Thingiverse

Extruder Belt Reduction by robberet

by Thingiverse

Last crawled date: 3 years ago

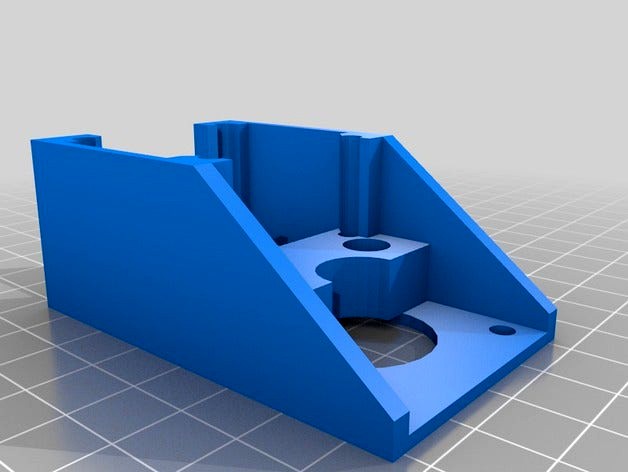

Extruder Belt Reduction

An Extruder with bowden cable has a much greater push resistance than a directly driven extruder.

When a small nozzle is used, the resistance becomes even greater, so that we come to a point where the stepper motor is no longer able to drive the filament wire.

A belt driven reduction can offer the solution.

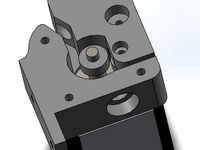

The Belt drive has been recovered from a RC plane 2: 1 reduction.

The big wheel is 36mm and the small wheel is 16mm outside diameter.

After making the reduction housing, it appeared that the belt was being rubbed against the middle mounting bolts.

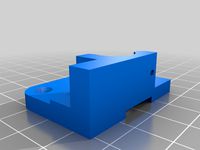

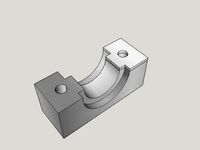

That is why I made a second part, namely the bearing block, this to push the belt a bit away from the bolts.

See assembled drawing, red is bad, green is good

This bearing block can be placed in the reduction house, or you can use the integrated bearing block.

Bill of material:

Big bearing in the reduction house : outside diameter 19mm inside diameter 6 mm height 6mm

Bearing on the extruder : outside diameter 11mm inside diameter 5mm height 5mm , glued with epoxy on printplate to support the axis of the big wheel the other side of the extruder , see picture

Small bearing block :

F693ZZ 3mmx8mmx4mm Double Shielded Flanged Ball Bearings from BG

Shaft diamter 3mm length : 25mm

F693ZZ 3mmx8mmx4mm Double Shielded Flanged Ball Bearings from BG

MK8 All Metal Remote Extruder For 1.75mm Filament from BG

NEMA 17 26N.cm 0.4A Stepper Motor 42mm Two Phase Hybrid Stepper Motor from BG

An Extruder with bowden cable has a much greater push resistance than a directly driven extruder.

When a small nozzle is used, the resistance becomes even greater, so that we come to a point where the stepper motor is no longer able to drive the filament wire.

A belt driven reduction can offer the solution.

The Belt drive has been recovered from a RC plane 2: 1 reduction.

The big wheel is 36mm and the small wheel is 16mm outside diameter.

After making the reduction housing, it appeared that the belt was being rubbed against the middle mounting bolts.

That is why I made a second part, namely the bearing block, this to push the belt a bit away from the bolts.

See assembled drawing, red is bad, green is good

This bearing block can be placed in the reduction house, or you can use the integrated bearing block.

