GrabCAD

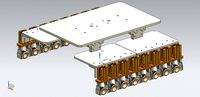

Explosion Proof Fluorescent Lights - Paint Booths, Rigs - 4', 4 Lamp Fixture - Bi-Axial Bulb Design

by GrabCAD

Last crawled date: 1 year, 11 months ago

https://www.larsonelectronics.com/product/49541/explosion-proof-fluorescent-lights-paint-booths-rigs-4-4-lamp-fixture-bi-axial-bulb-design

Made in the USA

The Larson Electronics EPL-48-2L-BX Explosion Proof Four Bi-Axial Bulb Fluorescent Light Fixture is NRTL Listed for United States and Canada Class 1 Division 1, Class 1 Division 2, carries a T6 temperature rating and ideal for hazardous locations where flammable chemical/petrochemical vapors exist or have the potential to exist.

The EPL-48-2LBX fixture is a 4 foot long, 4 lamp, Class 1 Division 1 and Class 2 Division 1 & 2 explosion proof fluorescent light which is also approved for use in paint spray booth applications. This T6 temperature rated fixture comes standard with four Bi-Axial 40 watt compact fluorescent bulbs which produce a combined 160 watts of illumination. The lamps are protected by heat and impact resistant Pyrex tubes and the fixture is constructed of copper free aluminum alloy. The lamp reflectors are corrosion resistant heavy gauge aluminum and coated with a high gloss reflective finish. The EPL-48-2L-BX provides operators in hazardous locations with an effective explosion proof lighting solution that provides more light than similar two bulb units.

This Biaxial Lamp fixture is multi-voltage capable and can operate on voltages ranging through 100/120 Volts 60 HZ, 220 Volt 50 HZ, 240 Volt 60 HZ, and 277 Volts 60 HZ with 347 Volt and 480 Volt versions available upon request.

Mounting Options: Unless otherwise specified, our standard, most popular configuration is the bracket end mounting shown enlarged below. We also offer a pendant mount for those needing to suspend the fixture away from the ceiling surface (i.e. suspend from pipe or conduit). Additional mounting configurations can be customized to meet the requirements on the application. Please contact us for special mounting configurations.

Adjustable Surface Mount Brackets: Each bracket is cinched to the bracket mounting peg on each side of the light. The angle of the bracket is set by tightening two cap screws on either side of the bracket. The cap screws act as a set screw. The bracket itself is mounted via a single bolt hole at the top the bracket. There are two brackets, one on each end of the light. Once the brackets are mounted to a surface (ceiling, floor or wall), the light fixture can be removed from the brackets by loosening the cap screws that hold the bracket to the mounting peg.

Suspension Mounting: Pendant mount fixtures hang from the ceiling and are suspended by rigid pipe. Each fixture features a 1/2” NPT junction box on one end, and a 1/2” NPT adjustable L-bracket on the other end of the fixture. Operators bring rigid pipe down to the threaded mounting hubs. Wiring is fed down through the rigid pipe to the junction box and tied in to the fixture’s lead wires, completing the electrical connection. The adjustable L-shape mounting bracket provides support for the opposite end of the fixture.

Made in USA Quality

1. Each unit dialectically tested.

2. Fixture arrives assembled and lamped to reduce installation time and cost. Adjustable mounting brackets enable the operator to choose any mounting angle for the fixture, where other models may only offer one or three choices.

3. Fixture constructed of extruded corrosion resistant copper free aluminum alloy.

4. Over-sized, finned ballast housing for 800 mA fixtures provides more heat dissipation and extends ballast life. Larger ballast box accommodates High Output lamp ballasts. Ballast housing easily accessible and externally mounted. Top and bottom covers secured with nuts and bolts, instead of threaded through holes, which can be damaged with dirt.

5. Heavy gauge extruded aluminum reflectors with high gloss reflective finish. Resists dents and corrosion.

6. A wrench is used to unscrew the end caps for relamping the fixture, while other models require the “tap and knock off” method to loosen the end cap.

7. Explosion proof, impact and heat resistant Pyrex tubes provide lamp protection.

Made in the USA

The Larson Electronics EPL-48-2L-BX Explosion Proof Four Bi-Axial Bulb Fluorescent Light Fixture is NRTL Listed for United States and Canada Class 1 Division 1, Class 1 Division 2, carries a T6 temperature rating and ideal for hazardous locations where flammable chemical/petrochemical vapors exist or have the potential to exist.

