Thingiverse

Exhaust Duct Adapter by hgm

by Thingiverse

Last crawled date: 3 years, 1 month ago

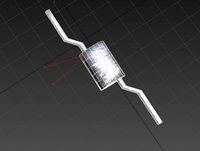

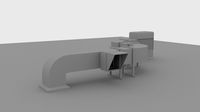

Exhaust Duct Adapter

for Snapmaker or other exhaust hose with diameter of 75 mm (approx. 3 inch)

In order to clamp the exhaust air hose (diameter 75 mm (approx. 3”) of my 3D printer in the window frame, I designed an adapter with FreeCAD (file enclosed).

This adapter consists of three separate parts, so that the individual parts can be printed separately on smaller machines or individually adapted.

Round nozzle with bars (connection to exhaust air hose),

H: 70 mm, diameter: 75 mm,

Printing time approx. 6 hours

Transition with connection

H: 90 mm, W: 155 mm, D: 25 mm, diameter: 74 mm

Printing time approx. 14 hours

Rectangular nozzle with bars and supports

H: 65 mm, W: 155 mm, D: 35 mm)

Printing time approx. 14 hours

The parts are designed with zero tolerance and can be plugged into one another. Eventually they must be carefully reworked with a file to make the parts fit perfectly. They can optionally be glued or screwed together.

General Print Settings

Printer brand: Snapmaker

Printer: A350

Rafts: yes

Supports: yes and no

Layer height: 0,2 mm

Infill: 15 %

Filament brand: snapmaker

Filament color: black

Filament material: PLA

Diameter: 1,75 mm

Flow: 100 %

Print temperature: 205 °C

First layer print Temperature: 205 °C

Final printing temperature: 200 °C

Heated bed temperature: 50 °C

Heated bed temperature, first layer: 70 °C

Interesting side effect:

As long as I was employed I drove with a car to my company (automobile manufacturer) in order to be able to afford a car.

Now I have a hobby to make parts that I need for my hobby.

Detailed printer settings, see file enclosed

for Snapmaker or other exhaust hose with diameter of 75 mm (approx. 3 inch)

In order to clamp the exhaust air hose (diameter 75 mm (approx. 3”) of my 3D printer in the window frame, I designed an adapter with FreeCAD (file enclosed).

This adapter consists of three separate parts, so that the individual parts can be printed separately on smaller machines or individually adapted.

Round nozzle with bars (connection to exhaust air hose),

H: 70 mm, diameter: 75 mm,

Printing time approx. 6 hours

Transition with connection

H: 90 mm, W: 155 mm, D: 25 mm, diameter: 74 mm

Printing time approx. 14 hours

Rectangular nozzle with bars and supports

H: 65 mm, W: 155 mm, D: 35 mm)

Printing time approx. 14 hours

The parts are designed with zero tolerance and can be plugged into one another. Eventually they must be carefully reworked with a file to make the parts fit perfectly. They can optionally be glued or screwed together.

General Print Settings

Printer brand: Snapmaker

Printer: A350

Rafts: yes

Supports: yes and no

Layer height: 0,2 mm

Infill: 15 %

Filament brand: snapmaker

Filament color: black

Filament material: PLA

Diameter: 1,75 mm

Flow: 100 %

Print temperature: 205 °C

First layer print Temperature: 205 °C

Final printing temperature: 200 °C

Heated bed temperature: 50 °C

Heated bed temperature, first layer: 70 °C

Interesting side effect:

As long as I was employed I drove with a car to my company (automobile manufacturer) in order to be able to afford a car.

Now I have a hobby to make parts that I need for my hobby.

Detailed printer settings, see file enclosed

Similar models

thingiverse

free

ODIN sculpture (top part) by C0ste

... time: 6 hrs

if you want something like this with a scultue that you have please contact me, i work in a company: master controls

thingiverse

free

Filament Spool Adapter Ø53mm for Snapmaker (Beta version) by rojaljelly

...t the newer version http://www.thingiverse.com/thing:3086844

especialy when you have the original enclosure with the teflon tube.

thingiverse

free

Adapter for Carbon filter, Snapmaker 2.0 Cabinet. by Cloudman42

...r can be glued together, else it works just fine to fit them together just after print, top part will fit inside the 125 mm ring.

thingiverse

free

Snapmaker enclosure to vacuum adapter by rgprints

...y not be a standard size, so you may have to modify the design. i used freecad and the fcstd files are included for that purpose.

thingiverse

free

SnapMaker A350 - Storage Drawer by franckfuziol

...

thingiverse

storage bin for the snapmaker a350.

printing time (fast print):

drawer - approx. 24 hours

divider - approx. 2 hours

thingiverse

free

Server box Exhaust duct adapter by WarHawkEcho

...rver case (which i use for my 3d printer housing. the duct converts from a fan to the 4inch hosing which is used for dryer ducts.

cg_trader

$3

Engine mounting brackets DL 550-C | 3D

...t fastening class 550 c project drive mount horizontal vertical 3d printing hobby diy hobby diy mechanical parts mechanical parts

thingiverse

free

Dremel 3D45 Exhaust Hose Adapter Kit by mrgizmo9999

...ached to a thin panel that fits in a window using the same screws (with or without the fan.

use zip ties to secure the hose ends.

thingiverse

free

Samsung Galaxy Note 8 case for Aleksandra by Lars89

...

print speed: 45 mm/s

retract: 3 mm

resolution: 0.1 mm better is a higher resolution (0.2 mm)

infill: 100 %

print time: 6-7 hours

thingiverse

free

BIBO 2 Hood Exhaust Duct

...; pvc duct adapter can be purchased at a hardware store and substituted. all parts print without supports except vent_housing_3.