Bill of material:

Big bearing in the reduction house : outside diameter 19mm inside diameter 6 mm height 6mm

Bearing on the extruder : outside diameter 11mm inside diameter 5mm height 5mm , glued with epoxy on printplate to support the axis of the big wheel the other side of the extruder , see picture

Small bearing block :

F693ZZ 3mmx8mmx4mm Double Shielded Flanged Ball Bearings from BG

Shaft diamter 3mm length : 25mm

F693ZZ 3mmx8mmx4mm Double Shielded Flanged Ball Bearings from BG

MK8 All Metal Remote Extruder For 1.75mm Filament from BG

NEMA 17 26N.cm 0.4A Stepper Motor 42mm Two Phase Hybrid Stepper Motor from BG

Similar models

thingiverse

free

Direct drive extruder for 1.75 mm material by tom4cad

... mm material by tom4cad

thingiverse

drive sleeve mk7 (12mm outside diameter) bearing size 626zz, stepper motor nema 17 1-1.2nm.

thingiverse

free

Makerbot MK8 1.75mm Filament all-Metal Bowden Extruder Wire feeder Ultimate Upgrade by Vanadusan

...ations search on www.instructables.com for: mk8 metal bowden extruder wire feeder ultimate upgrade)

i am sorry for my english ;)

thingiverse

free

Stepper motor feed knob by cfeniak

... designed for use with direct drive filament setups for manually feeding filament. push fit. smaller sized knob is big enough.

thingiverse

free

inverted bulldog extruder with mk8 drive gear with filament guide by justsomeone

...lock to use m3x16 screws.(in my setup 3mm thickness steel plate is between with main block and the stepper)

i hope u may like it.

thingiverse

free

Dual stepper MK8 gear direct drive bowden extruder

...

2x m3 washer for holding the bearings in place

2x pneumatic push-in fittings with m5 threads for the bowden tube diameter in use

thingiverse

free

Double Pinch Extruder idea by michthom

...n idea to take nophead's stepper-driven worm gear extruder and extend it to drive pinch wheels on both sides of the filament.

thingiverse

free

Bearing Block 12mm outside diameter, 5mm width by makeme12

...bearing block 12mm outside diameter, 5mm width by makeme12

thingiverse

bearing block for mini bearings

thingiverse

free

16_to_80 belt extruder by papa5468

...uder is a 5mm x 30mm screw and three nuts with blue thread lock . the belt is a 2gt-6 closed loop rubber length 200mm, width 6mm.

thingiverse

free

GT2 5mm 60T wide Large pulley for belt driven extruder. by ShaneGT

...ingiverse

for use with wade extruder to convert it to belt driven. use normal gt2 pulley on motor. calibrate accordingly after

thingiverse

free

Ender 3 - Direct Drive (bmg / clone, dual drive)

...o the reduction drive from the extruder.

looking for a simple cable holder/guide? -> https://www.thingiverse.com/thing:4140801

Robberet

thingiverse

free

KK2 QUAD copter by robberet

...kk2 quad copter by robberet

thingiverse

see information in kk2 quadcopter 01.pdf under thing files

thingiverse

free

drying rack hinge by robberet

...inges of our drying rack.

for a complete rack you have to print four of this hinge.

the rounded version needs supports to print !

thingiverse

free

Bowden tube fixing by robberet

...00

tip : twist one wire of a flexible electrical wire around the bowden tube, for mounting, to obtain a greater grip on the tube.

thingiverse

free

Power bank 2P 18650 2250 + 2250 = 4500mA by robberet

...ing part is used between the usb and the battery together with a small piece of foam while assembling., to keep the usb in place

thingiverse

free

Open Cable Chain Extra & Changed PARTS by robberet

...;high" in the file name are made a little bit higher so that the chain has a greater stiffness in the non-rolling direction.

thingiverse

free

RADIAL FAN ADAPTER ( POWER SUPPLY ) & FAN BAFFLE by robberet

... a litle bit more and protects my fingers.

ps: the photo is still a previous version, the fan baffle is now closed on both sides.

thingiverse

free

Quad 200mm RETLAW by robberet

...ight control board v1.17s1pro 6050mpu 644pa for rc

airplane fpv racing drone "banggood"

battery : 2200ma 3s 1p 30c

thingiverse

free

Attach 5 parts , extruder, guage, bowden, cable chain , BLTouch with one part by robberet

...

added 31/03/2019

bltouch base.stl ( replaces extruder pressure block.stl and extruder carriage_cap.stl)

bltouch base slider.stl

Reduction

thingiverse

free

reduction bobine PLA - coil reduction PLA by plumachau

...reduction bobine pla - coil reduction pla by plumachau

thingiverse

reduction bobine pla - coil reduction pla

thingiverse

free

Bose Reduction by BeStRiPeR

...bose reduction by bestriper

thingiverse

is the reduction of the standard support bose speakers.