The EPL-48-2LBX fixture is a 4 foot long, 4 lamp, Class 1 Division 1 and Class 2 Division 1 & 2 explosion proof fluorescent light which is also approved for use in paint spray booth applications. This T6 temperature rated fixture comes standard with four Bi-Axial 40 watt compact fluorescent bulbs which produce a combined 160 watts of illumination. The lamps are protected by heat and impact resistant Pyrex tubes and the fixture is constructed of copper free aluminum alloy. The lamp reflectors are corrosion resistant heavy gauge aluminum and coated with a high gloss reflective finish. The EPL-48-2L-BX provides operators in hazardous locations with an effective explosion proof lighting solution that provides more light than similar two bulb units.

This Biaxial Lamp fixture is multi-voltage capable and can operate on voltages ranging through 100/120 Volts 60 HZ, 220 Volt 50 HZ, 240 Volt 60 HZ, and 277 Volts 60 HZ with 347 Volt and 480 Volt versions available upon request.

Mounting Options: Unless otherwise specified, our standard, most popular configuration is the bracket end mounting shown enlarged below. We also offer a pendant mount for those needing to suspend the fixture away from the ceiling surface (i.e. suspend from pipe or conduit). Additional mounting configurations can be customized to meet the requirements on the application. Please contact us for special mounting configurations.

Adjustable Surface Mount Brackets: Each bracket is cinched to the bracket mounting peg on each side of the light. The angle of the bracket is set by tightening two cap screws on either side of the bracket. The cap screws act as a set screw. The bracket itself is mounted via a single bolt hole at the top the bracket. There are two brackets, one on each end of the light. Once the brackets are mounted to a surface (ceiling, floor or wall), the light fixture can be removed from the brackets by loosening the cap screws that hold the bracket to the mounting peg.

Suspension Mounting: Pendant mount fixtures hang from the ceiling and are suspended by rigid pipe. Each fixture features a 1/2” NPT junction box on one end, and a 1/2” NPT adjustable L-bracket on the other end of the fixture. Operators bring rigid pipe down to the threaded mounting hubs. Wiring is fed down through the rigid pipe to the junction box and tied in to the fixture’s lead wires, completing the electrical connection. The adjustable L-shape mounting bracket provides support for the opposite end of the fixture.

Made in USA Quality

1. Each unit dialectically tested.

2. Fixture arrives assembled and lamped to reduce installation time and cost. Adjustable mounting brackets enable the operator to choose any mounting angle for the fixture, where other models may only offer one or three choices.

3. Fixture constructed of extruded corrosion resistant copper free aluminum alloy.

4. Over-sized, finned ballast housing for 800 mA fixtures provides more heat dissipation and extends ballast life. Larger ballast box accommodates High Output lamp ballasts. Ballast housing easily accessible and externally mounted. Top and bottom covers secured with nuts and bolts, instead of threaded through holes, which can be damaged with dirt.

5. Heavy gauge extruded aluminum reflectors with high gloss reflective finish. Resists dents and corrosion.

6. A wrench is used to unscrew the end caps for relamping the fixture, while other models require the “tap and knock off” method to loosen the end cap.

7. Explosion proof, impact and heat resistant Pyrex tubes provide lamp protection.

Similar models

grabcad

free

Explosion Proof Fluorescent Lights - Paint Booths, Rigs - 4', 8 Lamp Fixture - Bi-Axial Bulb Design

...explosion proof lighting solution that provides more light than similar two bulb units. this biaxial lamp fixture is multi-voltage...

grabcad

free

Explosion Proof Fluorescent Light - Paint Booths, Rigs - 2', 2 Lamp Fixture - Bi-Axial Bulb Design

... tubes provide lamp protection.

lamp options

40 watt bi-axial compact fluorescent lamp - 4100k color temp, 3000 lumens per lamp

grabcad

free

Surface Mount Explosion Proof, Waterproof Fluorescent Lights - T12 Hotbox Configuration

...s to 165 degrees f.

for other lamp optoins please see our epl-48-2l fixture that is approved for paint spray booth applications.

grabcad

free

Low Profile Explosion Proof Fluorescent Light Fixture - 2 Foot 4 Lamp Compact Design - 8000 Lumens

...quire different lamp options, please see our epl-24-2l for fluorescent lamps or our epl-24-2l-led for fluorescent style led lamps

grabcad

free

Explosion Proof Fluorescent Lights for Paint Booths, Oil Rigs, Boats -2 foot - 2 lamp -Multi-voltage

... shows the access caps for changing the bulbs. the second picture shows the bracket at the opposite end of the fluorescent light.

