GrabCAD

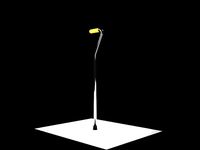

Explosion Proof LED Light - Magnetic Mount - Aluminum Base - C1D1 150 Watt LED Light

by GrabCAD

Last crawled date: 1 year, 11 months ago

http://www.larsonelectronics.com/p-70926-explosion-proof-led-light-magnetic-mount-aluminum-base-c1d1-150-watt-led-light.aspx

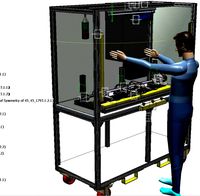

The EPL-MB-150LED-100 Magnetic Mount Explosion Proof LED Light from Larson Electronics is rated Class 1 Division 1-2 Groups C & D and Class 2 Division 1-2 and uses a low profile LED light head to produce 13,000 lumens of light while drawing only 150 watts.

The EPL-MB-150LED-100 magnetic mount explosion proof LED light provides 9,500 square feet of work area coverage with 13,000 lumens of light output. This portable LED light is mounted to a portable aluminum frame base with legs and has a low profile LED light head measuring 16 inches by 14 inches. This unit includes a magnetic mounting attachment that allows mounting the fixture to metallic surfaces for added versatility and easy setup. The LED light head on this unit produces a brilliant flood pattern of light that is ideal for illuminating enclosed areas and hazardous locations where flammable vapors, gases and dusts may be present.

This explosion proof LED light fixture is comprised of a 16x14 inch LED light head mounted atop a legged base stand fabricated from non sparking aluminum, with a separate shelf type magnetic mounting bracket that allows mounting to ferrous metallic surfaces. The lamp can be easily adjusted up or down 90 degrees and locked into position by simply loosening the two T-handle adjustment screws located on either side of the light head and retightening them once the desired angle is found.

The magnetic mounting bracket for this unit includes six 200 lbs. grip magnetic bases which provide a total of 1,200 lbs. of grip and allows operators to mount the unit to walls and flat metallic surfaces. Users simply attach the magnetic mounting bracket to the desired surface, then hang the lamp assembly from the bracket. This bracket is constructed of non-sparking aluminum for light weight and durability, and the simple hanging design allows operators to easily remove the lamp assembly to operate the unit as a pedestal lamp if desired.

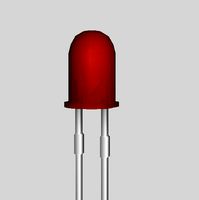

Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current applied and emitting light. With LED lights, there is no warm up time or cool down time before re-striking and provide instant illumination when powered on, adding to the reliability of LED technology. By nature, LED light sources run significantly cooler than traditional lamps, reducing the chance of accidental burns and increased temperatures due to heat emissions. This solid state design of light emitting diodes provides a more reliable, stable, durable, and energy efficient light source over traditional lighting.

Safety within the workplace is another benefit of LED work lights and temporary lighting. All light sources produce heat. With traditional work lamps, such as metal halide and high pressure sodium light sources, the lamp reaches high surface temperatures. These surface temperatures introduce a burn risk to anyone to anyone that allows prolonged skin contact with the light source, as well as a fire hazard if a flammable material is accidentally set too close to the light source for an extended period of time. While LED fixtures do still produce heat, they are designed with heat sinks to properly disperse the heat. The LED light assembly is engineered to disperse and expel this heat quickly and efficiently, keeping the lamp cooler than traditional light sources. This LED work light operates at a lower surface temperature than a comparable model with traditional light source, and thus does not present a significant burn risk if an operator or bystander accidentally brushed up against an exposed lamp, and reduce the fire hazard should they fixture accidentally come in contact with a flammable material for a short period of time. This significantly increases the safety within the work environment.

The EPL-MB-150LED-100 Magnetic Mount Explosion Proof LED Light from Larson Electronics is rated Class 1 Division 1-2 Groups C & D and Class 2 Division 1-2 and uses a low profile LED light head to produce 13,000 lumens of light while drawing only 150 watts.