thingiverse

free

Tube Reduction by NicoNeo

...tube reduction by niconeo

thingiverse

test model tube reduction 100mm to 99,5mm

thingiverse

free

Hp pen reduction

...hp pen reduction

thingiverse

pen reduction for hp plotters. especially for special pcb pens.

thingiverse

free

Reduction of vibration dampers by urusa

...reduction of vibration dampers by urusa

thingiverse

reduction of vibration dampers

thingiverse

free

ETA Robot reduction by geniv

...eta robot reduction by geniv

thingiverse

reduction for eta robor

thingiverse

free

Reduction for IBC barrel

...reduction for ibc barrel

thingiverse

reduction from 110 mm tube to 70 mm tube into ibc tank (inlet and overflow).

thingiverse

free

Gas mask reduction

... sure that it is gas tight. (it close gaps between layers).

use at your own risk! it is not designed for use against real danger.

thingiverse

free

Tube reduction 12x34 by Penax

...tube reduction 12x34 by penax

thingiverse

tube reduction 12x34 to the waste pipe.

thingiverse

free

Reduction for a clima by Majkeen

...atisation

inner diameter is 150mm

outer rectangle is 150x185mm

inner output rectangle is 130x165mm

used black pet-g 1,75 filament

Belt

thingiverse

free

belt

...belt

thingiverse

belt sleeve for 35mm wide..

use tpu or tpu95

gcode ready

thingiverse

free

Belt hanger for mission belt by maburke

...belt hanger for mission belt by maburke

thingiverse

hanger for mission belt- hangs belt nicely on the closet rod

thingiverse

free

Belt Hanger (For Belts With a Stud) by SamuelSVD

...belt hanger.

this belt hanger works by placing the stud on the belt in the hole, then hang the hanger.

yep, it's that simple.

thingiverse

free

Belt hanger for Trakline belt by tomasf

...belt hanger for trakline belt by tomasf

thingiverse

a hanger for a single trakline belt.

thingiverse

free

Belt clip for 9 mm belt by papat400

...belt clip for 9 mm belt by papat400

thingiverse

remix the belt lock gt2 for a 9mm belt

thingiverse

free

Belt Rack

...belt rack

thingiverse

belt hanger

thingiverse

free

Belt Holder

...belt holder

thingiverse

a simple belt holder.

thingiverse

free

Hermes belt buckle for 31mm belt by Hubiro

...hermes belt buckle for 31mm belt by hubiro

thingiverse

hermes belt buckle for 31mm belt

perfect to order as metal print :-)

thingiverse

free

Bugatti belt buckle for 31mm belt by Hubiro

...t buckle for 31mm belt by hubiro

thingiverse

bugati belt buckle made for 31mm hermes belt.

perfect to order as a metal print :-)

thingiverse

free

Belt tensioner for GT2 belts by Endlesscnc

...oner little different.

after print you will need a:

m3 nut

m3 x10+ (screw length your choice)

is for the gt2 belt with 6mm width

Extruder

thingiverse

free

Extruder

...extruder

thingiverse

extruder for 3dprinter

thingiverse

free

Linear extrude, rotation extrude by jtirado

...linear extrude, rotation extrude by jtirado

thingiverse

linear extrude, rotation extrude

thingiverse

free

extruder by brunoschoofs

...extruder by brunoschoofs

thingiverse

extruder

thingiverse

free

Extruder Catcher/Extruder Holder by Verdandi

...extruder catcher/extruder holder by verdandi

thingiverse

for holding extruder.

thx for clicking

designed on sketch up

thingiverse

free

extruder by nekro

...extruder by nekro

thingiverse

cooler extruder

thingiverse

free

Extruder by DViktor

...extruder by dviktor

thingiverse

extruder with three fans (1 unmanaged extruder and 2 managed to product) fans 20x20x10

thingiverse

free

Extruder Knob

...extruder knob

thingiverse

yet another extruder knob.

thingiverse

free

Extruder by ImHuman

...extruder by imhuman

thingiverse

my first extruder. my design.

thingiverse

free

BMG extruder

...bmg extruder

thingiverse

bmg extruder model : step, wrl, stl

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.