization.

archibase_planet

free

Tap

...tap

archibase planet

tap stop-cock faucet

tap b1195 - 3d model for interior 3d visualization.

archibase_planet

free

Tap

...tap

archibase planet

tap stop-cock faucet

tap b1109 - 3d model for interior 3d visualization.

archibase_planet

free

Tap

...tap

archibase planet

beer tap bar equipment

beer-tap - 3d model for interior 3d visualization.

archibase_planet

free

Tap

...tap

archibase planet

faucet stop-cock tap

tap - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Tap

...tap

archibase planet

faucet tap stop-cock

tap - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Tap

...tap

archibase planet

stop-cock tap faucet

tap - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Tap

...tap

archibase planet

stop-cock tap faucet

tap - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Tap

...tap

archibase planet

tap stop-cock faucet

tap - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Tap

...tap

archibase planet

tap stop-cock faucet

tap - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)