The EPL-MB-150LED-100 magnetic mount explosion proof LED light provides 9,500 square feet of work area coverage with 13,000 lumens of light output. This portable LED light is mounted to a portable aluminum frame base with legs and has a low profile LED light head measuring 16 inches by 14 inches. This unit includes a magnetic mounting attachment that allows mounting the fixture to metallic surfaces for added versatility and easy setup. The LED light head on this unit produces a brilliant flood pattern of light that is ideal for illuminating enclosed areas and hazardous locations where flammable vapors, gases and dusts may be present.

This explosion proof LED light fixture is comprised of a 16x14 inch LED light head mounted atop a legged base stand fabricated from non sparking aluminum, with a separate shelf type magnetic mounting bracket that allows mounting to ferrous metallic surfaces. The lamp can be easily adjusted up or down 90 degrees and locked into position by simply loosening the two T-handle adjustment screws located on either side of the light head and retightening them once the desired angle is found.

The magnetic mounting bracket for this unit includes six 200 lbs. grip magnetic bases which provide a total of 1,200 lbs. of grip and allows operators to mount the unit to walls and flat metallic surfaces. Users simply attach the magnetic mounting bracket to the desired surface, then hang the lamp assembly from the bracket. This bracket is constructed of non-sparking aluminum for light weight and durability, and the simple hanging design allows operators to easily remove the lamp assembly to operate the unit as a pedestal lamp if desired.

Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current applied and emitting light. With LED lights, there is no warm up time or cool down time before re-striking and provide instant illumination when powered on, adding to the reliability of LED technology. By nature, LED light sources run significantly cooler than traditional lamps, reducing the chance of accidental burns and increased temperatures due to heat emissions. This solid state design of light emitting diodes provides a more reliable, stable, durable, and energy efficient light source over traditional lighting.

Safety within the workplace is another benefit of LED work lights and temporary lighting. All light sources produce heat. With traditional work lamps, such as metal halide and high pressure sodium light sources, the lamp reaches high surface temperatures. These surface temperatures introduce a burn risk to anyone to anyone that allows prolonged skin contact with the light source, as well as a fire hazard if a flammable material is accidentally set too close to the light source for an extended period of time. While LED fixtures do still produce heat, they are designed with heat sinks to properly disperse the heat. The LED light assembly is engineered to disperse and expel this heat quickly and efficiently, keeping the lamp cooler than traditional light sources. This LED work light operates at a lower surface temperature than a comparable model with traditional light source, and thus does not present a significant burn risk if an operator or bystander accidentally brushed up against an exposed lamp, and reduce the fire hazard should they fixture accidentally come in contact with a flammable material for a short period of time. This significantly increases the safety within the work environment.

Similar models

grabcad

free

Explosion Proof Ultraviolet LED Light - Base Stand Mount - 100 Watt LED - Class I Div 1 C&D

... the led light head retains 80% of its light output after 60,000 hours of use, far longer than incandescent or fluorescent lamps.

grabcad

free

Explosion Proof LED Light - Magnetic Mount - Aluminum Base -140° Spread- C1D1 150 Watt LED Light

...bration/impact resistant.

10. significantly cooler operation.

11. less frequent outages, higher output improves workplace safety.

grabcad

free

Explosion Proof Light - Base Stand Mount - 16 Inch - 150 Watt LED - Class I Div 1 C&D

...ontact with a flammable material for a short period of time. this significantly increases the safety within the work environment.

grabcad

free

150W Explosion Proof LED Light - Base Stand Mount - 16 Inch Light - C1D1 - Jbox 100' Cord

... the led light head retains 80% of its lumen output after 60,000 hours of use, far longer than incandescent or fluorescent lamps.

grabcad

free

150 Watt Explosion Proof C1D1 LED Switch Blade Dock Light - 6' Pivoting Aluminum Arm - 13,000 Lumens

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

150 Watt Explosion Proof C1D1 LED Switch Blade Dock Light - 6' Pivoting Aluminum Arm - 17,500 Lumens

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

Explosion Proof 150 Watt Low Bay LED Light Fixture - 140° Spread - Paint Booth Approved - C1D1

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

Explosion Proof 150 Watt Adjustable Pole Top Slip Fit Mount LED Light Fixture - Slip Fitter Yoke