grabcad

free

Explosion Proof Fluorescent Light for Paint Booths, Oil Rigs, Boats -2 Foot-8 Lamp-T5HO Bulbs

...

f24-t5ho – 2000 lumens per bulb, 20,000 hours life, 5000 kelvin color, cri 85 rha-unv-254-lt5 ballast is thd<10% and hpf .98

grabcad

free

Explosion Proof T8 Fluorescent Light with Emergency Battery Backup -2ft 4 Lamp - Paint Booth Approve

...s provide lamp protection.

lamp options

f17-t8 – 1325 lumens per bulb (2650 lumens total), 24,000 hours life, 4100 kelvin color

grabcad

free

Explosion Proof Fluorescent Lights w/ Emergency Battery Backup - 2 foot 4 Lamp - Multi-Volatge

...mens per bulb (4000 lumens total), 20,000 hours life, 5000 kelvin color, cri 85 rha-unv-254-lt5 ballast is thd<10% and hpf .98

grabcad

free

Explosion Proof Emergency Fluorescent light Combination - 4 foot - 2 T5HO lamps - Class I, Div I

...ubes provide lamp protection.

lamps

f54-t5/850/ho – 54 watt, 5000 lumens per bulb, 20,000 hours life, 5000 kelvin color, cri 85

grabcad

free

Explosion Proof Emergency Lights & Fluorescent light Combination - 4 foot - 2 lamps - Class I, Div I

...ide lamp protection.

lamp options

f32-t8/841 – 32 watt, 2950 lumens per bulb, 24,000 hours life, 4100 kelvin color (suffix –t8)

Fluorescent

3d_ocean

$6

Energy Bulb Fluorescent

...energy bulb fluorescent

3docean

bulb eco ecological energy bulb fluorescent lamp light lighting

energy bulb fluorescent.

turbosquid

free

Fluorescent lamp

...bosquid

free 3d model fluorescent lamp for download as blend on turbosquid: 3d models for games, architecture, videos. (1313789)

3d_export

$5

Fluorescent 3D Model

...fluorescent 3d model

3dexport

florasan light lamb fluorescent bulb white high poly

fluorescent 3d model husky 49990 3dexport

turbosquid

$14

Fluorescence Microscope

...l fluorescence microscope for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1610738)

turbosquid

$2

Fluorescent light

... 3d model fluorescent light for download as max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1531043)

turbosquid

$39

Fluorescent Bulb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

fluorescent bulb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Fluorescent light

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Fluorescent Starter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Bulb fluorescent

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Axial

3d_export

$7

Axial fan

...axial fan

3dexport

axial fan

3d_export

$20

industrial axial blower253

...industrial axial blower253

3dexport

industrial axial blower industrial axial blower industrial axial blower

turbosquid

$2

Axial Capacitor

...

royalty free 3d model axial capacitor for download as blend on turbosquid: 3d models for games, architecture, videos. (1501098)

3d_export

$20

Axial compressor 3D Model

...xial compressor 3d model

3dexport

axial compressor jet engine turbine blades gas

axial compressor 3d model qepasol 93563 3dexport

turbosquid

$120

Axial Flow Pump

...id

royalty free 3d model axial flow pump for download as obj on turbosquid: 3d models for games, architecture, videos. (1533995)

turbosquid

free

Axial Wooden Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

collection of axial press fittings for pex pipes

...s fittings for pex pipes

3dexport

this is collection of axial press fittings for pex pipes. the collection includes next models:

turbosquid

free

Collection of axial press fittings for PeX Pipes

...n of axial press fittings for pex pipes for download as blend on turbosquid: 3d models for games, architecture, videos. (1639018)

3d_export

$20

Axial FLux Generator Small Scale Design

...3 rotor design this is a small scale design with a dimension of 11cm approx diameter this is auto desk fusion software compatible

3d_export

$149

axial-flow 9240 combine harvester

...y problem in this model, please do not hesitate to contact us, we are looking forward to continuously dealing with you. markos 3d

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

turbosquid

$25

Flame proof fibricks_lit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

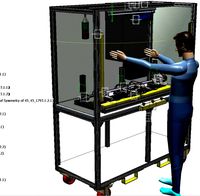

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

turbosquid

$29

Nikon Coolpix AW110 rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Armoured fighting vehicles armoured vehicles with explosion-proof wheels

