Thingiverse

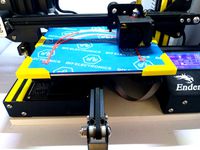

Ender 5 Plus Direct Drive Mod by Robert_L

by Thingiverse

Last crawled date: 2 years, 11 months ago

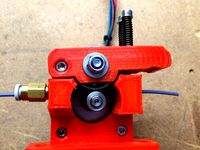

This provides a clean way to get the filament from the Filament Detector to the Extruder as well as a clean way to support the wire bundle. The wheel the filament goes around to get from the spool to the filament detector leaves enough room to easily feed the filament through the filament detector and all the way into the extruder. The Filament feeds through all the openings without any need for assistance.

The parts are broken up to be able to print all the parts without supports so every thing prints cleaner. The two parts the pneumatic fitting screw into the the tube are different for the filament detector and extruder ends (spacing is different for alignment). The screw spacing to attach them to their parts are different to ensure they are attached to the correct mounting plates. The "C" channel for the wire bundle is the same for both locations.

The mounting plate for the Extruder replaces the 3mm thick spacer that comes with the direct drive kit.

I used M3 screws to attach the tube holders and the "C" channels. 2 screws were probably enough but I used 3 just to be safe.

The screws and T-nuts that originally held the spool bracket and extruder can be re-used to hold the new spool bracket riser and filament detector mount. Two additional M4 or M5 screws and T-nuts are required to hold the bracket for the filament guide wheel and the wire bundle holder.

Four additional M5 x 8mm screws are required to attach the filament spool bracket to the riser.

A #6 screw is required to attach the filament guide roller to the bracket.

During printing the bowden tube from the filament detector and/or the wire loom may lay against the filament spool. It will not affect the operation of anything or the quality of the prints.

Parts Required: (I used Socket Head Cap Screws)

qty 12 M3 x 6mm screws (I used Pan Phillips Machine Screws)

qty 4 - M5 x 8mm screws (I used Socket Head Cap Screws)

qty 2 - M4 or M5 x 8mm screws and T-nuts

qty 1 - #6-32 x 1/2 screw (I used Socket Head Cap Screws)

qty 1 - 3/8 ID x 7/8 OD x 9/32 width Pre-Lubricated Bearing (I use these because I always have some on hand)https://www.amazon.com/gp/product/B07X93RV9L/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

This is the Direct Drive Kit I ordered but any kit of this design should work.https://amazon.com/dp/B08M93Y8ZT?psc=1&ref=ppx_yo2_dt_b_product_details

Rev 1: Revised the Spool Riser Support and Bracket to add more support to the front of the Riser. The spool does need to sit back like I had it. The issue was a full spool of filament caused it to lean forward some. The revised version corrects that issue. I also added two M3 screws to the front of the bracket to riser attachment.

The parts are broken up to be able to print all the parts without supports so every thing prints cleaner. The two parts the pneumatic fitting screw into the the tube are different for the filament detector and extruder ends (spacing is different for alignment). The screw spacing to attach them to their parts are different to ensure they are attached to the correct mounting plates. The "C" channel for the wire bundle is the same for both locations.

The mounting plate for the Extruder replaces the 3mm thick spacer that comes with the direct drive kit.

I used M3 screws to attach the tube holders and the "C" channels. 2 screws were probably enough but I used 3 just to be safe.

The screws and T-nuts that originally held the spool bracket and extruder can be re-used to hold the new spool bracket riser and filament detector mount. Two additional M4 or M5 screws and T-nuts are required to hold the bracket for the filament guide wheel and the wire bundle holder.

Four additional M5 x 8mm screws are required to attach the filament spool bracket to the riser.

A #6 screw is required to attach the filament guide roller to the bracket.

During printing the bowden tube from the filament detector and/or the wire loom may lay against the filament spool. It will not affect the operation of anything or the quality of the prints.

Parts Required: (I used Socket Head Cap Screws)

qty 12 M3 x 6mm screws (I used Pan Phillips Machine Screws)

qty 4 - M5 x 8mm screws (I used Socket Head Cap Screws)

qty 2 - M4 or M5 x 8mm screws and T-nuts

qty 1 - #6-32 x 1/2 screw (I used Socket Head Cap Screws)

qty 1 - 3/8 ID x 7/8 OD x 9/32 width Pre-Lubricated Bearing (I use these because I always have some on hand)https://www.amazon.com/gp/product/B07X93RV9L/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

This is the Direct Drive Kit I ordered but any kit of this design should work.https://amazon.com/dp/B08M93Y8ZT?psc=1&ref=ppx_yo2_dt_b_product_details

Rev 1: Revised the Spool Riser Support and Bracket to add more support to the front of the Riser. The spool does need to sit back like I had it. The issue was a full spool of filament caused it to lean forward some. The revised version corrects that issue. I also added two M3 screws to the front of the bracket to riser attachment.