...le size. for example, selecting a 2" od mount means that the yoke mount will fit onto pipes or bull horns with a 2" od.

grabcad

free

150 Watt Class 1 Div 1 Explosion Proof LED Light - Non-Spark Aluminum Base - 120-277V AC

...ion 1 & 2 explosion proof or hazardous location environment requiring durable and quality lighting in a portable form factor.

grabcad

free

Class II Division 1 Explosion Proof 100 Watt High Bay LED Light Fixture 11,667 Lumens - CID2 / CIID1

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

C1D1

grabcad

free

Explosion Proof Enclosure, C1D1, 8'' x 12'' x 6'' Internal Dims, Surface Mount, N3R

...; in height. a removable backplate for easy mounting of equipment outside of the enclosure can be provided at an additional cost.

grabcad

free

Explosion Proof Cable Gland, 2" NPT, Nickel Plated Brass, 1.40-1.73" OD, C1D1 ATEX IEC Ex N4X

...ctions, cable fittings, explosive work sites, hazardous locations, instrumentation, telecommunication, cable management and more.

grabcad

free

Explosion Proof Cable Gland, 1" NPT, Nickel Plated Brass, 0.67-1.03" OD, C1D1 ATEX IEC Ex N4X

...ctions, cable fittings, explosive work sites, hazardous locations, instrumentation, telecommunication, cable management and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

5000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

Explosion Proof Cable Gland, 3/4" NPT, Nickel Plated Brass, 0.44-0.78" OD, C1D1 ATEX IEC Ex N4X

...ctions, cable fittings, explosive work sites, hazardous locations, instrumentation, telecommunication, cable management and more.

Watt

3ddd

$1

Watt & Veke

...watt & veke

3ddd

watt & veke

настольная лампа messina фабрики watt & veke.

3ddd

$1

Watt & veke / Soomkai

...

watt & veke , ротанг

стильная люстра из ротанга soomkai фабрики watt&veke.;

3ddd

free

ROLLE Watt&Veke

...rolle , watt&veke

подвесной светильник rolle watt&veke; из осенней коллекции

turbosquid

$35

We Watt Kiosk

...yalty free 3d model we watt kiosk for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1461926)

3ddd

$1

Luceplan / OTTO Watt

...условия для любых задач, отдыха или работы. пожалуй, идеальный спутник вашего стола.

дополнительные форматы: max(2010), fbx, 3ds.

3d_export

free

1300 watt subwoofer for cars

...1300 watt subwoofer for cars

3dexport

the model is made to take up space in the house or in the car. power 1300 watts.

3ddd

free

Watt&Veke Spring

...авесной светильник от watt & veke spring, подойдет как для детских, так и для строгих интерьеров, особенно в стилистике лофт.

3d_export

$5

30 watts of power 3D Model

...port

30 watts power 3d model factory electric electrical energy high poly

30 watts of power 3d model karenmodeling 84649 3dexport

3ddd

$1

Watt&Veke Table Lamp

...ble lamp

3ddd

watt&veke

производитель watt&veke;

абажур - vivianne19 h16 ∅19 ∅14

опора для абажура - henning h30 ∅12

3d_export

$5

Substation 110 watts power 3D Model

...odel factory electric electrical energy high poly substation 110

substation 110 watts power 3d model karenmodeling 84650 3dexport

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

turbosquid

$25

Flame proof fibricks_lit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

turbosquid

$29

Nikon Coolpix AW110 rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Armoured fighting vehicles armoured vehicles with explosion-proof wheels

...ured vehicles with explosion-proof wheels for download as max on turbosquid: 3d models for games, architecture, videos. (1629664)

turbosquid

$27

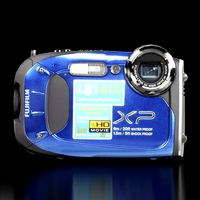

Fujifilm FinePix XP60 Blue rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$23

Panasonic Lumix DMC-TS5 rugged and proof digital gamera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