...ured vehicles with explosion-proof wheels for download as max on turbosquid: 3d models for games, architecture, videos. (1629664)

turbosquid

$27

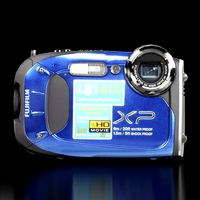

Fujifilm FinePix XP60 Blue rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$23

Panasonic Lumix DMC-TS5 rugged and proof digital gamera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

Bi

3ddd

$1

Treesse Bis

... treesse , bis

гидромассажная ванна treesse bis

max 2013+fbx+obj

3ddd

free

BAGA 624 BI

...baga 624 bi

3ddd

baga

baga 624 bi

3ddd

$1

Globo SSSN2.BI, SSSN9.BI

...ef;=819

биде cod. sssn9.bihttp://www.ceramicaglobo.com/eng/schedaprodotto.aspx?cat=3⊂=13&ref;=820

turbosquid

$10

Bis-m Monika

...squid

royalty free 3d model bis-m monika for download as max on turbosquid: 3d models for games, architecture, videos. (1536016)

turbosquid

$10

Bis-m Monika

...squid

royalty free 3d model bis-m monika for download as max on turbosquid: 3d models for games, architecture, videos. (1536012)

3d_export

$15

mig 15 bis

...mig 15 bis

3dexport

3ddd

free

EOS Bi-o mini

... печь , баня

парогенератор для бани eos bi-o mini

turbosquid

$160

bis 6.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Chair Bi Silla

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

bi-pedal robot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Booths

3d_export

$10

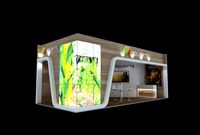

Booth Devassa

...booth devassa

3dexport

booth 10x10

3d_export

$10

Booth VENEZA

...booth veneza

3dexport

booth 12x10

3d_export

$10

Booth MSD

...booth msd

3dexport

booth 8.00x6.00

3d_export

$10

Booth Oncoclincas

...booth oncoclincas

3dexport

booth 14.00x11.00

3d_export

$10

Booth SOLINFTEC

...booth solinftec

3dexport

booth 11.00x5.00

3d_export

$7

Booth Janssen

...booth janssen

3dexport

booth 6.00x6.00

3d_export

$7

Booth Astellas

...booth astellas

3dexport

booth 6.00x6.00

3d_export

$7

Booth Galvani

...booth galvani

3dexport

booth 4.00x4.50

3d_export

$5

exhibition booth

...exhibition booth

3dexport

exhibition booth

3d_export

$5

Booth Camil

...booth camil

3dexport

booth 6x3

Bulb

archibase_planet

free

Bulb

...base planet

bulb electric light bulb electric bulb

bulb lamp isle n230814 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bulb

...bulb

3dexport

bulb

archibase_planet

free

Bulb

...bulb

archibase planet

bulb glass-ware

bulb - 3d model for interior 3d visualization.

3d_ocean

$7

Light bulb

...6) polygon. material, lighting and rendering using vray. very easy to use. it is very detailed one. it is modeled in 3ds max 2013

design_connected

$16

Bulb

...bulb

designconnected

&tradition bulb computer generated 3d model. designed by refer, sofie.

3d_export

$5

bulb

... used in game engines (unity/unreal)<br>note the renders are done in keyshot. the model only has separate material assigned

3d_ocean

$6

Energy bulb

...energy bulb

3docean

bulb eco ecological energy bulb lamp light lighting

energy bulb.

archibase_planet

free

Bulb

...bulb

archibase planet

jug pitcher pots and pans

bulb - kitchen accessories - 3d model for interior 3d visualization.

3ddd

$1

BULBING lamp

...ulbing lamp

studio cheha

дизайнер nir chehanowskihttp://www.bulbing-light.com/collections/bulbing/products/bulbing-lamp

turbosquid

$21

Bulb

...lb

turbosquid

royalty free 3d model bulb for download as c4d on turbosquid: 3d models for games, architecture, videos. (1144841)

Fixture

turbosquid

$5

Fixture

...turbosquid

royalty free 3d model fixture for download as max on turbosquid: 3d models for games, architecture, videos. (1160462)

turbosquid

$39

FIXTURE

...id

royalty free 3d model fixture for download as ige and obj on turbosquid: 3d models for games, architecture, videos. (1332983)

turbosquid

$2

Fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

ROBOT FIXTURE

...fixture

3dexport

it is a robot fixture. it is used to pick the insert from the table and place that insert into the mold cavity.

turbosquid

free

lighting fixtures

...odel lighting fixtures for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1428616)

