GrabCAD

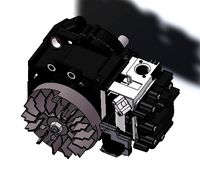

Engine Model Mk3

by GrabCAD

Last crawled date: 3 years, 1 month ago

One of the most ambitious projects completed so far, the knowledge acquired from every product designed previously has been implemented into this, the 3rd generation engine model. The powertrain has been created from scratch within an estimated timespan of 80 hours.

It is inspired by the 1.6 litter Formula 1 engines of today, measuring at 80mm bore and 53mm stroke. The calculated compression ratio is equal to 13:1, alongside the total capacity numbering at 1598cc. This over squared setup allows for a high revving characteristic, configuring the engine to achieve peak power at a high RPM range. Parameters are as follows: DOHC, 24 valves (4 valves per cylinder), 6 cylinders arranged in a V with a 90° angle, a 4 – stroke combustion engine with direct injection weighing at 99.93 kg.

Every component has been designed thoroughly with a high emphasis on attention to detail. All components, besides the ISO standard bolts, are created from scratch, allowing the engineer to have freedom in adjustability and reconfiguration if necessary. Engine block cooling ducts have been created so that an implementation of a water-based cooling system is possible. The block has been designed around the forged aluminium pistons, connecting rods, and crankshaft. The cylinder heads required extensive preparation, therefore most of the time was allocated for them and they’re parts. They are constructed of all components necessary to function accordingly, from valves, spark plugs, and gasket, all the way to cams, coil plugs and injectors. All measurements are thoroughly analysed, for the engine to experimentally be manufactured and operated reliably. The main materials used for this project are aluminium allocated for components such as the engine block, cylinder head housing and pistons, whereas steel constructed parts are represented by bolts, engine studs, and washers. Furthermore, gear ratio analysis and mathematical calculus have been conducted for the timing belt design.

This project proves the ingenuity and dedication invested into making this F1 inspired internal combustion engine, thus extending the computer-aided design experience for future applications within the automotive industry.

It is inspired by the 1.6 litter Formula 1 engines of today, measuring at 80mm bore and 53mm stroke. The calculated compression ratio is equal to 13:1, alongside the total capacity numbering at 1598cc. This over squared setup allows for a high revving characteristic, configuring the engine to achieve peak power at a high RPM range. Parameters are as follows: DOHC, 24 valves (4 valves per cylinder), 6 cylinders arranged in a V with a 90° angle, a 4 – stroke combustion engine with direct injection weighing at 99.93 kg.

Every component has been designed thoroughly with a high emphasis on attention to detail. All components, besides the ISO standard bolts, are created from scratch, allowing the engineer to have freedom in adjustability and reconfiguration if necessary. Engine block cooling ducts have been created so that an implementation of a water-based cooling system is possible. The block has been designed around the forged aluminium pistons, connecting rods, and crankshaft. The cylinder heads required extensive preparation, therefore most of the time was allocated for them and they’re parts. They are constructed of all components necessary to function accordingly, from valves, spark plugs, and gasket, all the way to cams, coil plugs and injectors. All measurements are thoroughly analysed, for the engine to experimentally be manufactured and operated reliably. The main materials used for this project are aluminium allocated for components such as the engine block, cylinder head housing and pistons, whereas steel constructed parts are represented by bolts, engine studs, and washers. Furthermore, gear ratio analysis and mathematical calculus have been conducted for the timing belt design.

This project proves the ingenuity and dedication invested into making this F1 inspired internal combustion engine, thus extending the computer-aided design experience for future applications within the automotive industry.

Similar models

grabcad

free

Engine Model Mk2

...ave been built with observable attention to detail, mainly focus being allocated for the cylinder head and the components within.

grabcad

free

V6 Internal Combustion Engine

...s arranged in a v configuration at a 90° angle, a 4-stroke internal combustion engine with direct injection weighing at 99.93 kg.

grabcad

free

2 piston, 1 cylinder engine

...2 piston, 1 cylinder engine

grabcad

4-stroke gas engine with rotary intake valve. inspired by a jan ridders design

3dwarehouse

free

Four stroke engine

...e_176 #admision #compresion #compression #cuatro #engine #escape #exhaust #explosion #four #intake #motor #power #stroke #tiempos

grabcad

free

Valve

...ocated below the combustion chamber in the engine block. the camshaft in a traditional ohv engine is located in the engine block.

grabcad

free

car engine

...y providing different gear ratios.

engine block and components:

the engine block is the main structural component containing the

grabcad

free

Piston HEAD

...mbustion into mechanical power. its design and construction significantly impact engine performance, efficiency, and reliability.

cg_trader

$35

Single cylinder 4-stroke engine

...r motorcycle piston valve motorbike automobile crankshaft camshaft combustion fourstroke 4stroke singlecylinder motorcycle engine

grabcad

free

For Stroke Petrol Engine

...s to top dead centre while the exhaust valve is open. this action expels the spent fuel-air mixture through the exhaust valve(s).

grabcad

free

Piston cylinder combustion engine

...piston cylinder combustion engine

grabcad

combustion engine cylinder with piston. this is not my design

Mk3

turbosquid

$50

cention mk3

...ty free 3d model cention mk3 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454148)

turbosquid

$129

MK3 Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$100

Toyota Supra MK3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$44

cention mk3 low poly

...d model cention mk3 low poly for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454666)

turbosquid

$30

Challenger I Mk3 Falcon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

American Frag hand grenade MK3

...free 3d model american frag hand grenade mk3 for download as on turbosquid: 3d models for games, architecture, videos. (1393624)

turbosquid

$20

Mk3 US Navy Combat Knife

...ty free 3d model mk3 us navy combat knife for download as fbx on turbosquid: 3d models for games, architecture, videos. (1172791)

3d_export

$29

Ford Fiesta MK3 Modified 3D Model

...7 tumerfx mtumer mehmet t?mer 1993 1995 1996 wrc special modifed modifiye

ford fiesta mk3 modified 3d model mtumer 30698 3dexport

3d_export

$99

Toyota Supra Mk3 19861993 3D Model

...ort fast coupe japan 1986 1987 1988 1989 1990 1991 1992 1993 tuning turbo

toyota supra mk3 19861993 3d model squir 62530 3dexport

turbosquid

$5

Timothy Oulton Mars Chair MK3

...on mars chair mk3 for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1209782)

Engine

3d_export

$5

engine

...engine

3dexport

engine

3d_export

free

Engine

...engine

3dexport

engine

archibase_planet

free

Engine

...engine

archibase planet

motor engine

engine - 3d model for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

motor engine mover

engine n170708 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

engine locomotive train

locomotive - 3d model for interior 3d visualization.

turbosquid

$49

ENGINE

...

turbosquid

royalty free 3d model engine for download as max on turbosquid: 3d models for games, architecture, videos. (1206116)

turbosquid

$1

ENGINE

...osquid

royalty free 3d model ic engine for download as sldas on turbosquid: 3d models for games, architecture, videos. (1382781)

3d_export

$5

engine

...engine

3dexport

3d_export

free

engine

...engine

3dexport

turbosquid

$7

Engine

...d model animated engine mograph element3d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1380716)