Hgm

thingiverse

free

Luceplan Titania Adapter for R7 Sockets / LED by bastianeggers

...it to the 5th.) example of the r7s sockets: https://www.reichelt.de/de/de/lampenfassung-r7s-messing-1-stueck-hgm3088802-p214165.html?r=1 example of a matching led lamp:...

grabcad

free

HGM

...hgm

grabcad

hgm

3dwarehouse

free

catering -yemek uertimtesisi gurkan bey hgm

...catering -yemek uertimtesisi gurkan bey hgm

3dwarehouse

catering -yemek uertimtesisi gurkan bey hgm

3dwarehouse

free

Classic Single Handle Bathroom Faucet - 520-HGM-DST

...l flange and plastic tail piece• models with suffix 'ppu' have plastic pop-up type fitting with plated flange and stopper

3dwarehouse

free

hank plek van eric

...hank plek van eric 3dwarehouse hgm ...

3dwarehouse

free

Modern Single Handle Project-Pack Bathroom Faucet - 534LF-HGM-PP

...with plated flange and stopper• models with suffix “mpu” have metal drain with pop-up type fitting with plated flange and stopper

3dwarehouse

free

Modern Single Handle Project-Pack Bathroom Faucet - 573LF-HGM-PP

...ted flange and stopper• models with suffix 'mpu' have metal drain with pop-up type fitting with plated flange and stopper

3dwarehouse

free

Modern Single Handle Project-Pack Bathroom Faucet - 581LF-HGM-PP

... fitting with plated flange and stopper• 581lf-blgpm-pp has a metal drain with pop-up type fitting with plated flange and stopper

3dwarehouse

free

Modern Single Handle Project Pack Faucet- Low Flow - 567LF-HGM-PP

... fitting with plated flange and stopper• 567lf-blgpm-pp has a metal drain with pop-up type fitting with plated flange and stopper

Exhaust

turbosquid

$2

Exhaust

...id

royalty free 3d model exhaust for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1603373)

turbosquid

$1

Exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

exhaust manifold

...exhaust manifold

3dexport

this is a 3d design of an exhaust manifold used in automobile.

archive3d

free

Exhauster 3D Model

... air exhauster hoover

exhauster n101015 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$13

Exhaust 3D Model

...exhaust 3d model

3dexport

exhaust smoke engine motor bike car detail detailed

exhaust 3d model cesar_vonc 12007 3dexport

turbosquid

free

car exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Exhaust system

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

MSX EXHAUSTS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Duct

turbosquid

$19

Duct Set

...d

royalty free 3d model duct set for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1145038)

turbosquid

$10

Duct Tape

...id

royalty free 3d model duct tape for download as ma and ma on turbosquid: 3d models for games, architecture, videos. (1580351)

turbosquid

free

Duct Tape

...

free 3d model duct tape for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1486518)

3d_ocean

$7

Air-duct

... ventilation

high quality industrial air duct ventilation model. created in cinema 4d but comes in various other formats as well.

turbosquid

$20

Air ducts

...lty free 3d model air ducts for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1262476)

3d_export

$10

Supply air duct

...supply air duct

3dexport

supply air duct with two axial fans and hangers

turbosquid

$2

Duct Tape

...e 3d model duct tape for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1473972)

turbosquid

free

Duct Tape

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Duct tape

...polys. includes: cinema 4d project. model in 3 formats (obj, fbx, 3ds). 6 .tga texture maps (albedo, ambient occlusion, diffus...

turbosquid

$40

Ventilation Duct PACK

...tion duct pack for download as ma, obj, fbx, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1287068)

Adapter

3d_export

$10

Adapter 3D Model

...adapter 3d model

3dexport

adapter

adapter 3d model mur 20260 3dexport

archive3d

free

Adapter socket 3D Model

...dapter socket adapter

adapter socket n090211 - 3d model (*.3ds) for interior 3d visualization.

turbosquid

$400

cell adaptation

...

royalty free 3d model cell adaptation for download as blend on turbosquid: 3d models for games, architecture, videos. (1701655)

archive3d

free

Adapter 3D Model

...ups pc equipment

adapter extron n180813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

usb adapter

...royalty free 3d model usb adapter for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1582234)

turbosquid

$15

Power adapter

...free 3d model power adapter for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1510024)

turbosquid

$8

USB adapter

...e 3d model usb adapter for download as max, fbx, obj, and dwg on turbosquid: 3d models for games, architecture, videos. (1713542)

turbosquid

$30

adapter.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Nokia Adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Universal adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.