3d_ocean

$2

Light Fixture 02

...reat for any game enviroment. the light fixture has texture with both lid bulb, and unlid bulb. low poly (238 polygons – 245 v...

turbosquid

$29

bathroom fixtures

...odel bathroom fixtures for download as 3ds, max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1180328)

turbosquid

$20

Wall Fixture

... 3d model wall fixture for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1270353)

Rigs

3d_export

$25

rigged chimpanzee

...rigged chimpanzee

3dexport

rigged chimpanzee

3d_export

$25

rigged wolf

...rigged wolf

3dexport

rigged wolf

3d_export

$25

rigged cicada

...rigged cicada

3dexport

rigged cicada

3d_export

$20

triceratops rigged

...triceratops rigged

3dexport

triceratops rigged

3d_export

$20

rigged horse

...rigged horse

3dexport

rigged horse

3d_export

$15

rigged cheetah

...rigged cheetah

3dexport

rigged cheetah

3d_ocean

$16

Rigged Mannequinn

...es .this rig contains two textures.however it is not uv mapped. the parts and the rig controls are named with proper naming co...

3d_ocean

$35

Rigged Bicycle

...rigged bicycle

3docean

bicycle cycle rigged bicycle slim tire

rigged bicycle ready for animation..

turbosquid

$40

knight-rigged RIGGED

...ree 3d model knight-skeleton for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1576606)

turbosquid

$2

rig

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Paint

archibase_planet

free

Paints

...paints

archibase planet

paints paint

paints n241211 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Paint

...paint

archibase planet

jar of paint paint can

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

paint

...paint

3ddd

paint

archibase_planet

free

Paint

...paint

archibase planet

paint

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Painting

...painting

3ddd

картина

painting in double wooden frame decorated antique

3ddd

$1

The collection of paintings

...

картина , фото

collection of modern and contemporary paintings.

contemporary paintings.

turbosquid

$29

painting

...free 3d model painting for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1383201)

turbosquid

$1

Painting

...ee 3d model painting for download as 3ds, obj, md3, and blend on turbosquid: 3d models for games, architecture, videos. (1207611)

turbosquid

free

Painting

... 3d model painting for download as ma, 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1219609)

3ddd

$1

PAINTINGS

...paintings

3ddd

панно

размеры:

1170х900

Lamp

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp table lamp reading lamp

lamp - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Lamp

...lamp

archibase planet

lamp reading lamp table lamp lantern

lamp - 3d model (*.3ds) for interior 3d visualization.

3d_ocean

$6

Lamp

...lamp

3docean

lamp

a high quality lamp.

Lights

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...

4

turbosquid

$9

Office Chair 4-4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

doors- 4

...doors- 4

3dexport

doors 4

3d_export

$5

hinge 4

...hinge 4

3dexport

hinge 4

3ddd

$1

Штора №4

...штора №4

3ddd

штора №4

3d_export

free

playstation 4

...playstation 4

3dexport

playstation 4

turbosquid

$1

re 4-4 electric locomotive

... free 3d model re 4 4 electric locomotive for download as obj on turbosquid: 3d models for games, architecture, videos. (1707845)

3ddd

$1

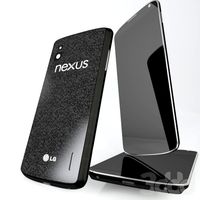

nexus 4

...nexus 4

3ddd

lg , телефон

nexus 4

3ddd

$1

4 Poufs

...4 poufs

3ddd

пуф

4 soft poufs

turbosquid

$12

Calligraphic Digit 4 Number 4

...hic digit 4 number 4 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389332)

3ddd

$1

Dauphin 4+

...dauphin 4+

3ddd

кресло

dauphin 4+ конференц кресло

Design

3ddd

$1

LINE DESIGN (Doors Design)

...line design (doors design)

3ddd

дверь

modern doors design - line design concept

turbosquid

$5

designer

...alty free 3d model designer for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1422665)

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

кресло ver design

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

диван ver design

3ddd

$1

Bagno design

...bagno design

3ddd

bagno design , унитаз

санитария bagno design

3ddd

free

VER DESIGN

...ver design

3ddd

ver design , стеллаж

полка ver design

3ddd

$1

VER DESIGN

...ver design , лежак , шезлонг

шезлонг ver design

3d_export

free

designer

..., trees and much more. the model has 3 types of parts: - 4 cells - 6 cells - 8 cells the *.max file contains 5 colored materials.

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

3d_export

$7

Crusher design

...crusher design

3dexport

crusher design