Similar models

thingiverse

free

Ender 5+ Spool and Extruder Top Mount by Robert_L

...ecause i always have some on hand)https://www.amazon.com/gp/product/b07x93rv9l/ref=ppx_yo_dt_b_search_asin_title?ie=utf8&th=1

thingiverse

free

U-type direct drive extruder by Sharque

...

m3-nut - 3

m3 cap screw 40mm - 5

m3 cap screw 20mm - 2

m3 screw head noicheskoy - 1

4mm bearing - 1

direct drive gear mk7 or mk8

thingiverse

free

70mm Router Dust Boot

...p screws

qty 2 - m5 nuts

qty 2 - m5 x 20mm socket head cap screws

i used a plumbers wrench to press the magnets into their spots.

thingiverse

free

Flashlight Holder Bracket by mikeymakesit

... washers to fit m5

1 qty. m5 metal washer

1 qty. m5 butterfly nut

1 qty. replacement screw for taz 6 frame corner mount - m5 10mm

thingiverse

free

Pinch Wheel Extruder v1.1 by hoeken

...r

1 x magnetic rotary encoder v1.x board

1 x extruder controller v2.x board

2 x 5mm leds

1 x 1k ohm resistor

various wires / etc.

thingiverse

free

Wanhao Duplicator i3 Filament Riser by justinrsmith23

...i3. works with saaber's filament guide. allows larger filament spools to fit on top.

requires two m5 x 30 mm cap screw bolts.

thingiverse

free

Mini Kossel 1.75mm extruder by wallie

...et head cap screw

2x spring

1x m5 pneumatic straight threaded-to-tube adapter, push in 4 mm 4mm male

tools

m5 manual screw tap

thingiverse

free

Cetus spring loaded extruder (TPU purposed) by baltazed

...#39;t use this extruder to print pla or petg because the stock extruder is better for this job but both can provide good results.

thingiverse

free

Fostruder K4 - Dual Drive Extruder by walter

...her dual drive bowden extruders i've just uploaded on thrinter.com

printed in inland translucent yellow petg*

*affiliate link

thingiverse

free

Ender 5 Direct Drive Extruder Mtr Wire Supports by IMAhobbyist

... these two brackets to function as replacement. bracket located adjacent to extruder mtr uses 3 x 10 mm screw to cinch new plate.

Robert

turbosquid

$18

Robert

...royalty free 3d model robert for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1694905)

3ddd

$1

Asnaghi Robert

...asnaghi robert

3ddd

asnaghi

asnaghi robert armchair

выполнен по фотографии

3ddd

$1

стул Meridiani Roberts

...стул meridiani roberts

3ddd

meridiani roberts

стул meridiani roberts

3ddd

$1

Robert Abbey / Meilleur

...lleur

3ddd

robert abbey , meilleur

robert abbey lighting - s427x - david easton meilleur

3d_export

$8

Robert Smith

...robert smith

3dexport

robert smith normal pose and singing. give him the hair and the look you want. enjoy !

turbosquid

$19

Robert Patrick

...uid

royalty free 3d model robert patrick for download as ztl on turbosquid: 3d models for games, architecture, videos. (1319898)

3ddd

$1

Robert Abbey

..., chrome desk lamp

цвет: хром

материал: металл

размер: база ~ r=85mm, h=430mm

формат: 3dsmax2013,3dsmax2010 и fbx, v-ray 2.30

3ddd

$1

Robert langford Armchair Finn

...robert langford armchair finn

3ddd

robert langford , finn

w620xd780xh840

3ddd

free

Robert Abbey B253 Odyssey

...robert abbey b253 odyssey

3ddd

robert abbey

robert abbey b253 odyssey - one light small pendant, matte black glazed finish

cg_studio

$39

Robert Pattinson3d model

...model

cgstudio

.3ds .max .obj .xsi - robert pattinson 3d model, royalty free license available, instant download after purchase.