150

3ddd

$1

МООН 150

...моон 150

3ddd

moon

модель 150

3d_export

$5

f 150

...f 150

3dexport

f 150 formats max 3ds obj stl

3ddd

free

Тема 150

... акватика , ванна , угловая

ванна тема 150

design_connected

$11

Bolero 150

...bolero 150

designconnected

bolero 150 computer generated 3d model. designed by lazzeroni, roberto.

turbosquid

$25

Earrings 150

...alty free 3d model earrings 150 for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1203665)

turbosquid

$25

Ring 150

...royalty free 3d model ring 150 for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1203661)

turbosquid

$15

Cornice 150

...y free 3d model cornice 150 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1537239)

turbosquid

$15

Curtain 150

...e 3d model curtain 150 for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1707882)

turbosquid

$15

TZ-150

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Table 150

...d model table 150 for download as max, max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1592365)

Magnetic

3d_ocean

$2

Magnet

...magnet 3docean 3d 3ds max electric magnet magnetic magnetism max model polygon realistic tesla magnet created in...

turbosquid

$6

Magnet

...

turbosquid

royalty free 3d model magnet for download as obj on turbosquid: 3d models for games, architecture, videos. (1548733)

turbosquid

$6

magnet

...uid

royalty free 3d model magnet for download as 3dm and max on turbosquid: 3d models for games, architecture, videos. (1670606)

turbosquid

$1

Magnet

...y free 3d model magnet for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1215037)

turbosquid

$7

Magnet

...agnet for download as blend, unitypackage, fbx, gltf, and obj on turbosquid: 3d models for games, architecture, videos. (1576588)

3d_export

$5

magnetic knife holder

...magnetic knife holder

3dexport

ordinary magnetic knife holder

archive3d

free

Fridge magnet 3D Model

...3d model archive3d refrigerator magnet fridge magnet magnet toy magnetic s n280712 - 3d model (*.3ds) for interior 3d...

turbosquid

$35

Magnetic butterflies

...alty free 3d model magnetic butterflies for download as blend on turbosquid: 3d models for games, architecture, videos. (1315792)

turbosquid

$2

Magnetic Board

...quid

royalty free 3d model magnetic board for download as ma on turbosquid: 3d models for games, architecture, videos. (1264141)

turbosquid

$977

Magnetic Lego

...oyalty free 3d model magnetic lego for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1142761)

Aluminum

3d_export

$5

aluminum crutch

...aluminum crutch

3dexport

aluminum crutch

3d_export

free

aluminum cane

...aluminum cane

3dexport

aluminum cane

3d_export

$5

the aluminum canister

...

3dexport

the aluminum canister is designed for storing and transporting liquids( water), fuels and lubricants (gasoline, oils).

turbosquid

$2

Aluminum Wheel

...uid

royalty free 3d model aluminum wheel for download as fbx on turbosquid: 3d models for games, architecture, videos. (1371918)

turbosquid

$2

aluminum pulley

...

royalty free 3d model aluminum pulley for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1671716)

turbosquid

$40

Aluminum Can

... free 3d model aluminum can for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301606)

turbosquid

$15

Curved aluminum

...ee 3d model curved aluminum for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1260293)

turbosquid

$12

Aluminum pot

... free 3d model aluminum pot for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1653492)

3d_export

$5

Aluminum Bottle

... for shampoo, conditioner or any liquids (500ml 17floz) separated all parts, able to customize any color, material and finishing.

turbosquid

$19

Aluminum windows

...model aluminum windows for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1646740)

Led

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...

Base

archibase_planet

free

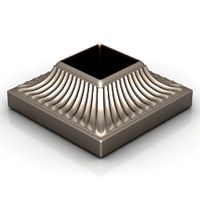

Base

...base

archibase planet

base column column base

base 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

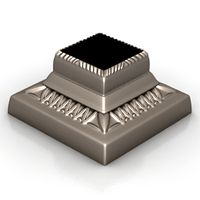

free

Base

...base

archibase planet

base column base column

base 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column column base

base 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

base column base column

base 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

foundation base

column base ionic - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Base

...base

archibase planet

foundation base

column base tuscan - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$18

Base

...base

designconnected

tom dixon base computer generated 3d model. designed by dixon, tom.