Ender

3ddd

$1

Enders / Elegance

...enders / elegance

3ddd

обогреватель

уличный газовый обогреватель enders elegance

высота: 2200 мм

3d_export

free

ender 3 frame cavity covers

... of the creality ender 3 - makes it look a bit more attractive it just slides into the open channels of the aluminium framework

turbosquid

$1

pen support for ender 3

...y free 3d model pen support for ender 3 for download as blend on turbosquid: 3d models for games, architecture, videos. (1611282)

3d_ocean

$9

Ender Dragon Minecraft

...ojang obj poly videogames

ender dragon minecraft created with cinema 4d r15 formats included: max 2013 – fbx 2012 – c4d r15 – obj

3d_export

free

Creality ender enclosure webcam mount

...e creality enclosure. sure is better than a tripod. change it up if it helps. i printed pla with 50% infill on my dd ender 3 pro.

3d_export

free

ender 3 enclosure corners

...er corners and 4 upper corners, using 25mmx25mm angled aluminium pieces that gets covered on inside of the frame with plexiglass

3d_export

free

ender 3 3d print bed clips

...ed + normal aluminium bed frame of the creality ender 3 = 6mm (b) these clips are designed for glass plate + aluminium bed = 4mm

3d_export

$5

GRUMPY CAT

...grumpy cat 3dexport grumpy cat to print in ender ...

3d_export

$5

Logs fire

...with one multi material for corona and vray r ender. albedo, normal, uvmap, roughness format jpg 4096x4096 models:...

3d_export

$42

excavator

...is the original size. 0.12 mm printing surface creality ender5 ...

Mod

design_connected

$13

MOD. 4233 - MOD. 4234 Table Lamp

...mod. 4233 - mod. 4234 table lamp

designconnected

arcahorn mod. 4233 - mod. 4234 table lamp computer generated 3d model.

design_connected

$11

MOD.1095

...mod.1095

designconnected

mod.1095 computer generated 3d model. designed by sarfatti, gino.

3ddd

$1

fireplaces mod Spec

...fireplaces mod spec

3ddd

камин

fireplaces mod spec 180x90x125h

3ddd

free

Flos Mod. 2129

... mod

фабрика: flos

модель: mod. 2129

описание: подвесной светильник, металл, белый, черный.

сайт: www.flos.com

turbosquid

$34

Mod Lamp.c4d

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

MOD A 001

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Maars Mod

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Mod 70..

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

MOD Sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

pc mod

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

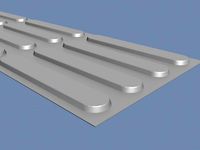

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Plus

turbosquid

$2

plus-plus puzzle and lego

...d model plus-plus puzzle and lego for download as stl and obj on turbosquid: 3d models for games, architecture, videos. (1662633)

3ddd

$1

Стенка Plus

...стенка plus

3ddd

plus , модная мебель

фабрика "модная мебель", модель plus

3ddd

$1

Спальня METIS plus

... hulsta , metis , спальня

спальня metis plus

design_connected

$11

be plus B+

...be plus b+

designconnected

blå station be plus b+ chairs computer generated 3d model. designed by börge lindau.

design_connected

$11

Bank Plus

...bank plus

designconnected

röthlisberger kollektion bank plus coffee tables computer generated 3d model. designed by atelier oi.

3ddd

$1

elos Plus

... candela

elos plus — мультифункциональный аппарат для проведения лазерного и ipl лечений

3ddd

$1

Calligaris Even Plus

...calligaris even plus

3ddd

calligaris

calligaris_chair_even plus

design_connected

$29

Basket Plus

...nconnected

photo-realistic 3d models of the basket plus bed from bonaldo for 3d architectural and interior design presentations.

3ddd

free

Artpole Faktum Plus

... артполе , панель

artpole faktum plus

размеры:

высота 625мм

ширина 800мм

глубина 17мм

3ddd

$1

Мария / Jazz Plus

...мария / jazz plus

3ddd

мария

кухня фабрики мария модель__jazz plus

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

5

turbosquid

$6

Rock 5-5

...urbosquid

royalty free 3d model rock 5-5 for download as obj on turbosquid: 3d models for games, architecture, videos. (1639063)

3d_export

$5

hinge 5

...hinge 5

3dexport

hinge 5

turbosquid

$10

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 5 Number 5

...hic digit 5 number 5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389333)

3ddd

$1

5 роз

...5 роз

3ddd

5 роз в стеклянной вазе

design_connected

$11

iPhone 5

...iphone 5

designconnected

apple iphone 5 computer generated 3d model.

3ddd

$1

Lola 5

...lola 5

3ddd

miniforms

lola 5 miniforms 300*65*134

3ddd

$1

Nexus 5

...dd

nexus , phone , телефон

google nexus 5 phone

3d_ocean

$15

iPhone 5

...iphone 5

3docean

3d 4d apple cinema iphone model modeling phone screen texture

iphone 5 3d model and texture realistic iphone 5.